Disc brake braking leaf spring

A technology of brake pads and disc brakes, which is applied in the field of motorcycle accessories, can solve the problems of brake pads colliding with fixed pins, unstable brakes, etc., and achieve the effect of eliminating noise and preventing collisions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

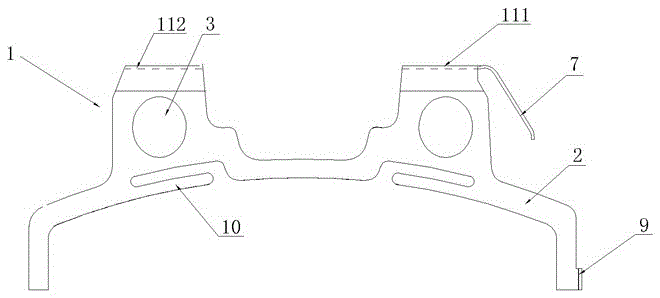

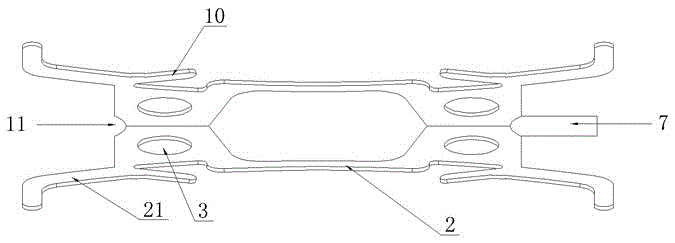

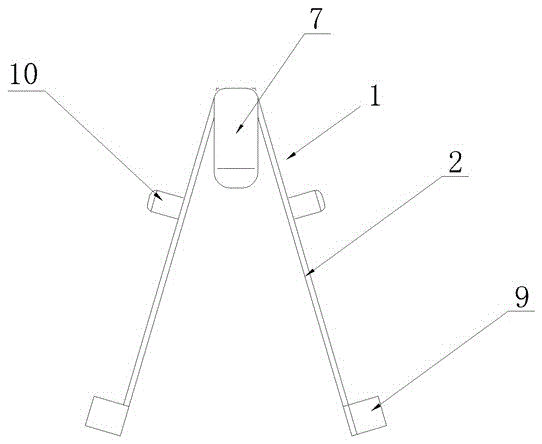

[0022] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, a disc brake leaf spring includes a leaf spring body 1, the leaf spring body 1 is composed of two fins 2, the upper part of the fins 2 is provided with a mounting hole 3, and the mounting hole 3 is used for The leaf spring body 1 is installed on the disc brake pump body 4, and the fixing pin 5 is used to pass through the installation hole 4 to fix it. The two fins 2 are connected as a whole through the connecting part 11 arranged at the top, and the side is an inverted V shape, the bottom of the wing 2 includes two feet 21, so that the lower part of the wing 2 is n-shaped, that is, a semi-enclosed frame structure, and the periphery of the braking surface of the brake pad 6 is provided with a step for the installation of the wing, which is assembled with the brake pad 6 At this time, the n-shaped frame structure of the wing 2 is installed on the step of the brake pad 6, so that the two feet 21 of the wing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com