Sealed master cylinder and plunger of vehicle hydraulic-brake system

A technology of hydraulic braking and sealing structure, applied in the direction of engine sealing, brake actuator, brake, etc., can solve the problems of fluid obstruction, return oil flow path obstruction, unable to form return oil flow path, etc., to reduce the The effect of impedance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

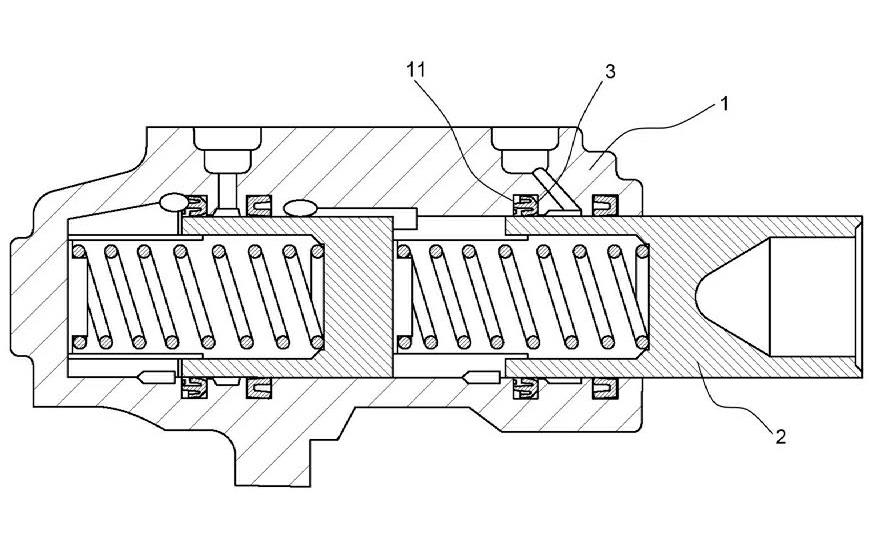

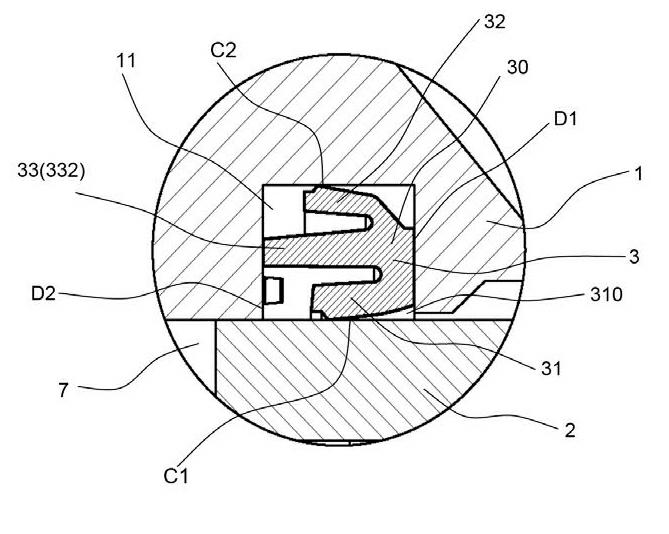

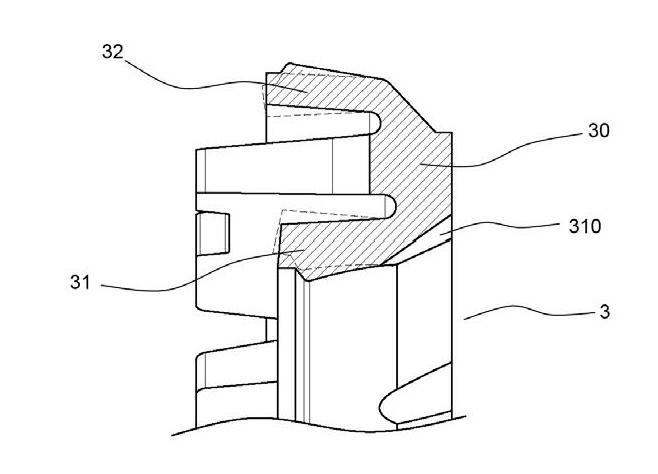

[0020] see figure 1 , please cooperate with the detailed diagram figure 2 , 3 As shown, the seal structure between the master cylinder and the plunger of the vehicle hydraulic braking system of the present invention includes a master cylinder 1 and a plunger 2 adjacent to each other, and the master cylinder 1 is provided with an accommodating cylinder adjacent to the plunger 2 Groove 11; and a sealing collar 3 is set, and the sealing collar 3 is arranged in the receiving groove 11, and the sealing collar 3 cooperates with the material characteristics and the tightness of the structure and assembly, so as to limit the passage of the fluid around the plunger 2 . And under the dynamic reciprocating action of the plunger 2, it can also be affected by the action of the plunger 2, and the fluid (such as brake oil) that allows pressure relief can be deformed by the sealing collar 3 (for the deformation state, please refer to image 3 ) through the two oil paths generated. That ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com