Vehicle body floor structure

A vehicle body bottom plate and structure technology, applied in the direction of superstructure, substructure, vehicle parts, etc., can solve the problems of light weight of the body, narrowing of the interior space of the vehicle, and increase in the weight of the extension of the central frame, so as to expand the joint range, Effect of reducing air resistance and maintaining quiet performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Next, embodiments of the present invention will be described with reference to the drawings.

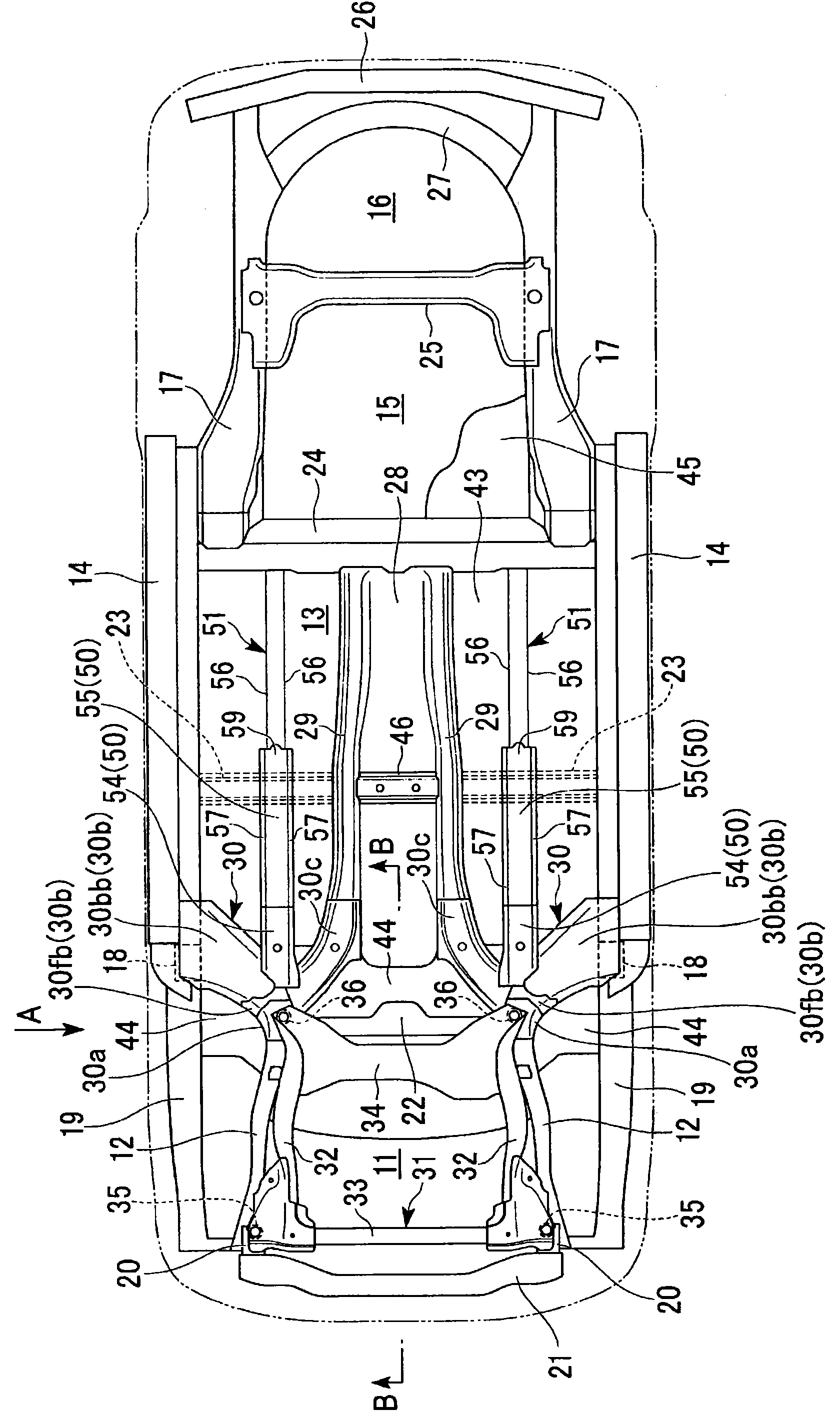

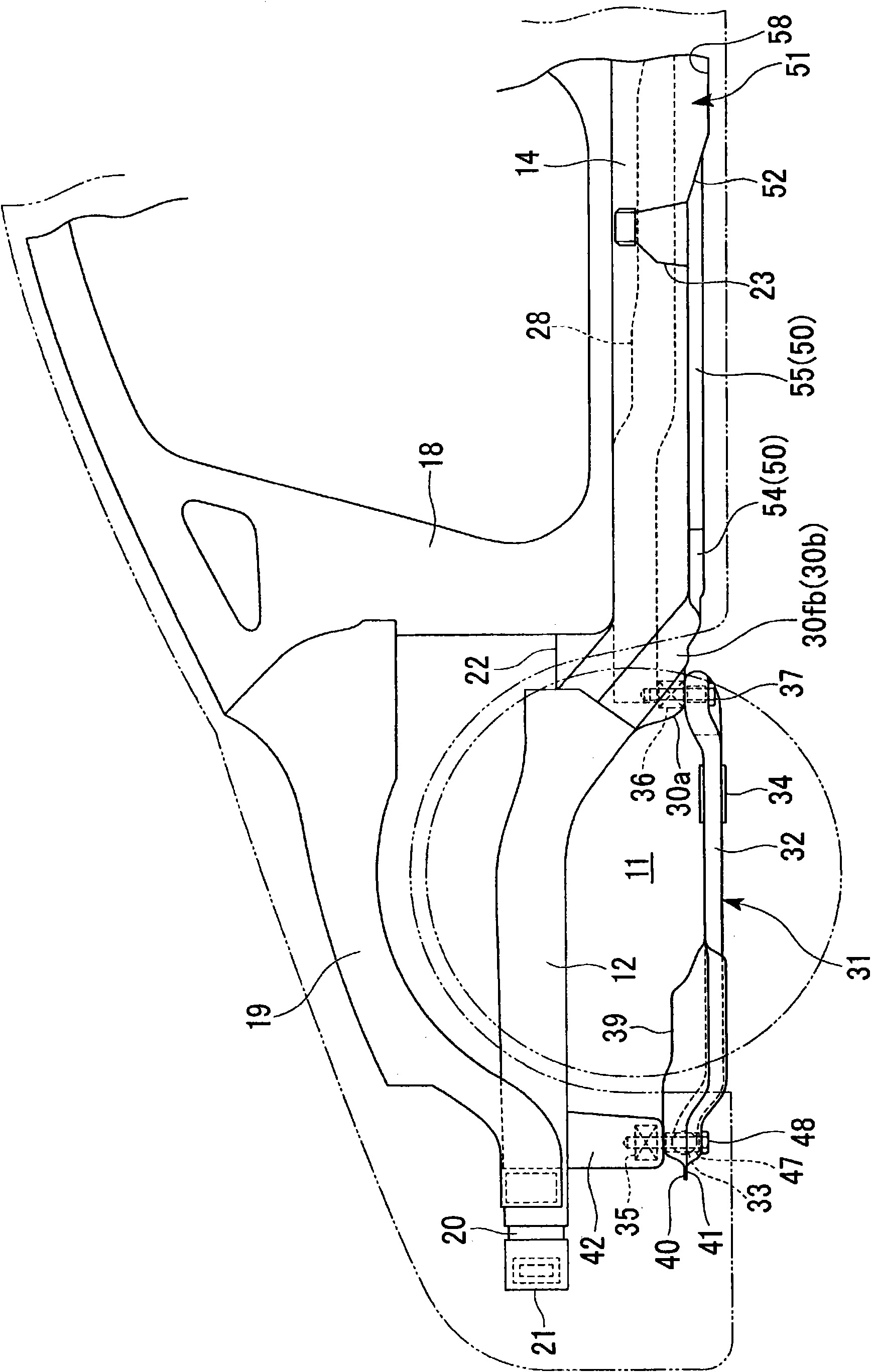

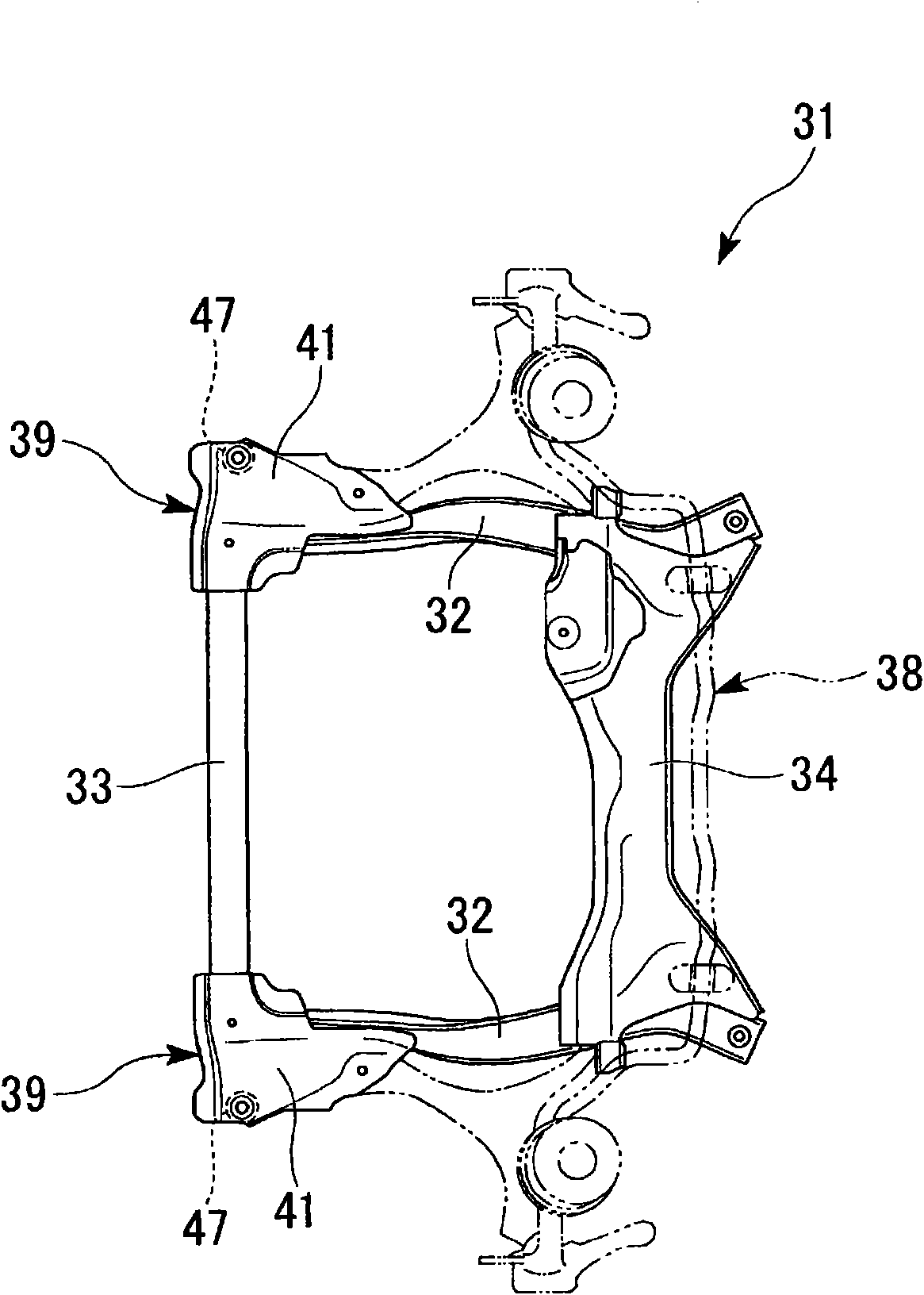

[0030] figure 1 is a diagram of a car body as viewed from below, figure 2 yes figure 1 A view from direction A. exist figure 1 , figure 2 The shape of the body is indicated by a dotted line. Such as figure 1 , figure 2 As shown, the body frame (underbody structure) of the automobile has: front side frames 12, 12; lower side members 14, 14; rear side frames 17, 17; front lower pillars 18, 18; .

[0031] The front side frames 12 , 12 extend in the front-rear direction of the vehicle body along the left and right sides of the engine room 11 , and have a pair of left and right closed cross-sectional structures. The side members 14 , 14 extend in the front-rear direction of the vehicle body along the left and right side portions of the cabin 13 , and have a pair of left and right closed cross-sectional structures. The rear side frames 17, 17 extend in the front-rear di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com