A suction nozzle for a road sweep and a road sweeper

A technology for road sweepers and suction pipes, which is applied in the field of road sweeper suction nozzles and road sweeper vehicles. The suction nozzle has a strong comprehensive dust collection ability, the fan speed and power are low, and the effect of improving the horizontal conveying ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

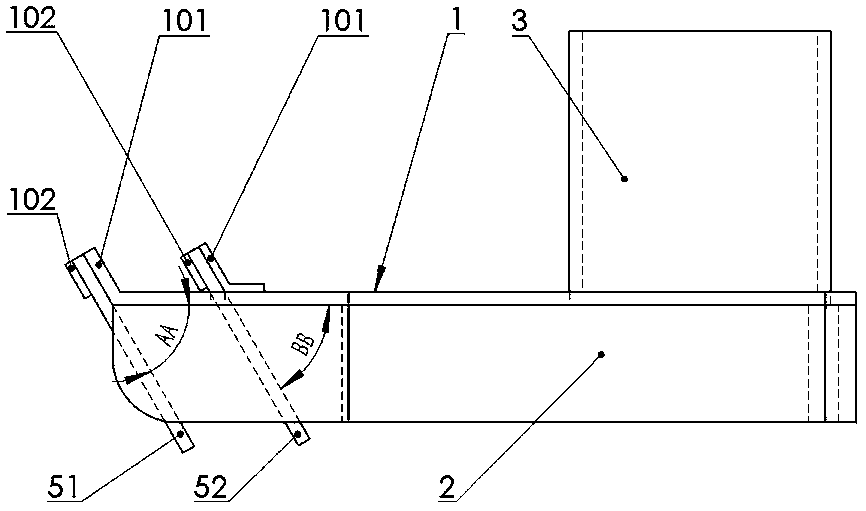

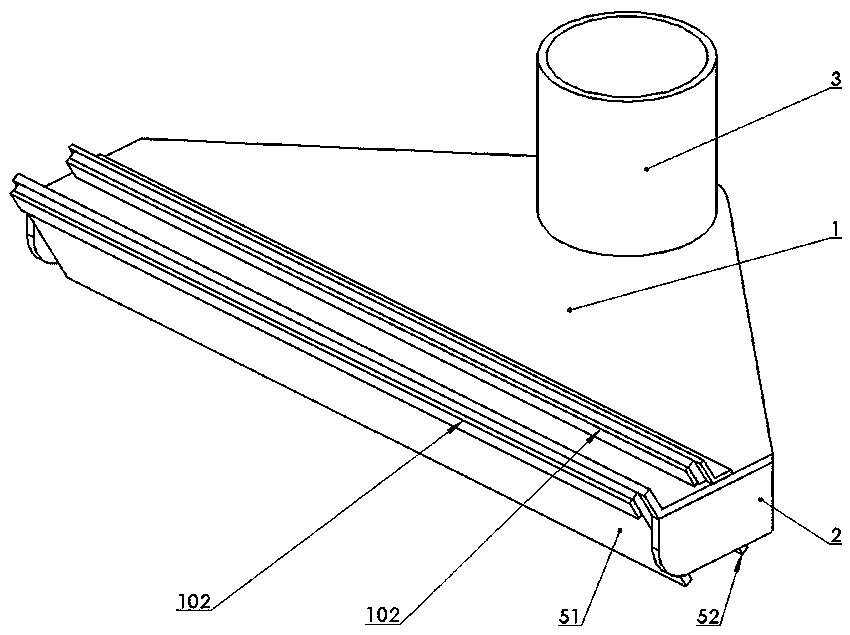

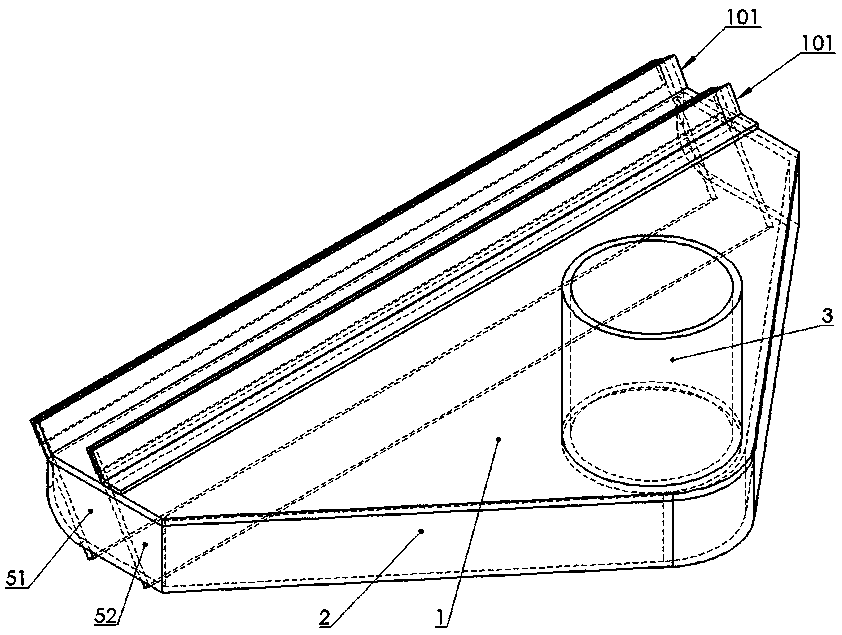

[0066] Example 1 see figure 1 , figure 2 , image 3 . In Embodiment 1, the top view of the upper cover 1 is pentagonal, and the suction nozzle includes a suction pipe 3, which is located in the middle of the rear end of the upper cover 1, and the suction pipe 3 is connected to the upper cover 1 from above and communicates with the upper cover 1. The nozzle cavity.

Embodiment 2

[0067] Example 2 see Figure 4 , Figure 5 , Figure 6 . In Embodiment 2, the upper cover 1 is quadrangular in plan view, and the side rear baffle 2 includes two types of baffles, side baffle 21 and rear baffle 22, and the side baffle 21 faces the suction side close to the ground. The position of the nozzle cavity is provided with a horizontal air inlet 211 to introduce air into the nozzle cavity from the side.

[0068] Figure 7 It is a schematic diagram of the vortex air flow similar to the rotating effect of the rolling brush in Embodiment 3.

[0069] In Embodiment 3, the rear baffle is two or more layers of baffles, parallel to each other and separated by a certain distance. From the inside to the outside, that is, from the nozzle cavity to the outside of the nozzle, each layer of rear baffle is defined as the first layer of back baffle, the second layer of back baffle, and so on. The space between the first layer of rear baffle and the second layer of rear baffle fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com