Patents

Literature

44results about How to "Eliminate impact noise" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

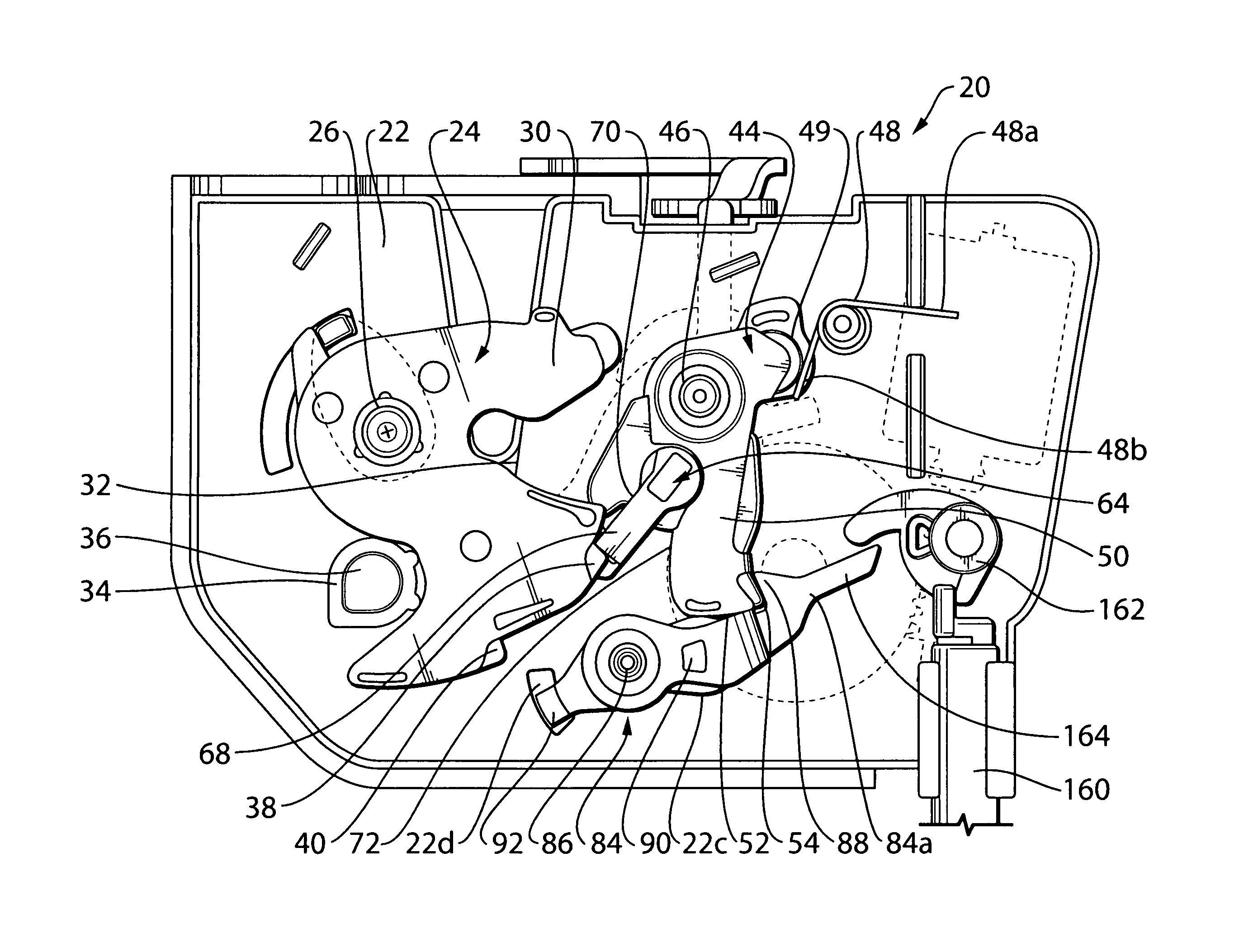

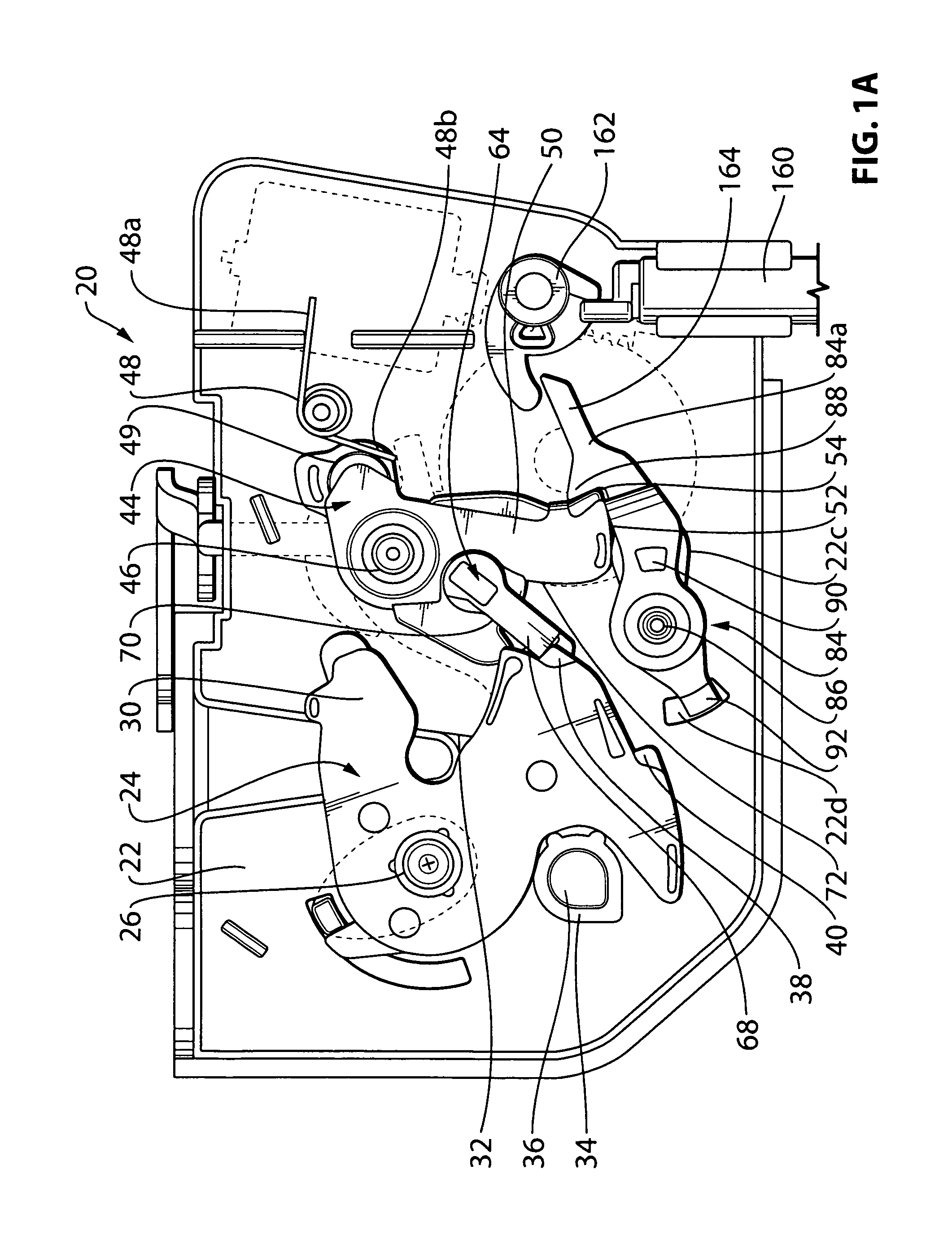

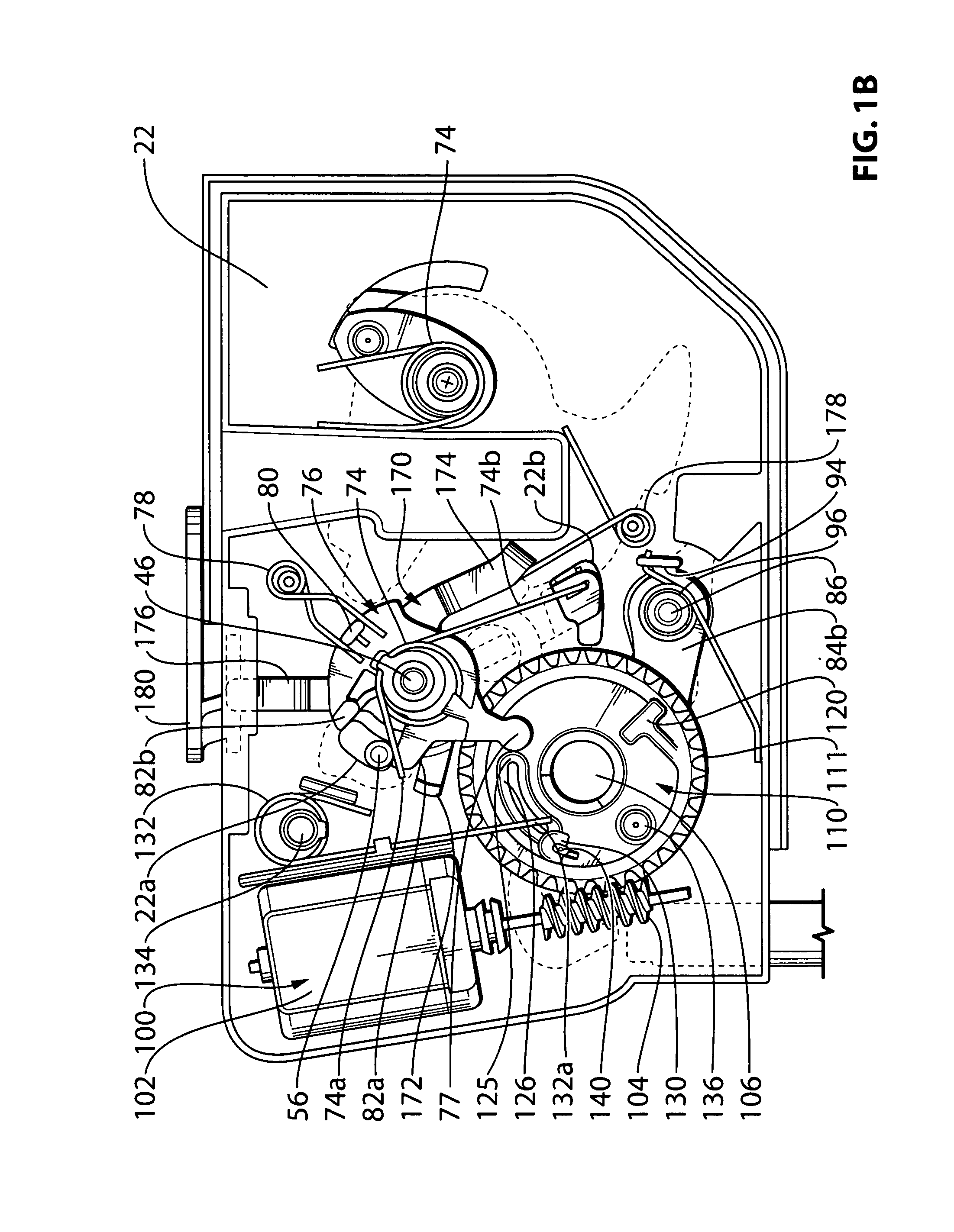

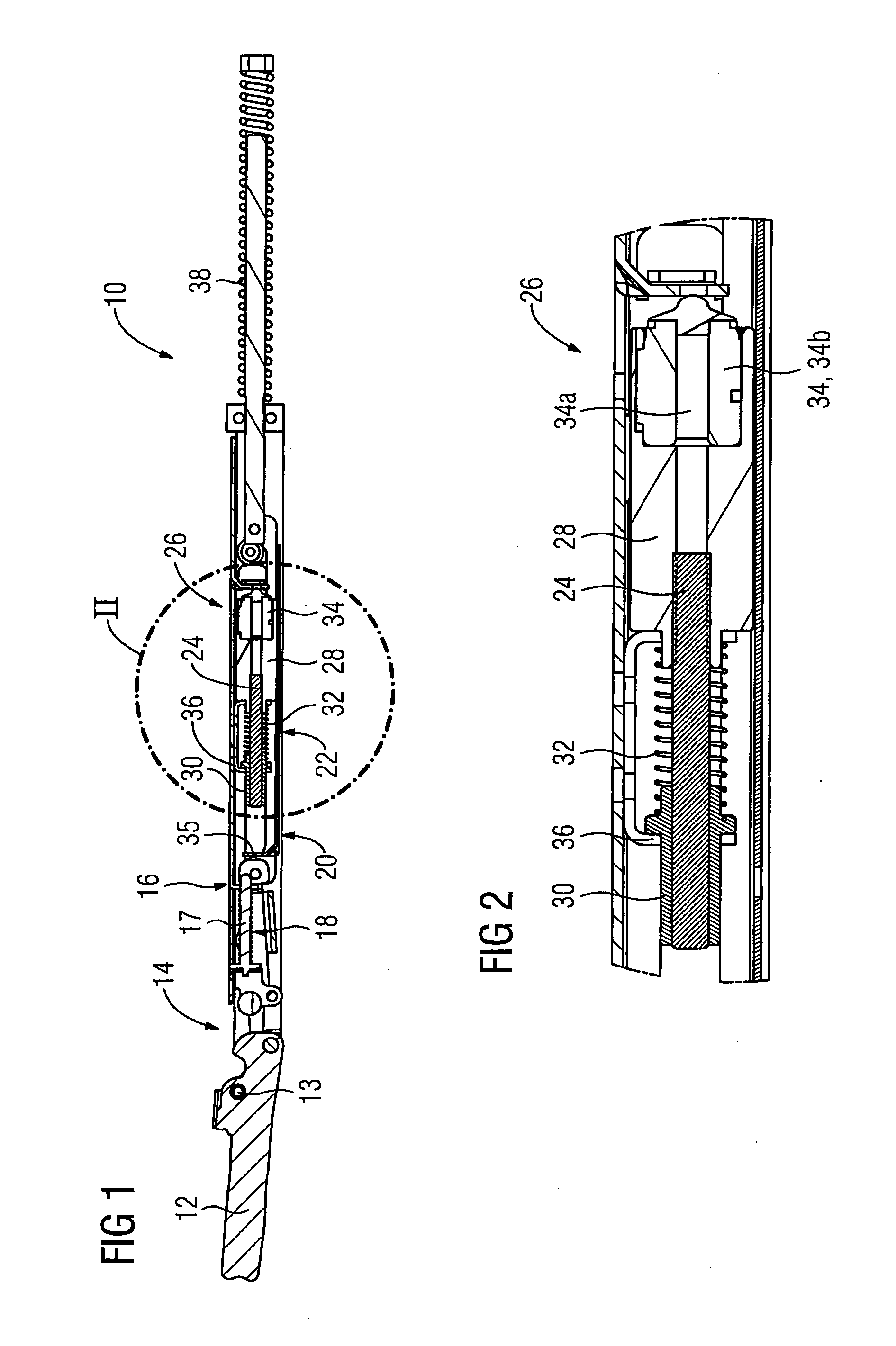

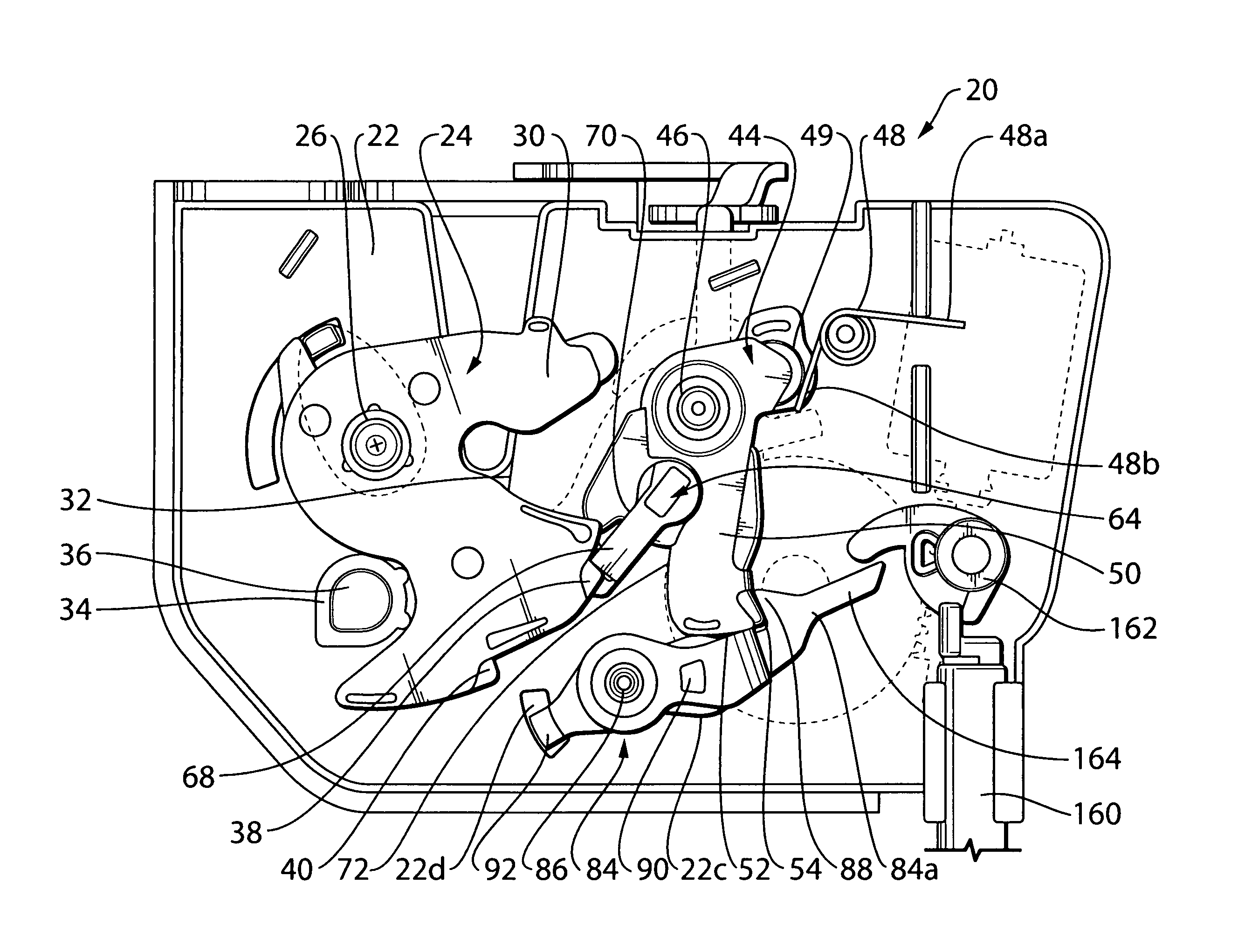

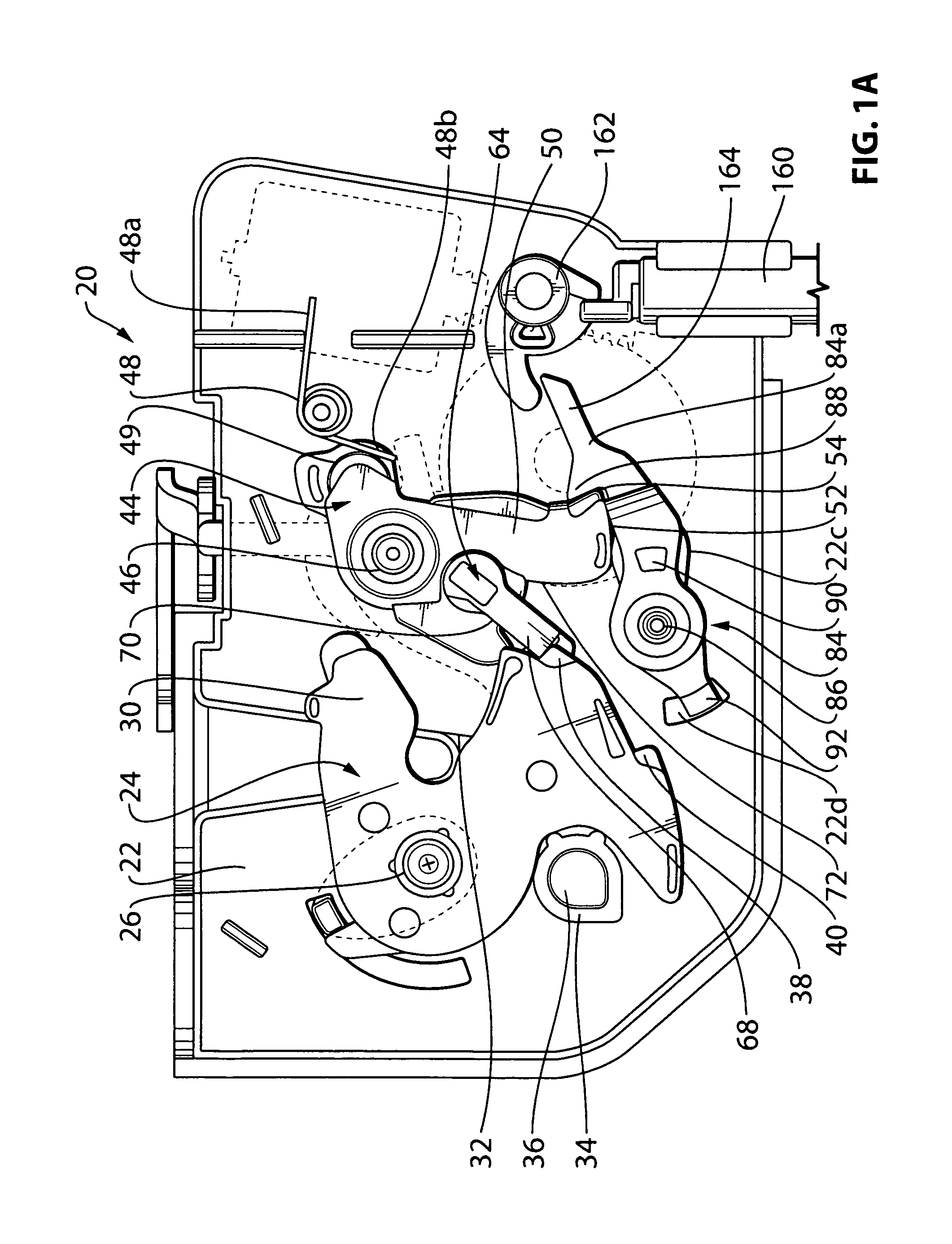

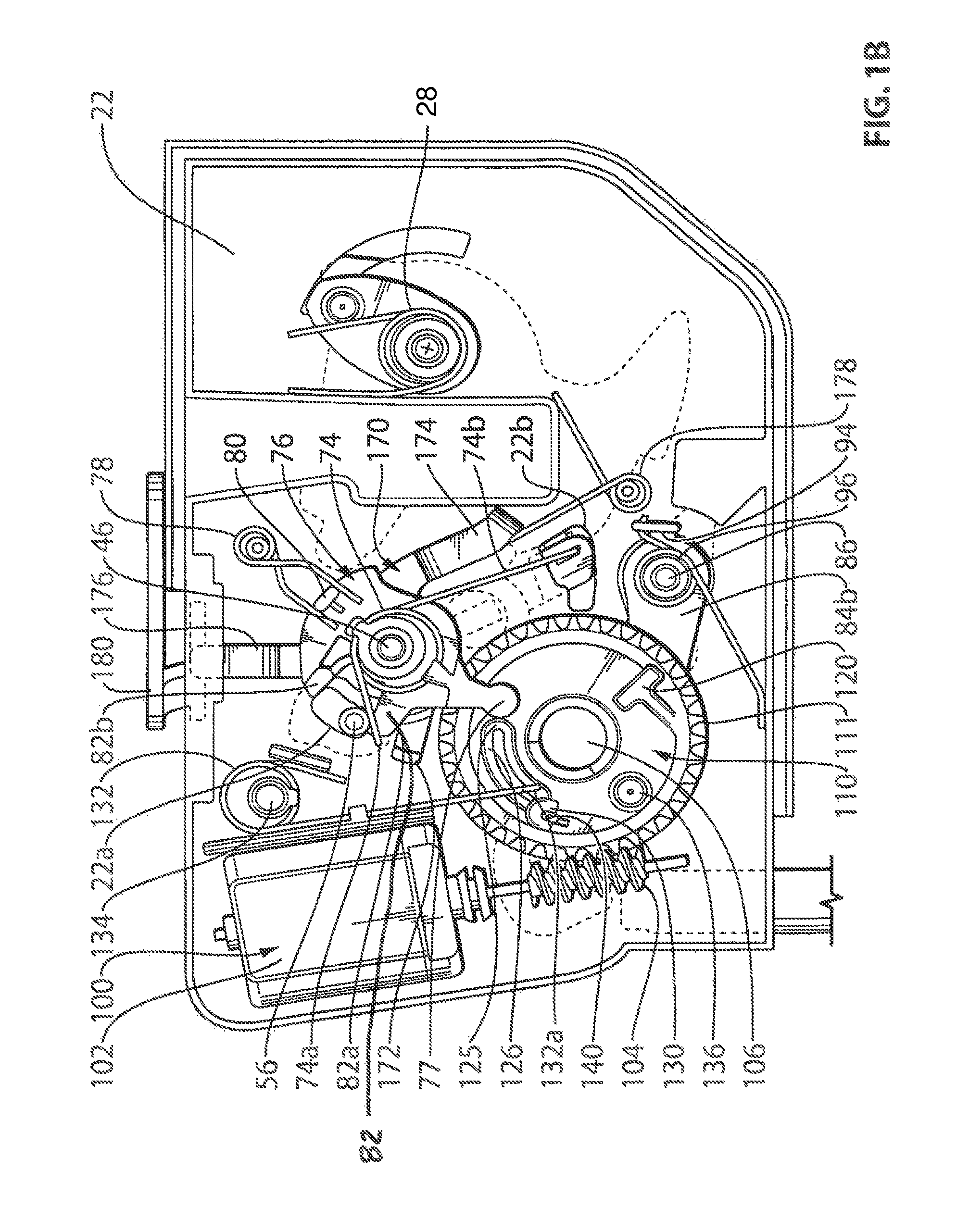

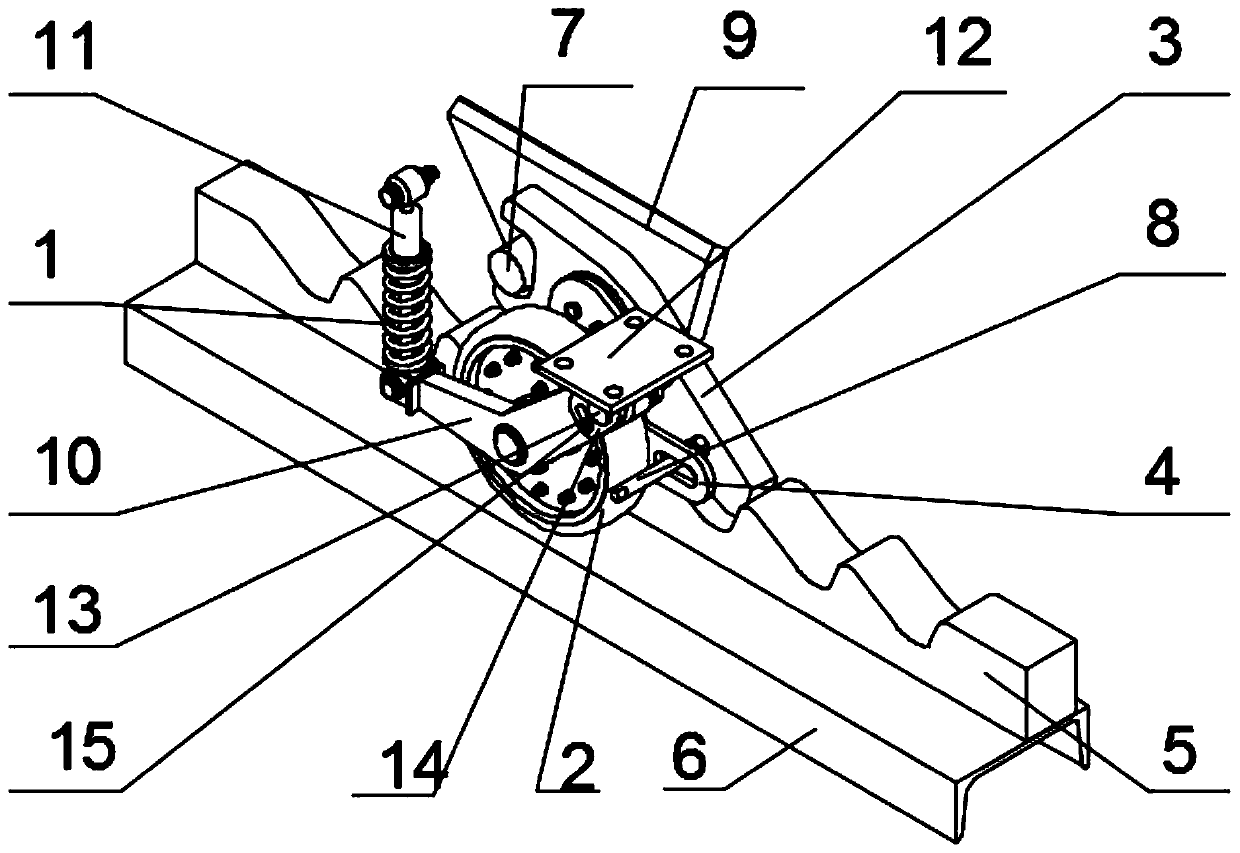

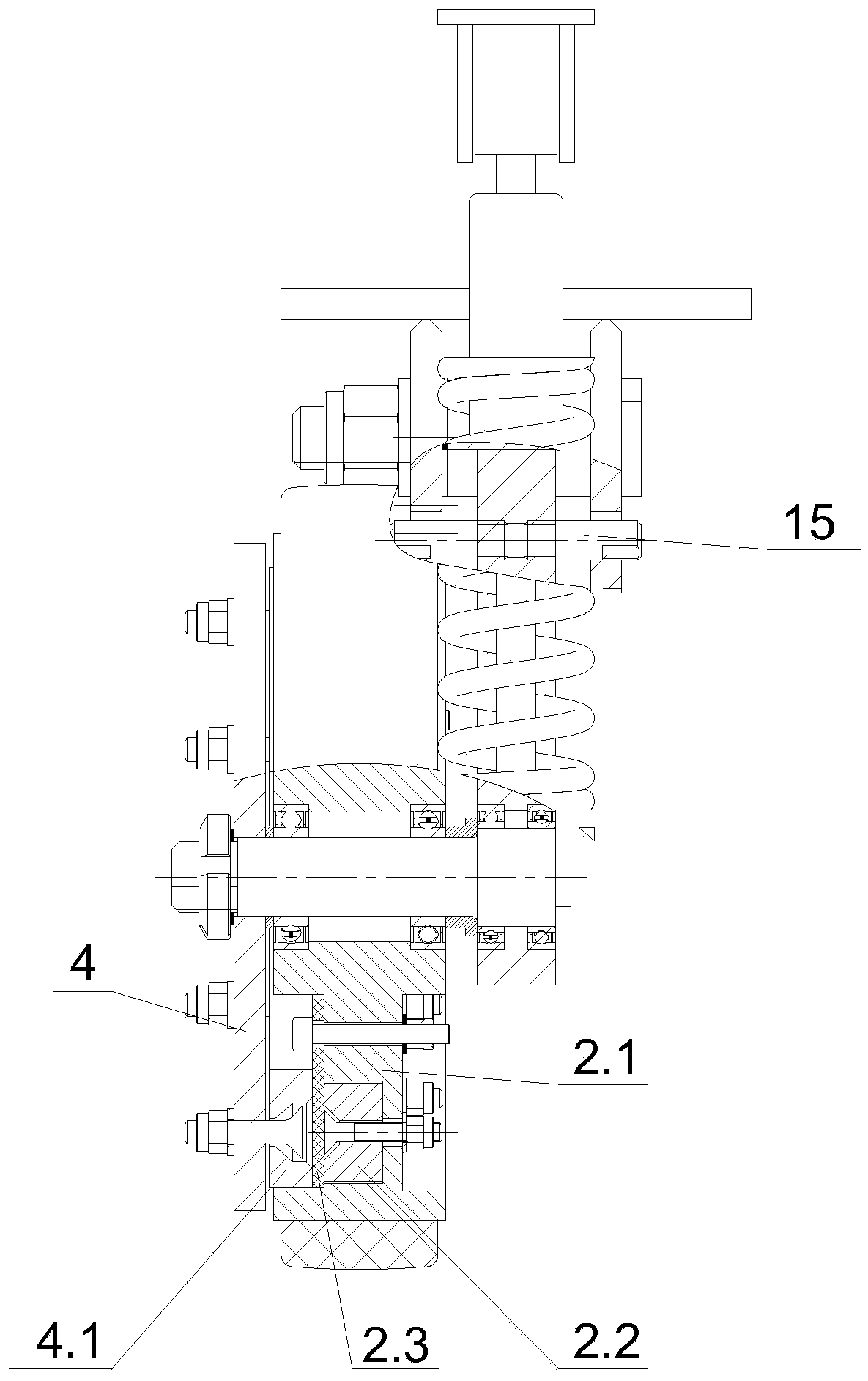

Double ratchet, double pawl vehicular latch with soft stop on reset

ActiveUS20140091581A1Preventing full travel impact noiseEliminate impact noiseNoise-prevention/anti-rattling lockingConstruction fastening devicesRatchetGear wheel

A low release effort eccentric double ratchet, double pawl vehicle latch includes a ratchet, a primary pawl, an auxiliary ratchet and a secondary pawl. A drive mechanism including a gear cam wheel sequences movement of the secondary pawl to open and reset the latch. Upon reset, the drive mechanism actuates the auxiliary ratchet back to a closed state in a soft manner without using a hard stop; instead the latch has a cushioning spring that is used to softly stop the gear train during the reset absorbing motor energy and thus eliminating impact noise.

Owner:MAGNA CLOSURES SPA

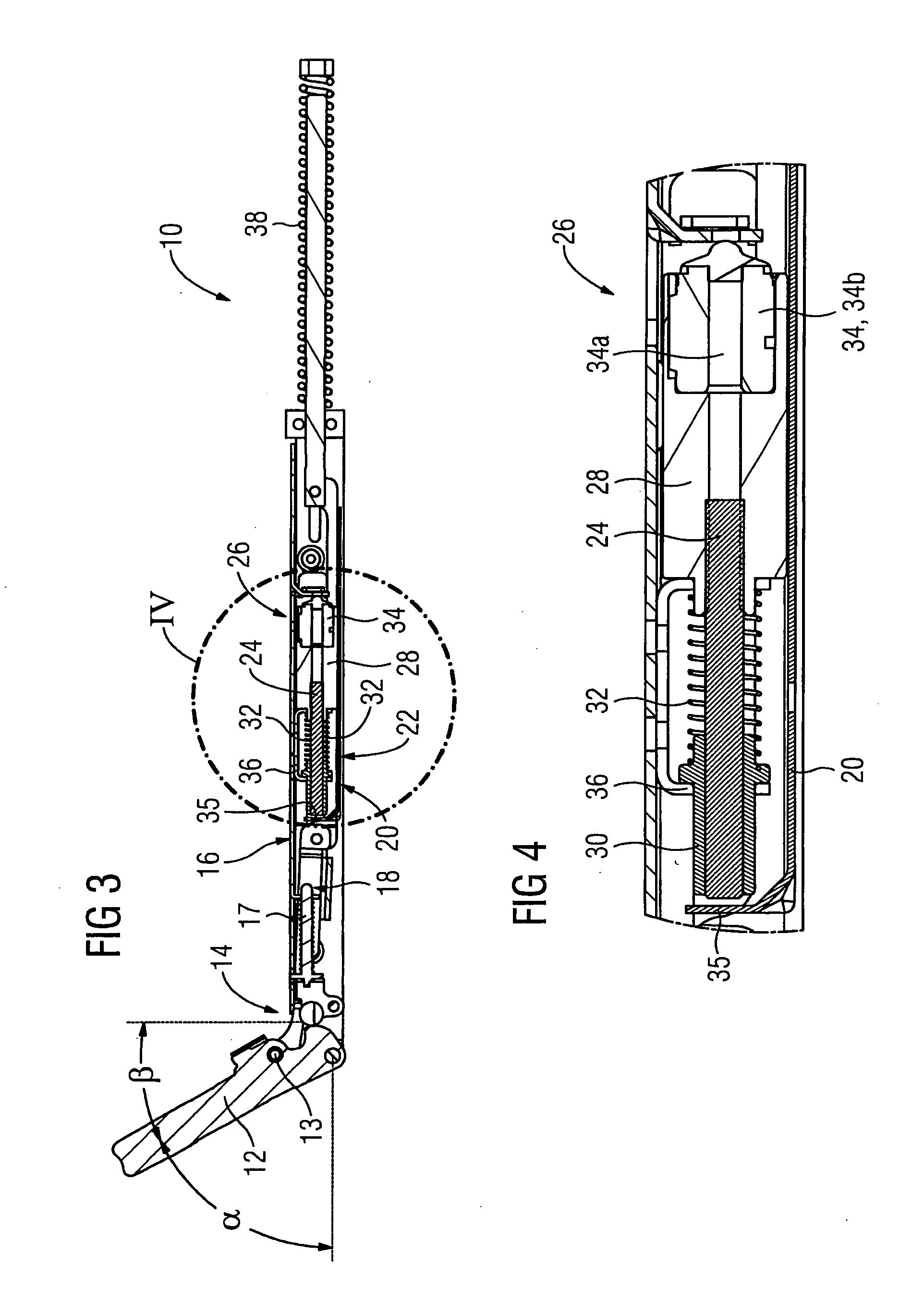

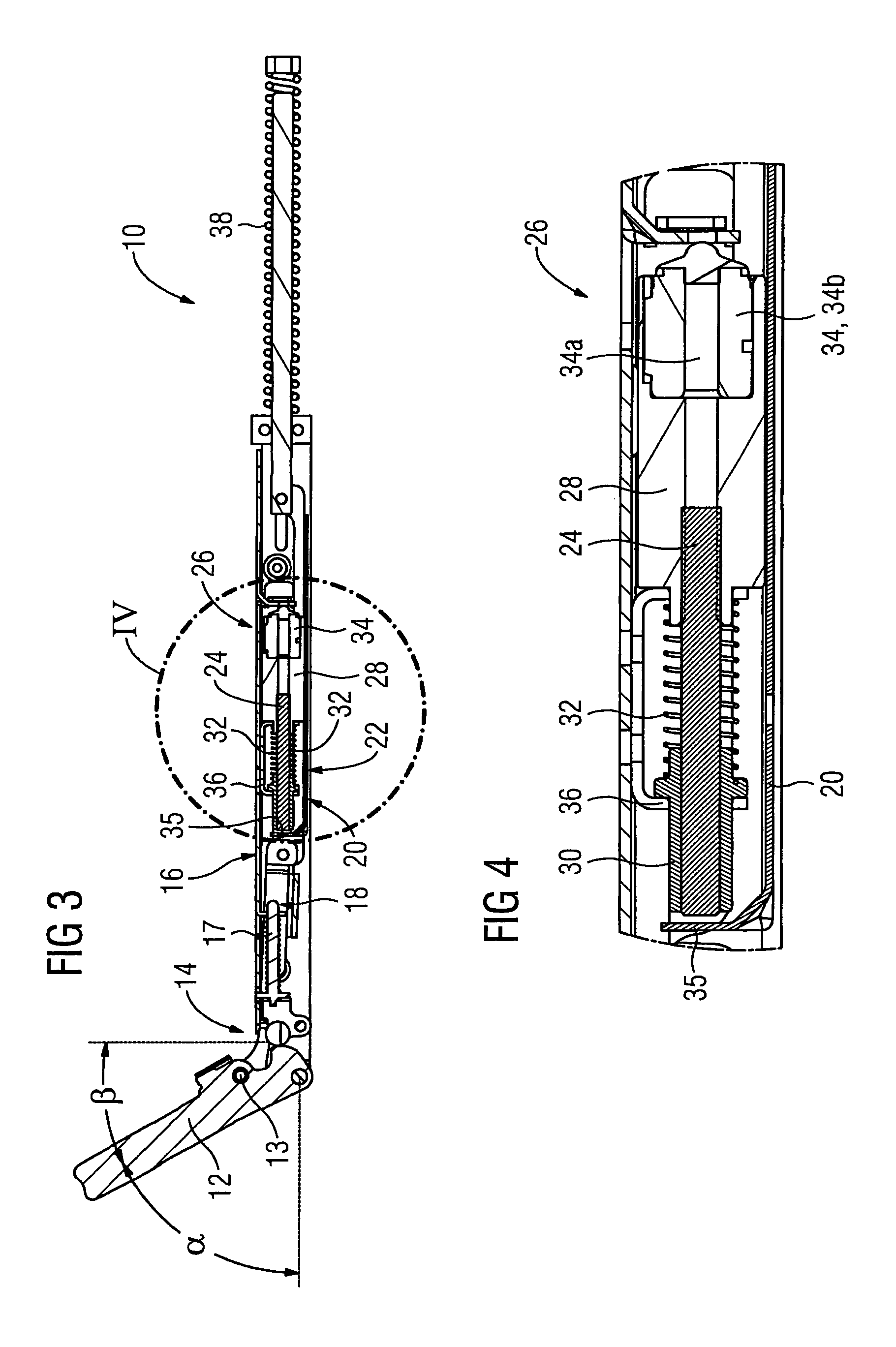

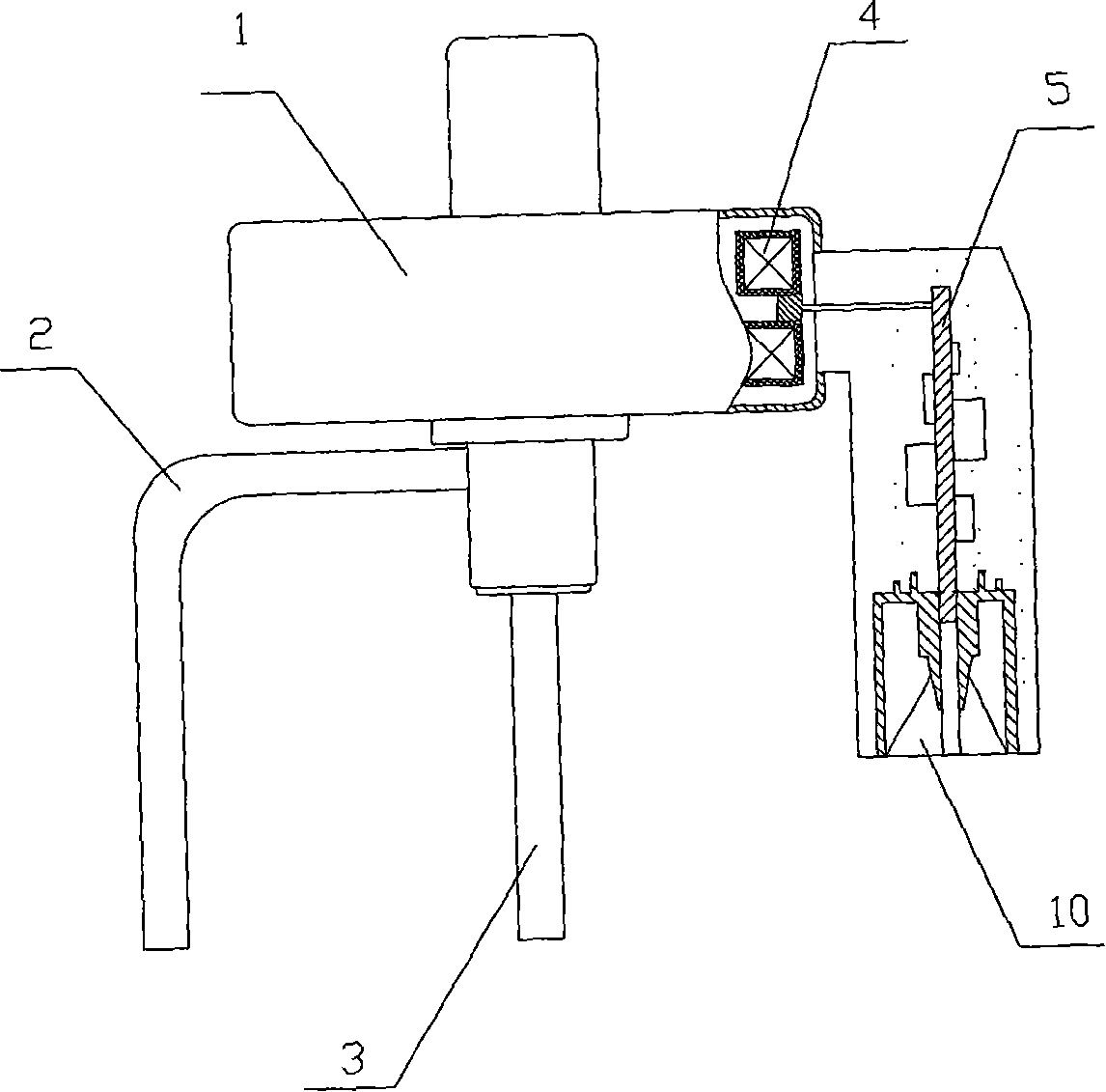

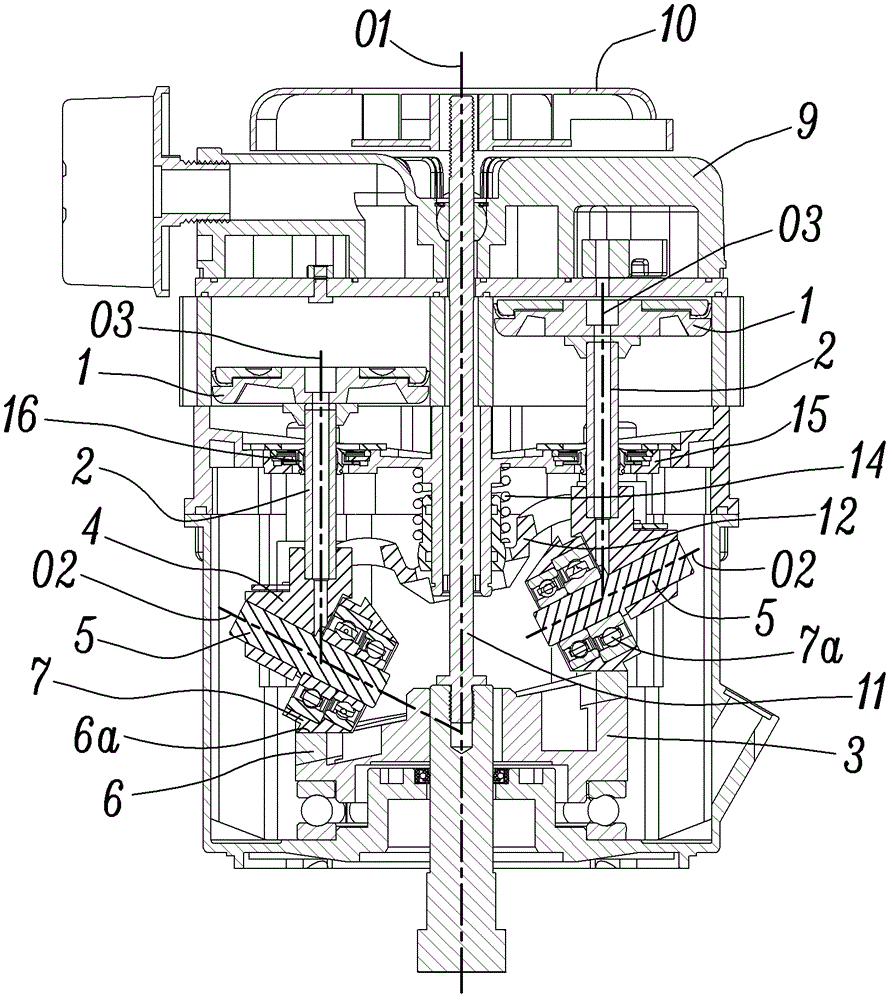

Oven door opening and closing device

InactiveUS20120067333A1Accurate reciprocating movementEliminate impact noiseDomestic stoves or rangesDoors for stoves/rangesKinematicsEngineering

The present invention relates to an oven door opening and closing device comprising at least one hinge, which is connectable to an oven door and to an oven housing for realizing a predetermined pivoting opening and closing movement of the oven door relative to the oven housing between an open and a closed position; at least one closing force generating means for generating a predetermined closing force; kinematic means, which are coupled to the hinge and to a moveable element in such a manner, that the predetermined pivoting opening and closing movement of the hinge is converted into a predetermined reciprocating opening and closing movement of the moveable element; and at least one damping system having a damper for generating a damping force which counteracts the closing movement of the movable element within a predetermined section, which corresponds to a predetermined angle section of the pivoting closing movement of the hinge shortly prior to the closed position.

Owner:ELECTROLUX HOME PROD CORP NV

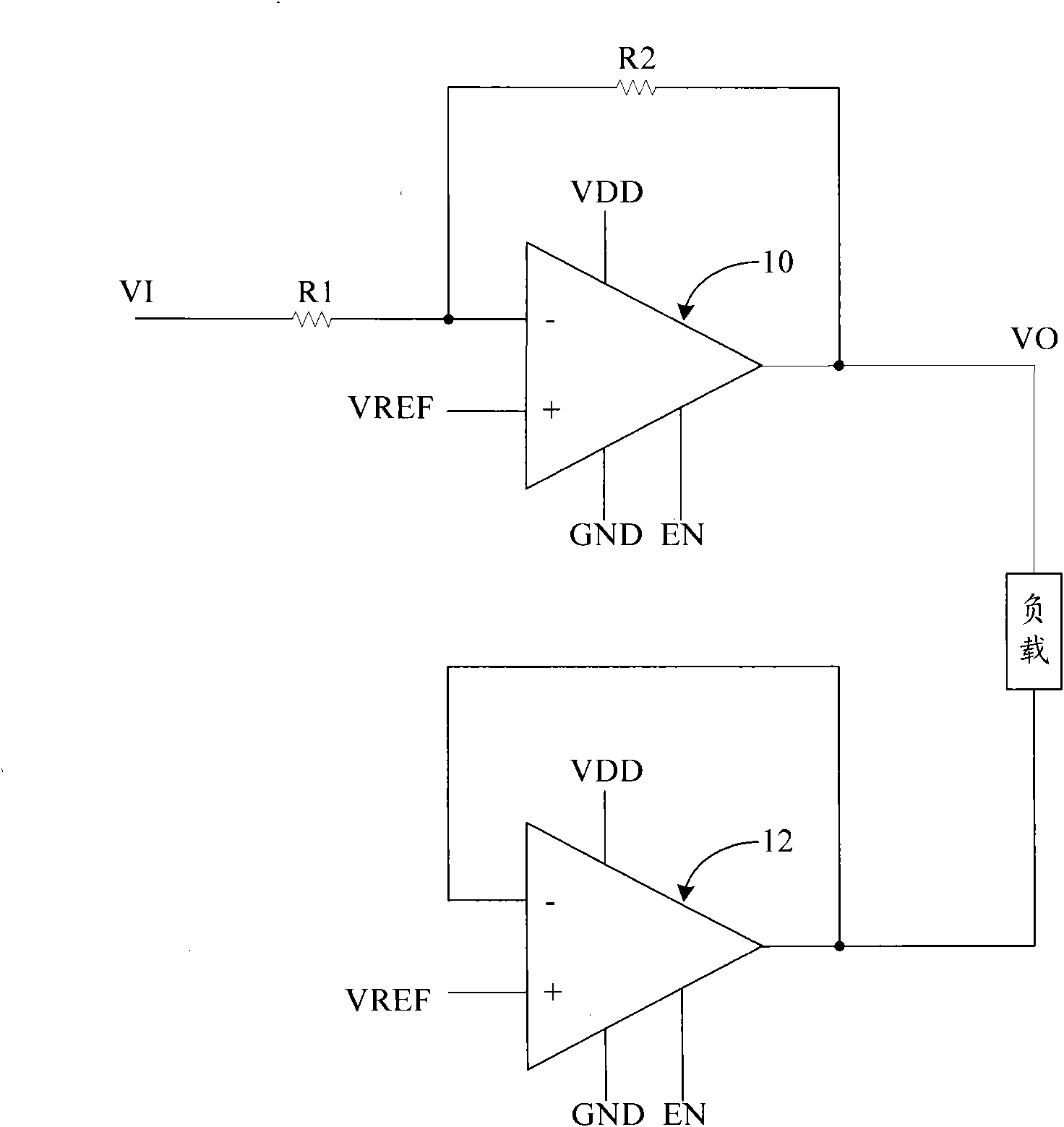

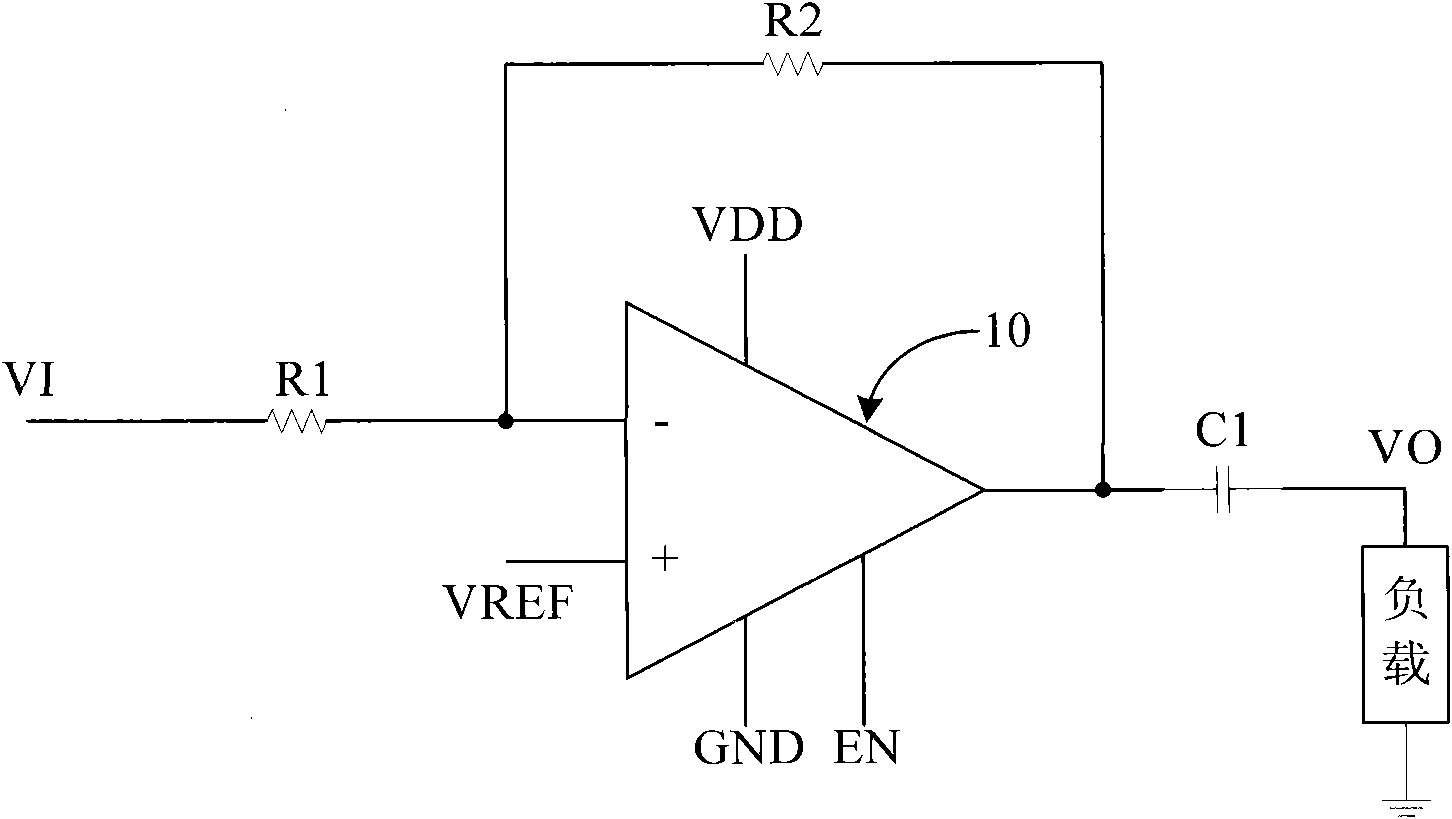

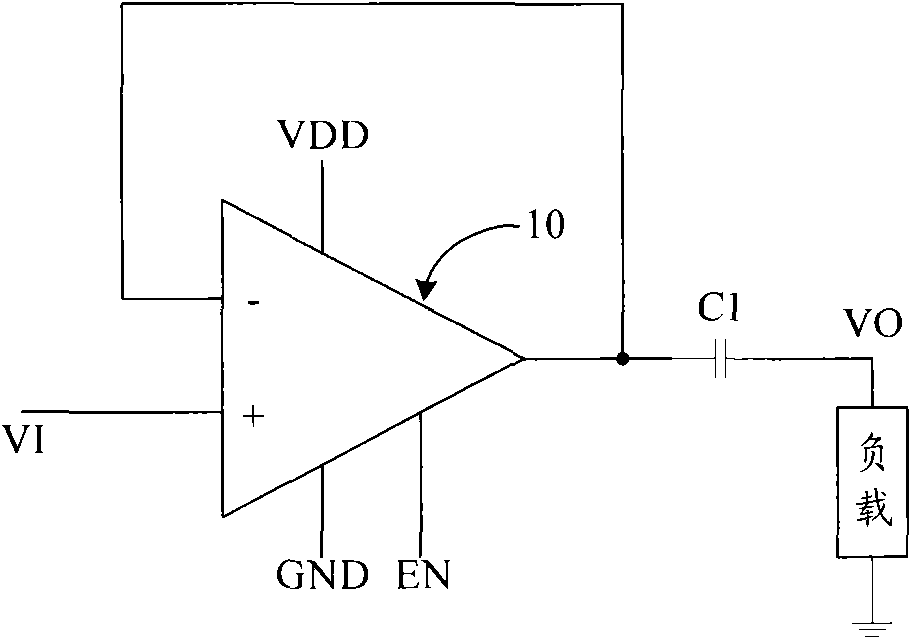

Amplifier

InactiveCN101540585AReduce power consumptionLow costPulse generatorAmplifier modifications to reduce temperature/voltage variationAudio power amplifierControl signal

The invention relates to the field of circuit design and discloses an amplifier. The amplifier is provided with a slope voltage generating circuit, an enabling signal delay controlling circuit and an analog switch inside to enable the amplifier to realize lower circuit power consumption and low cost and reduce the impact noise during switching on or switching off, wherein the slope voltage generating circuit outputs a slope voltage signal to an operating positive signal input terminal when the external enabling signal is available; the voltage starts to rise from 0 V and reaches a reference voltage after passing T1, and then is continuously stabilized on the reference voltage; the enabling signal delay controlling circuit carries out the following operation when the input external enabling signal is available: changing the enabling signal which is output and connected with an operating enabling terminal into the available enabling signal, starting to operate, changing a switch controlling signal which is output and connected with a controlling terminal of the analog switch into the available switch controlling signal after delaying T2, and conducting the analog switch; and the analog switch conducts or cuts off the connection of an input impedance circuit and the operation under the control of the switch controlling signal.

Owner:ALLWINNER TECH CO LTD

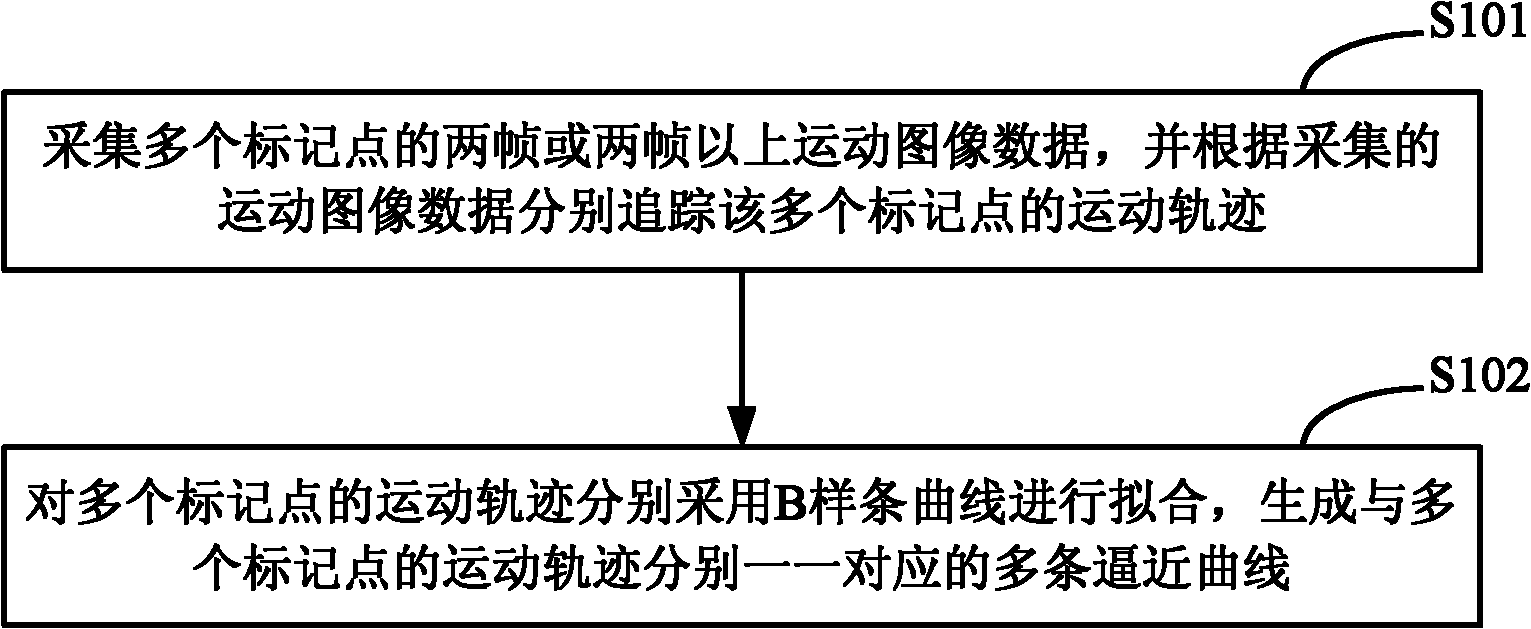

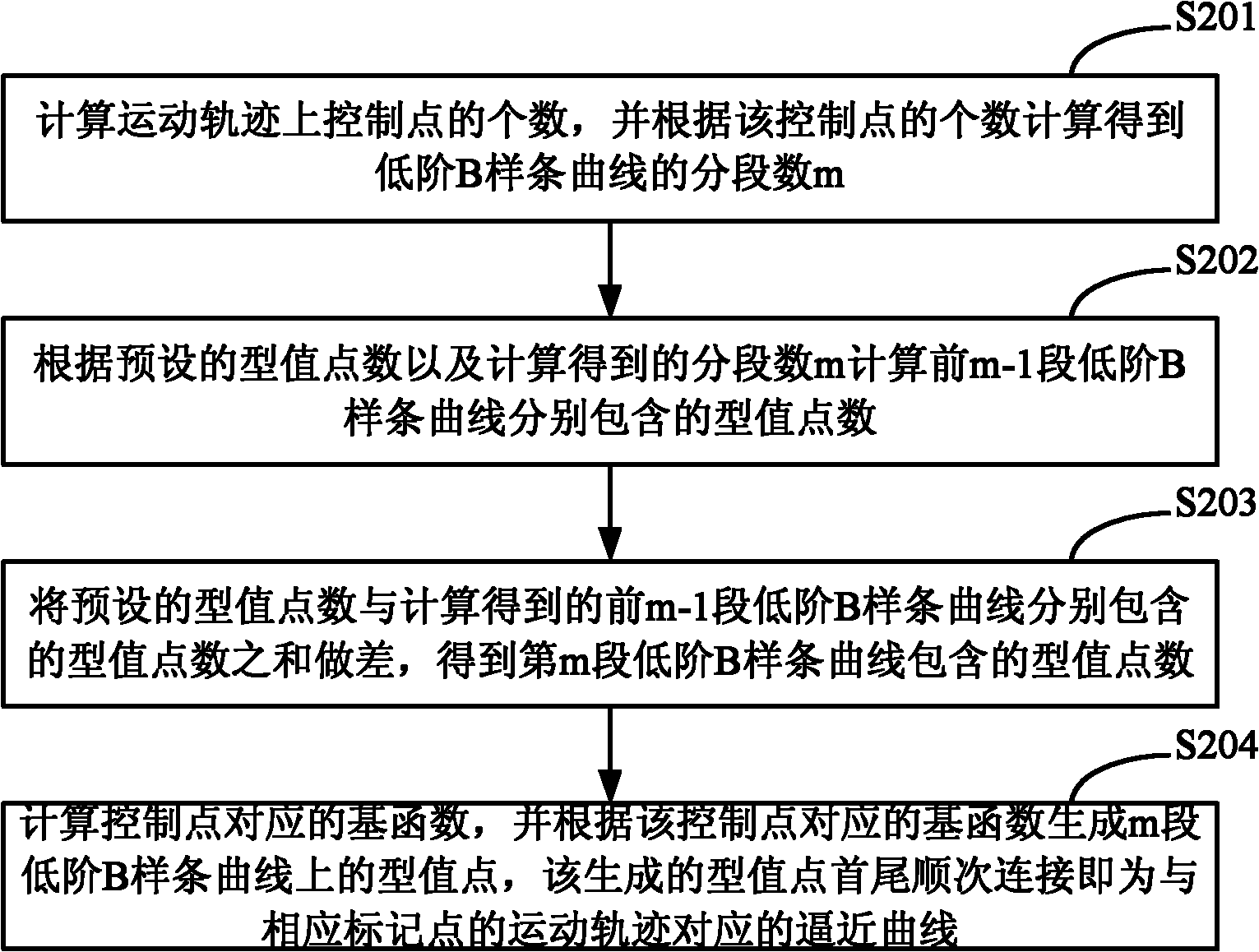

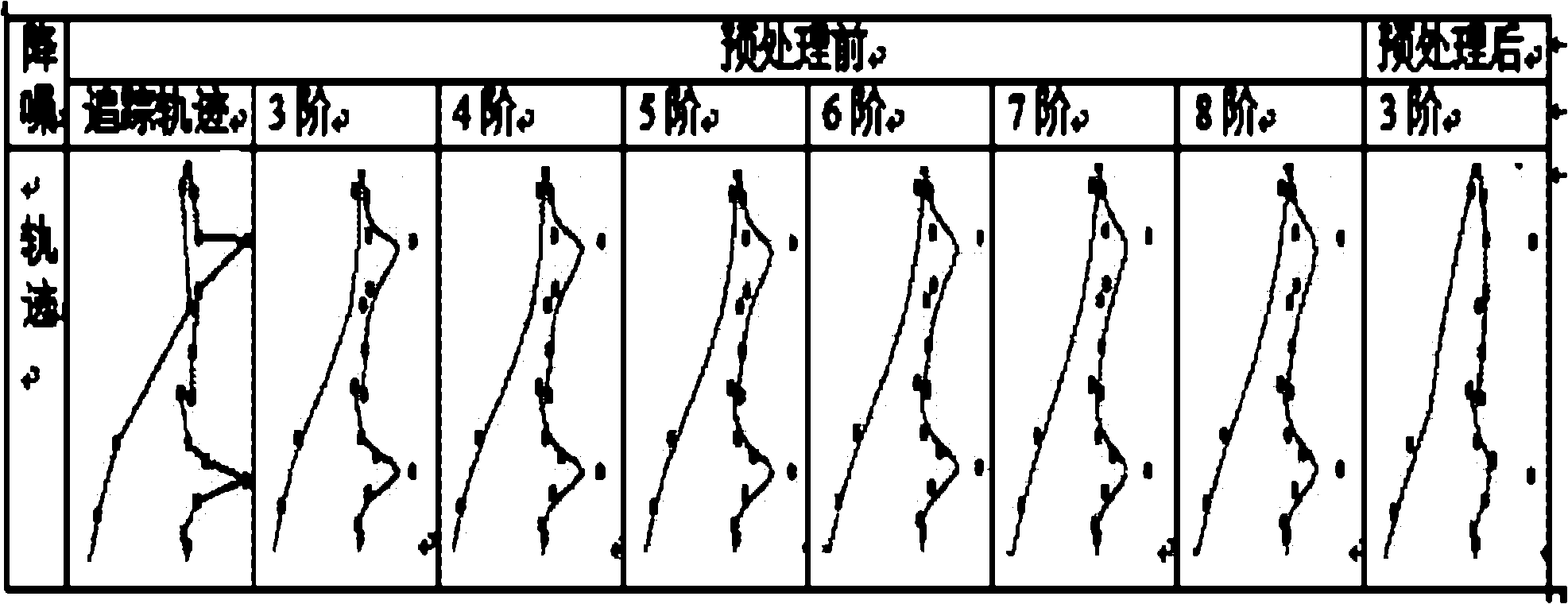

Motion capture system, data noise reduction method and system of motion capture

ActiveCN102201122AKeep detailed data informationEliminate impact noiseImage enhancementImage analysisMotion graphicsData information

The invention discloses a data noise reduction method of motion capture. The method comprises the following steps: collecting two frames or more motion graphic data of a plurality of mark points and tracing movement tracks formed by the mark points in each frame according to collected motion graphic data; fitting the movement tracks of the mark points by using low-order B-spline Curves respectively so as to generate a plurality of approximation curves which are one-to-one corresponding to the movement tracks of the mark points. The approximation curves are the movement tracks of noise reduced movement tracks of the mark points. Through using the data noise reduction method of motion capture provided by an embodiment of the invention, detail data information of movement tracks of the mark points is maintained when capturing face expression movements. Therefore, the system has the characteristic of good real-time property.

Owner:DALIAN UNIV

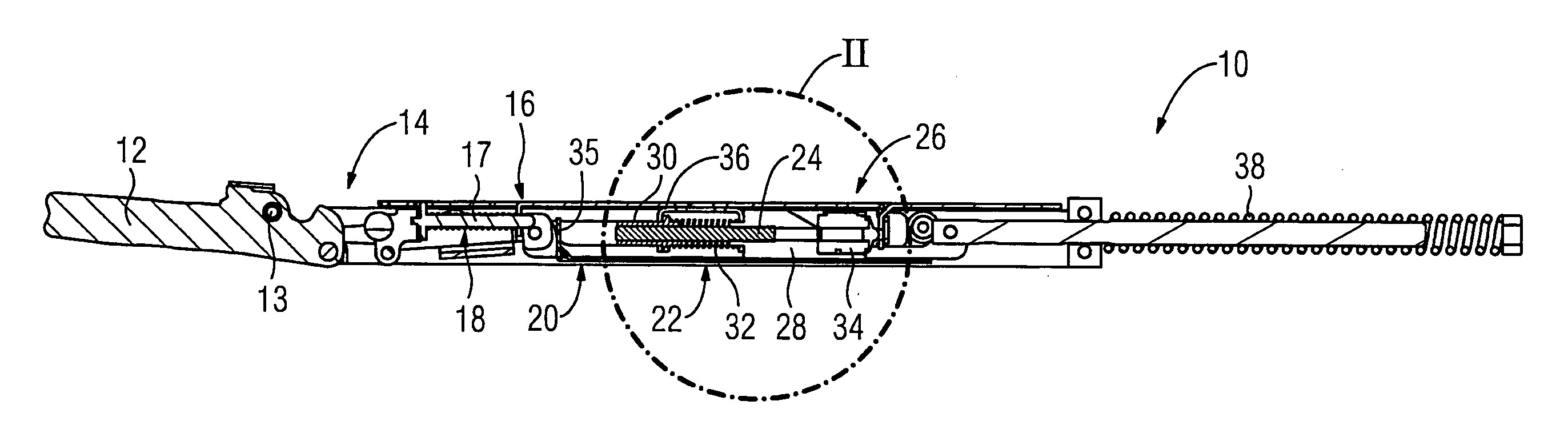

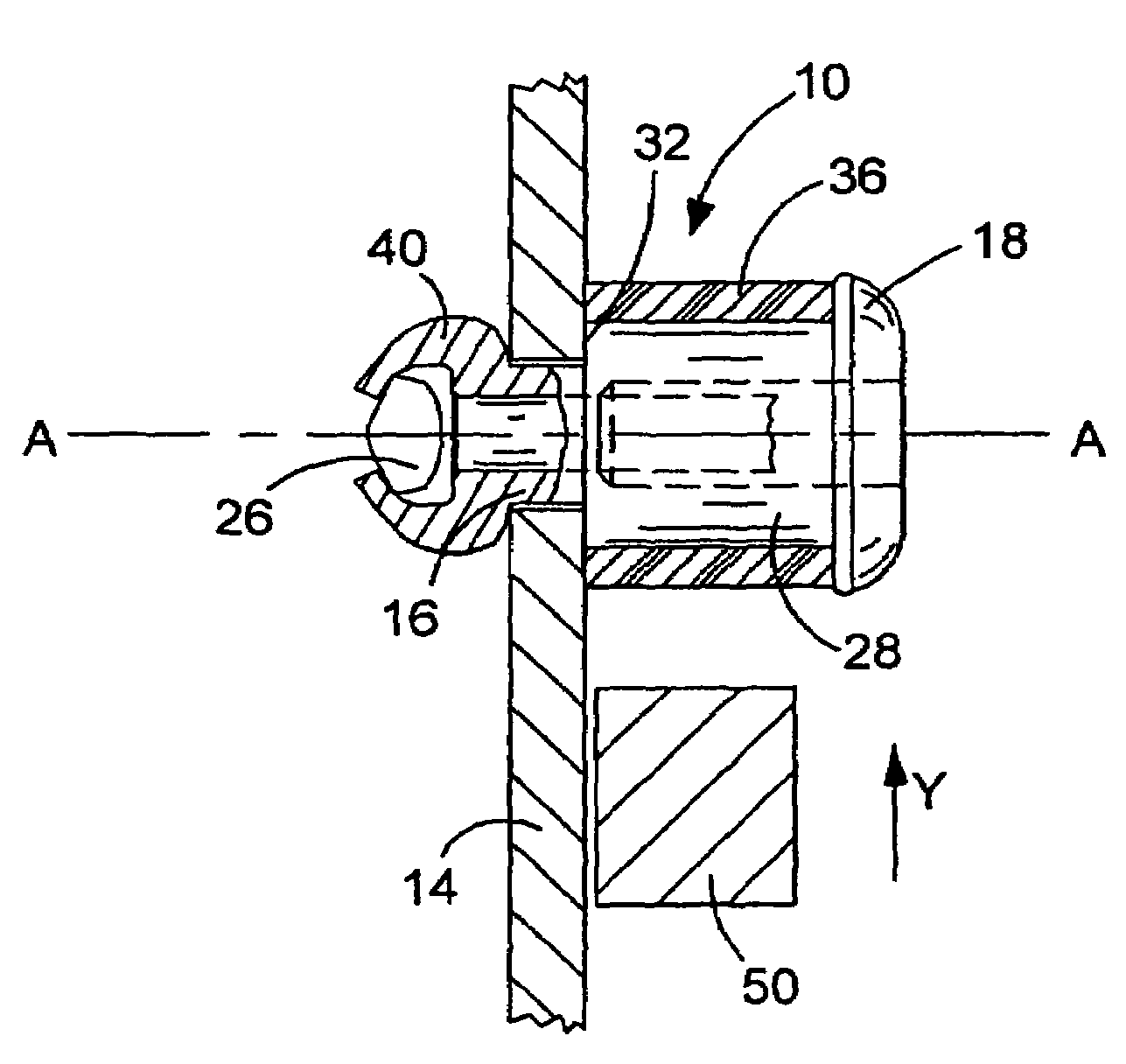

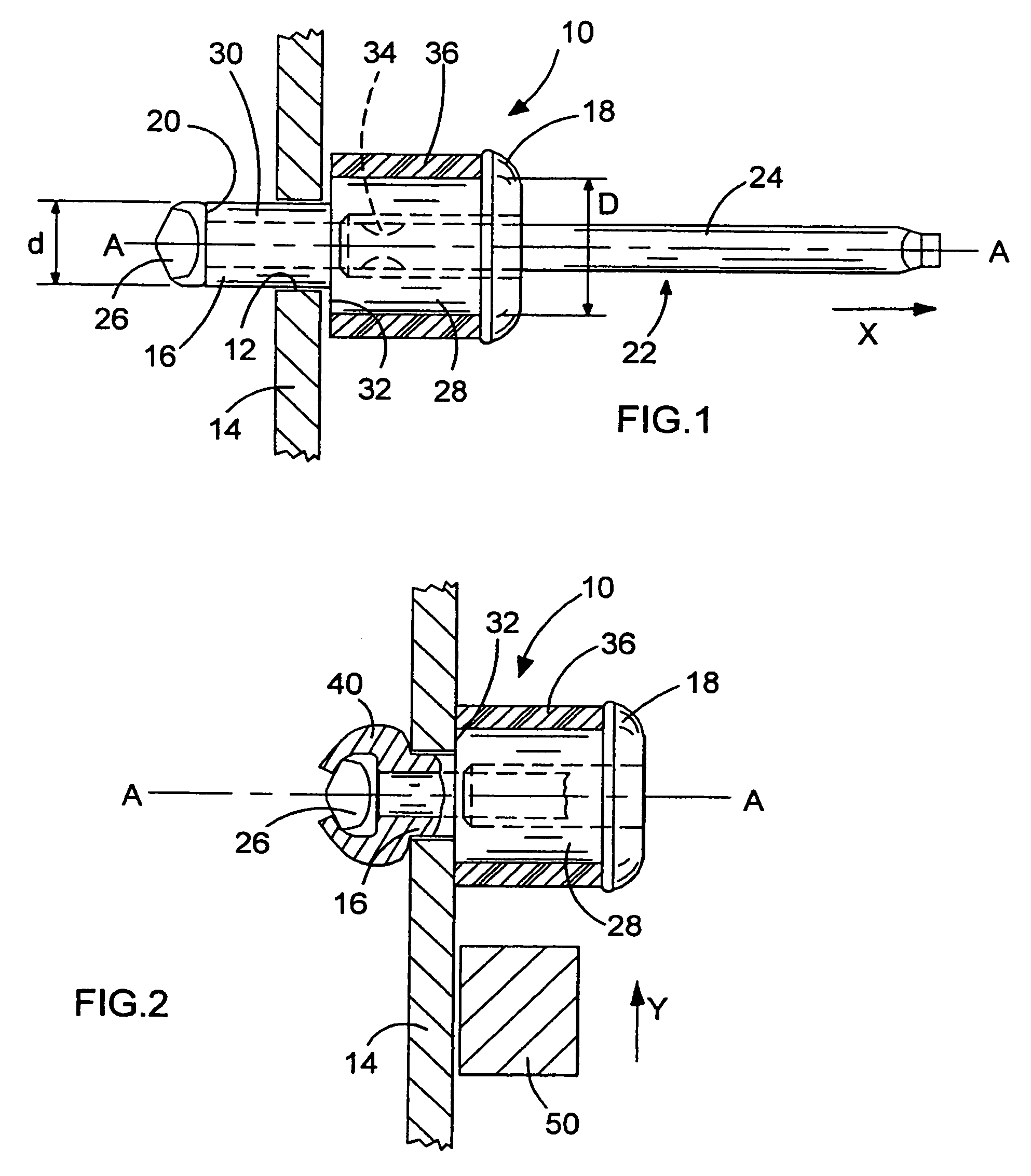

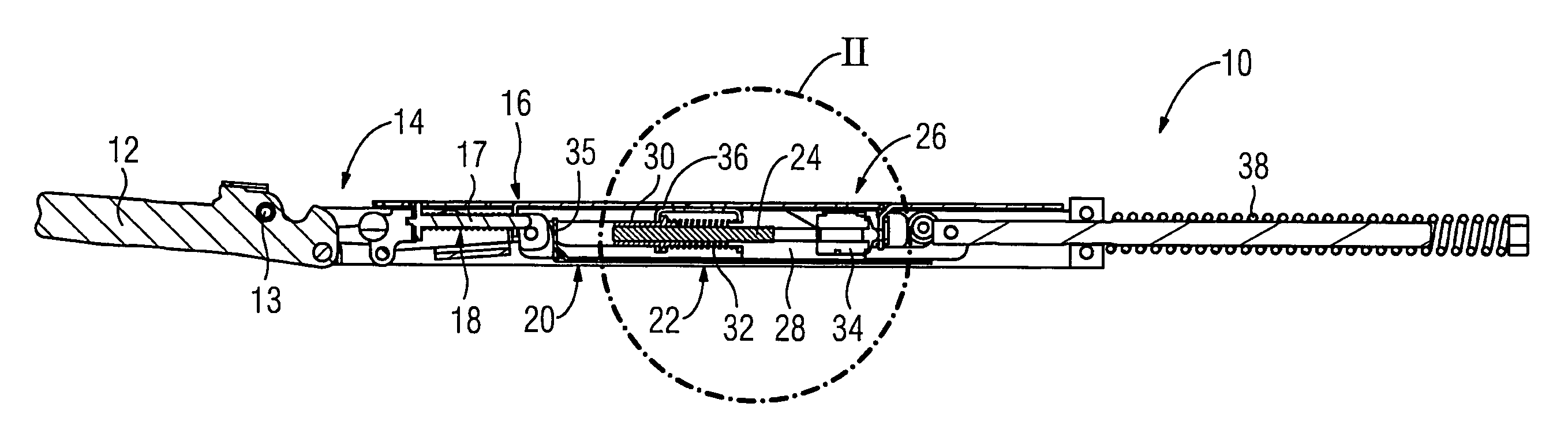

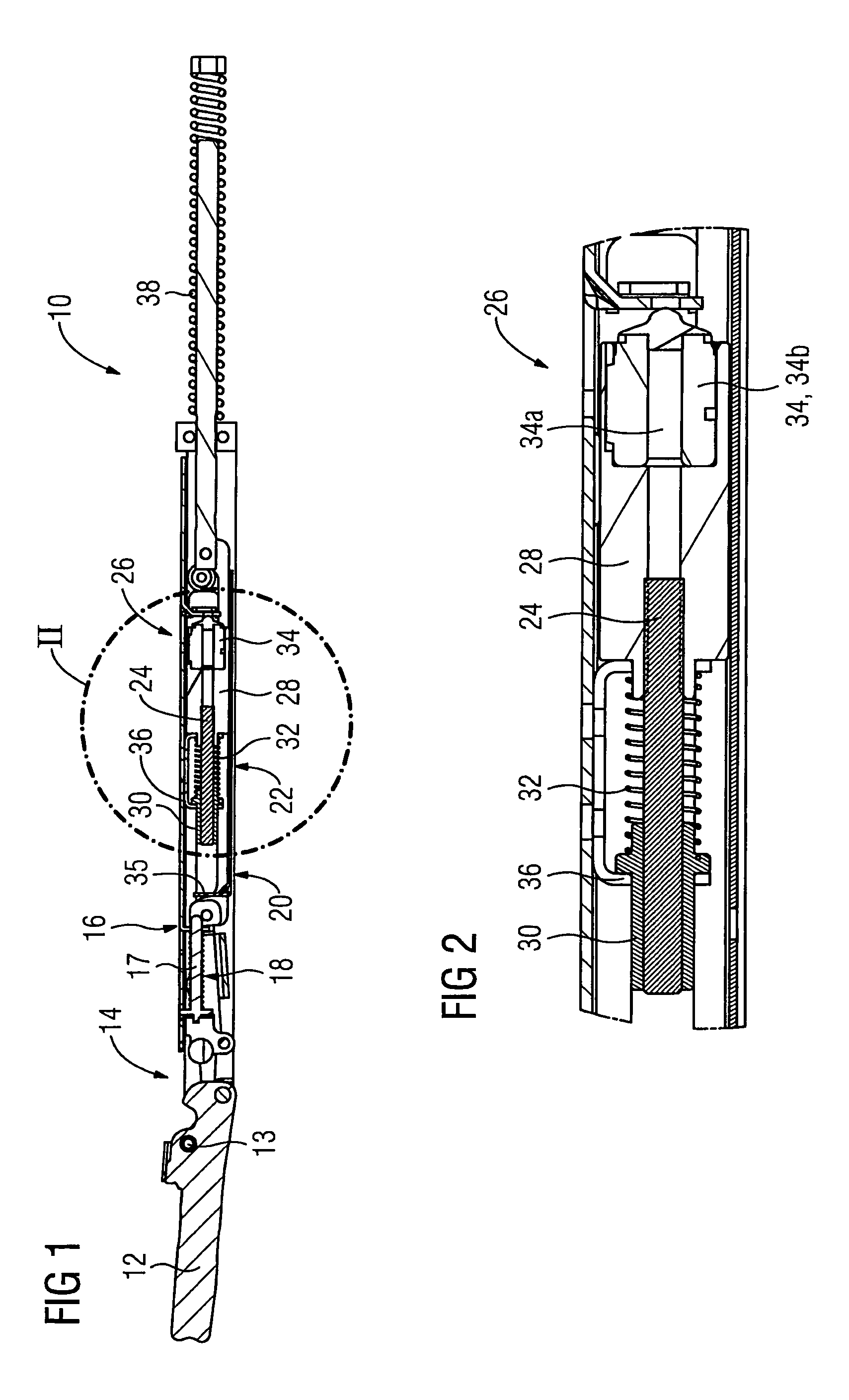

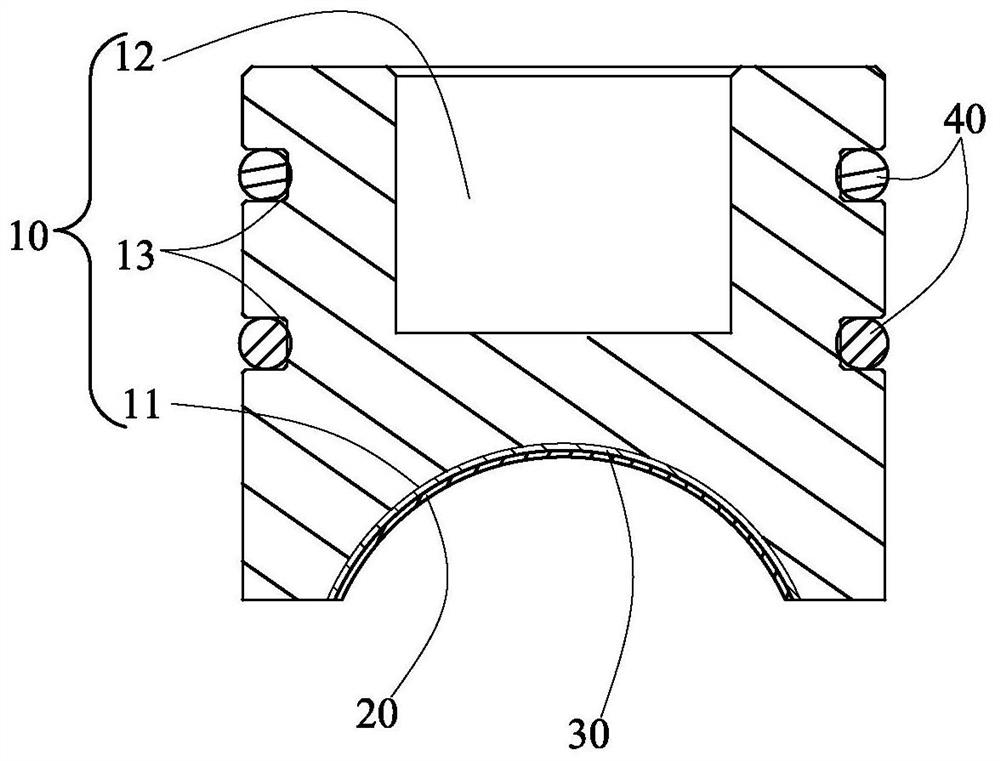

Blind fastener

The present invention is directed to a blind fastener, usually a blind rivet, (10) comprising a mandrel (22) and an elongate cylindrical body (16) mounted on a stem (24) of such mandrel so as to extend co-axially about a central axis A of such blind rivet, the body (16) having a flange (18) at one end and a tail end (20) at an axially opposed end, for insertion through a hole in a workpiece, the mandrel having a mandrel head (26) in operative engagement with this tail end (20) for transmitting force thereto during setting of such fastener, wherein the body (16) has two different external diameters (d, D) and a radially extending shoulder (32) therebetween such that the external diameter (D) of the body adjacent to the flange (18) is greater than the external diameter (d) of the body adjacent to the tail end, wherein the body between this shoulder (32) and the flange is at least partially encased in a resilient, shock absorbing material (36).

Owner:NEWFREY

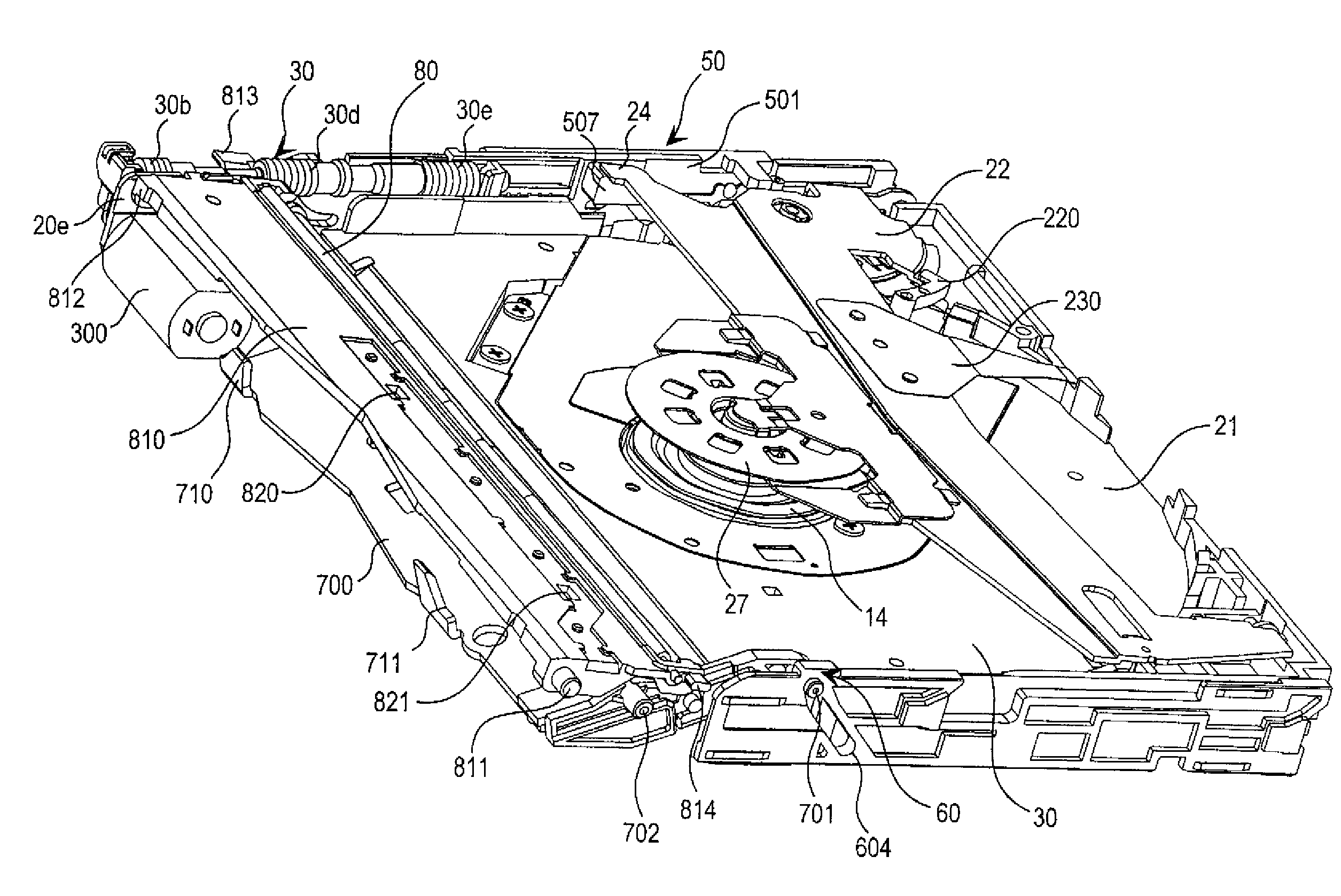

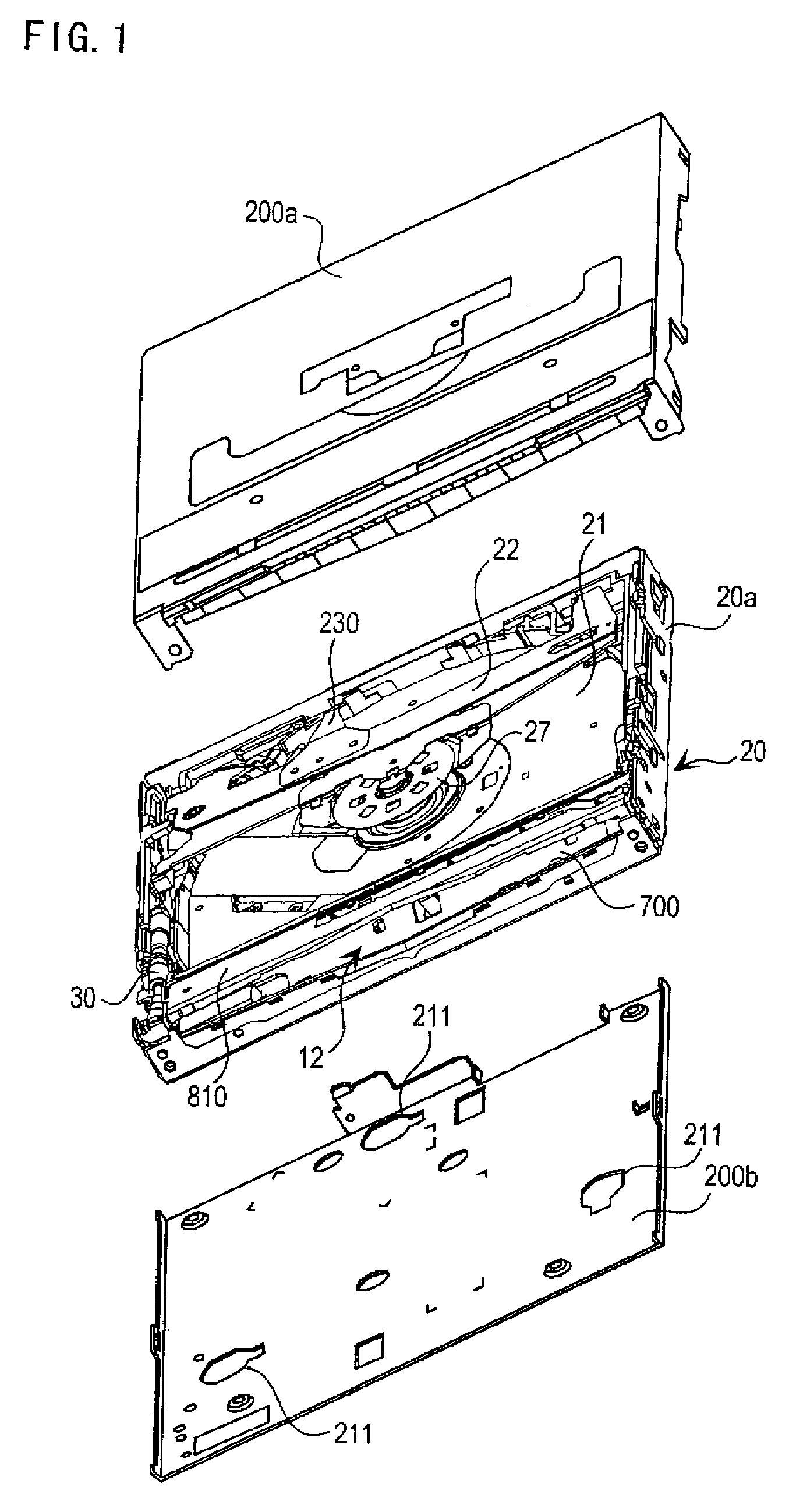

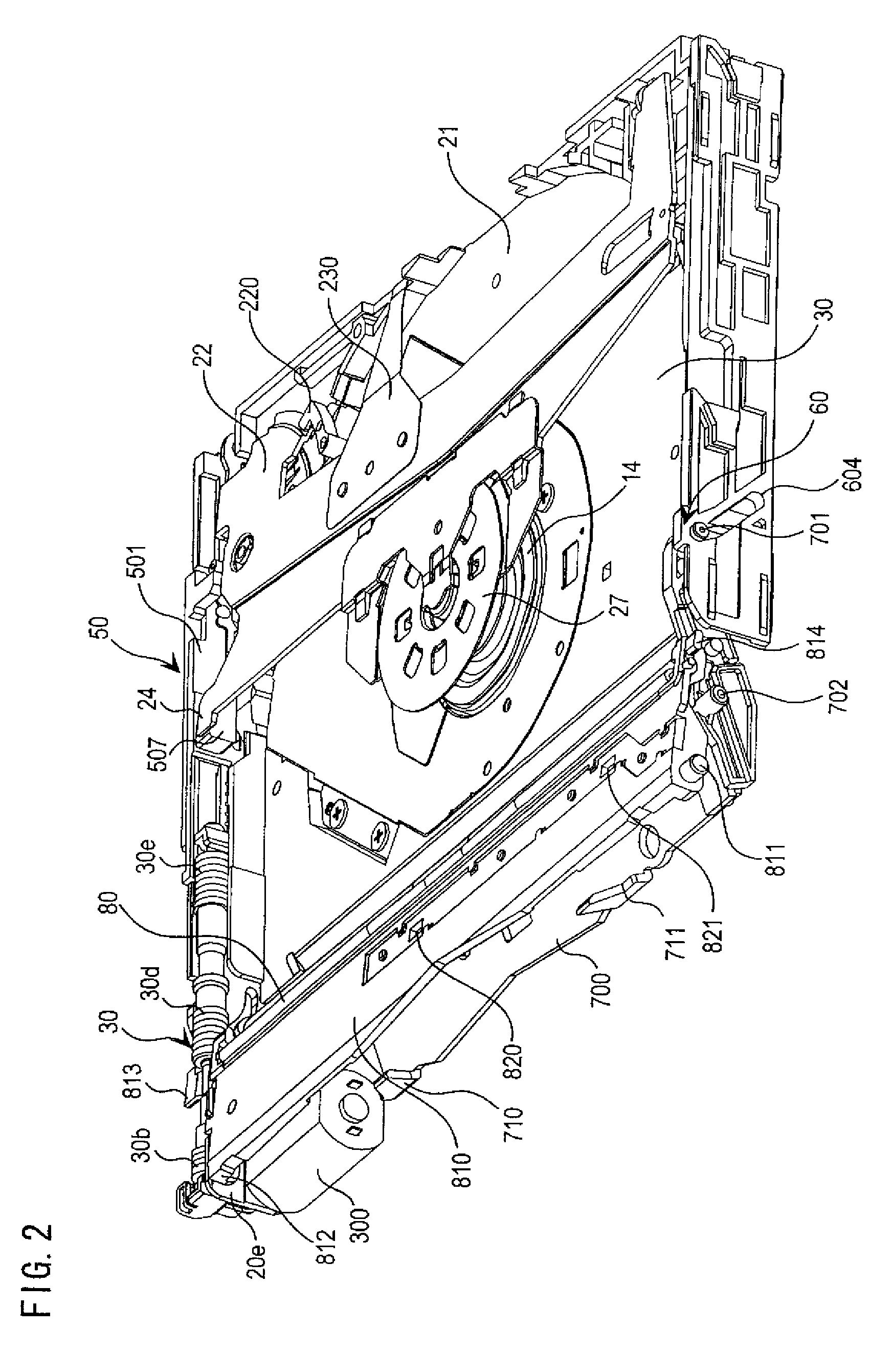

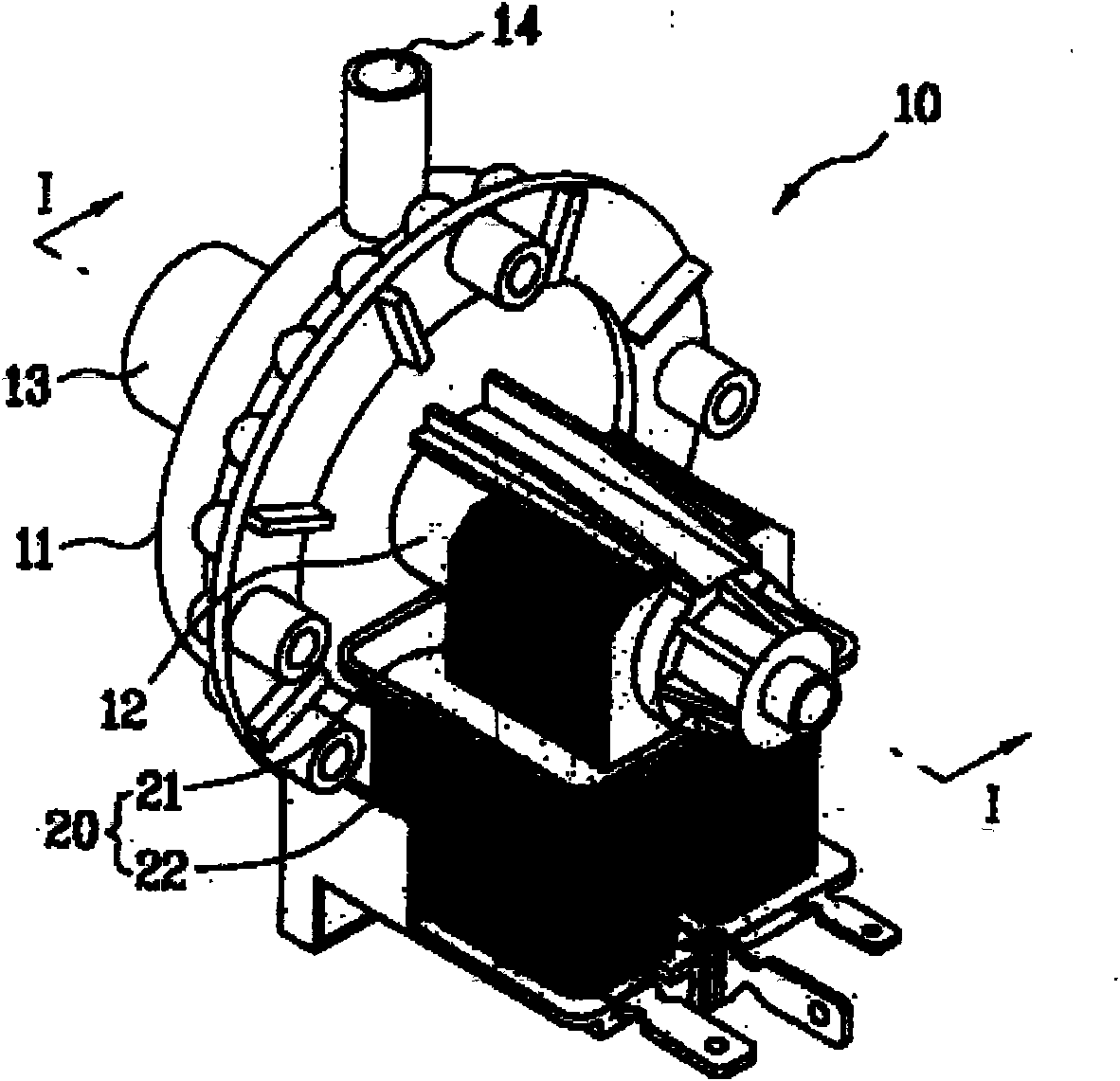

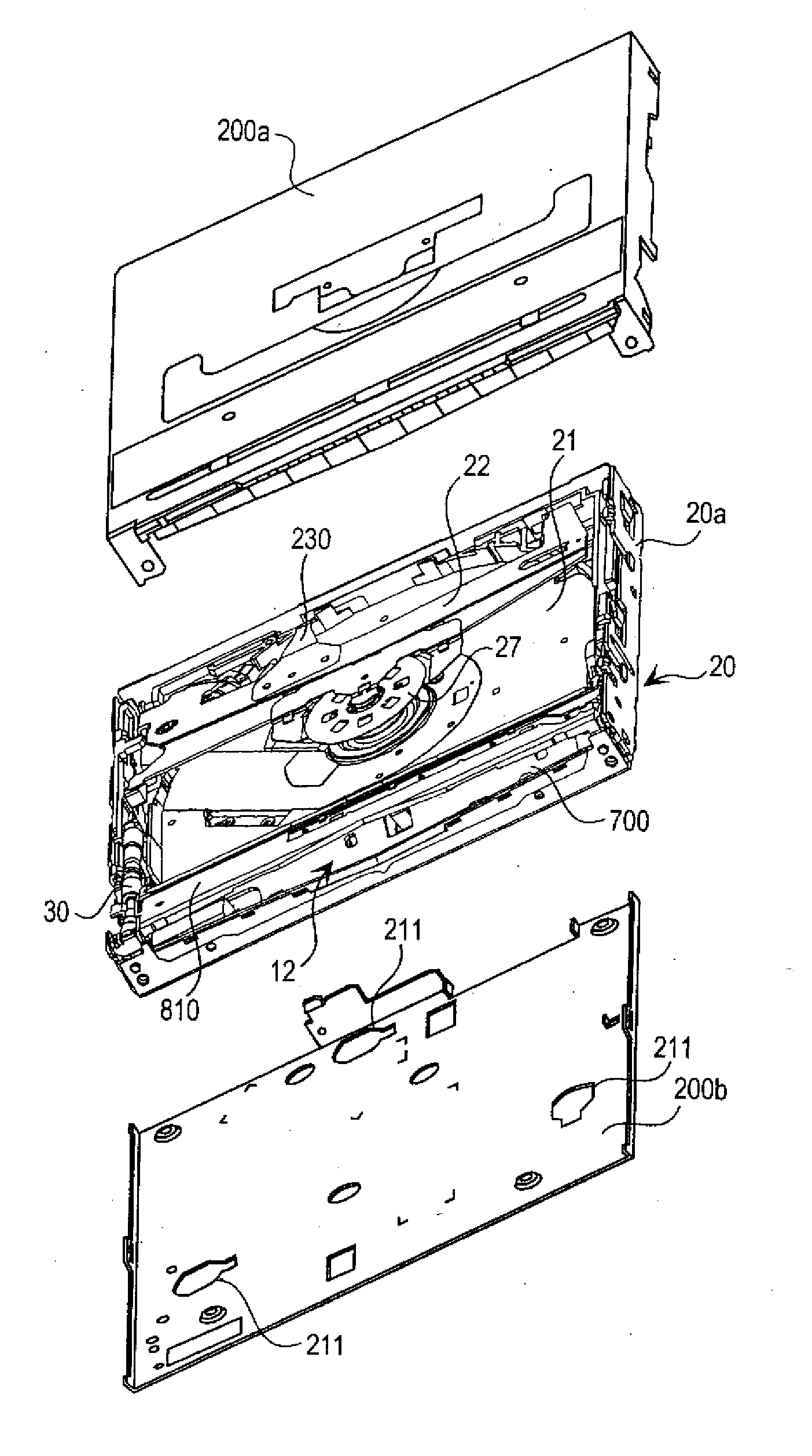

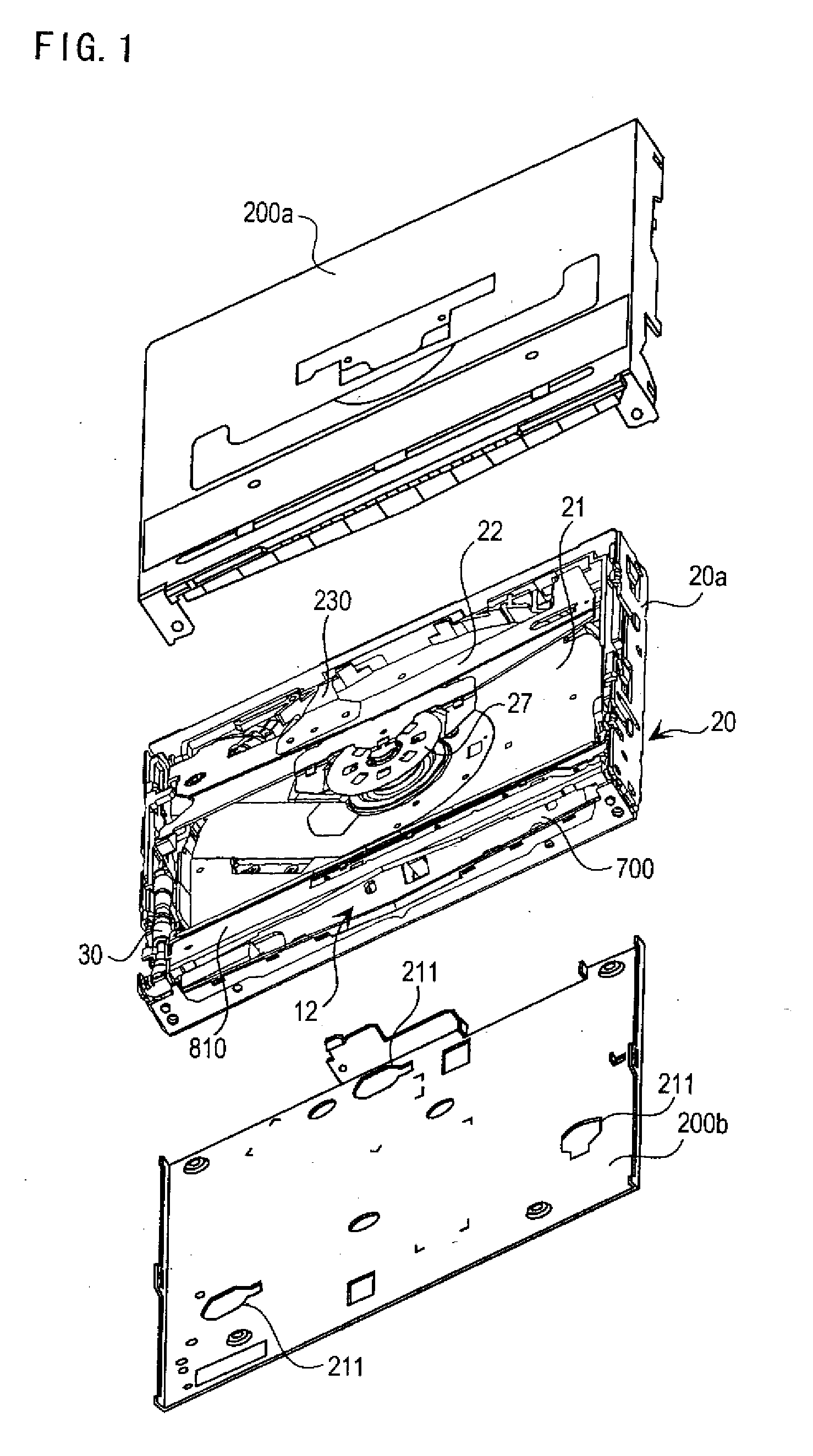

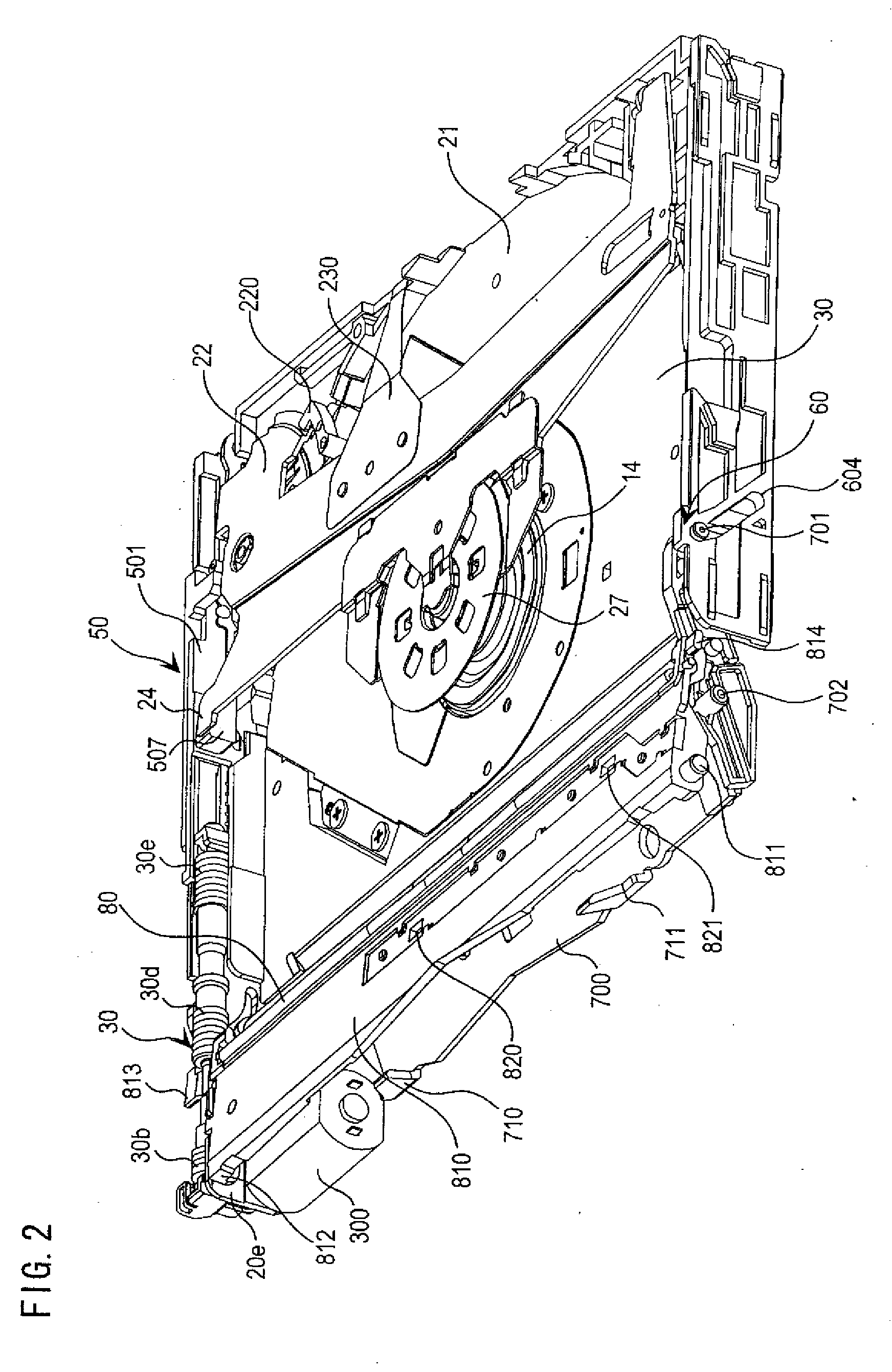

Disc player apparatus with upper and lower rollers for transporting and guiding a disc

InactiveUS7814504B2Easy to assembleEliminate impact noiseUndesired vibrations/sounds insulation/absorptionRecord information storageMechanical engineering

There is provided a disc player apparatus capable of transporting a disc (11) by holding the disc (11) between a lower roller (70) and an upper roller (80). The lower roller (70) and the upper roller (80) are rockably supported with respect to a main body (20a). A flat spring (210) which urges the upper roller (80) is attached to an upper case (200a) that is attached to the main body (20a). The urge of the flat spring (210) is applied via a roller support member (810) which supports the upper roller (80). The pressure is applied evenly to the upper roller (80), enabling to reduce diagonal travel of the disc for example, and to transport the disc smoothly.

Owner:SANYO ELECTRIC CO LTD +1

Oven door opening and closing device

InactiveUS9074400B2Eliminate impact noiseImprove handlingDoors for stoves/rangesBuilding braking devicesEngineeringShock absorber

Owner:ELECTROLUX HOME PROD CORP NV

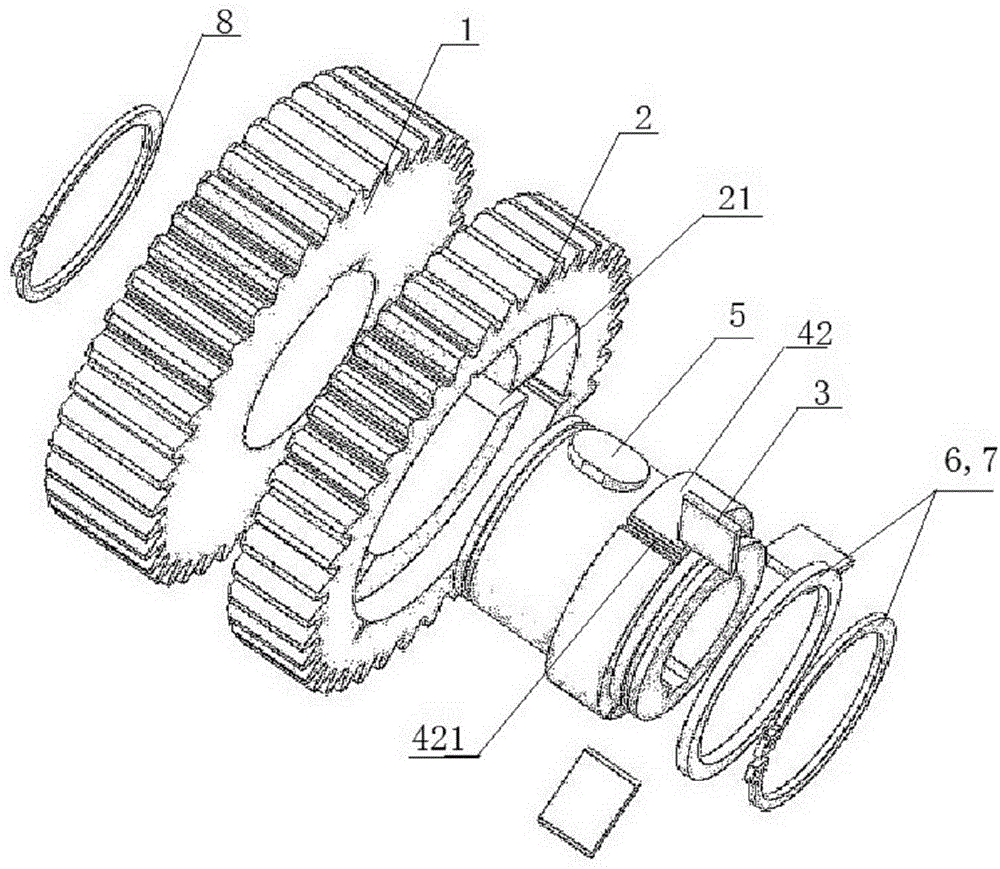

Double ratchet, double pawl vehicular latch with soft stop on reset

ActiveUS9512651B2Eliminate impact noiseAvoid knocking noiseNoise-prevention/anti-rattling lockingConstruction fastening devicesGear wheelGear train

A low release effort eccentric double ratchet, double pawl vehicle latch includes a ratchet, a primary pawl, an auxiliary ratchet and a secondary pawl. A drive mechanism including a gear cam wheel sequences movement of the secondary pawl to open and reset the latch. Upon reset, the drive mechanism actuates the auxiliary ratchet back to a closed state in a soft manner without using a hard stop; instead the latch has a cushioning spring that is used to softly stop the gear train during the reset absorbing motor energy and thus eliminating impact noise.

Owner:MAGNA CLOSURES SPA

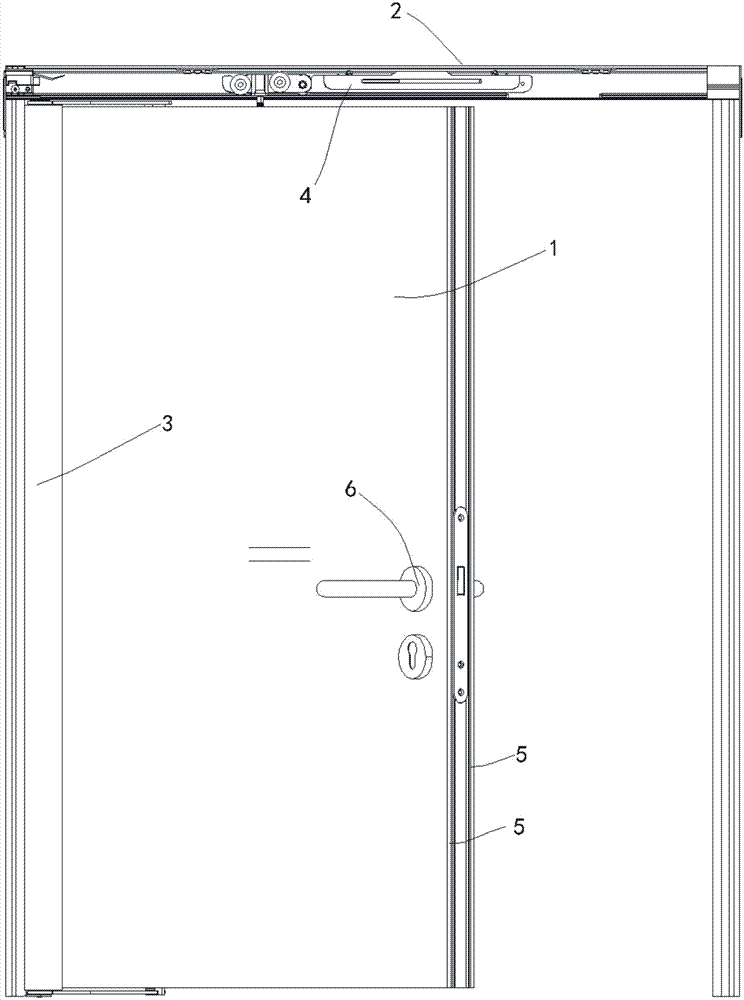

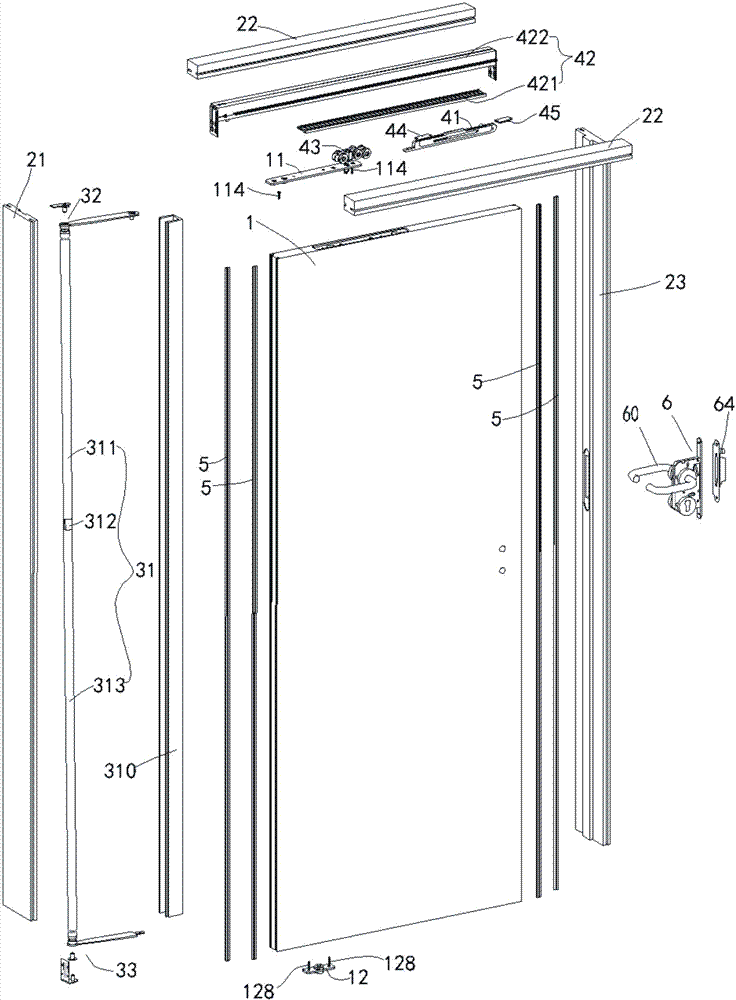

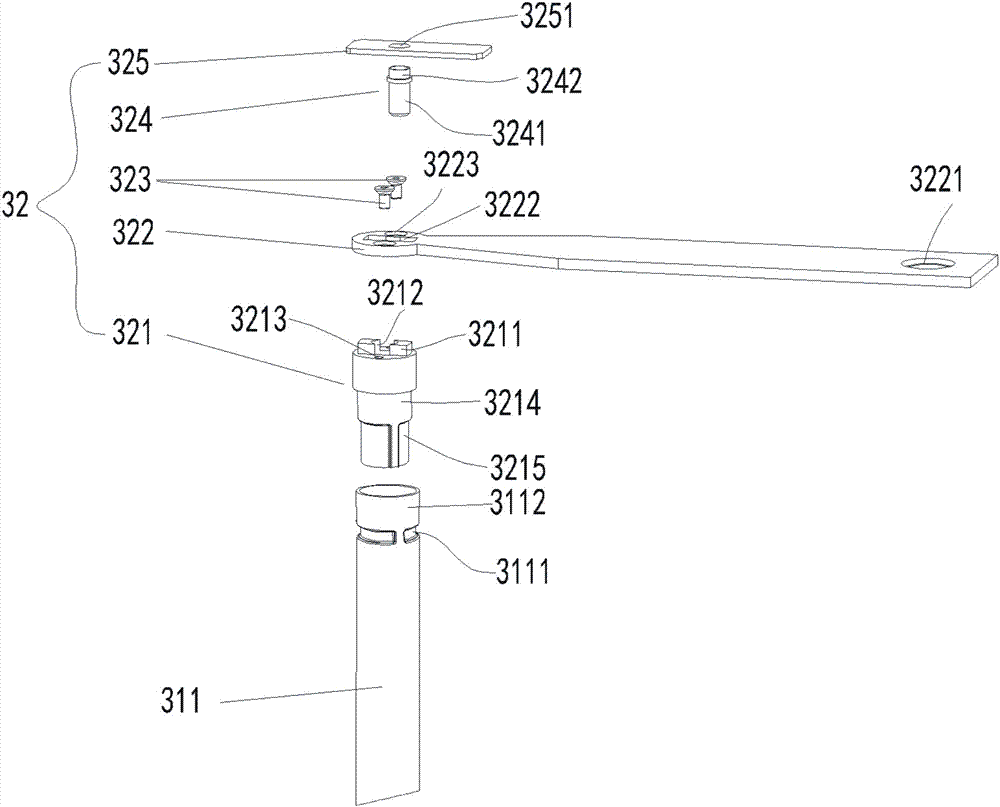

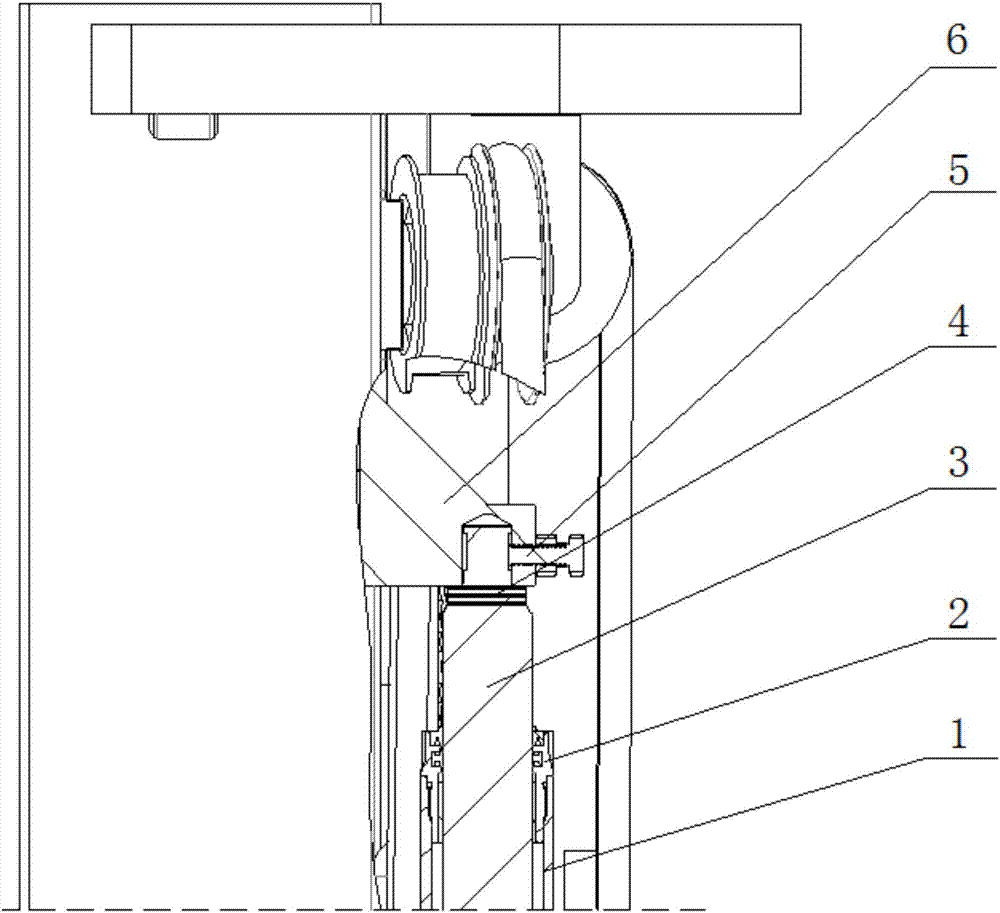

Noiseless vertical hinged lateral overturned door system

ActiveCN104328990AEliminate impact noiseReduce the impactWing arrangementsWing suspension devicesEngineeringPulley

The invention relates to a vertical hinged lateral overturned door system, and provides a noiseless vertical hinged lateral turned door system. An overturn mechanism is arranged between a door leaf and a rotating shaft vertical plate of a door frame, so that the door leaf is overturned laterally in the process of horizontally pushing a door, and a door-opening sweeping space is reduced; meanwhile, a buffer component is arranged in the overturn mechanism, and friction during rotation is reduced; damping pulley mechanism is arranged between a lintel horizontal plate and the door leaf, and collision between the door leaf and the door frame is eliminated in the door opening and door closing travels; side edges of the door leaf is provided with sealing strips to further reduce the collision between the door leaf and the door frame and achieve a soundproof effect; the locking end of the door leaf is provided with a noiseless lock body, and noise in the locking and unlocking process is avoided. According to the scheme, the noise generated in the door using process is comprehensively eliminated, and home and office environments are silenced.

Owner:GUANGDONG MINGMEN LOCKS IND

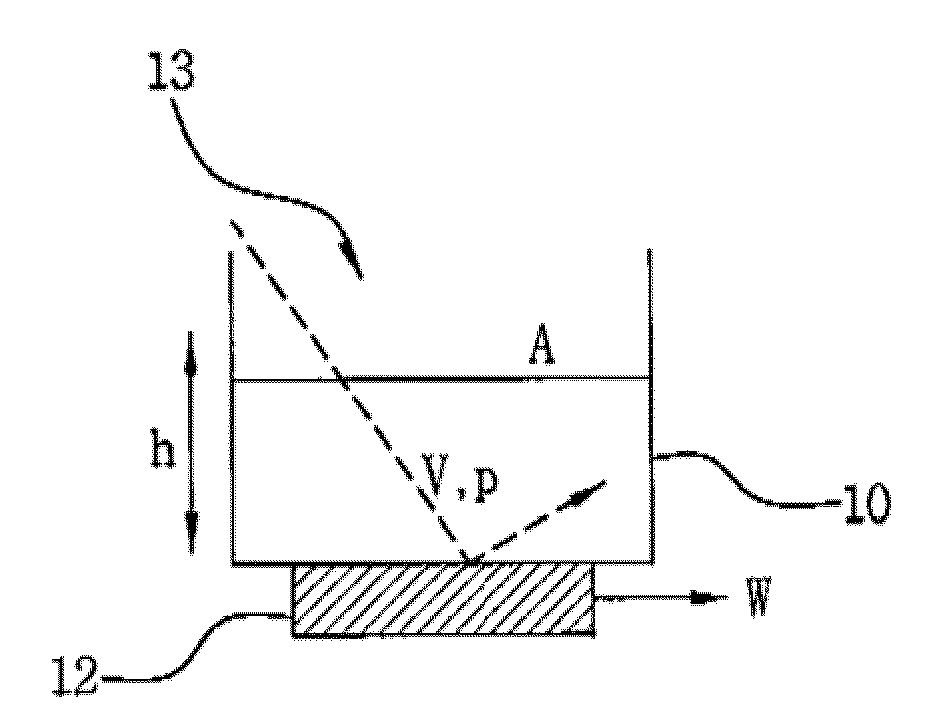

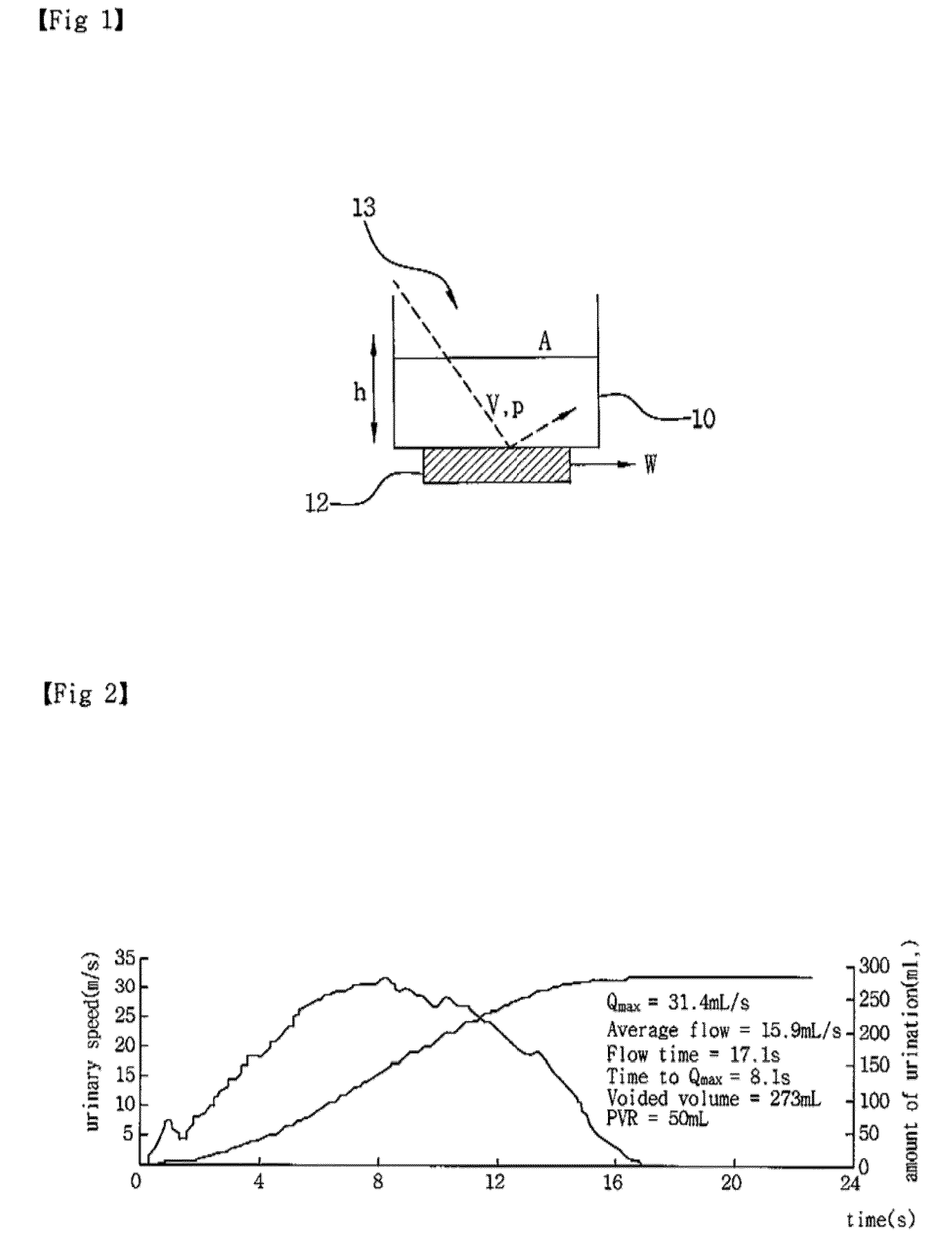

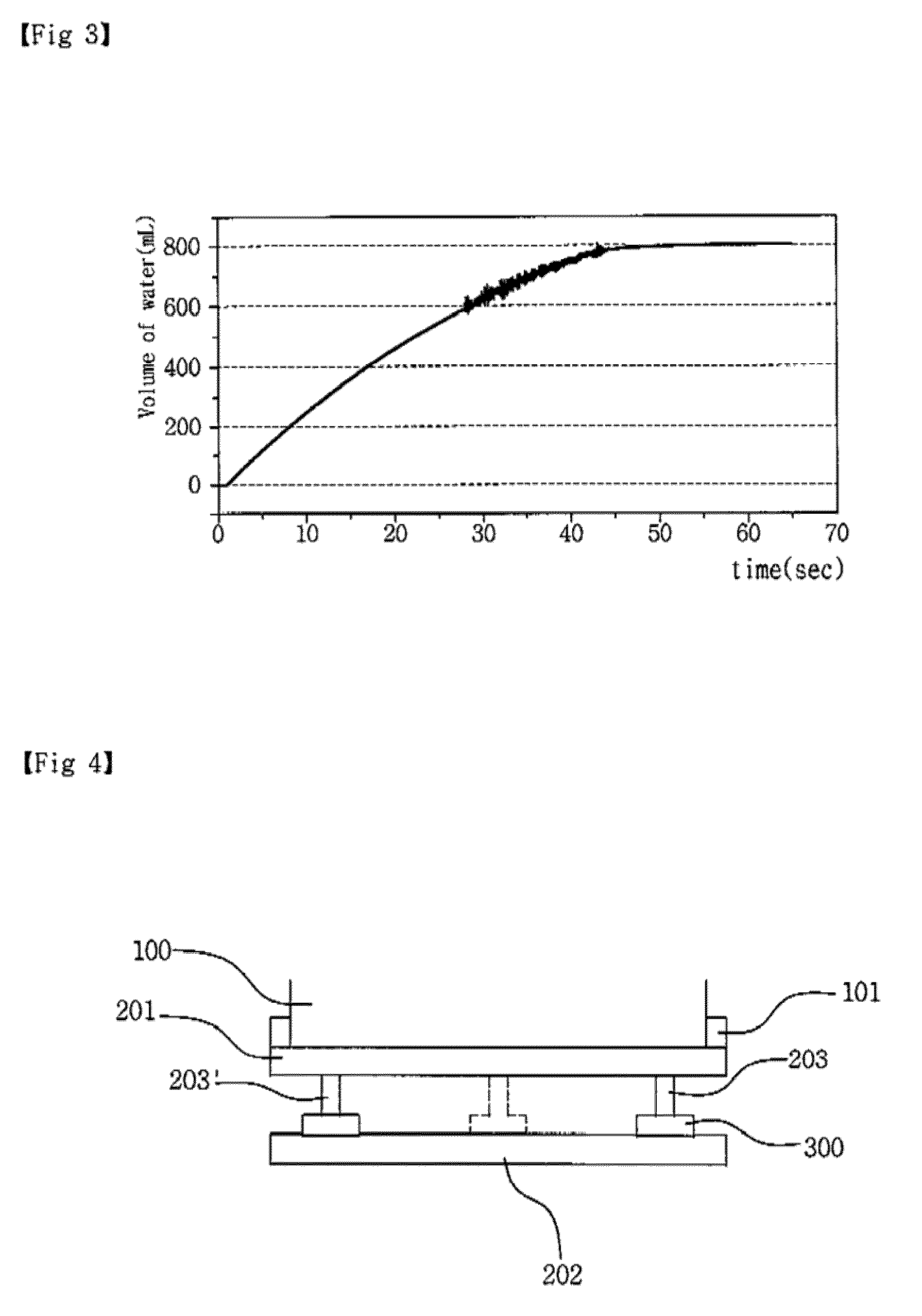

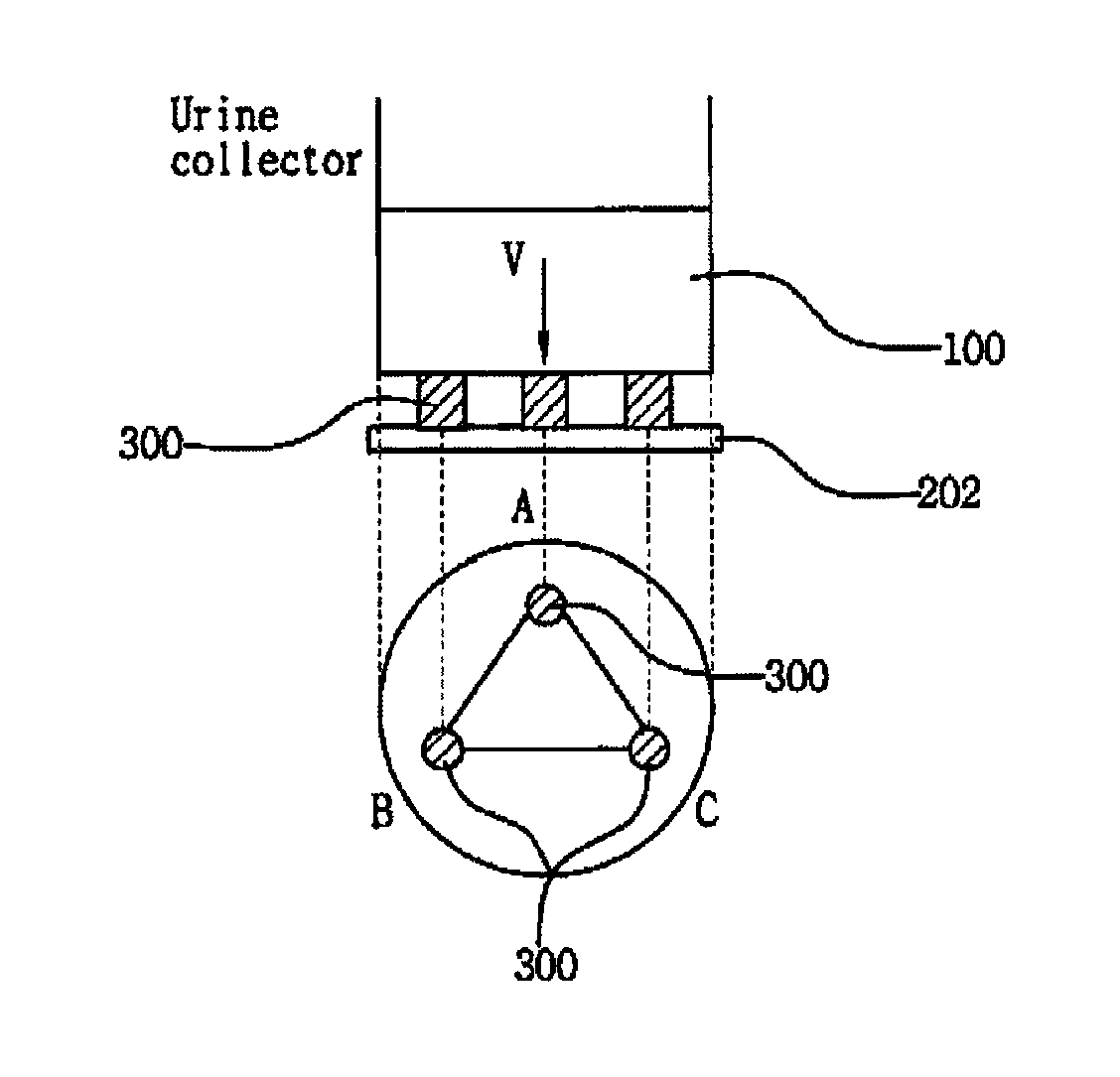

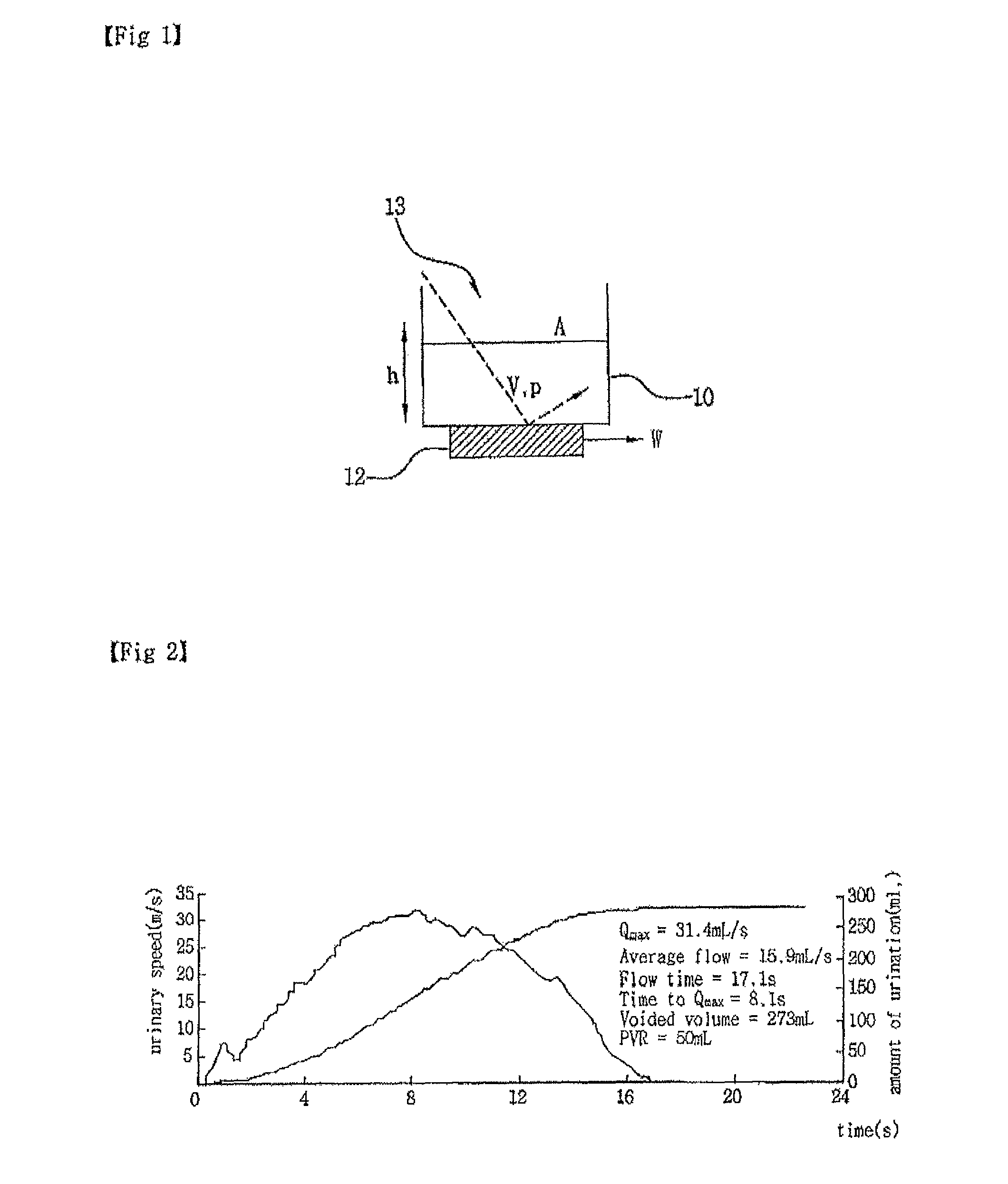

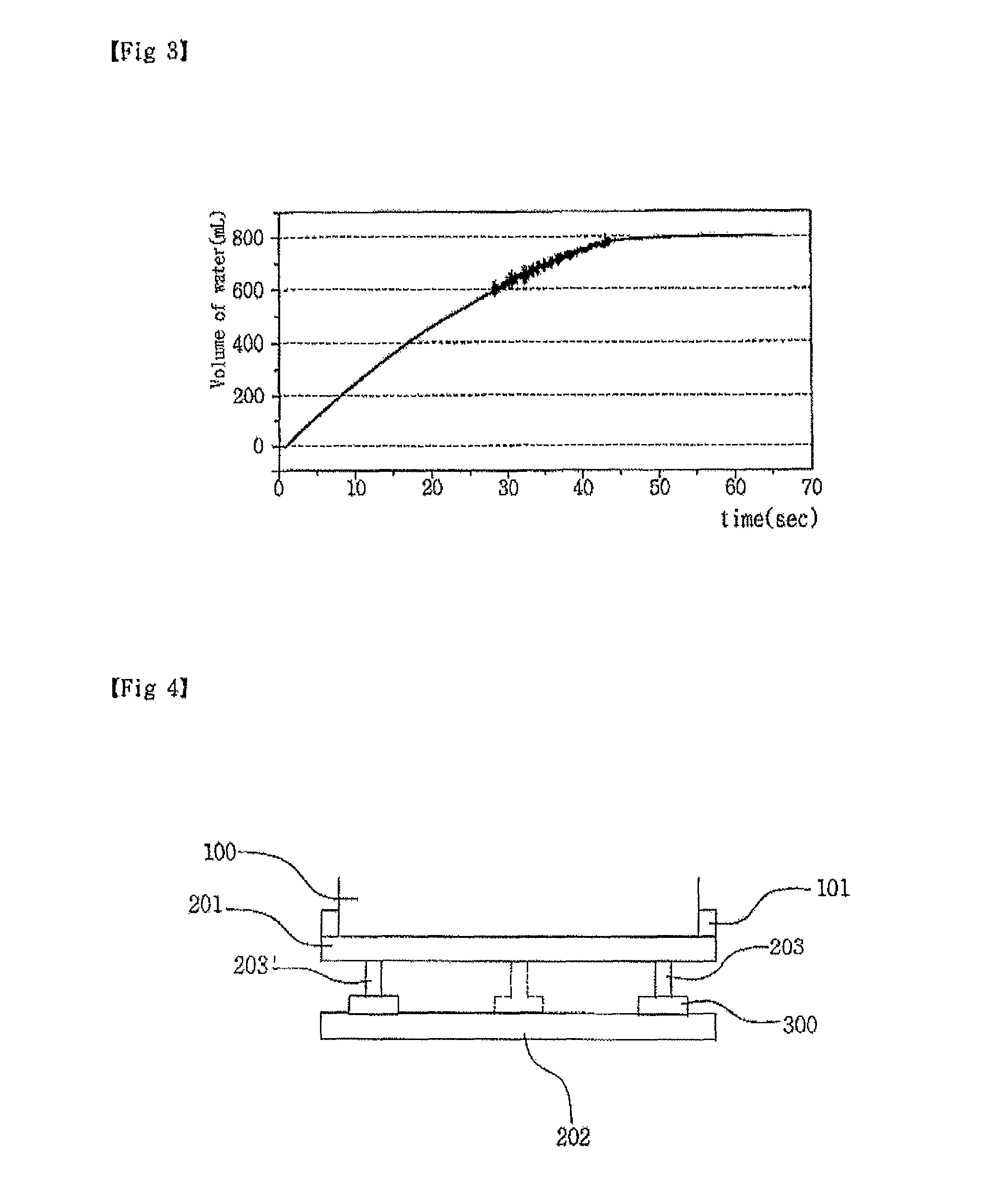

Method and system for measuring urinary flow rate

InactiveUS20100152684A1Minimizing impact noiseNoise minimizationDiagnostic recording/measuringSensorsEccentric hypertrophyPersonal computer

A method and system for measuring a urinary flow rate minimizes impact noise caused by urine to measure the urinary flow rate using a plurality of load cells when prostatic hypertrophy is diagnosed. The method includes measuring an amount of urine collected into a container using a plurality of load cells, extracting and averaging urinary flow rate signals from the measured results, and removing the impact noise from the urinary flow rate signals, converting the urinary flow rate signals into digital signals through an A / D converting circuit, and outputting the digital signals using a personal computer or a microprocessor analyzer which is interfaced with the A / D converting circuit.

Owner:CHUNGBUK NAT UNIV IND ACADEMIC COOPERATION FOUND

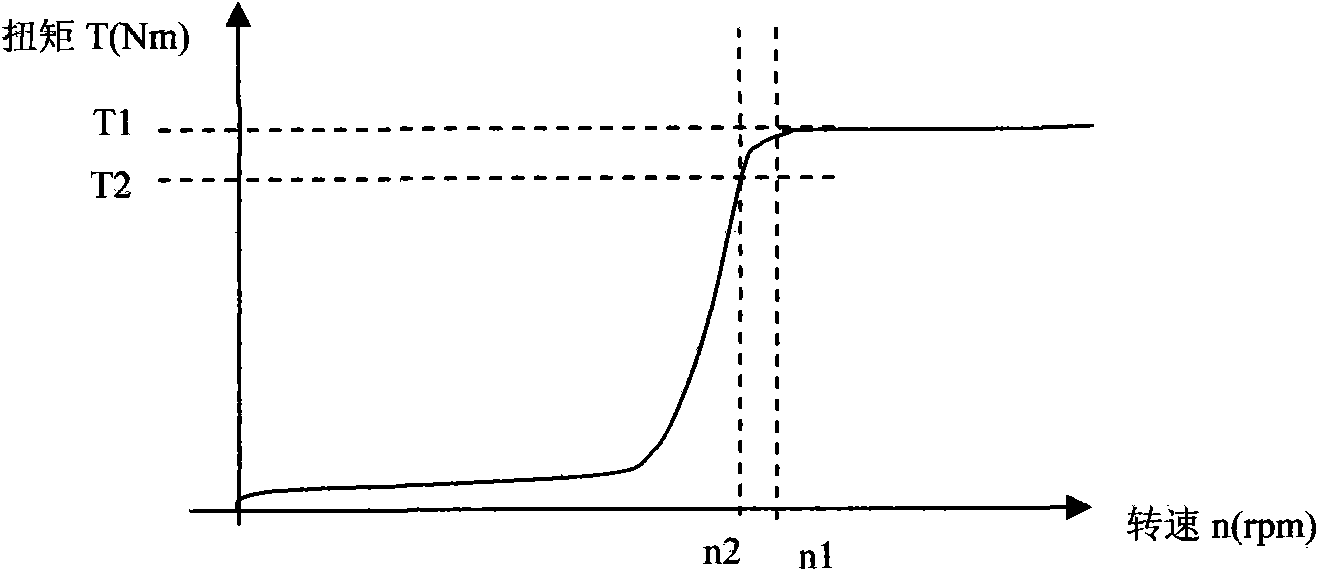

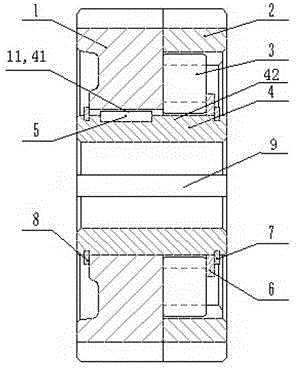

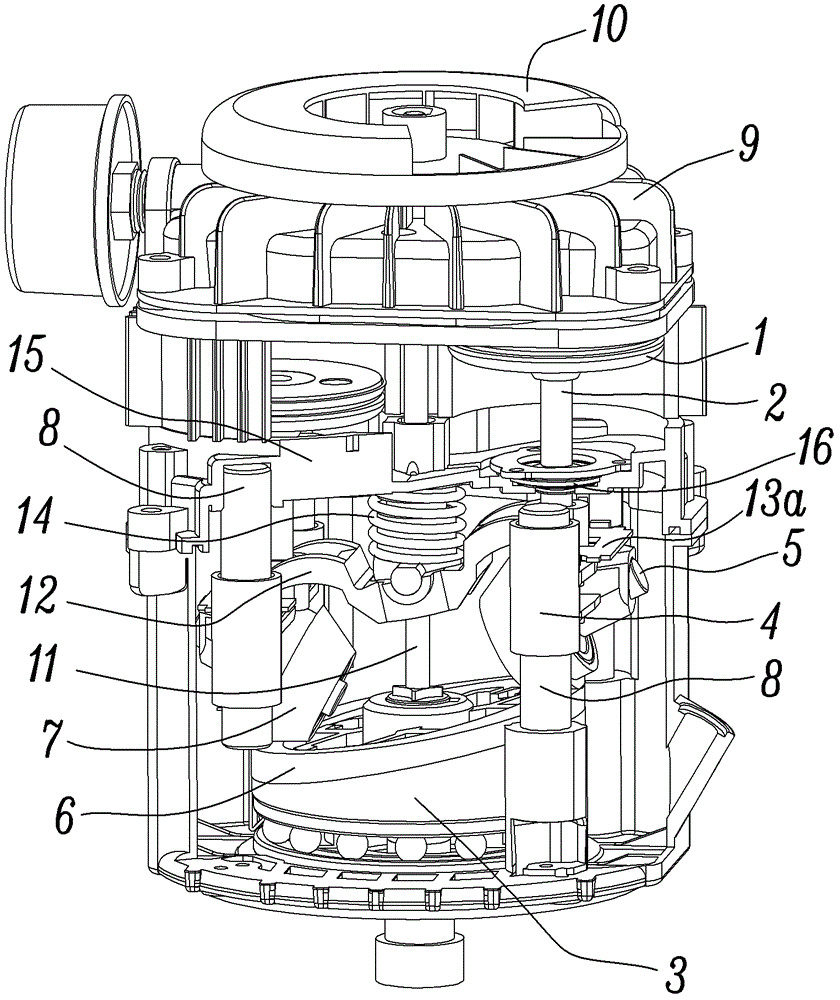

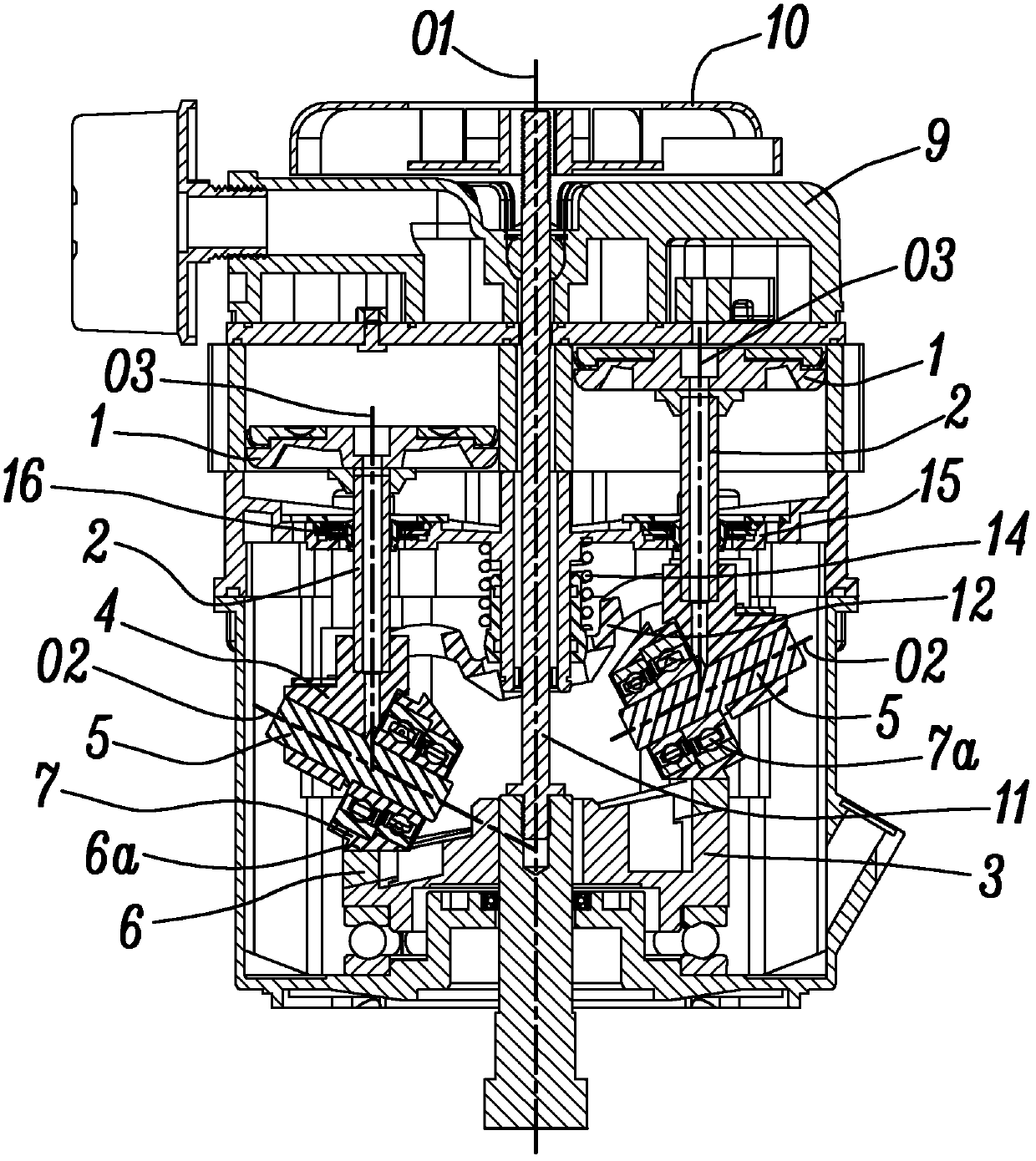

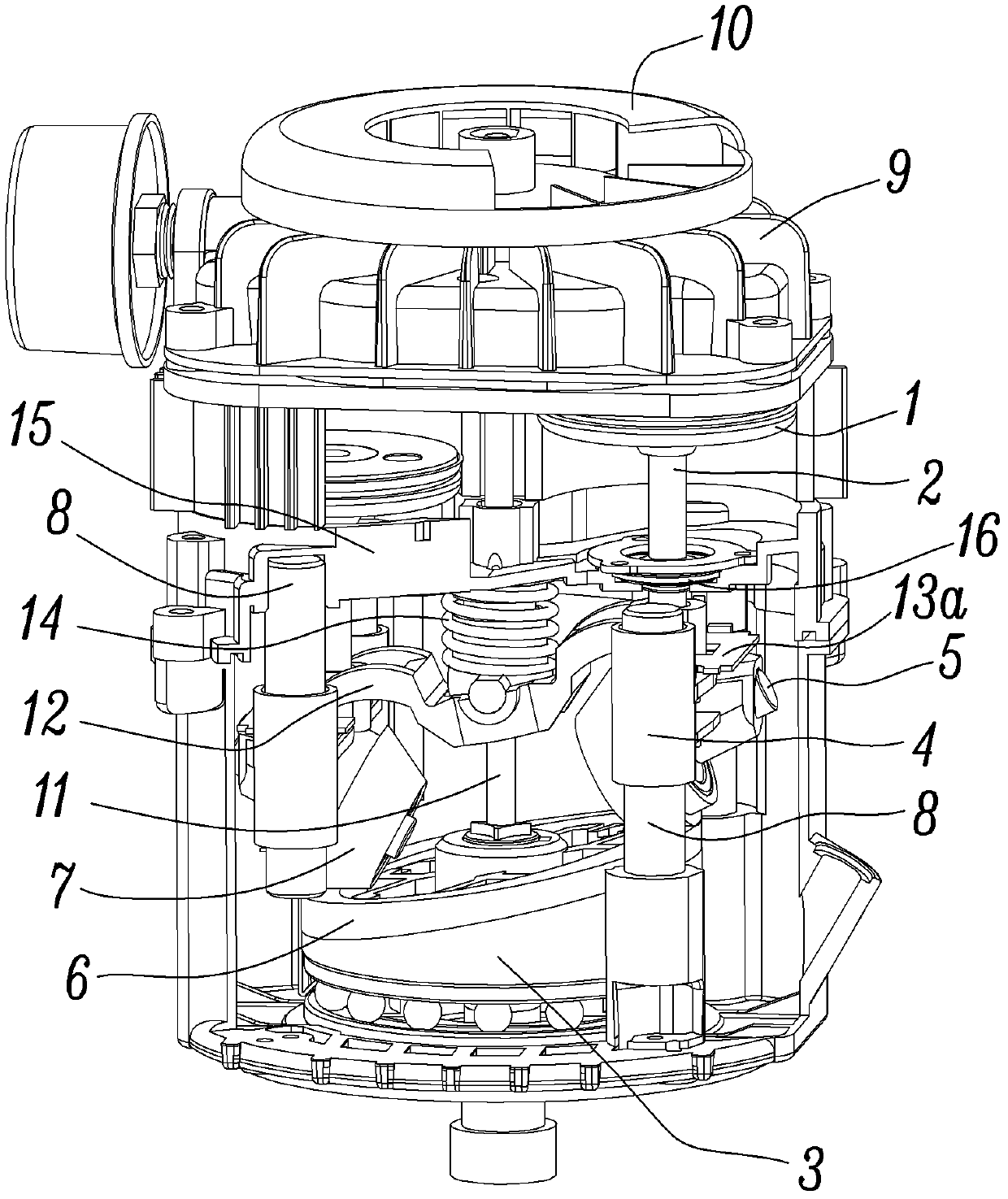

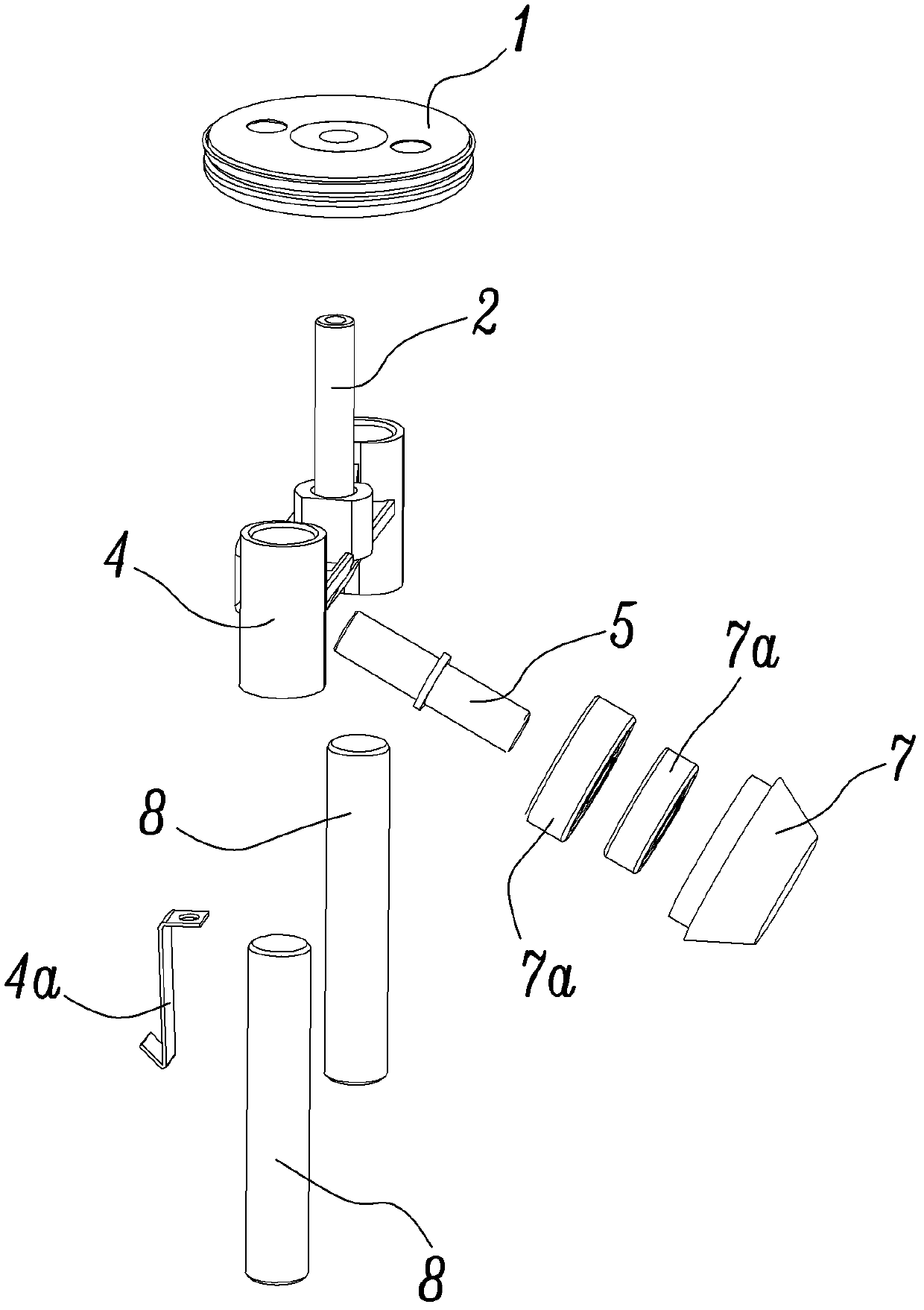

High-efficiency axial flow synchronous draining pump

InactiveCN101581309ASolve the problem of uncontrolled rotation directionSolve the impactPump componentsAxial flow pumpsAxial-flow pumpImpeller

The invention relates to a synchronous water pump used for household appliances, in particular to a synchronous draining pump. The synchronous pump is characterized in that by changing the driving mode of a synchronous motor to an impeller and combining an impeller component structure with a rotor component structure, the cost of materials and manufacture is reduced greatly; by a directional braking structure, the rotating direction of the impeller is controlled effectively, the traditional centrifugal synchronous pump is changed into an axial flow pump and the draining efficiency and performance of the pump are improved; by changing a transmission structure, the driving of the motor is more smooth, the impact on the product is minimized, the noise is reduced, and the service life of the pump is prolonged; and an iron-core split-type design reduces the material cost and improves the electromagnetic performance. Therefore, the draining pump is characterized by comprising the following parts of an axial flow impeller 310 provided with a directional braking structure and accessories thereof; a magnetic ring for matching with the directional braking structure of the axial flow impeller 310 and accessories thereof; stainless steel sleeve 270 with highly-bright inner wall; and a stator core 240 of the split-type structure. The combination of the structures realizes the functions of buffering, directional rotating and axial flow type water draining.

Owner:何丽英 +1

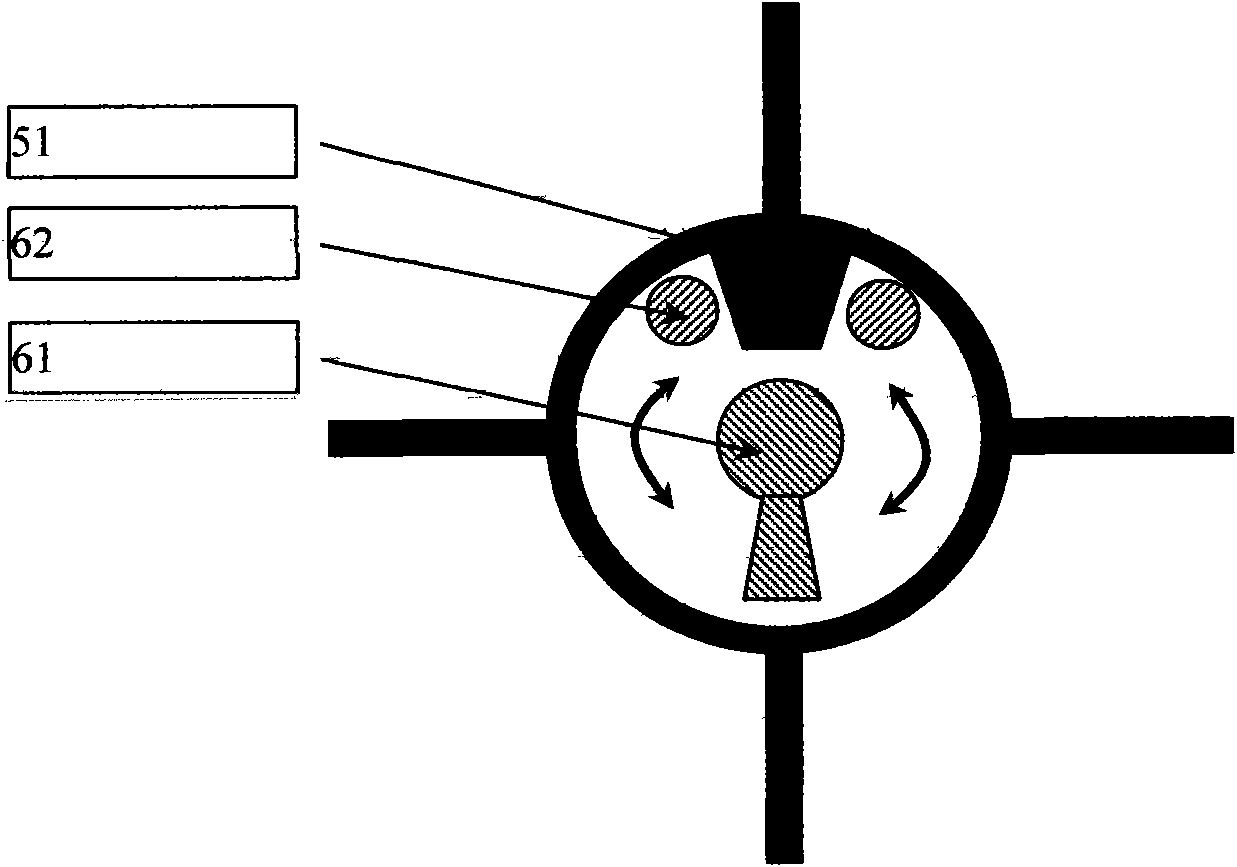

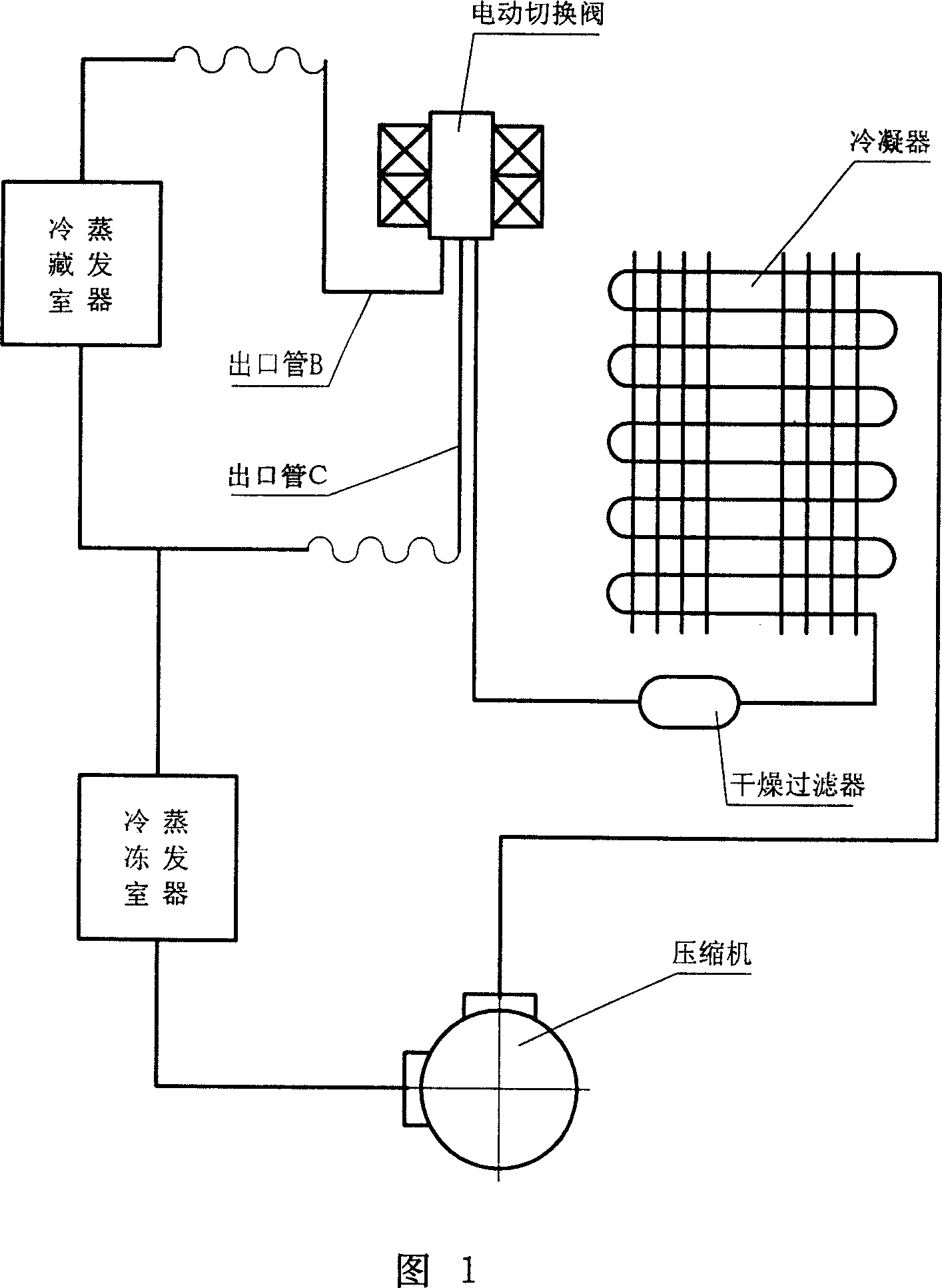

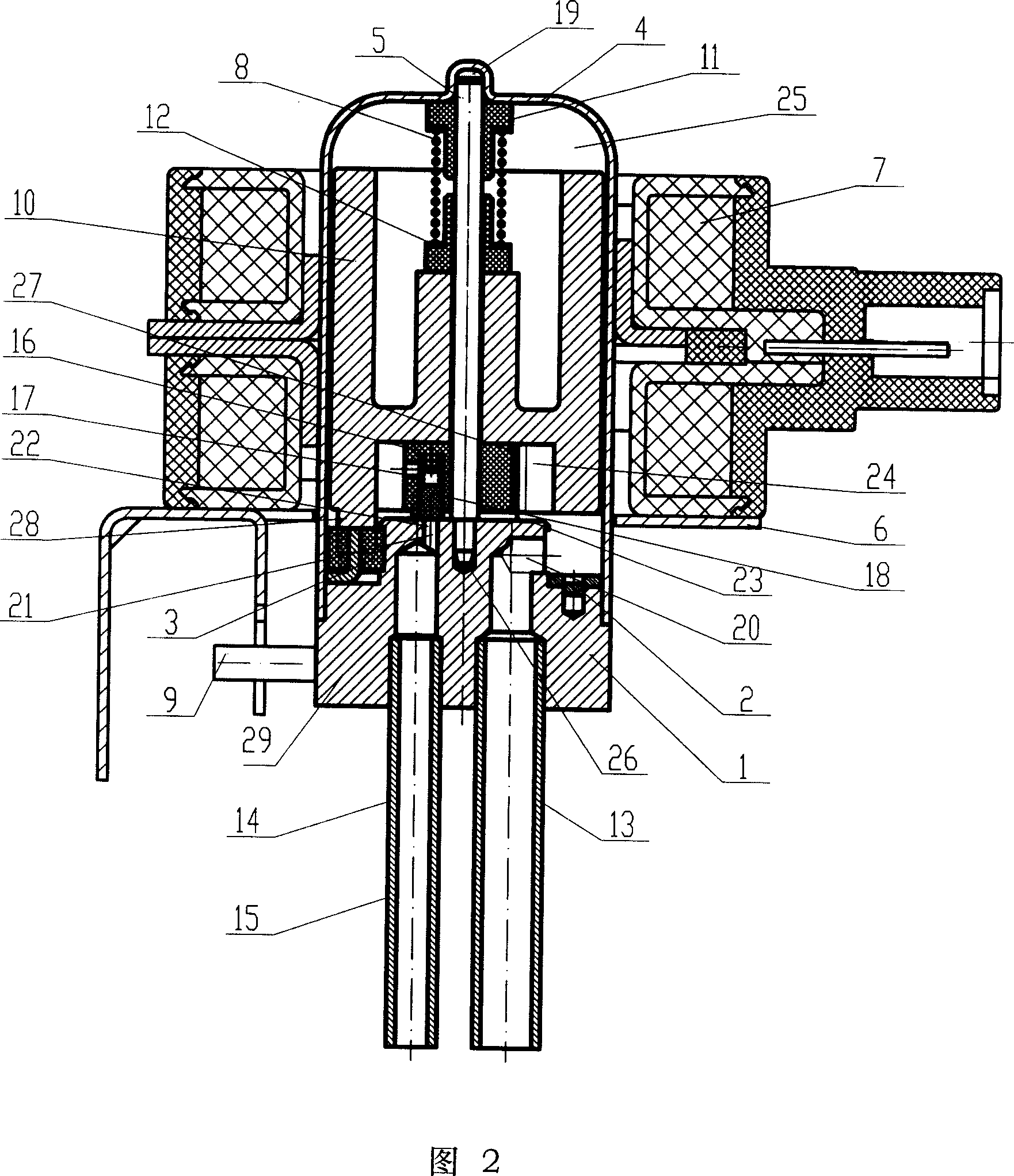

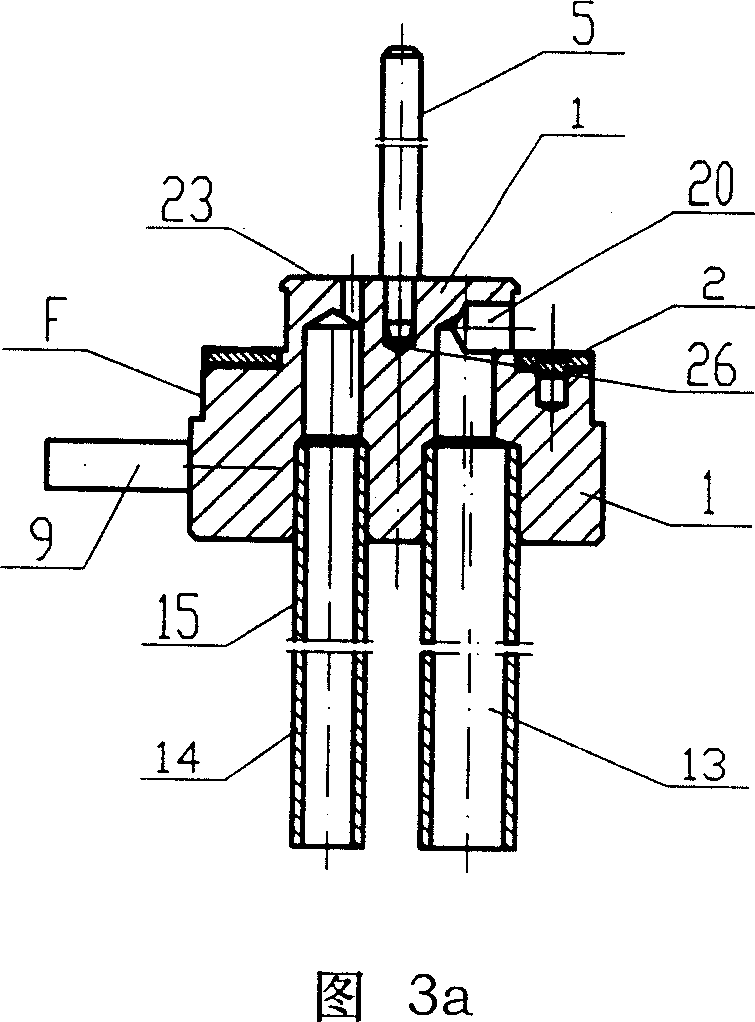

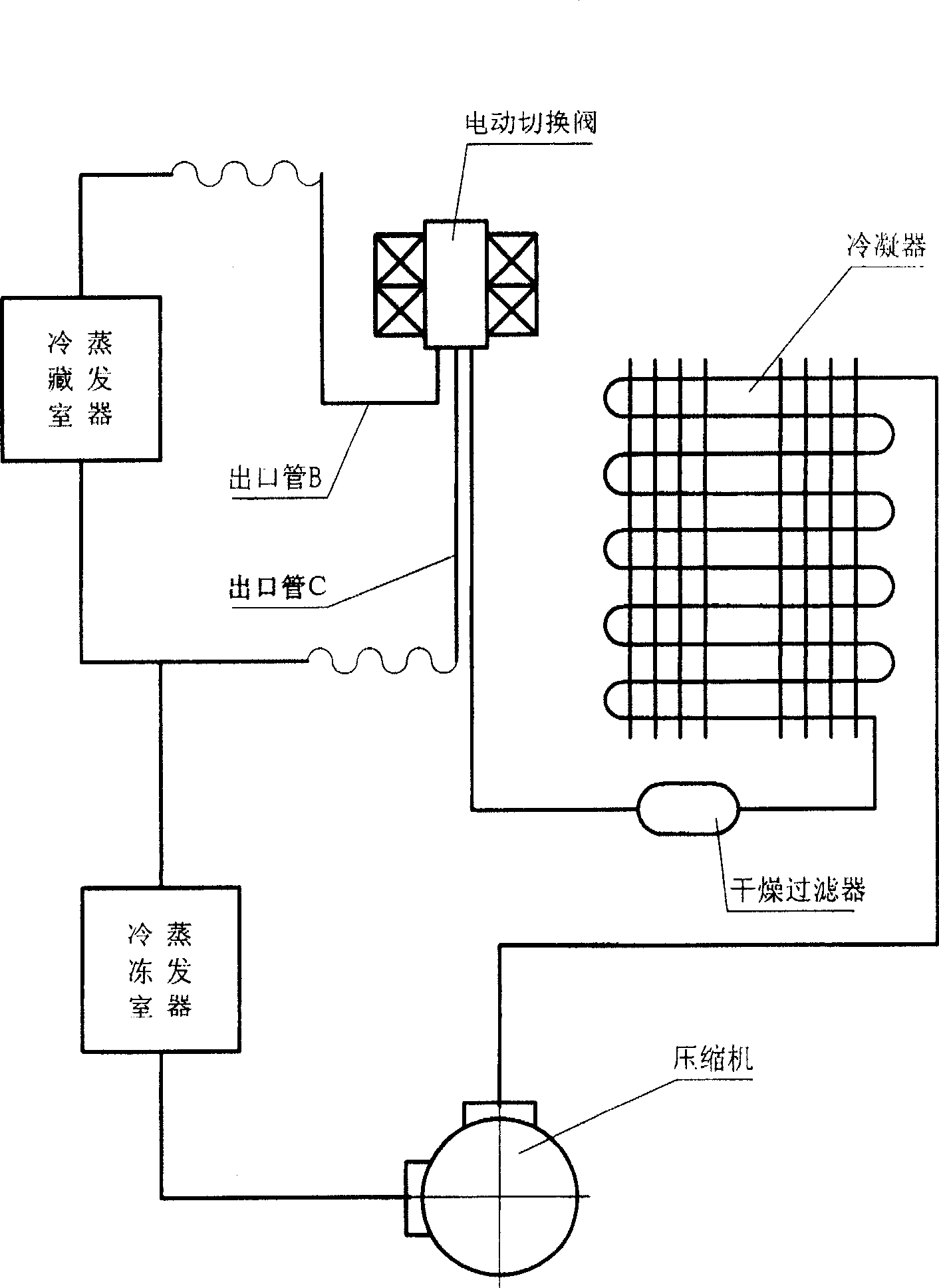

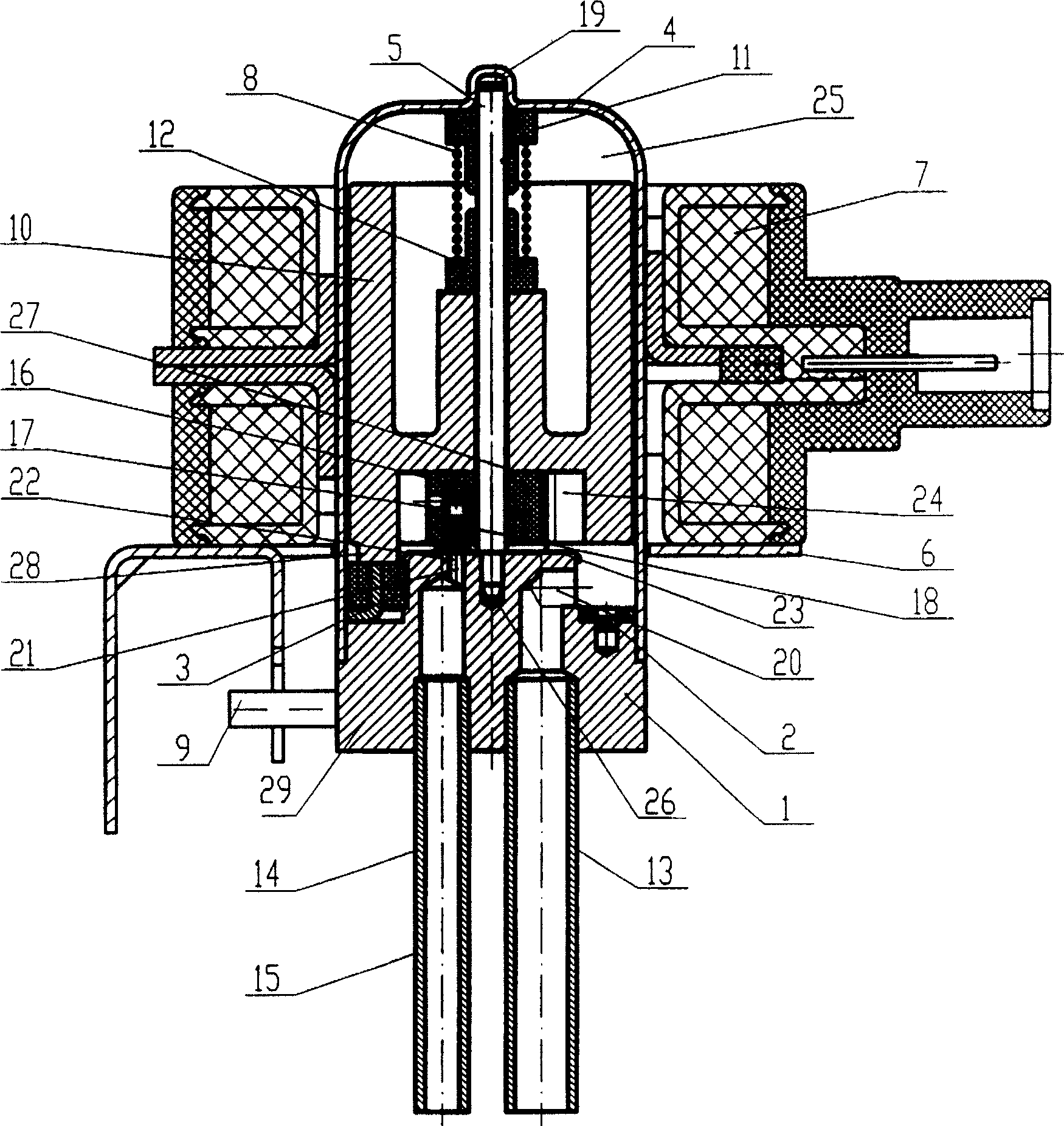

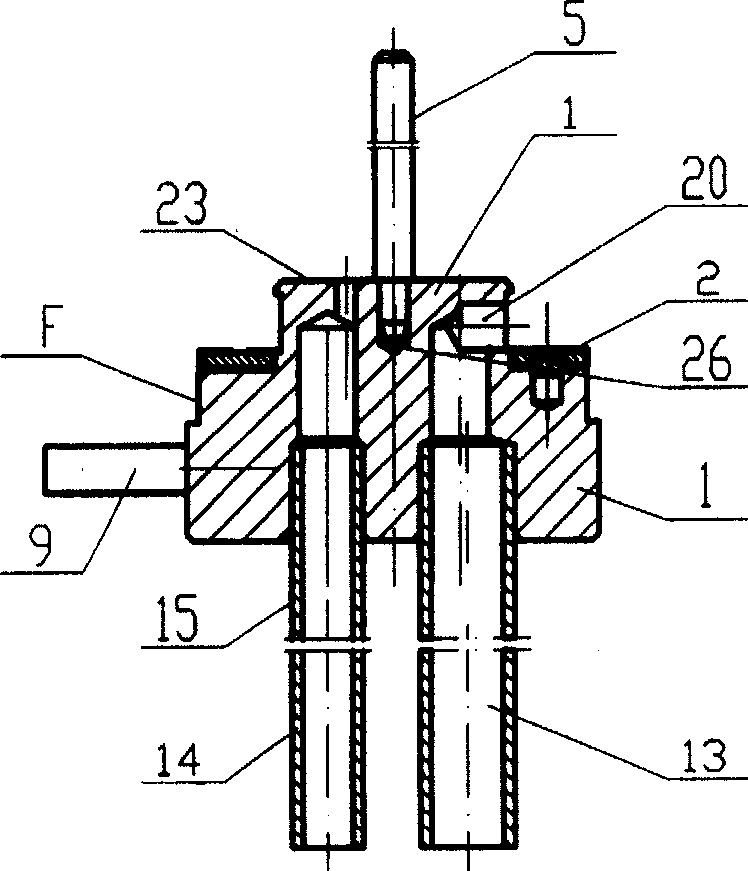

Electric change-over valve

ActiveCN1928408AImprove stabilityImprove sealingOperating means/releasing devices for valvesMultiple way valvesMachiningCooling Units

The invention relates to an electric switching valve for cooling unit for freezing and cold storage so as to improve the performance and energy-saving, comprising valve cavity, one inlet, at least two outlet, step motor and sliding parts, which is driven by step motor rotor and rotates on the flat sealing face towards to valve cavity so as to change the switching status of said outlet, characterized in that said sliding parts contain rotary bracket driven by said rotor and valve core embedded in the rotary bracket and pre-fastening to said flat sealing surface by encouragement means; valve core is driven by rotary bracket so rotate on the said flat sealing surface and change switching status of said outlet, meanwhile the sealing between valve core and flat sealing surface is guaranteed. In the invention sliding parts with partial structure is applied to replace prior valve body to guarantee good sealing between valve core and flat sealing surface and decrease the rigor demand in machining, based on the rotary bracket through pre-fastening to said flat sealing surface with the valve core by encouragement means.

Owner:ZHEJIANG SANHUA INTELLIGENT CONTROLS CO LTD

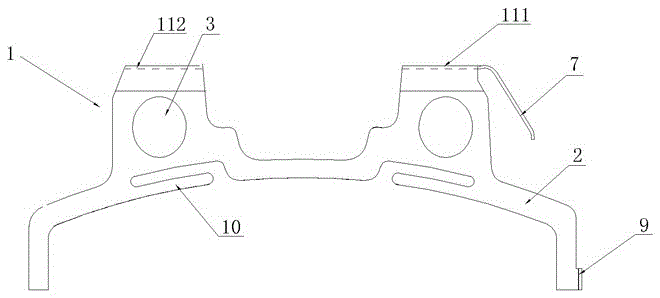

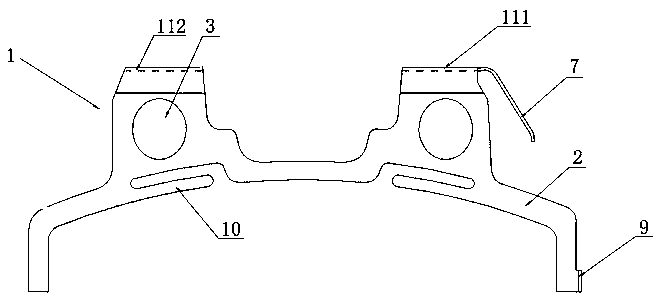

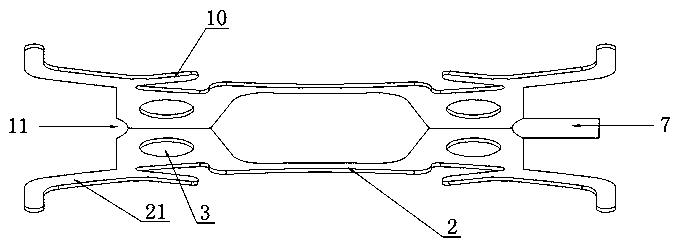

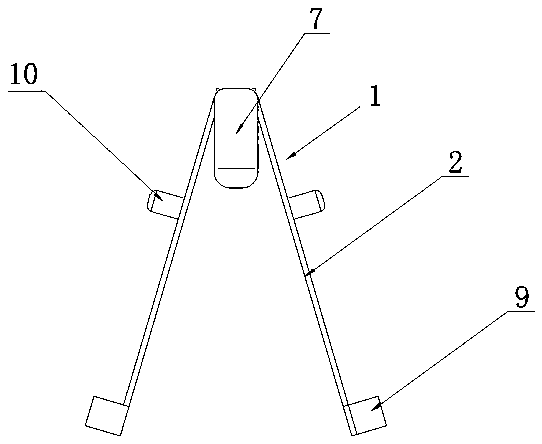

Disc brake braking leaf spring

The invention discloses a disc brake braking leaf spring. The disc brake braking leaf spring comprises a leaf spring body of an inverted V shape; the leaf spring body is formed by connecting two wing sheets, installation holes are formed in the upper parts of the wing sheets, and the two wing sheets are connected into a whole through connection parts arranged at the top end. The disc brake braking leaf spring is characterized in that a limiting strip used for abutting against the inner wall of a disc brake pump body is arranged at the top end of the leaf spring body, extends towards one side and is arranged towards the driving direction during working conditions. In the braking process, when brake pads are driven to move by a brake disc, the brake disc exerts force in the tangential direction of the disc and torque opposite to the rotation direction of the disc on the brake pads, and if fast inching braking is executed, the brake pads and fixing pins continuously collide with each other and generate the collision noise due to the connection gaps. By designing the limiting strip, the gaps between the braking pads and the fixing pins are eliminated in the braking process, the braking pads and the fixing pins are prevented from colliding with each other in the braking process, and therefore the braking process is more stable, and the noise generated by collision of the braking pads and the fixing pins can be lowered or eliminated.

Owner:ZHEJIANG ZHANXIANG AUTOMOBILE & MOTORCYCLE PARTS

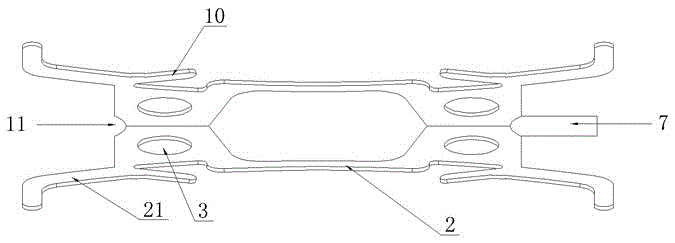

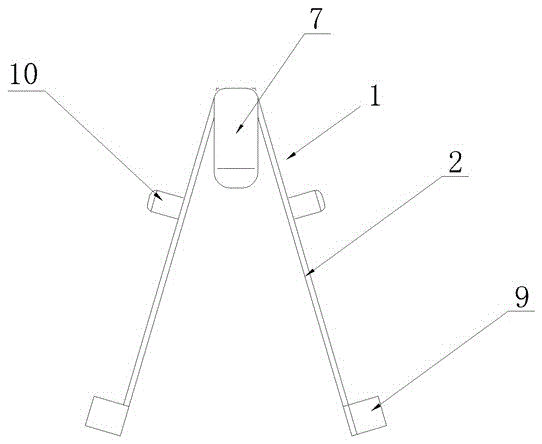

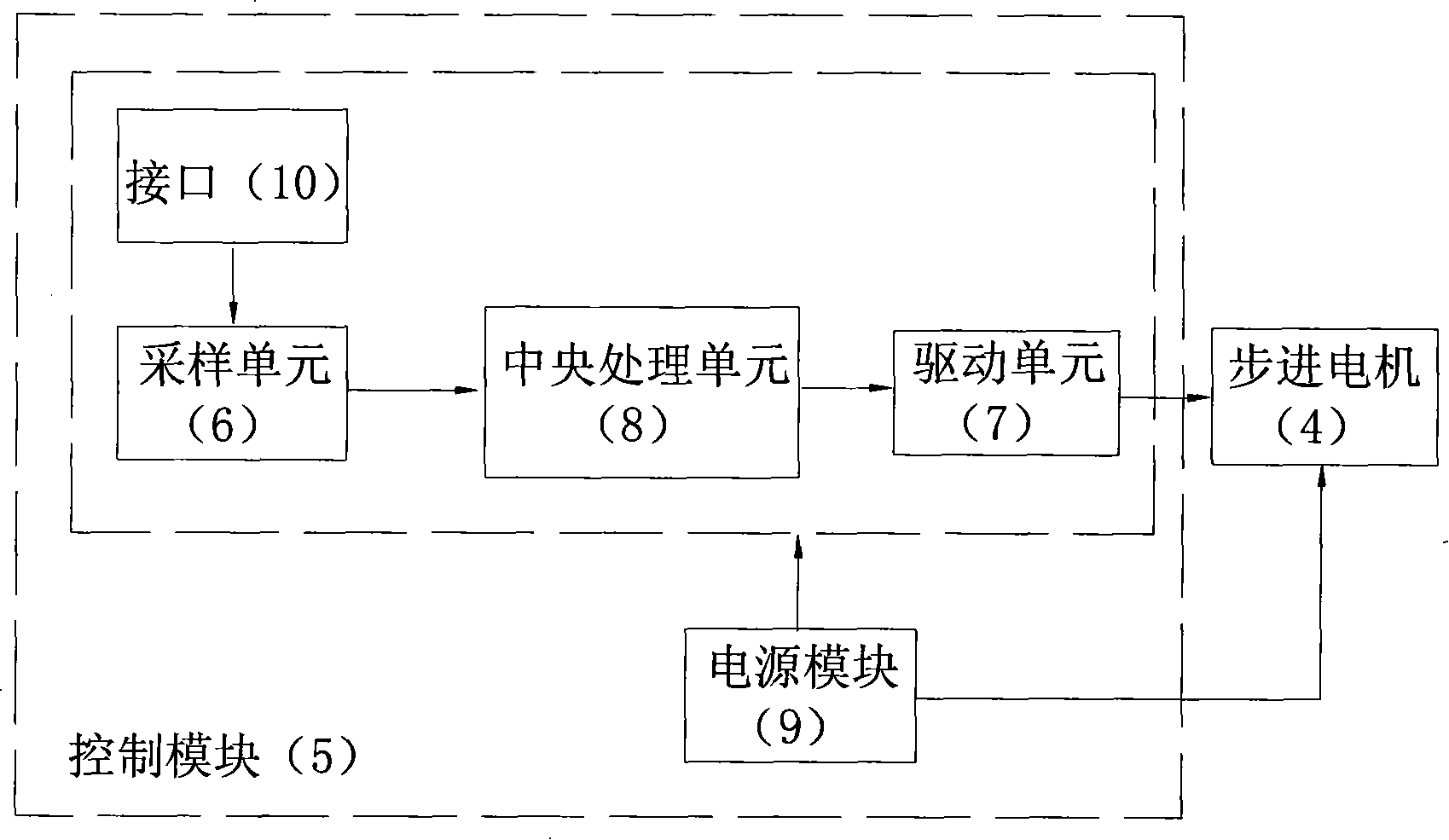

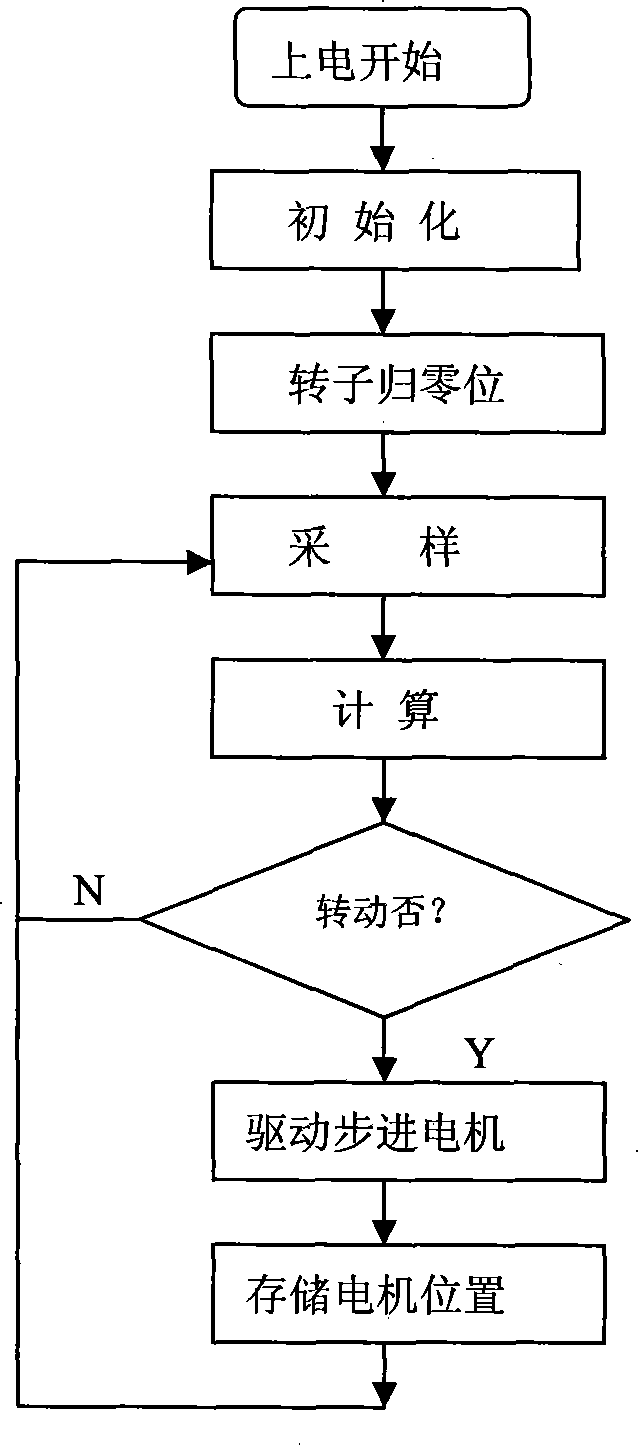

Integrated electric valve

InactiveCN101158418AEasy to assembleStrong connectionOperating means/releasing devices for valvesEfficient regulation technologiesReturn-to-zeroComputer module

The invention relates to an integrated electric valve. A stepping motor, a control module and a valve cavity which is connected with an induction tube and a plurality of eduction tubes are encapsulated in a housing of the valve. A valve mechanism connected with the stepping motor is arranged at a tube mouth where the eduction tube and the valve cavity are connected. The control module comprises a central processing unit which is connected with a sampling unit and a drive unit and a power module supplying working power to the entire valve. The drive unit is connected with the stepping motor. The sampling unit is provided with one or two signal input lines for a TTL level contact signal or voltage and current signals. The central processing unit is stored with control programs which ensure the smooth and stable returning to zero of a rotor. The rotor winding is provided with drive pulse only when rotating and is zero consumption when still, saving energy effectively. The control strategy of the stepping motor of the invention is implemented by the control module in the valve, thus the matching of the valve with refrigerating equipment is ensured and the assembly of the refrigerating equipment is facilitated, increasing remarkably the production efficiency.

Owner:蒋庆

Disc Player Apparatus

InactiveUS20070258347A1Easy to assembleEliminate impact noiseUndesired vibrations/sounds insulation/absorptionRecord information storageMechanical engineeringOptical disc

There is provided a disc player apparatus capable of transporting a disc (11) by holding the disc (11) between a lower roller (70) and an upper roller (80). The lower roller (70) and the upper roller (80) are rockably supported with respect to a main body (20a). A flat spring (210) which urges the upper roller (80) is attached to an upper case (200a) that is attached to the main body (20a). The urge of the flat spring (210) is applied via a roller support member (810) which supports the upper roller (80). The pressure is applied evenly to the upper roller (80), enabling to reduce diagonal travel of the disc for example, and to transport the disc smoothly.

Owner:SANYO ELECTRIC CO LTD +1

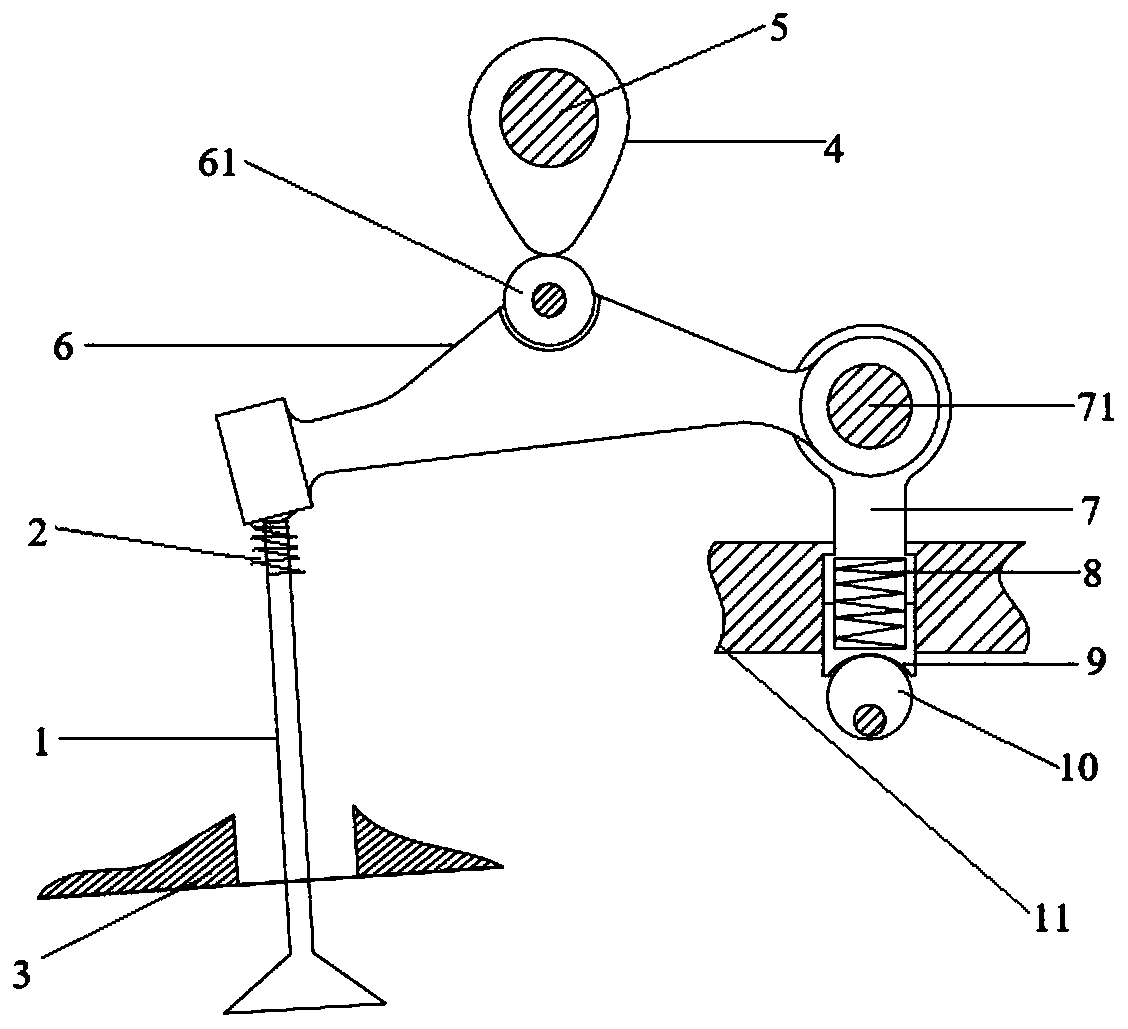

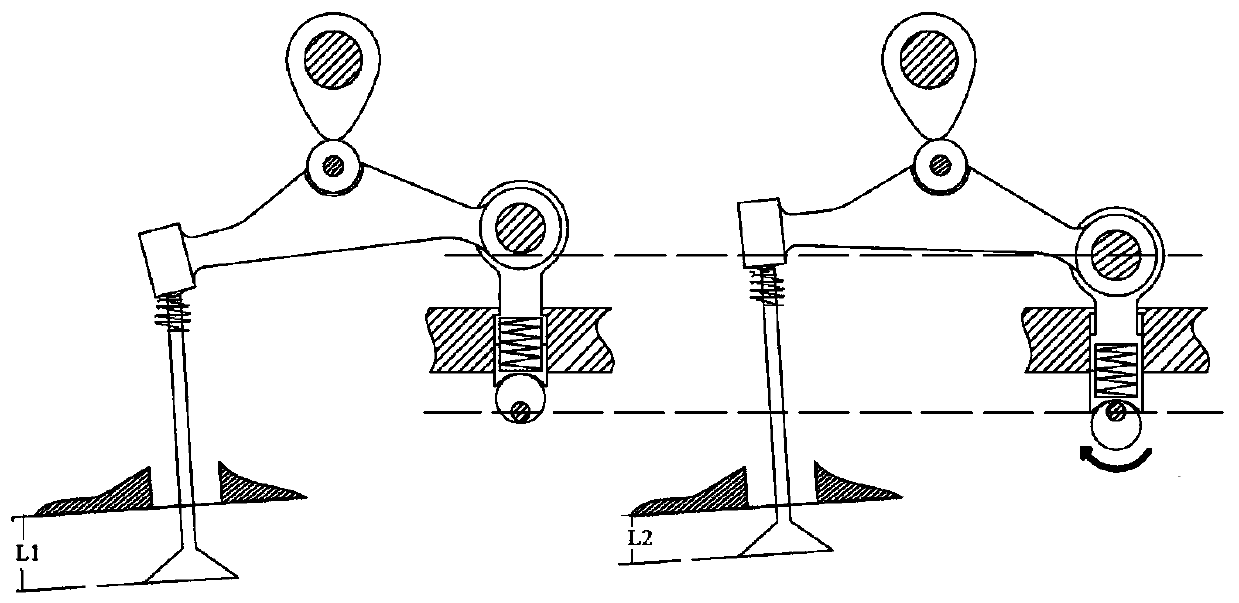

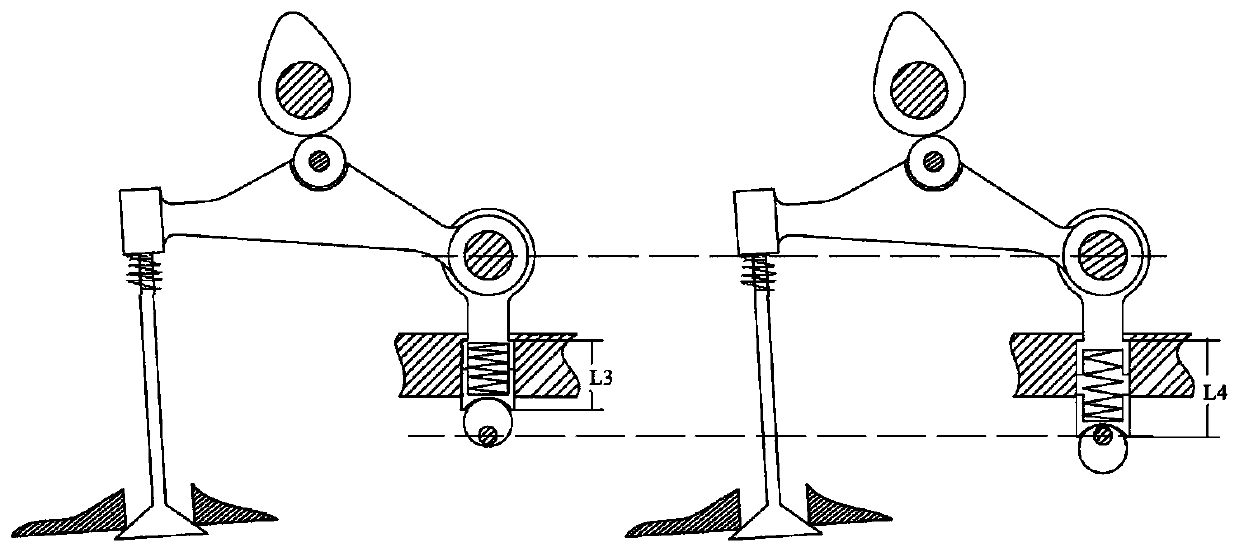

Continuous variable-lift device, engine and automobile

InactiveCN110374707AImprove powerImprove economyValve arrangementsMachines/enginesContact modeEngineering

The invention discloses a continuous variable-lift device. The device comprises a valve mechanism, a transmission mechanism and an adjusting mechanism; the valve mechanism is used for distributing airfor an engine cylinder; the transmission mechanism comprises a rocker arm and a cam; the rocker arm is arranged between the cam and the valve mechanism; a first end of the rocker arm is connected tothe adjusting mechanism; a second end of the rocker arm is matched with the valve mechanism in a contact mode; a rolling wheel is arranged on the rocker arm; the cam is matched with the rolling wheelin a rolling mode; the adjusting mechanism comprises a rocker arm base, a rocker arm adjusting base and an elastic part which is arranged between the rocker arm base and the rocker arm adjusting base;the rocker arm base is used for supporting the rocker arm; and an eccentric wheel is arranged below the rocker arm adjusting base and provides different eccentricity in the rotating process so as tocontinuously and variably adjust the lift of the valve mechanism. The invention further discloses an engine containing the continuous variable-lift device and an automobile. Compared with the prior art, the continuous variable-lift device, the engine and the automobile have the advantages that the continuous variable lift is realized, meanwhile, the cam and the rolling wheel can be kept attached to each other all the time, the structure is simple, the number of parts is small, and the reliability is high.

Owner:ZHEJIANG GEELY HLDG GRP CO LTD +1

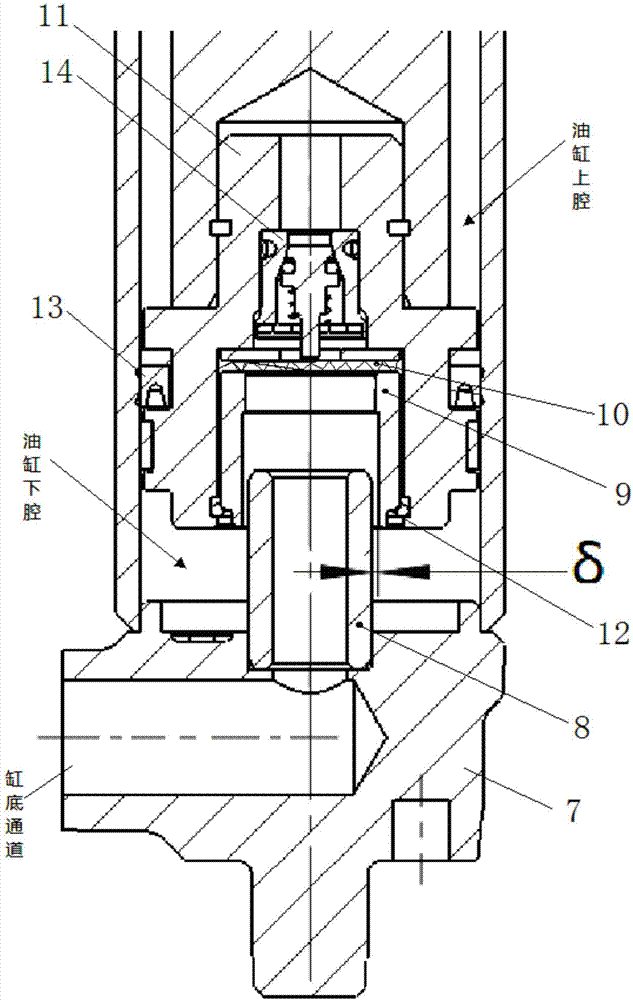

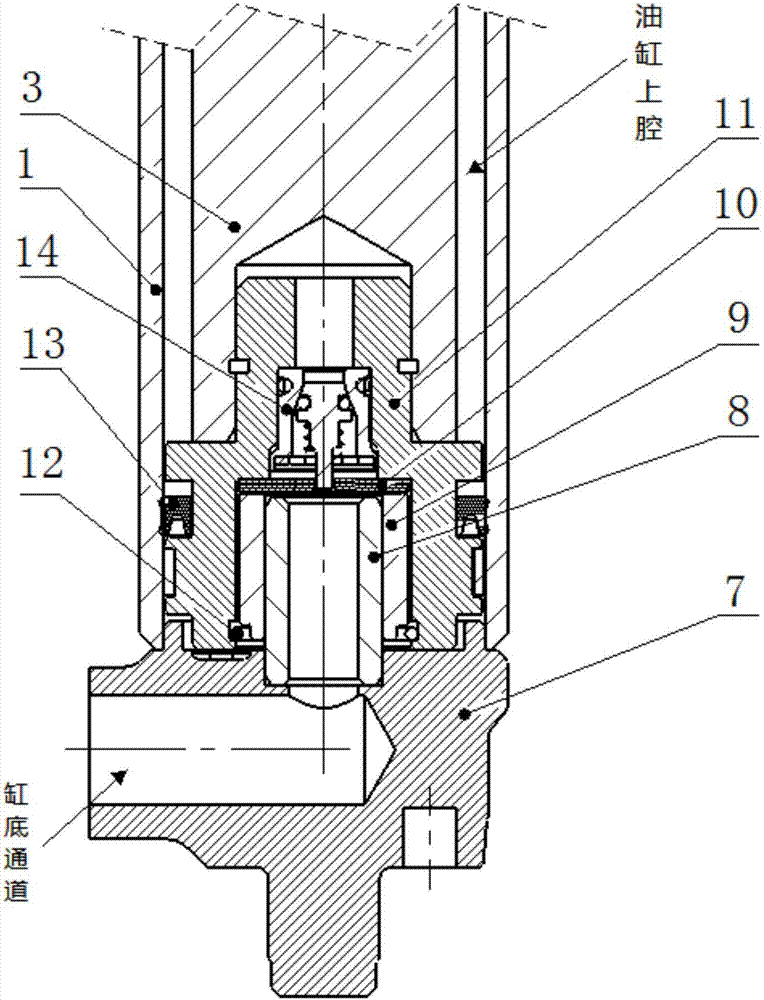

Synchronous adjustment mechanism for forklift frame and regulation method

PendingCN107352471AReduce manual labor intensityIncrease productivityLifting devicesStructural engineeringForklift truck

The invention discloses a synchronous adjustment mechanism for a forklift frame and a regulation method. The synchronous adjustment mechanism comprises oil cylinders symmetrically and fixedly arranged on two side columns of the frame. Each oil cylinder comprises a cylinder bottom, a cylinder cover and a piston rod connected with a piston into a whole. The cylinder covers are embedded cylinder covers. The side portion of each piston rod is connected with a frame support, fixedly arranged on the frame, through a fastening bolt. An interception buffer mechanism is arranged at each cylinder bottom and comprises a buffer column fixed to the center position of the corresponding cylinder bottom. A buffer sleeve is arranged on the periphery of each buffer column in a sleeving manner. The buffer sleeves are embedded in inner cavities of the pistons. Floating blocking pieces are arranged at the positions of oil injection openings of the pistons located on the tops of the buffer sleeves. By means of the device, the production efficiency and the oil cylinder reliability are improved, the phenomenon that because the cylinder covers are rotated, sealing pieces are damaged and leak oil is avoided, fault points of the forklift frame are reduced, and the forklift product quality is improved. According to the device, the descending interception buffer mechanisms are added to the cylinder bottoms, striking noise and vibration during oil cylinder descending are eliminated, and the operation comfort of the forklift frame is improved.

Owner:ANHUI HELI CO LTD

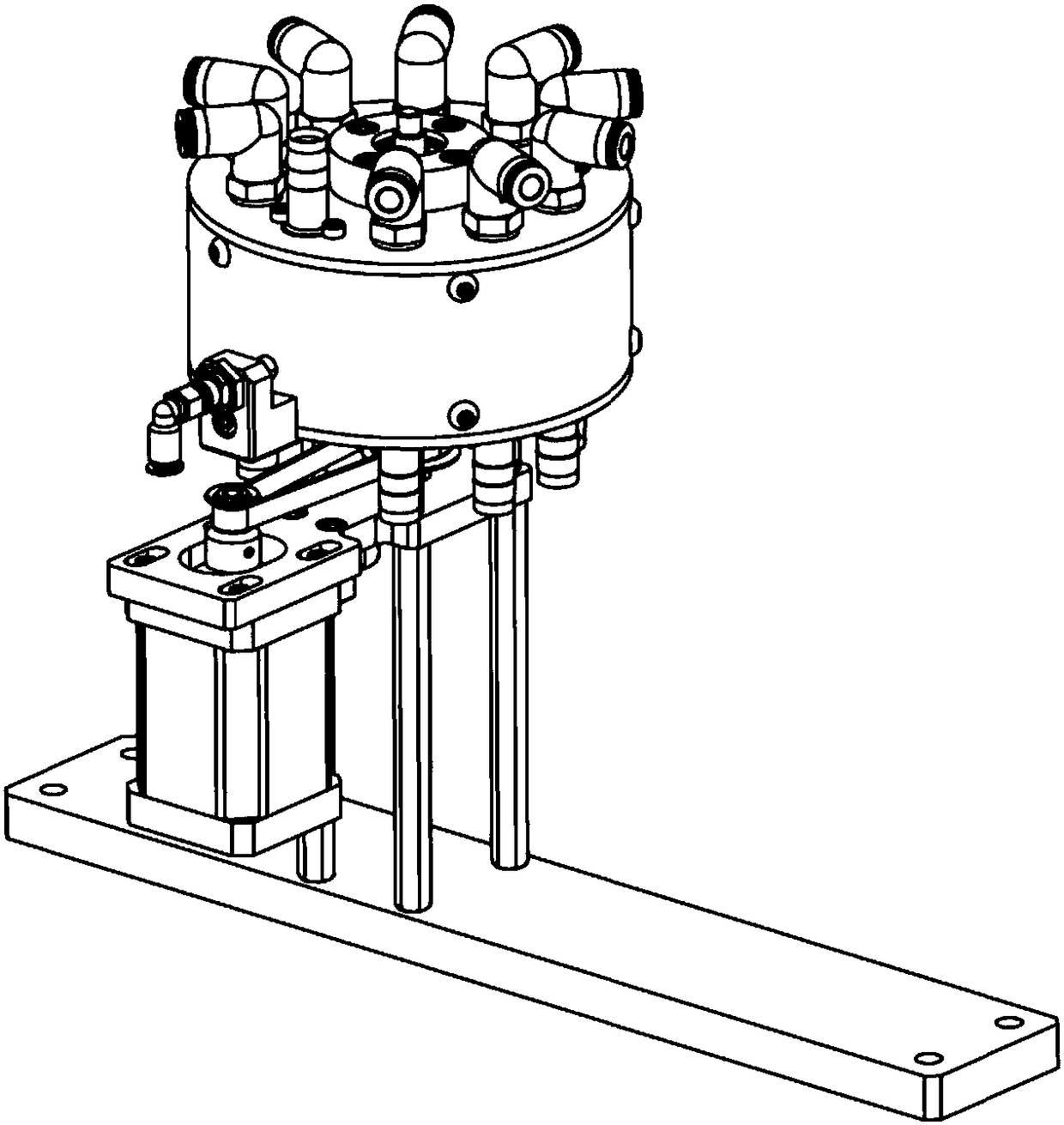

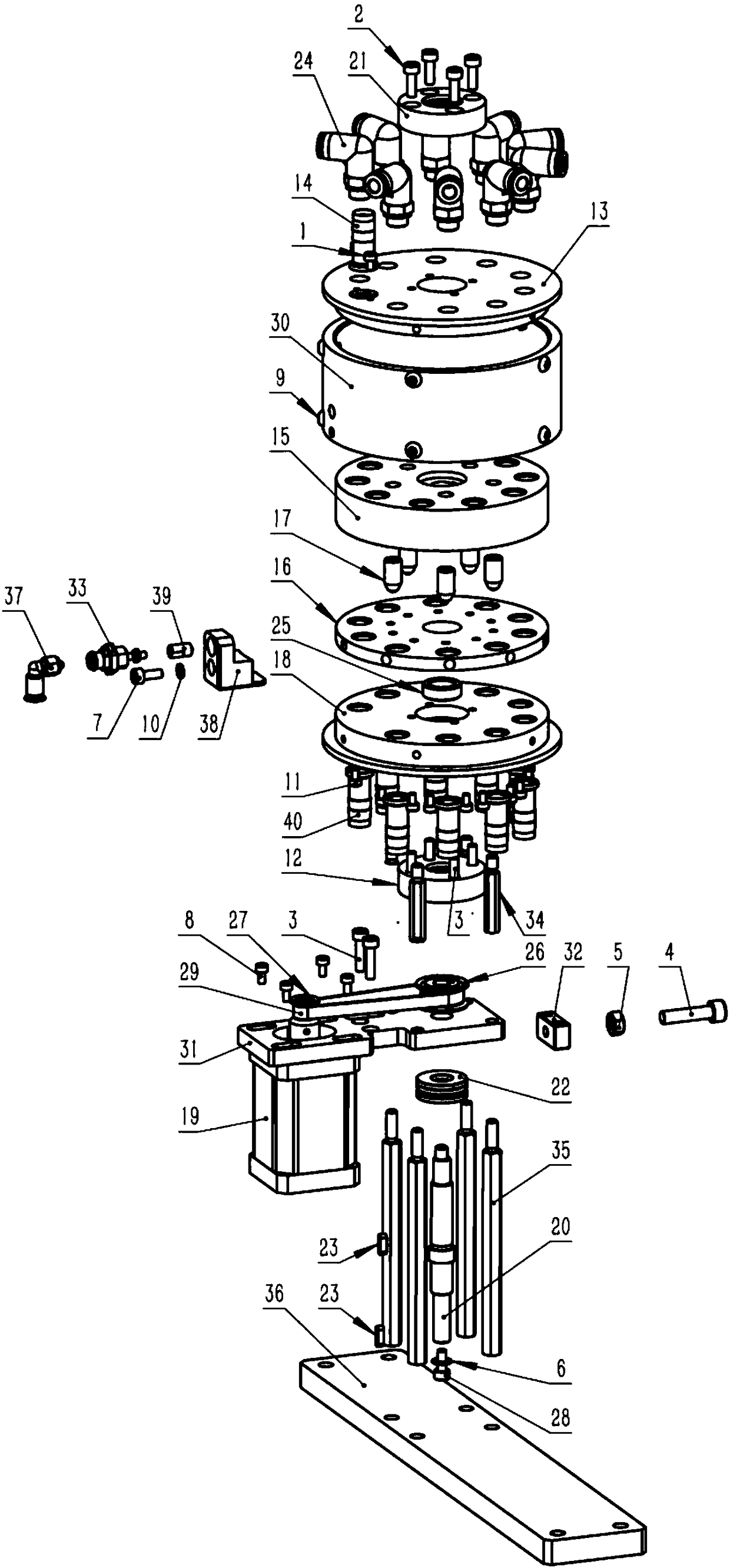

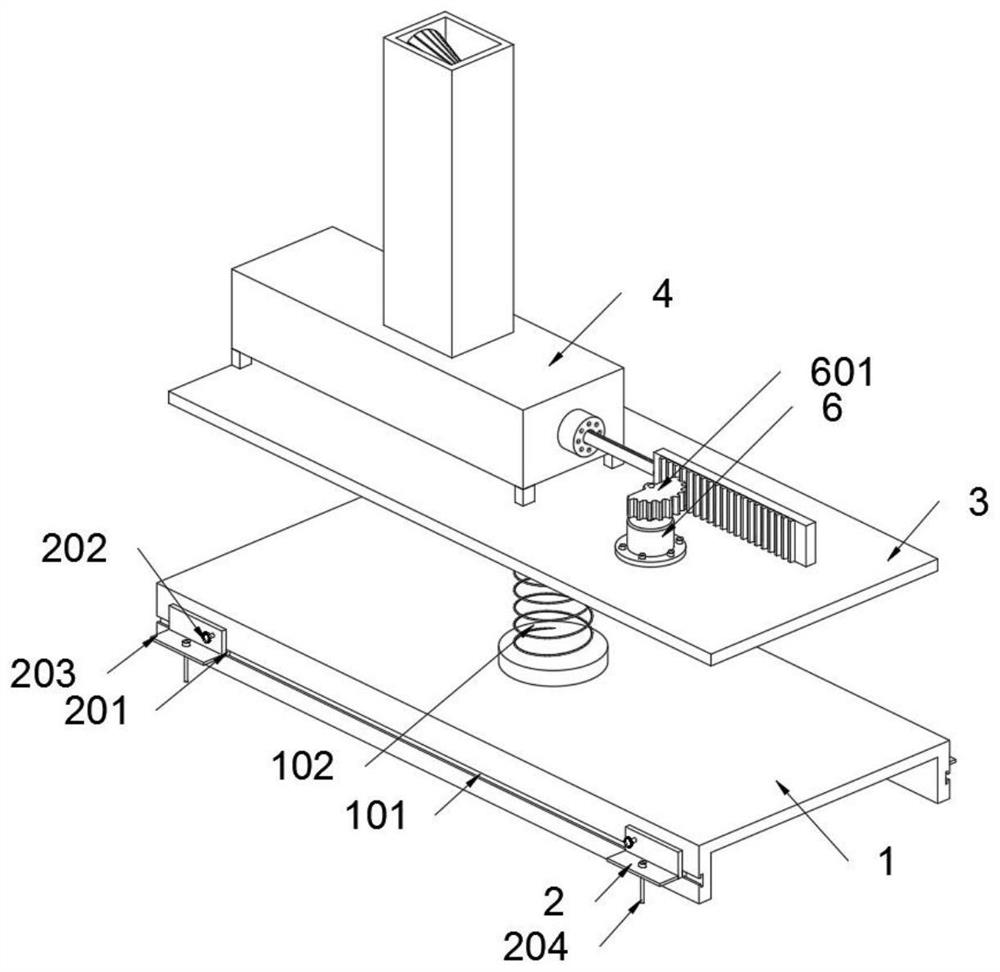

Multi-split material distributor based on motor and belt wheel transmission

ActiveCN108098287AAccurate indexing functionHigh matching precisionMetal working apparatusSteel ballEngineering

The invention discloses a multi-split material distributor based on motor and belt wheel transmission. The multi-split material distributor comprises a feeding inlet, a material distributing assembly,a transmission assembly, discharging outlets and a supporting assembly. The material distributing assembly comprises a shell fixing base. An upper rotating fixing plate and a lower rotating fixing plate are fixed to the two ends of the shell fixing base correspondingly. The shell fixing base is internally provided with a material distributing disc. A separation plate is arranged below the material distributing disc. A plunger is arranged between the material distributing disc and the separation plate. One end of the plunger is fixed to the material distributing disc, and the other end of theplunger is provided with an elastically supported steel ball which is matched with the spherical concave surface of the separation plate. A bolt air cylinder used for fixing the separation plate is further fixedly arranged at the side edge of the shell fixing base. According to the multi-split material distributor based on motor and belt wheel transmission, an internal rotating assembly is driventhrough transmission of a servo motor and a belt wheelk, mutual connection between the feeding inlet and all the discharging outlets is achieved through the precise control of the moving position of the servo motor and the internal positioning plunger of the rotating assembly, and thus the brand new multi-split motor-belt transmission type rotating material distributor can be achieved.

Owner:CHANGZHOU INST OF TECH

Method and system for measuring urinary flow rate

InactiveUS8048048B2Noise minimizationEliminate impact noiseDiagnostic recording/measuringSensorsEccentric hypertrophyPersonal computer

A method and system for measuring a urinary flow rate minimizes impact noise caused by urine to measure the urinary flow rate using a plurality of load cells when prostatic hypertrophy is diagnosed. The method includes measuring an amount of urine collected into a container using a plurality of load cells, extracting and averaging urinary flow rate signals from the measured results, and removing the impact noise from the urinary flow rate signals, converting the urinary flow rate signals into digital signals through an A / D converting circuit, and outputting the digital signals using a personal computer or a microprocessor analyzer which is interfaced with the A / D converting circuit.

Owner:CHUNGBUK NAT UNIV IND ACADEMIC COOPERATION FOUND

Roller coaster non-return noise reduction device

The invention provides a roller coaster non-return noise reduction device. The roller coaster non-return noise reduction device comprises a buffer device, a magnetic wheel, a non-return claw, a transmission plate, anti-reverse teeth and an auxiliary rail. The anti-reverse teeth are strip-shaped and are fixed on one side of the upper surface of the auxiliary track in parallel. The non-return claw is located above the anti-reverse teeth, one end of the non-return claw is rotationally connected with a roller coaster body, the end face of the other end of the non-return claw is attached to the upper surfaces of the anti-reverse teeth, and an adjusting rod is fixed to the side face, close to the magnetic wheel, of the non-return claw. The magnetic wheel is positioned on the auxiliary guide railby virtue of the buffer device. The device is safe and stable, and can effectively reduce the noise generated by the roller coaster in the lifting stage. When the train runs to the lifting section, the non-return claw moves upwards along the anti-reverse teeth, and the magnetic wheel moves along the auxiliary rail on the edges of the anti-reverse teeth. The magnetic wheel drives the transmissionplate to rotate, so that the non-return claw is driven to tilt upwards to leave the anti-reverse teeth, and the impact noise of the non-return claw and the anti-reverse teeth is eliminated.

Owner:HEBEI ZHI PAO AMUSEMENT EQUIP MFG

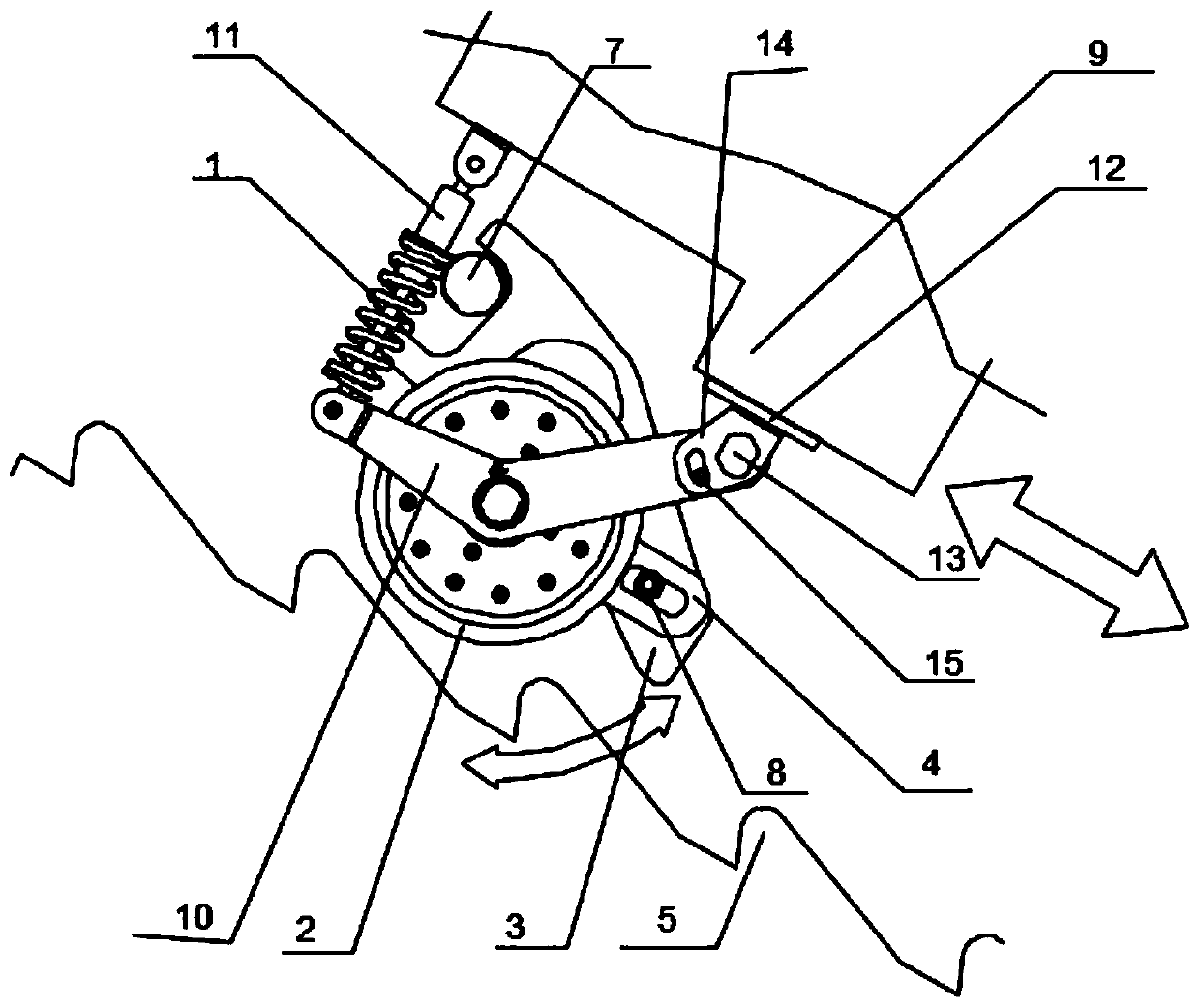

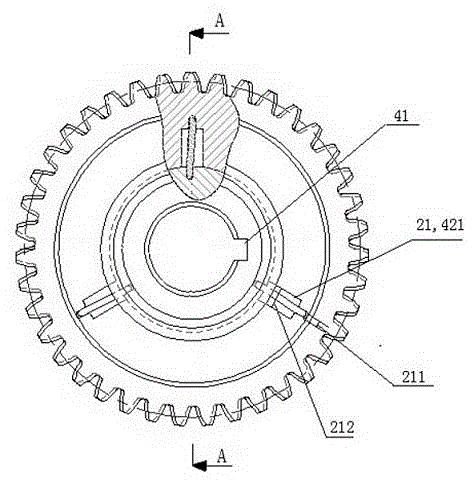

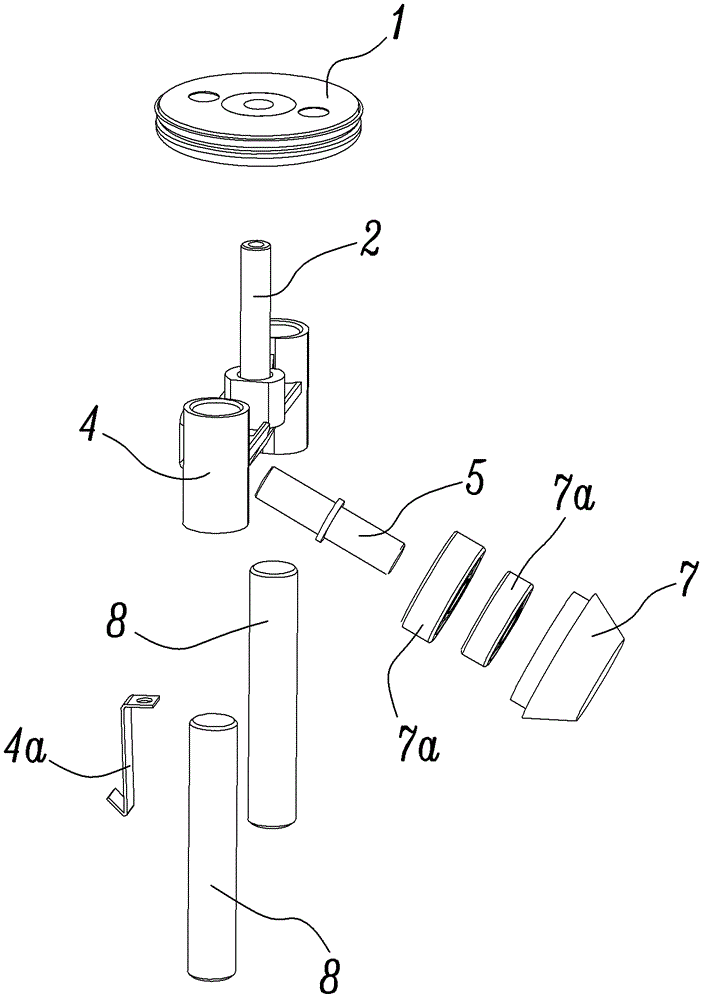

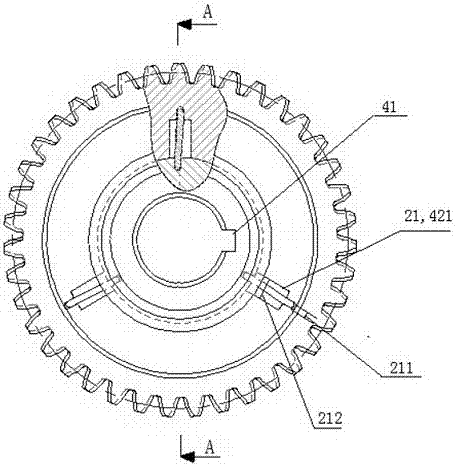

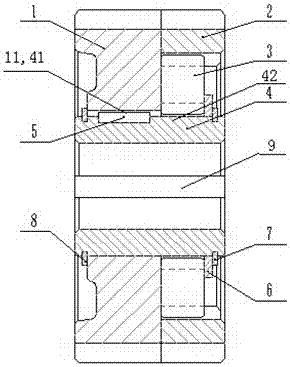

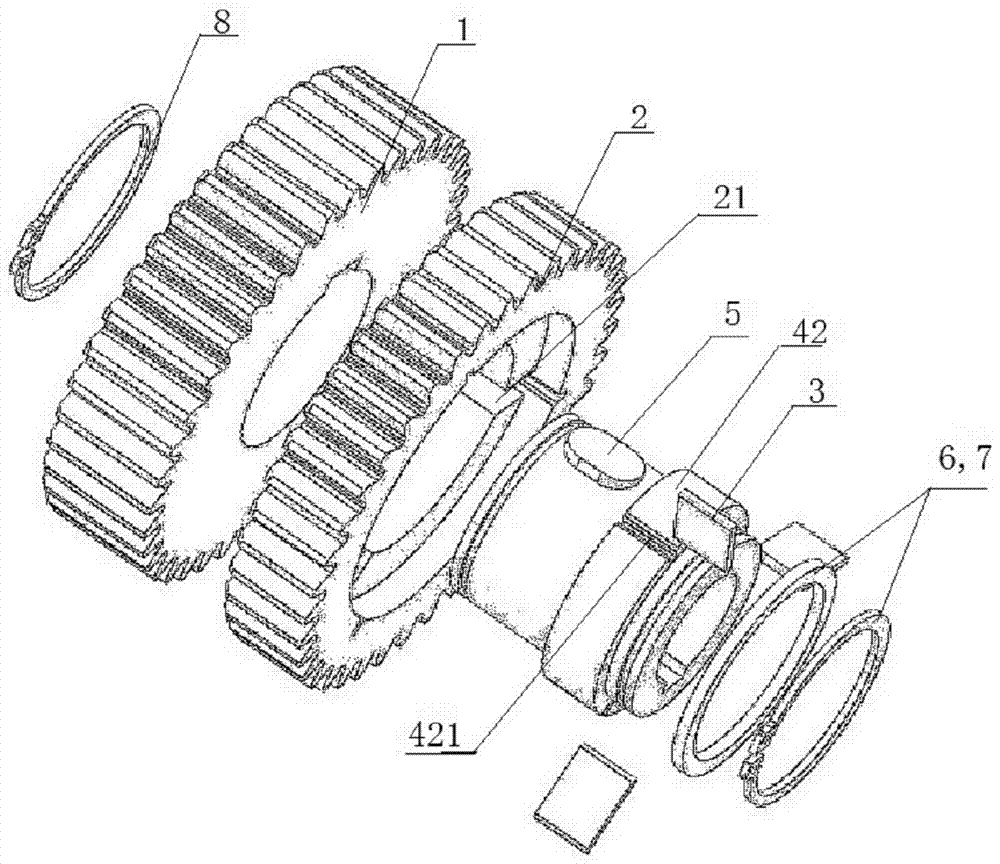

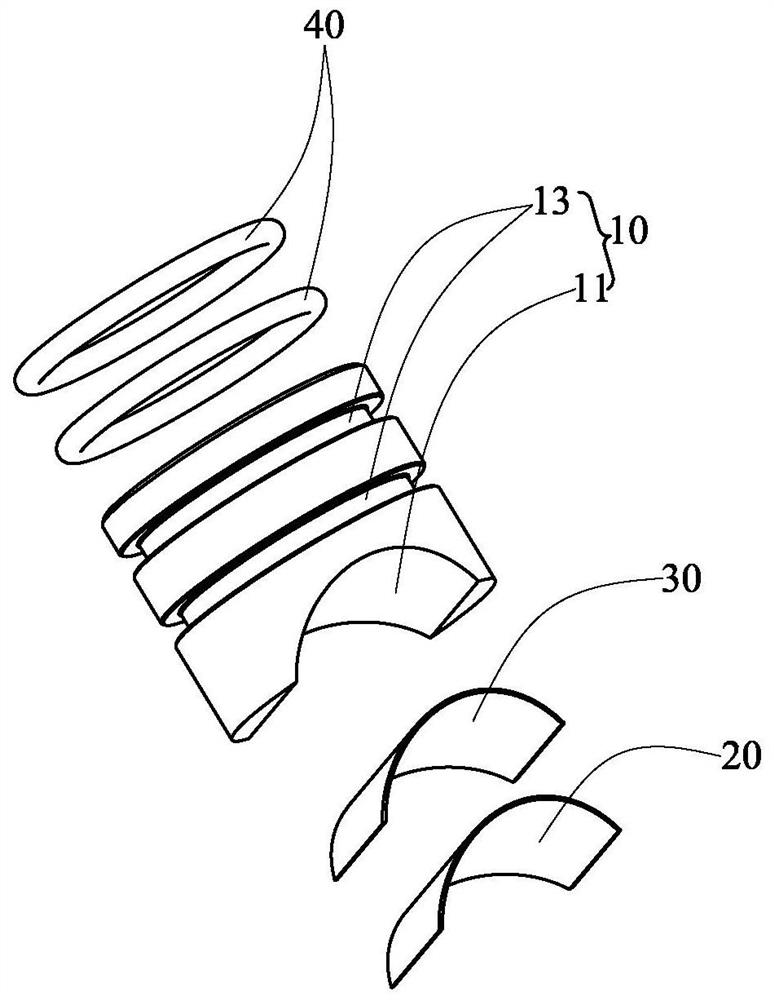

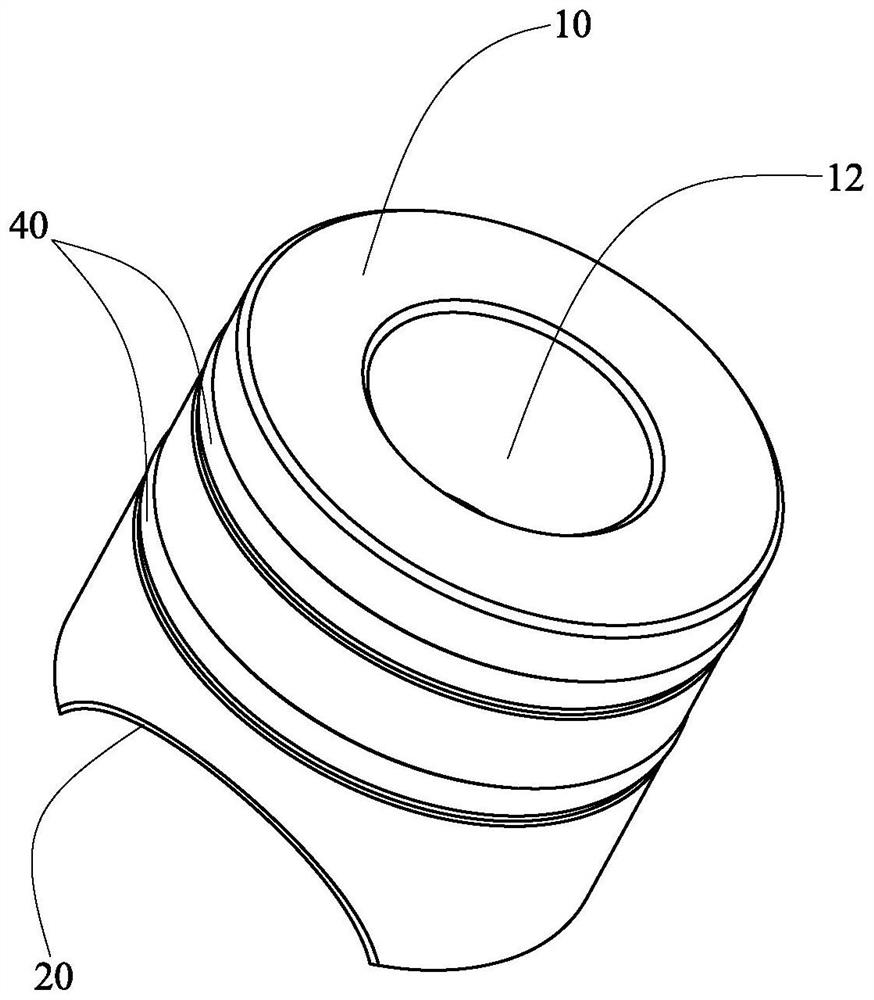

Flexible clearance eliminating gear with rigidity easy to control

ActiveCN104455319AEliminate impact noiseImprove controllabilityPortable liftingGearing elementsContact pressureGear wheel

The invention discloses a flexible clearance eliminating gear with rigidity easy to control. The gear comprises a first malposed gear and a second malposed gear which are jointly connected in the axial direction of a transmission shaft, wherein a shaft sleeve is also connected among the first malposed gear, the second malposed gear and the transmission shaft; key grooves are paired in a connected position of the shaft sleeve and the first malposed gear, and a key is connected between the paired key grooves; a boss is also arranged at a connected part of the shaft sleeve and the second malposed gear, at least a paired penetrating groove is formed in corresponding positions of the boss and the second malposed gear which sleeves outside the boss in the circumference direction, and a plate spring is connected between each pair of the paired penetrating grooves in the shaft sleeve; the paired penetrating groove in the second malposed gear and the key groove in the first malposed gear are relatively malposed in the circumference direction. For the gear disclosed by the invention, a connection structure of the flexible clearance eliminating gear is simplified, the problem that the normal contact pressure of a meshed tooth side of a gear pair is hard to be ensured effectively is solved, a clearance in the tooth side is flexibly eliminated, and the impact noise of the gear is eliminated.

Owner:NANJING INST OF TECH

Spin-orbit type reciprocating piston compressor

ActiveCN102434426BLower the temperature of the whole machineReduce wearMulti-stage pumpsPositive-displacement liquid enginesSpinsOrbit

Owner:ZHEJIANG HONGYOU AIR COMPRESSOR MFG

A kind of flexible anti-backlash gear with easy controllable stiffness

InactiveCN104455319BAdjust the axial connection positionEliminate impact noisePortable liftingGearing elementsContact pressureDrive shaft

Owner:NANJING INST OF TECH

Electric change-over valve

InactiveCN100464100CEasy to installImprove sealingOperating means/releasing devices for valvesMultiple way valvesEngineeringMachining

The invention relates to an electric switching valve for cooling unit for freezing and cold storage so as to improve the performance and energy-saving, comprising valve cavity, one inlet, at least two outlet, step motor and sliding parts, which is driven by step motor rotor and rotates on the flat sealing face towards to valve cavity so as to change the switching status of said outlet, characterized in that said sliding parts contain rotary bracket driven by said rotor and valve core embedded in the rotary bracket and pre-fastening to said flat sealing surface by encouragement means; valve core is driven by rotary bracket so rotate on the said flat sealing surface and change switching status of said outlet, meanwhile the sealing between valve core and flat sealing surface is guaranteed. In the invention sliding parts with partial structure is applied to replace prior valve body to guarantee good sealing between valve core and flat sealing surface and decrease the rigor demand in machining, based on the rotary bracket through pre-fastening to said flat sealing surface with the valve core by encouragement means.

Owner:ZHEJIANG SANHUA INTELLIGENT CONTROLS CO LTD

Pressing block of linear guide shaft

PendingCN111810532AEliminate gapsEliminate impact noiseLinear bearingsBearing unit rigid supportStructural engineeringMechanical engineering

The invention discloses a pressing block of a linear guide shaft. The pressing block of the linear guide shaft comprises a body, a wear-resisting layer and an elastic ring; the body comprises a pressing arc face, a spring containing hole and an elastic ring containing groove; the central axis of the pressing arc face is perpendicular to the central axis of the body, and the central axis of the pressing arc face intersects with the central axis of the body; the arch height of an arc where the contour line of the pressing arc surface is located is smaller than the diameter of the arc; the central axis of the spring containing hole coincides with the central axis of the body; and the wear-resisting layer is pasted to the pressing arc face, the elastic ring is contained in the elastic ring containing groove, and part of the elastic ring is exposed out of the elastic ring containing groove. According to the pressing block of the linear guide shaft, the loss of the contact surface caused byfriction between the wear-resisting layer and the shaft can be compensated in time, so that the pressing block can be tightly propped against the pressing arc surface of a matching shaft all the time,and the purpose of eliminating a gap is achieved.

Owner:JIASHAN CSB PLASTIC BEARING TECH CO LTD

Disc brake leaf spring

The invention discloses a disc brake braking leaf spring. The disc brake braking leaf spring comprises a leaf spring body of an inverted V shape; the leaf spring body is formed by connecting two wing sheets, installation holes are formed in the upper parts of the wing sheets, and the two wing sheets are connected into a whole through connection parts arranged at the top end. The disc brake braking leaf spring is characterized in that a limiting strip used for abutting against the inner wall of a disc brake pump body is arranged at the top end of the leaf spring body, extends towards one side and is arranged towards the driving direction during working conditions. In the braking process, when brake pads are driven to move by a brake disc, the brake disc exerts force in the tangential direction of the disc and torque opposite to the rotation direction of the disc on the brake pads, and if fast inching braking is executed, the brake pads and fixing pins continuously collide with each other and generate the collision noise due to the connection gaps. By designing the limiting strip, the gaps between the braking pads and the fixing pins are eliminated in the braking process, the braking pads and the fixing pins are prevented from colliding with each other in the braking process, and therefore the braking process is more stable, and the noise generated by collision of the braking pads and the fixing pins can be lowered or eliminated.

Owner:ZHEJIANG ZHANXIANG AUTOMOBILE & MOTORCYCLE PARTS

Spin-orbit type reciprocating piston compressor

ActiveCN102434426AEliminate speed differencesReduce mechanical wear and friction noiseMulti-stage pumpsPositive-displacement liquid enginesPistonSpins

The invention relates to a spin-orbit type reciprocating piston compressor, belonging to the technical field of compressors. According to the spin-orbit type reciprocating piston compressor, a conical thrust pin or a rolling body is in contact and matched with a spin-orbit surface of a rotor, and therefore a speed difference at the contact part between the conical thrust pin or rolling body and the spin-orbit surface of the rotor can be reduced or even eliminated, and a slippage phenomenon between the thrust pin or rolling body and the spin-orbit surface of the rotor can be eased, thus reduction of part abrasion and frictional noise caused by slippage can be facilitated; because a cooling fan is used for directly cooling a cylinder cover of the compressor, whole unit temperature of the compressor can be reduced, temperature rise of lubricating oil is further reduced and lubricating performance of the lubricating oil is increased, and therefore reduction abrasion and frictional noise is facilitated as well; and because a release link mechanism is adopted and an interval eliminating spring is arranged on the release link at the same time, the release link can be well close to a sliding block under the action of the interval eliminating spring, and the sliding block enables the thrust pin or rolling body or the spin-orbit surface of the rotor to be well contact and matched, and therefore various intervals among parts are effectively eliminated, and reduction of impact noise and impact abrasion of parts can be facilitated.

Owner:ZHEJIANG HONGYOU AIR COMPRESSOR MFG

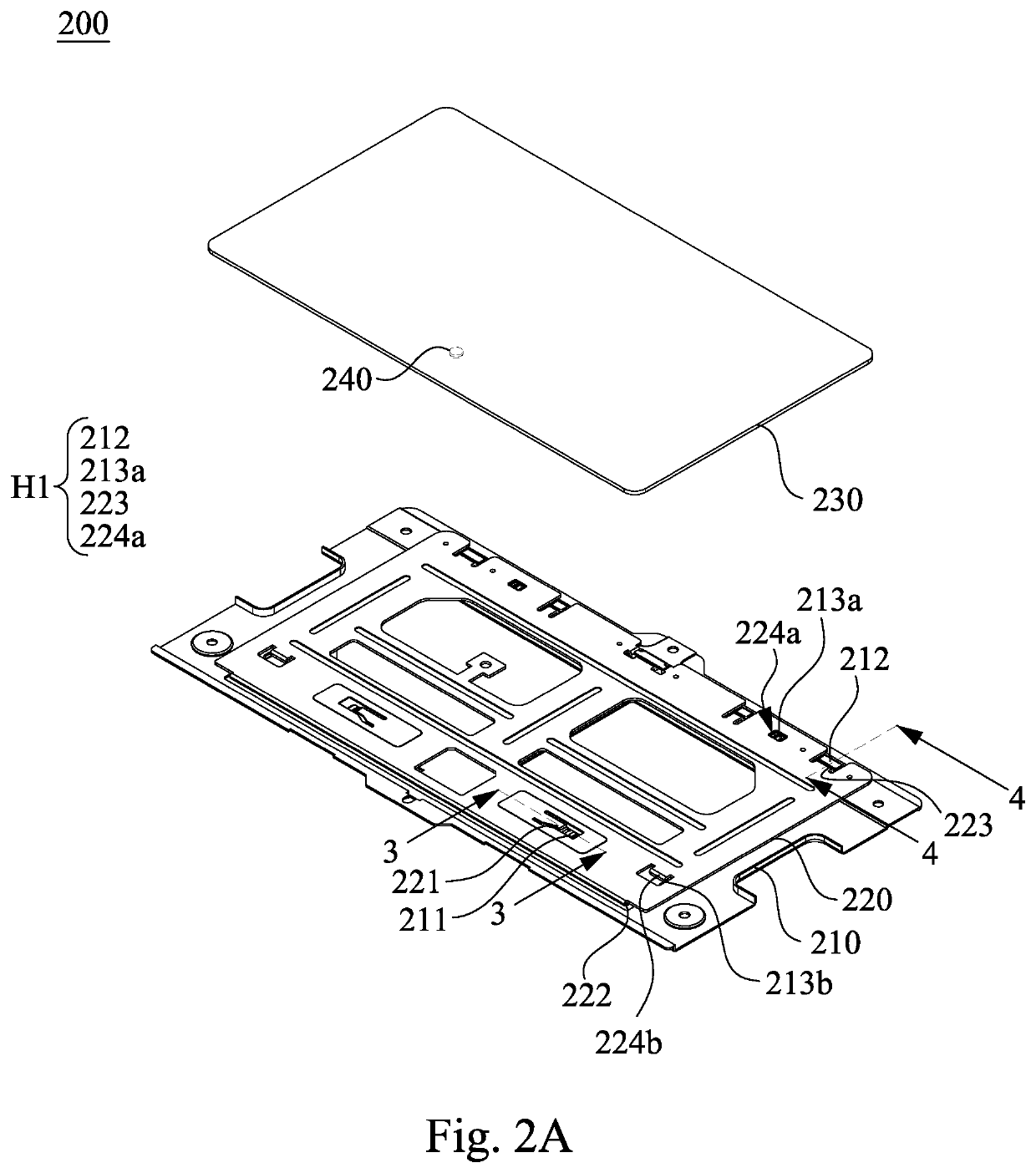

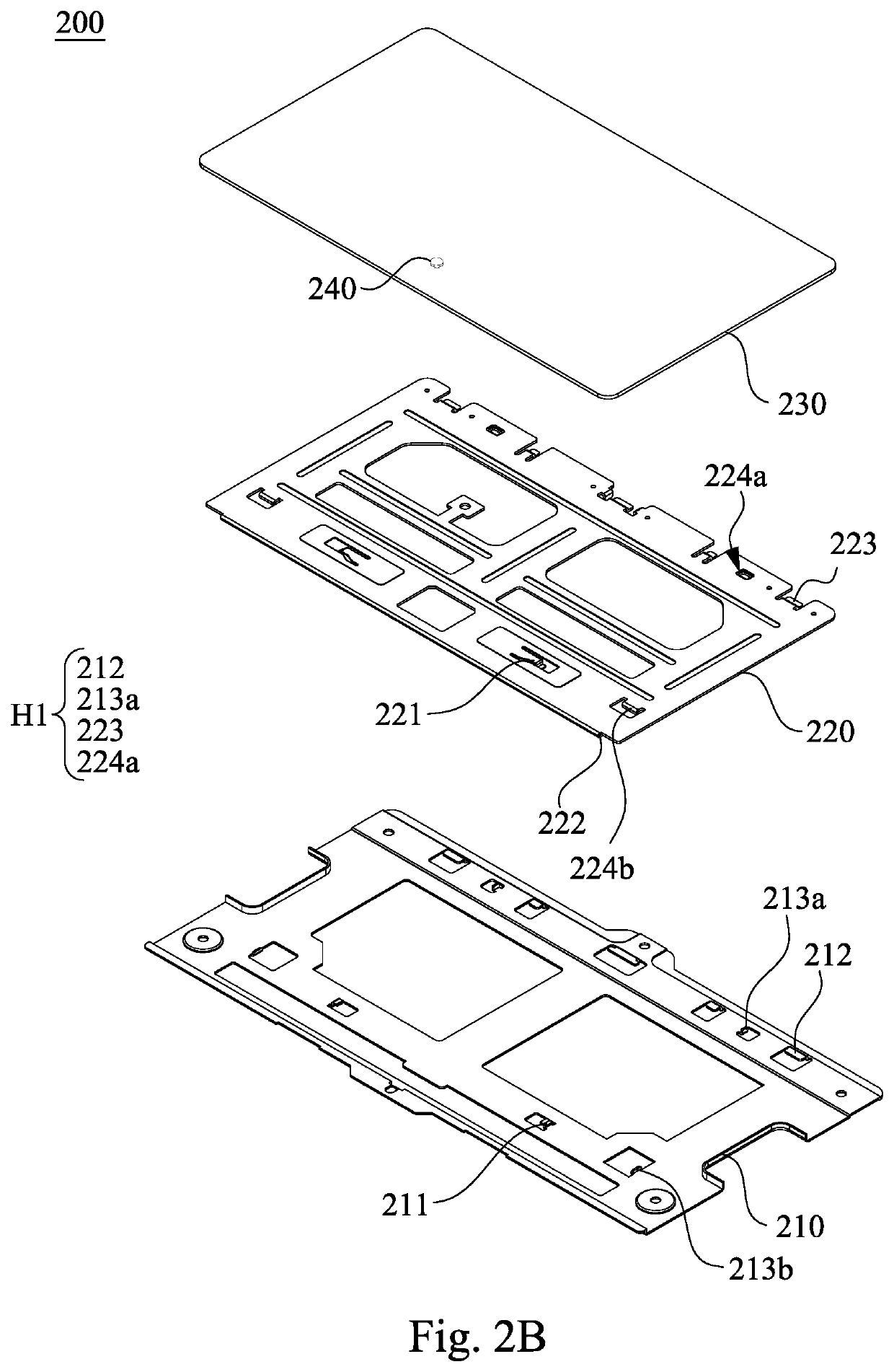

Touchpad device

ActiveUS20210375562A1Efficient solutionReduce decreaseKey-laykey mechanismElectric switchesTouchpadMechanical engineering

A touchpad device includes a bottom board, at least one supporting board, a circuit board, a first extending structure, and a second extending structure. The bottom board is configured to be fixed to a housing. The supporting board is coupled to the bottom board and configured to swing relative to the bottom board. The circuit board is attached to a side of the supporting board away from the bottom board. The first extending structure is disposed on the bottom board and extends toward the supporting board. The second extending structure is disposed on the supporting board and extends toward the bottom board. The first extending structure partially extends to a side of the second extending structure adjacent to the supporting board, or the second extending structure partially extends to a side of the first extending structure adjacent to the bottom board.

Owner:CHICONY ELECTRONICS

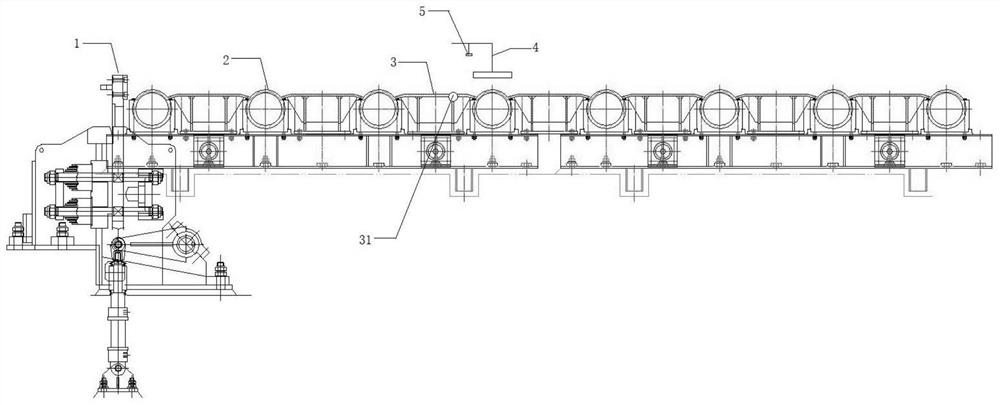

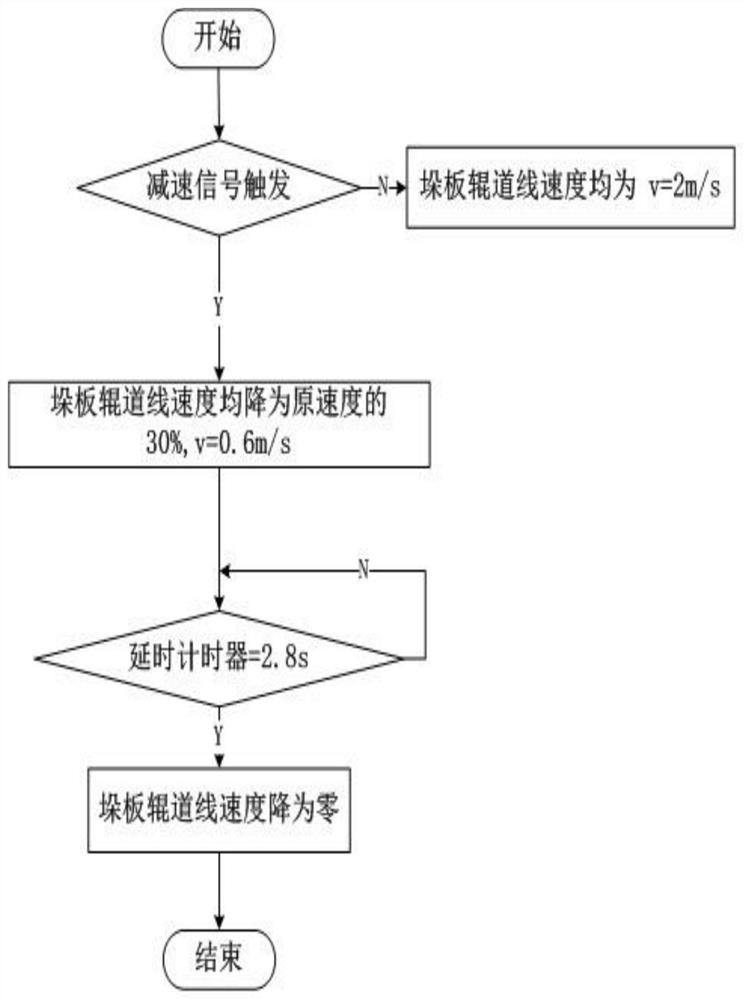

Piled plate lifting baffle protection device and control method thereof

InactiveCN112850171AExtended service lifeAvoid strong impactControl devices for conveyorsStacking articlesPhotoswitchControl system

The invention discloses a piled plate lifting baffle protection device and a control method thereof. The piled plate lifting baffle protection device comprises a piled plate lifting baffle and a piled plate roller way, the piled plate lifting baffle is located at the tail end of the piled plate roller way, the piled plate roller way is further provided with a roller way cover plate, the roller way cover plate is provided with a rectangular opening, and the rectangular opening is located at the position 3 m away from the piled plate lifting baffle. A photoelectric switch installed on a photoelectric switch bracket is arranged above the rectangular opening. According to the control method of the piled plate lifting baffle protection device, a detection signal of the photoelectric switch serves as a speed decrease signal of a PLC control system; when the speed decrease signal is triggered, the linear speed of the piled plate roller way is decreased to 30% of the original speed, and v is equal to 0.6 m / s; and 2.8 s after the speed decrease signal is triggered, the linear speed of the piled plate roller way is decreased to zero, the roller way stops rotating, and v is equal to 0 m / s. By means of the piled plate lifting baffle protection device and the control method of the piled plate lifting baffle protection device, soft contact between the piled plate lifting baffle and a steel plate is achieved, on one hand, strong impact of the steel plate on the lifting baffle is effectively avoided, and the service life of the piled plate lifting baffle is prolonged; and on the other hand, impact noise is eliminated.

Owner:SD STEEL RIZHAO CO LTD

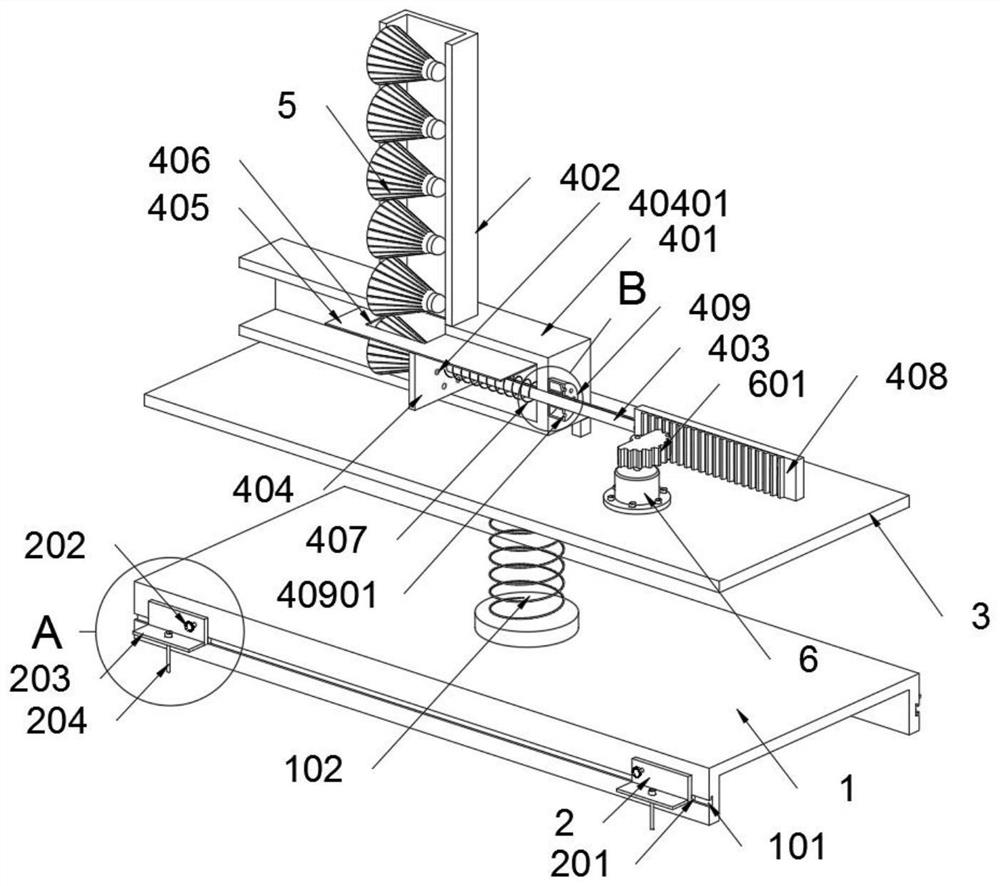

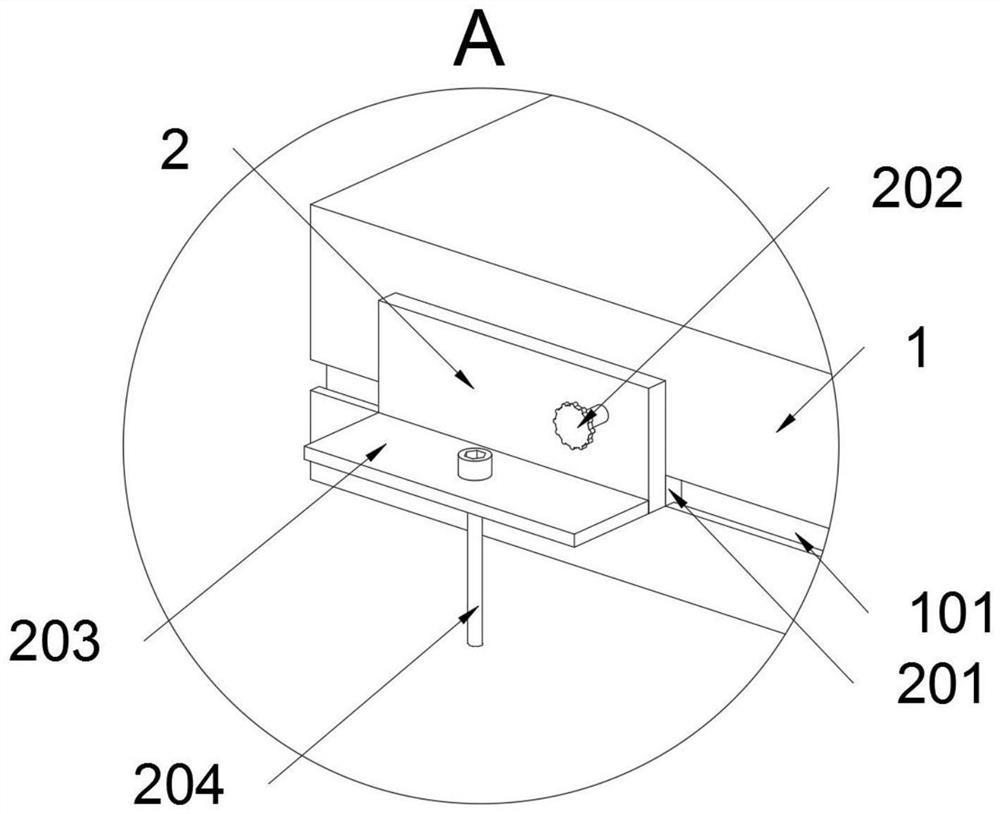

A continuous ball-serving device for high-level sports badminton training

ActiveCN112870673BRealize airflow coolingRealize automatic goalsSport apparatusPhysical medicine and rehabilitationSports equipment

The invention provides a continuous serving device for high-level sports badminton training, which relates to the technical field of sports equipment, and solves the problem that the continuous serving can not be achieved through structural improvement while realizing the airflow heat dissipation of the sliding rod and the airflow of the driving motor Type heat dissipation; the problem of automatic irregular adjustment of the serve can be realized through structural improvement. A continuous ball serving device for high-level sports badminton training, comprising a base; four fixing seats are installed on the base, and a mounting plate is also installed on the base. Because the tail end of the elastic member A is welded on the top surface of the base, and the head end of the elastic member A is welded to the bottom surface of the mounting plate, and the elastic member A forms a non-directional serving structure of the serving structure, so that the gear row and the protective pad When impacting, the serving structure will continuously swing under the action of the elastic member A, and then the badminton sent at this time can reflect randomness.

Owner:舒城县河棚科技创新协会

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com