Glass cleaning robot with scraping module capable of doing autonomous reciprocating motion

A glass-wiping robot, reciprocating movement technology, applied in robot cleaning machines, machine parts, cleaning machinery and other directions, can solve the problems of insufficient extrusion force, stubborn particle stains can not achieve cleaning effect, etc., to achieve low resistance, good technical support , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

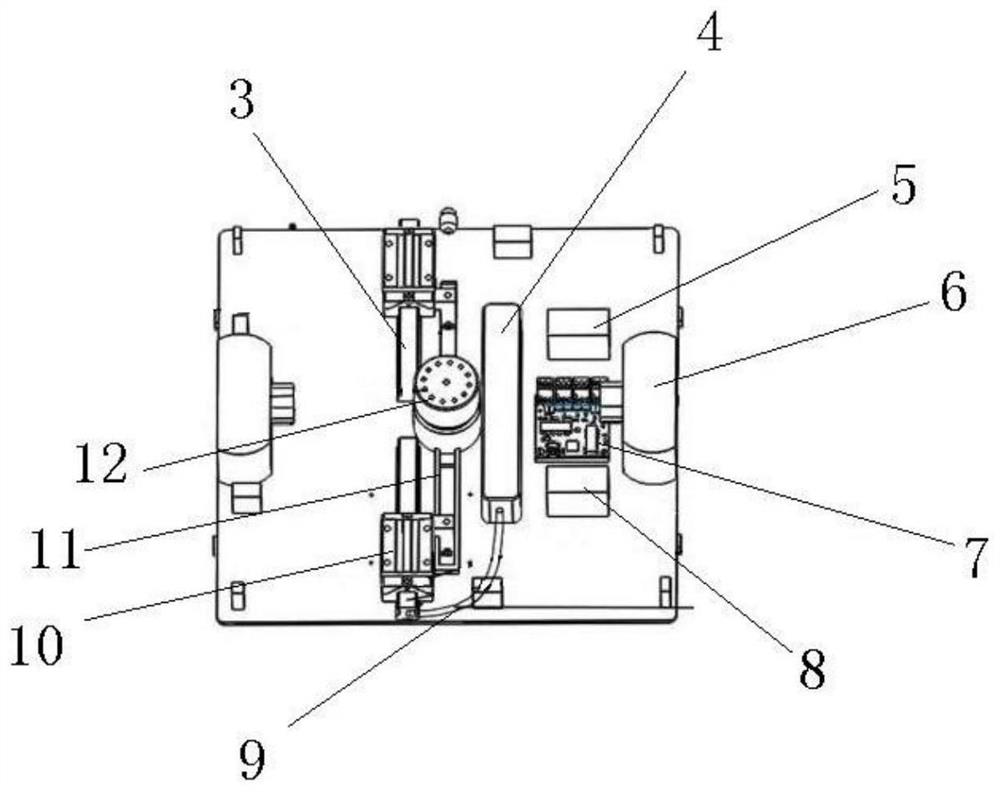

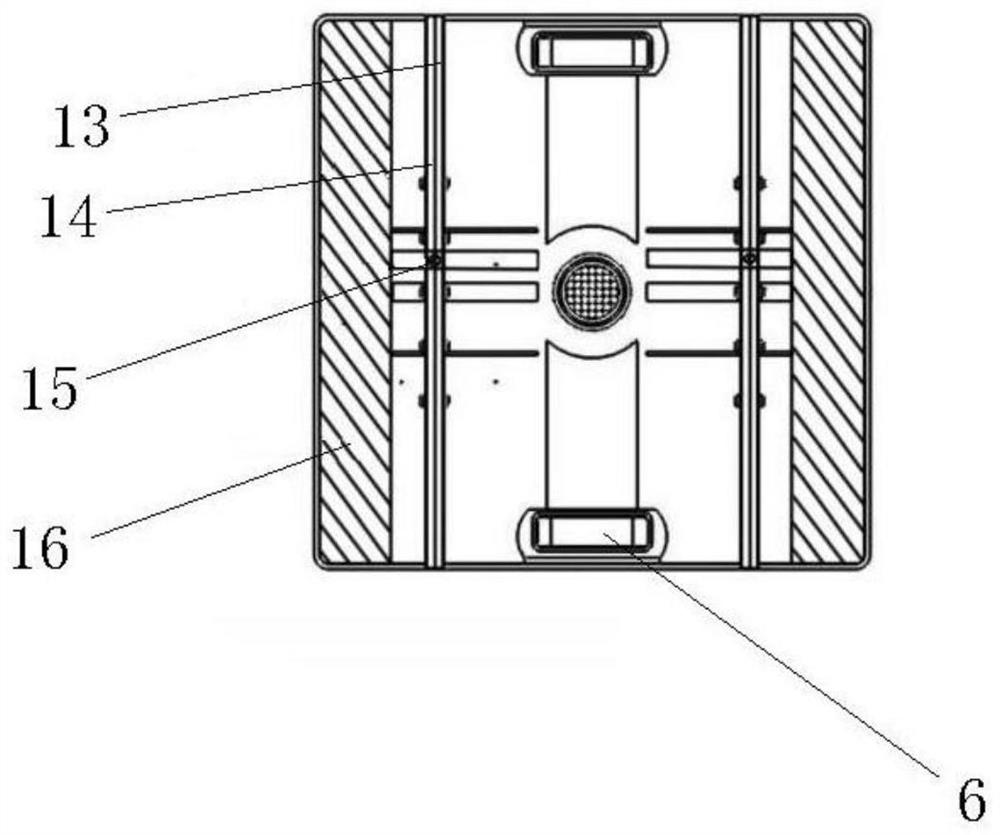

[0021] The robot of this embodiment is cube-shaped, and this cube is provided with upper cover plate 1 and lower box body 2, and lower box body 2 bottom surface centers are provided with blower fan 12, fan 12 both sides are provided with metal track 3, and metal track 3 is provided with There is a cleaning head 10, the cleaning head 10 can slide on the metal track 3, the side of the cleaning head 10 is connected with the connecting rod 11 to improve the sliding stability of the cleaning head 10, the bottom of the cleaning head 10 is connected with the cleaning strip, and the cleaning strip The head is set in the cleaning head 10, the bottom of the cleaning strip is set on the bottom surface outside the lower box body 2, the cleaning strip is provided with a water mist generator 15, and the water mist generator 15 is connected to the water tank in the lower box body 2 through the hose 9. 4 are connected, the side of the water tank 4 is provided with a PLC controller 7, the two s...

Embodiment 2

[0023] Working process: start the robot, the motor a5 drives the driving belt 6 to work, the robot moves, and at the same time, the motor b8 drives the cleaning head 10 to move on the metal track 3, the cleaning head 10 drives the cleaning strip to reciprocate, the fan 12 and the water mist generator 15 Work, blow and wipe the dust on the glass surface.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com