Integrated electric valve

A technology for electric valves and shells, which is applied to valve details, valve devices, engine components, etc. It can solve the problems of many external connections of electric valves, poor matching of refrigeration equipment, and affecting the life of components, so as to achieve simple internal connections and reduce Effects of interference and radiation, prolonging component life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

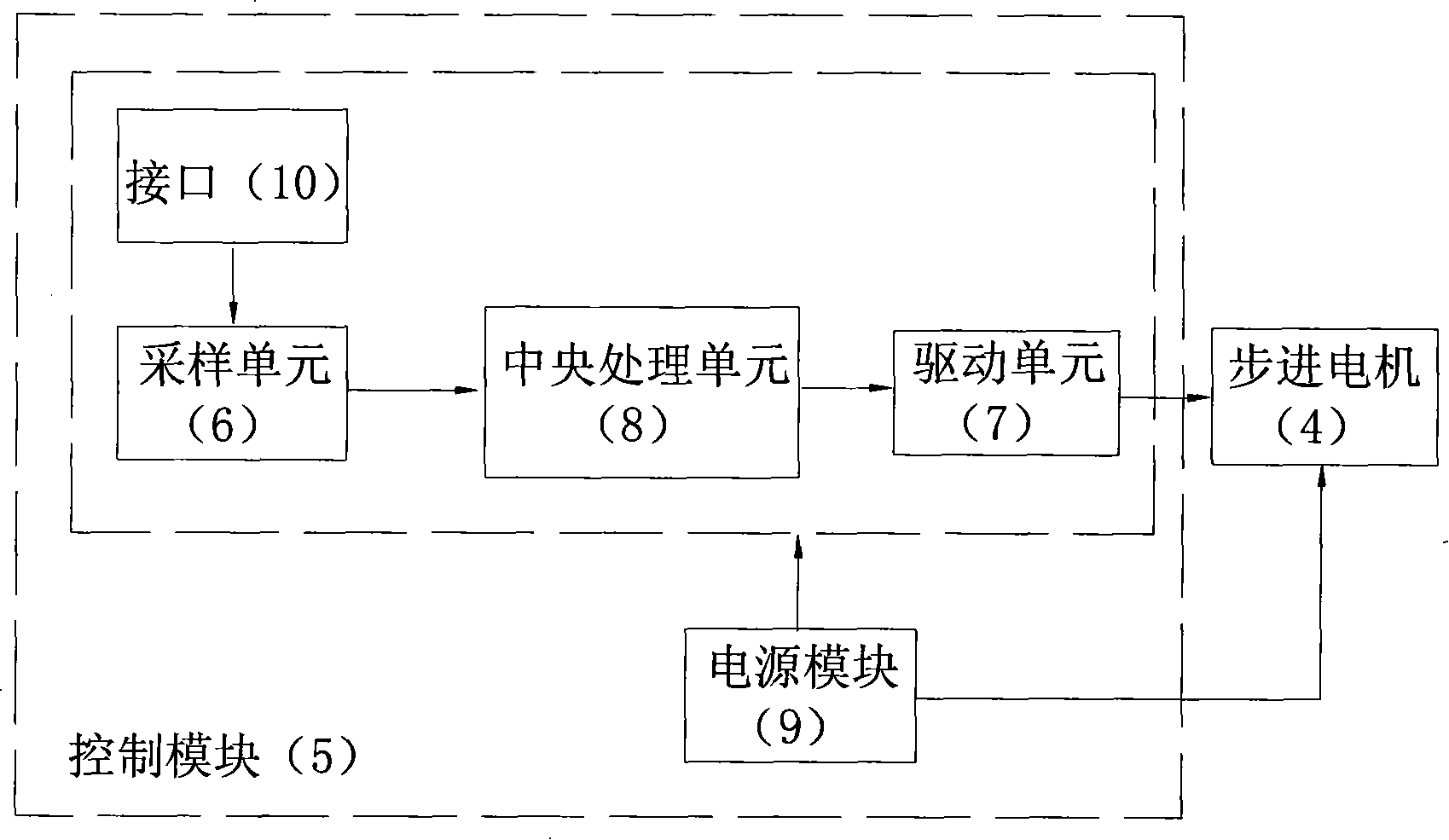

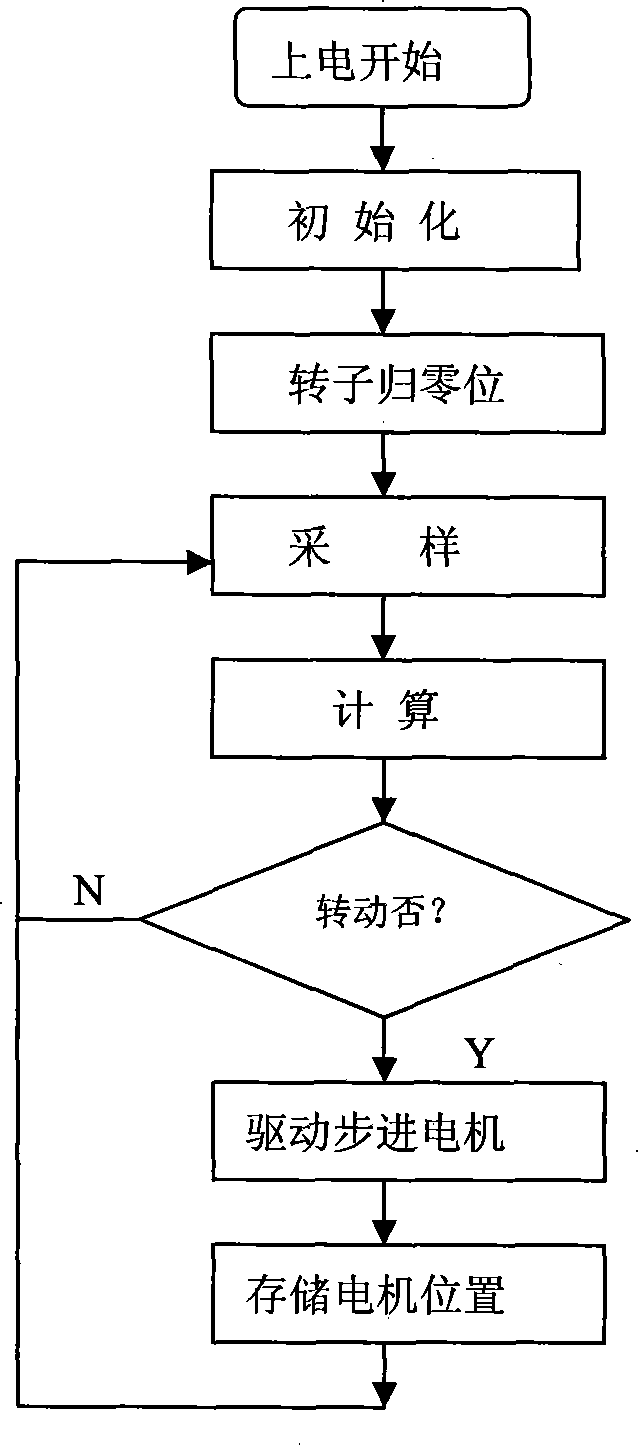

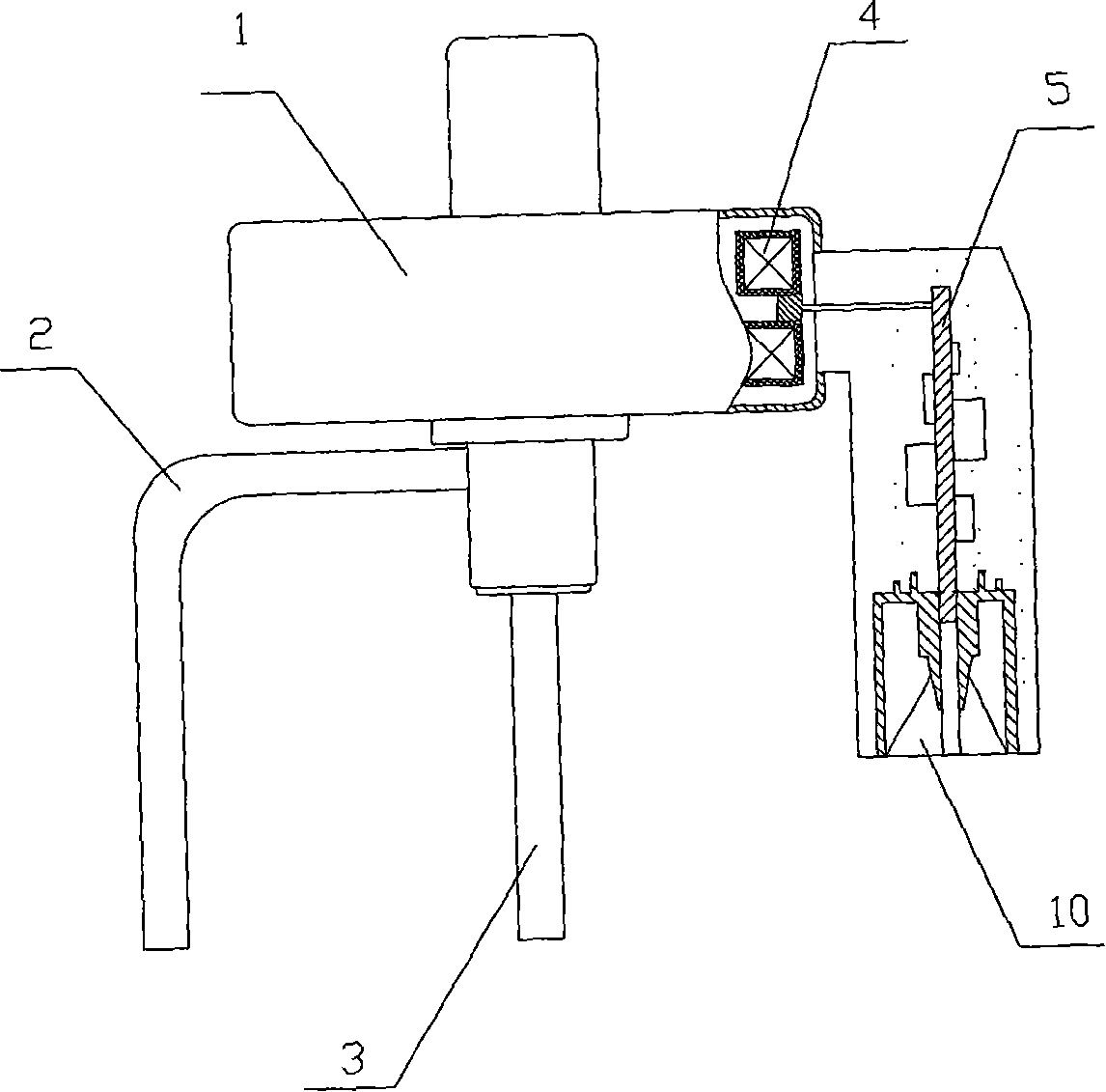

[0021] Embodiment 1: the integrated electric valve of this embodiment, such as image 3 As shown, a stepper motor 4, a control module 5, and a valve cavity connected with an inlet pipe 2 and an outlet pipe 3 are integrally packaged in the housing 1, and the outlet pipe 3 is located at the mouth of the housing 1 and is installed with a stepper motor. Into the valve mechanism connected to motor 4. Such as figure 1 As shown, the control module 5 includes a central processing unit 8 connected with a sampling unit 6, a drive unit 7, and a power supply module 9 that provides operating power for the entire valve. The drive unit 7 is connected to the stepper motor 4 through a stepper motor interface. A three-core interface 10 is installed on the body 1, one core of the three-core interface 10 is connected to the sampling unit 6, and the other two cores are connected to the power module 9, and the central processing unit 8 stores a control program. The matching between the valve and ...

Embodiment 2

[0029] Embodiment 2: the integrated electric valve of this embodiment, such as Figure 5 As shown, a stepper motor 4, a control module 5, and a valve cavity connected with an inlet pipe 2 and two outlet pipes 3 are integrally packaged in the housing 1, and the outlet pipe 3 is located at the mouth of the housing 1 and installed with a The stepping motor 4 is connected to the valve mechanism. A four-core interface 10 is installed on the housing 1 , two cores of the four-core interface 10 are connected to the sampling unit 6 , and the other two cores are connected to the power module 9 . All components on the control module 5 in the present embodiment are welded on a circuit board, as Figure 6 As shown, the sampling unit 6 is composed of resistors R1, R2, and capacitors C5 and C6. The two control signals input by the refrigeration equipment control part are input through the interface JP2 and the two resistance values of R1 and R2 are pulled up respectively. The two input si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com