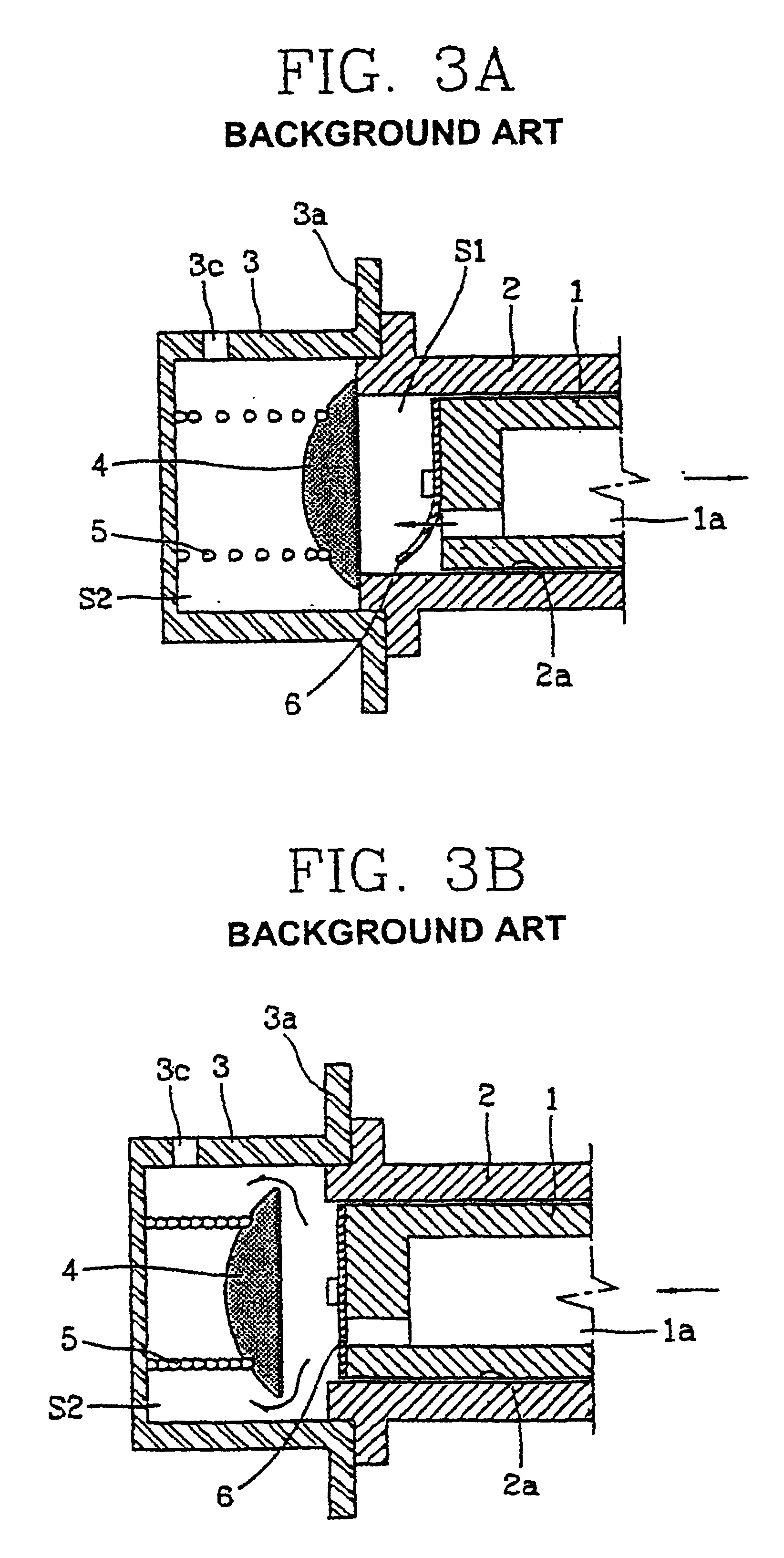

Patents

Literature

79results about How to "Avoid knocking noise" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

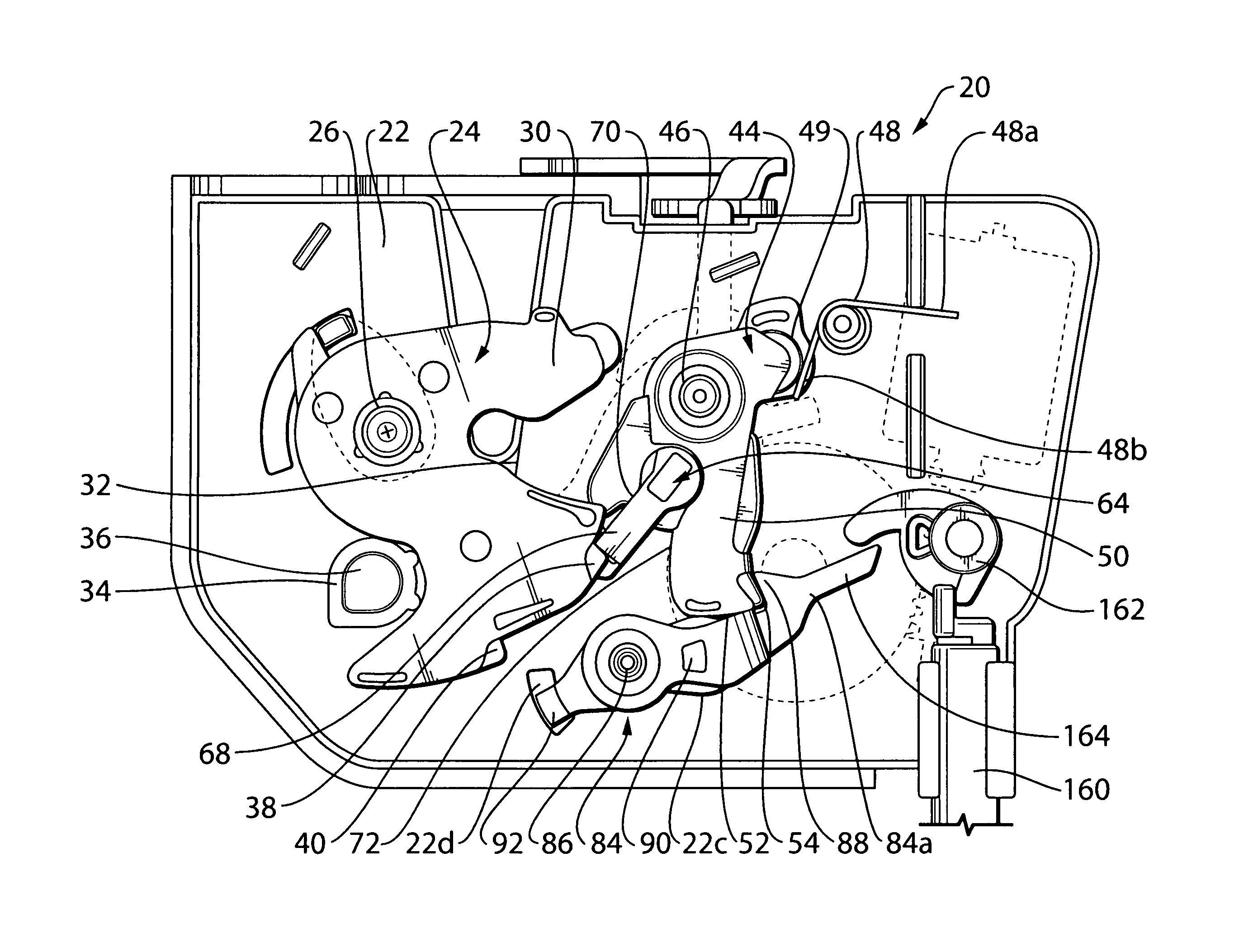

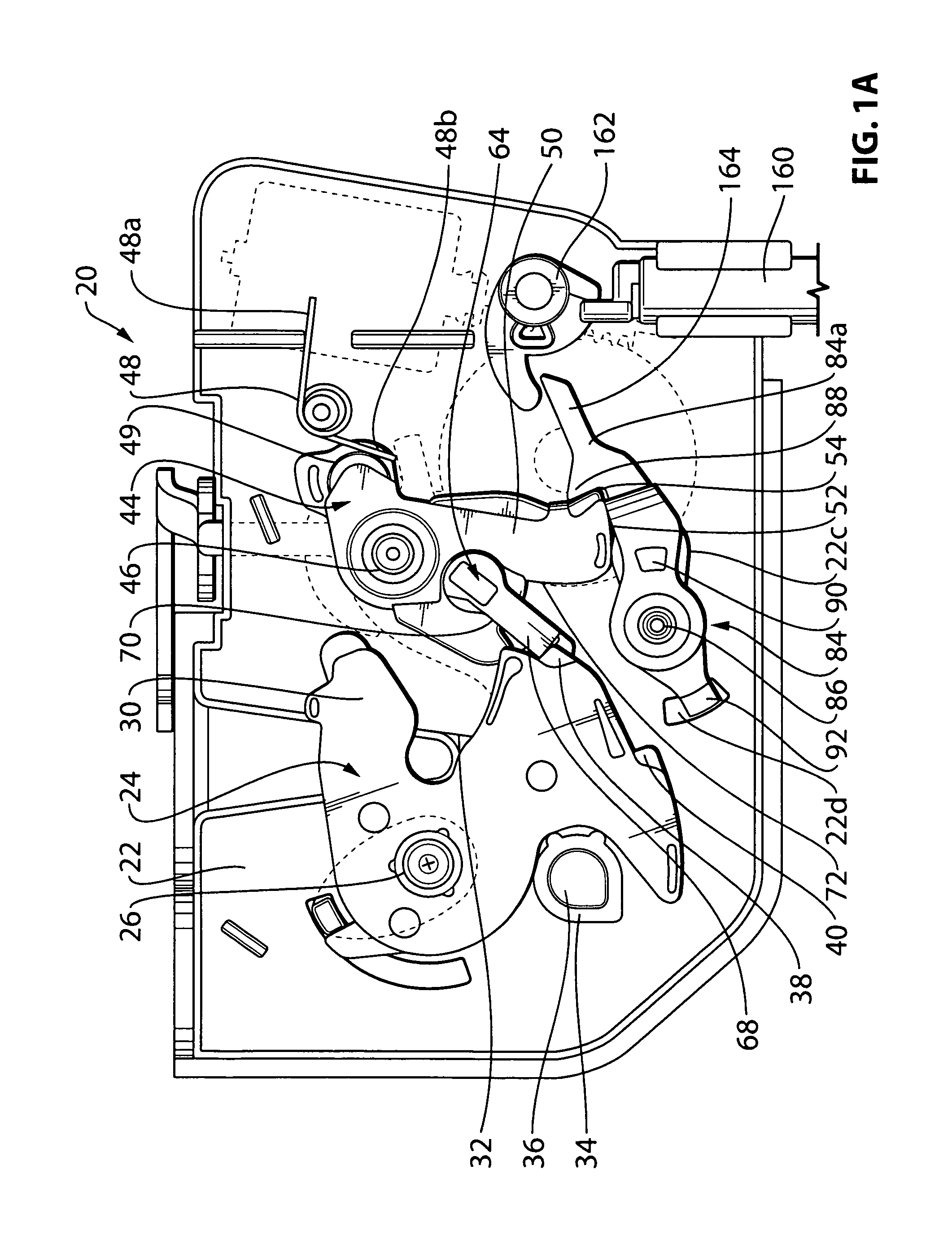

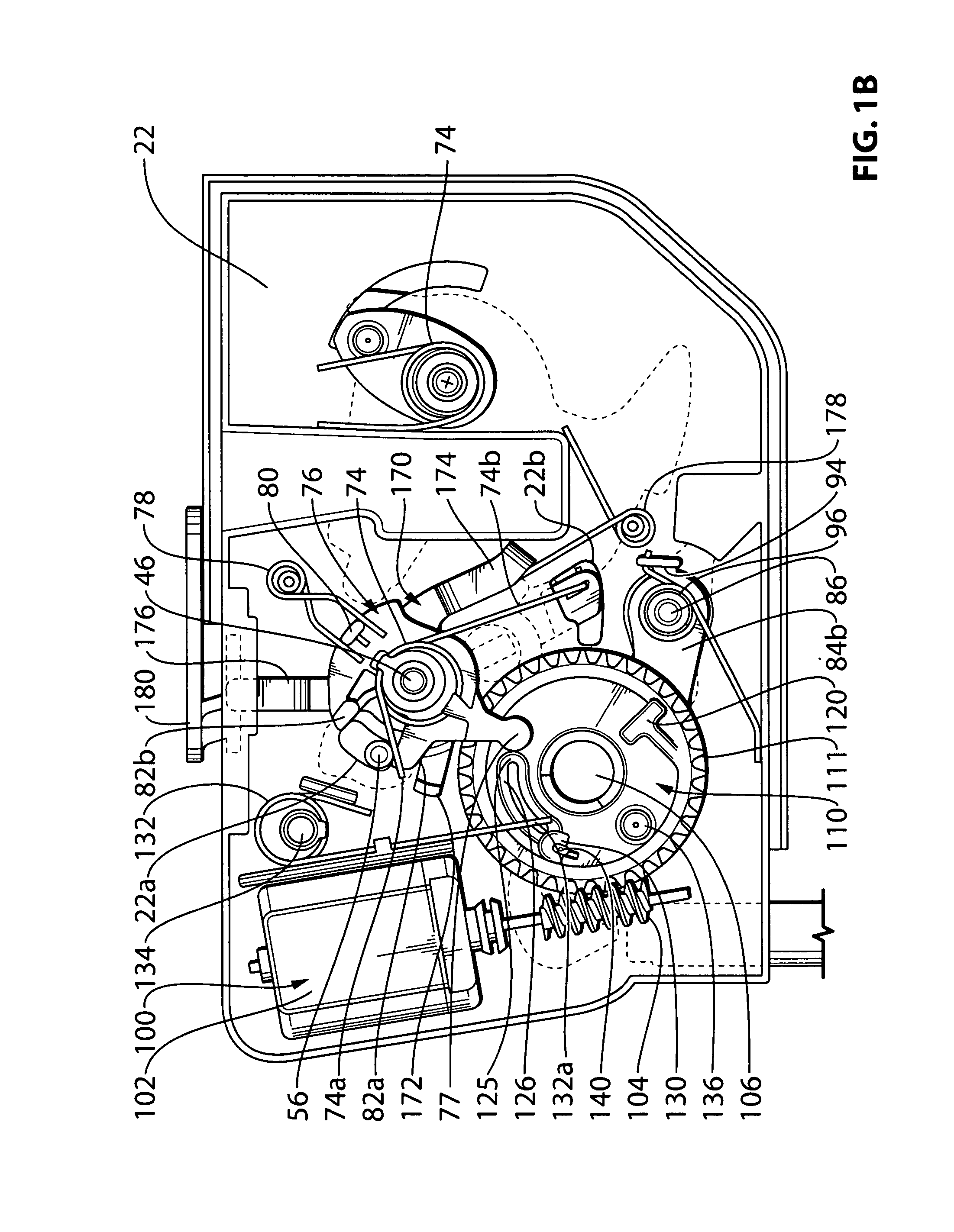

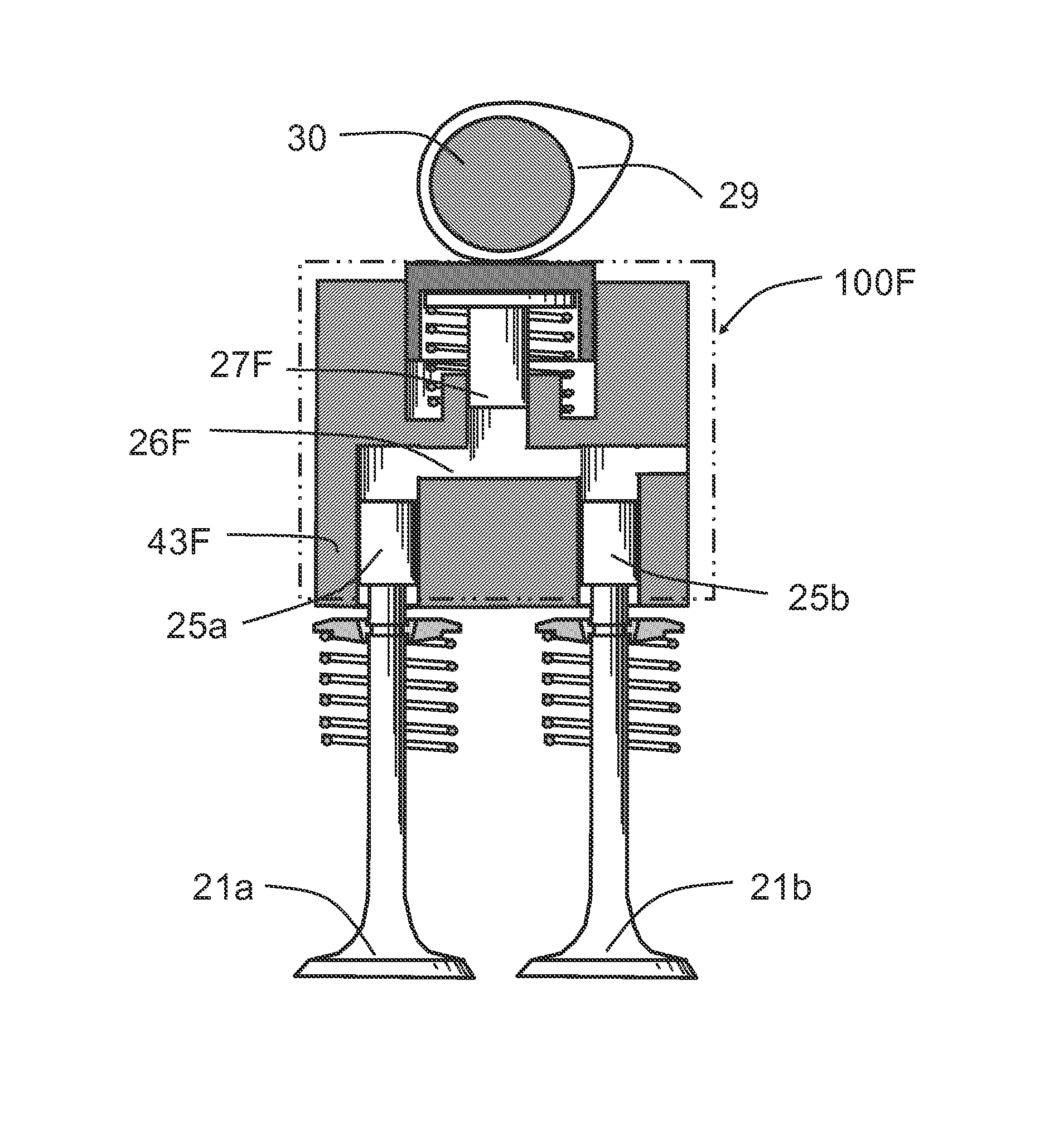

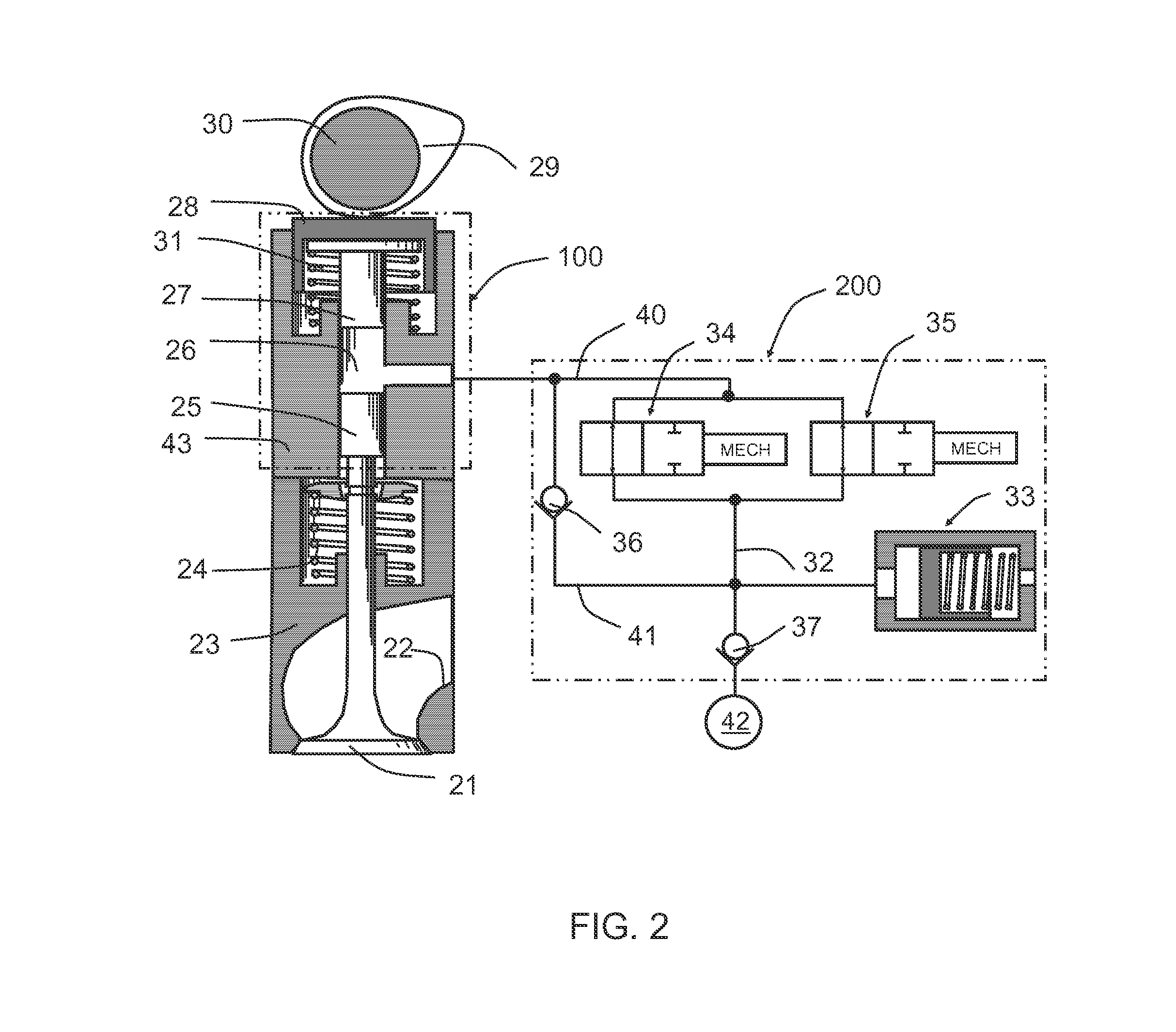

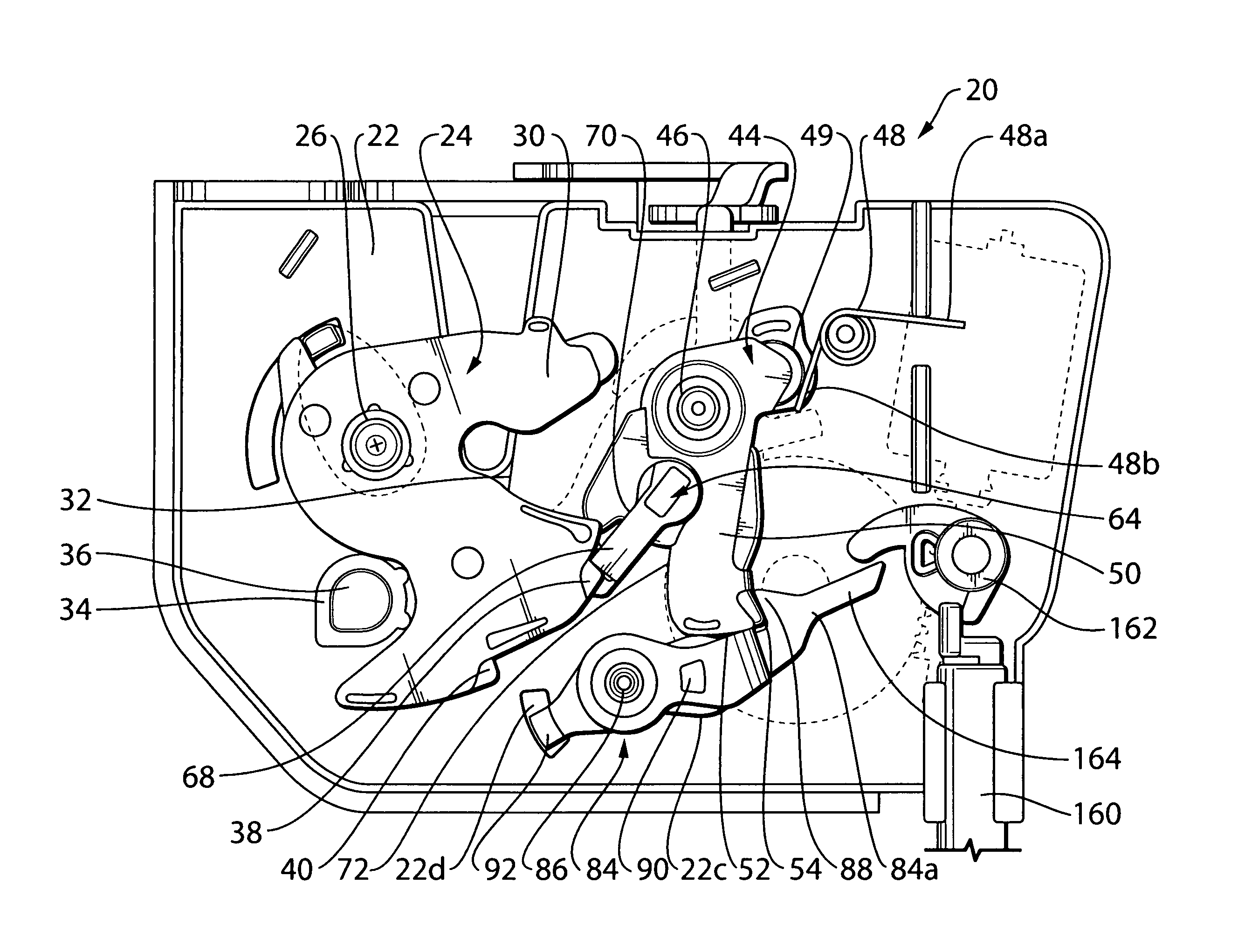

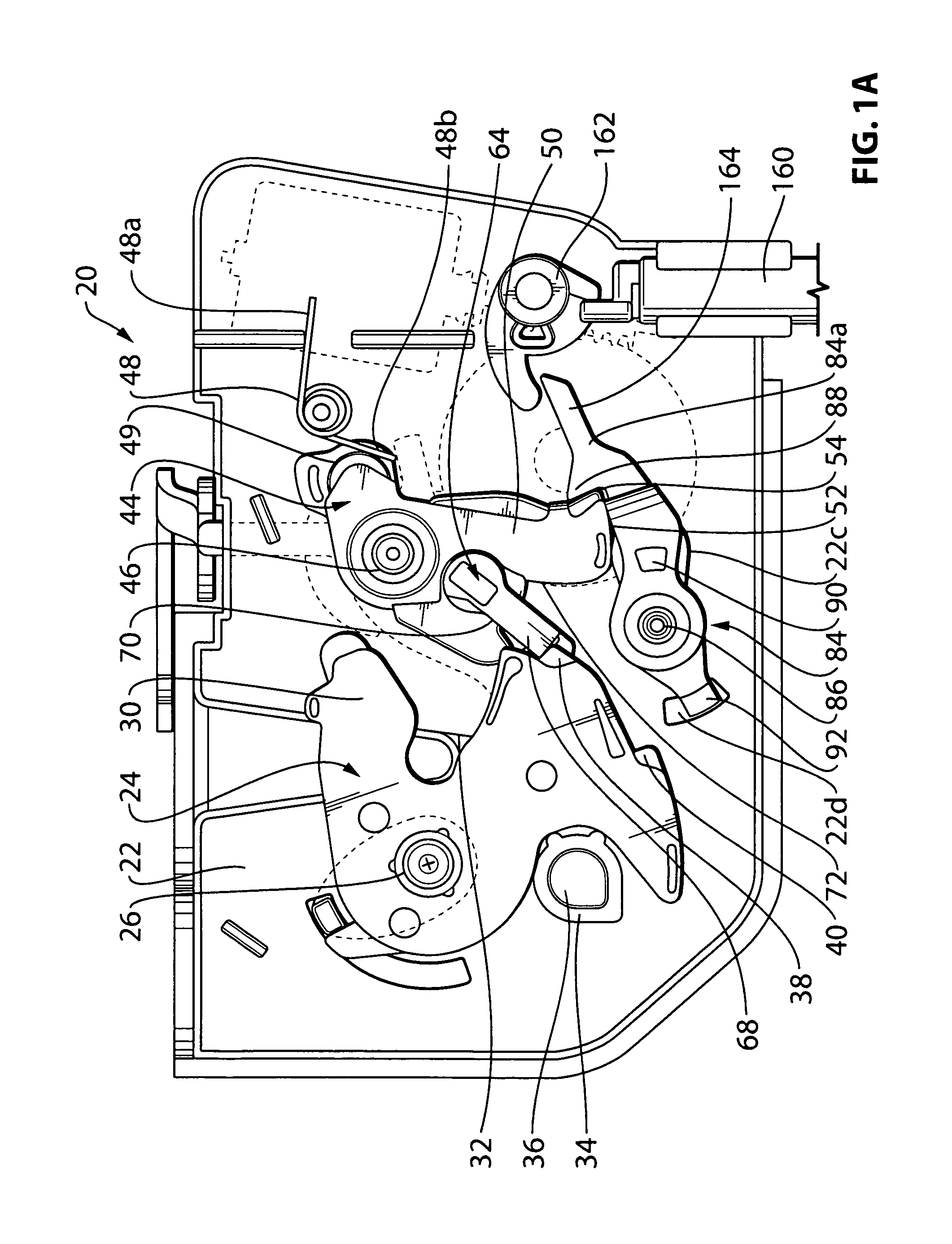

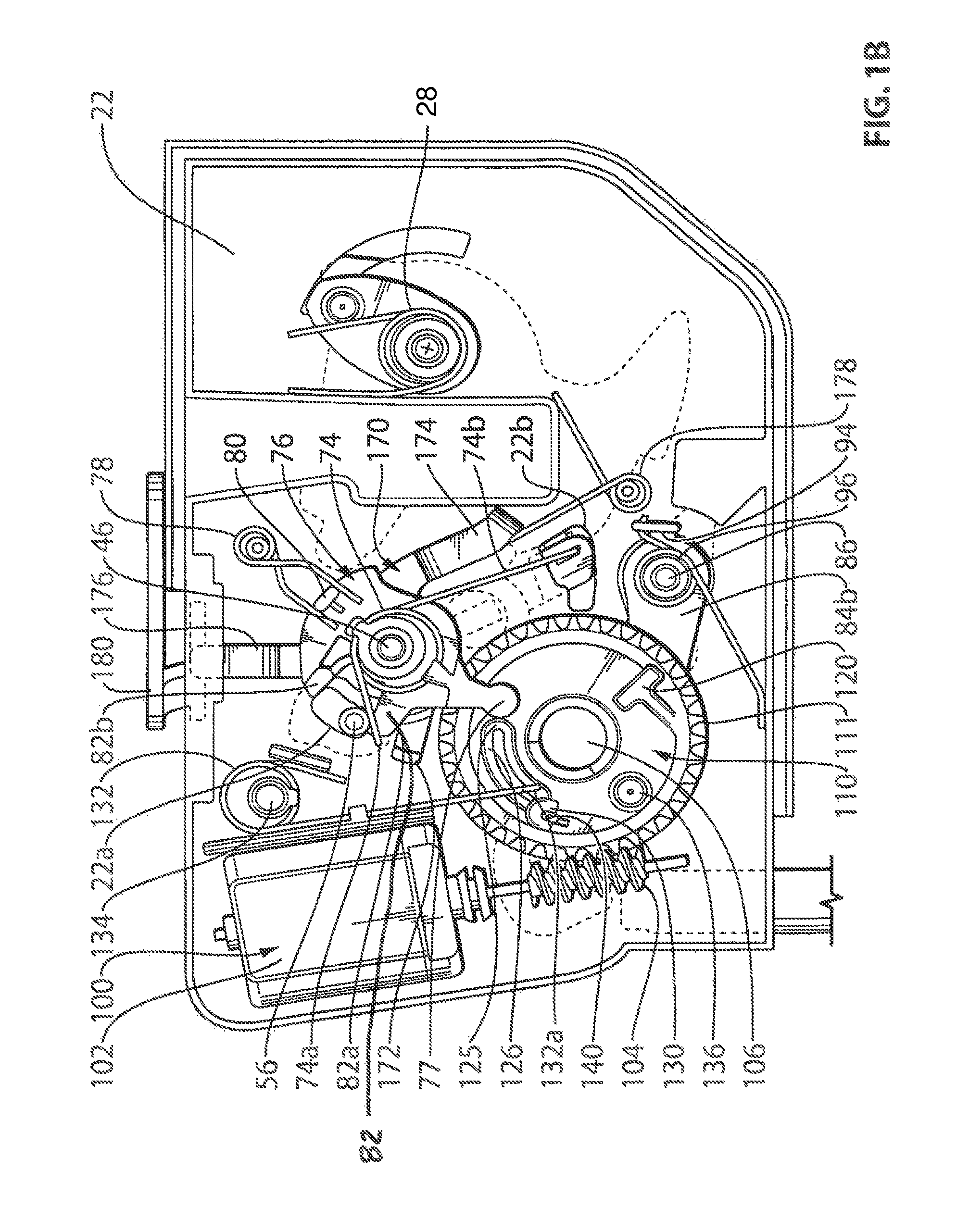

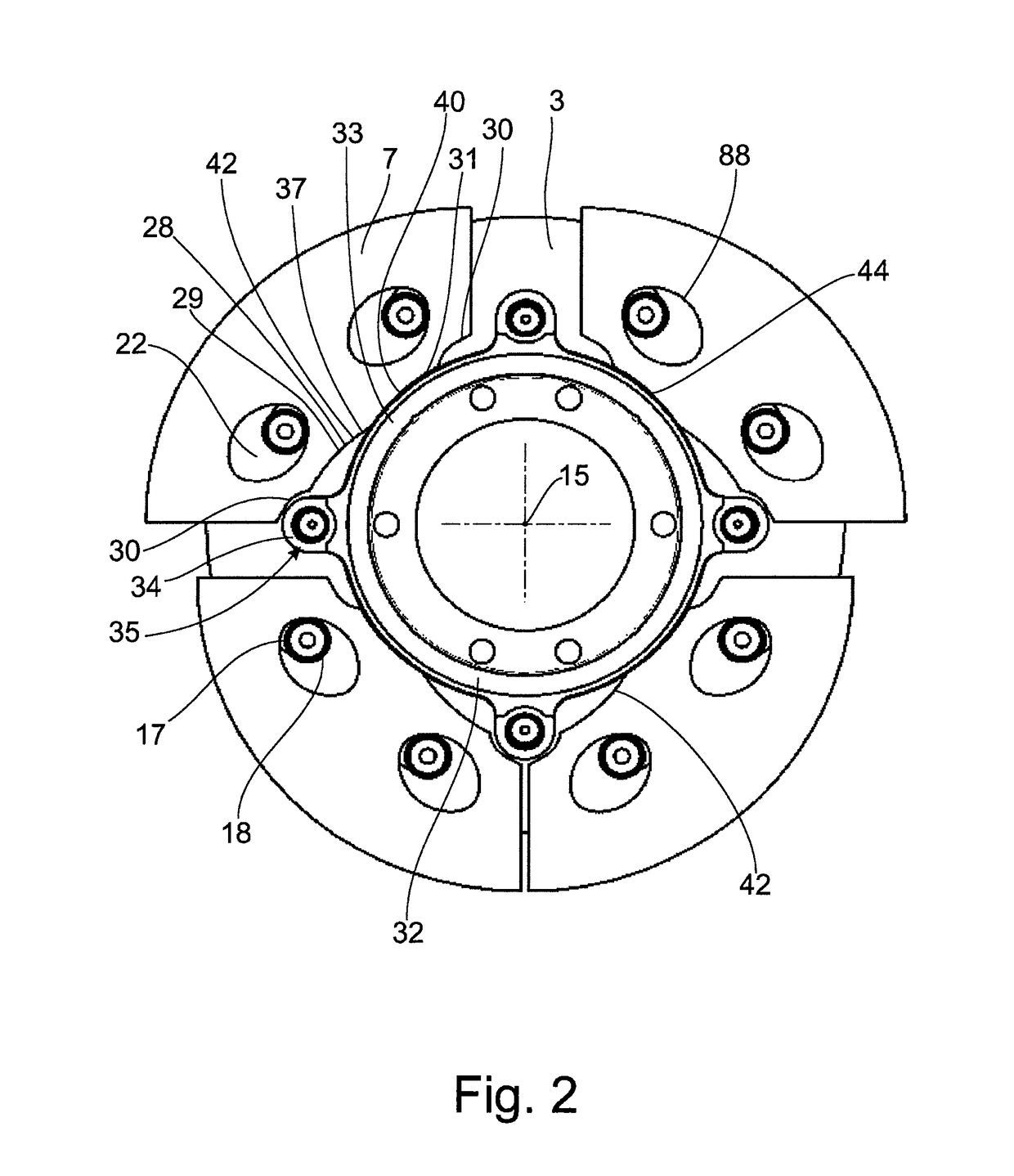

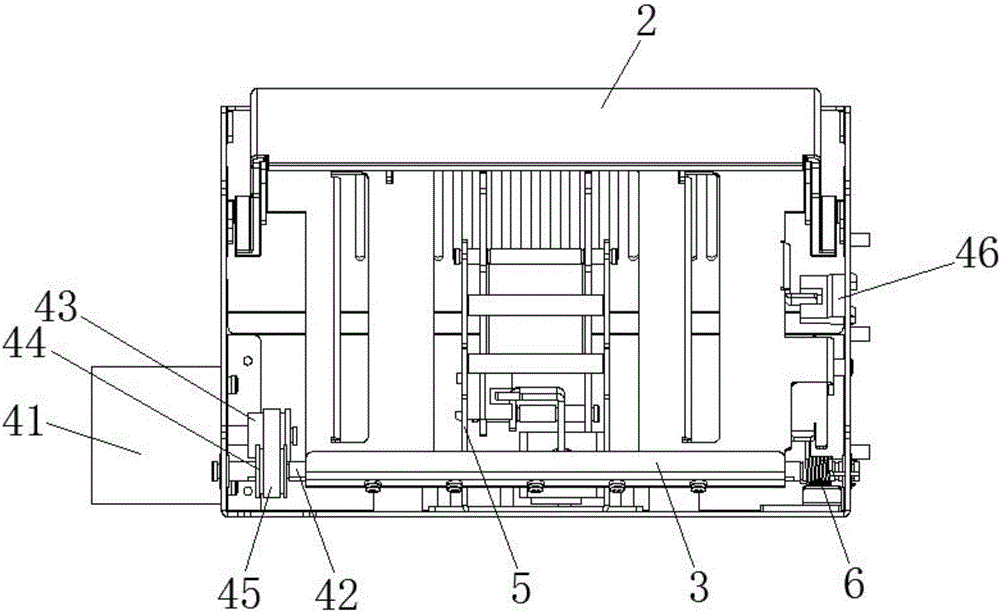

Double ratchet, double pawl vehicular latch with soft stop on reset

ActiveUS20140091581A1Preventing full travel impact noiseEliminate impact noiseNoise-prevention/anti-rattling lockingConstruction fastening devicesRatchetGear wheel

A low release effort eccentric double ratchet, double pawl vehicle latch includes a ratchet, a primary pawl, an auxiliary ratchet and a secondary pawl. A drive mechanism including a gear cam wheel sequences movement of the secondary pawl to open and reset the latch. Upon reset, the drive mechanism actuates the auxiliary ratchet back to a closed state in a soft manner without using a hard stop; instead the latch has a cushioning spring that is used to softly stop the gear train during the reset absorbing motor energy and thus eliminating impact noise.

Owner:MAGNA CLOSURES SPA

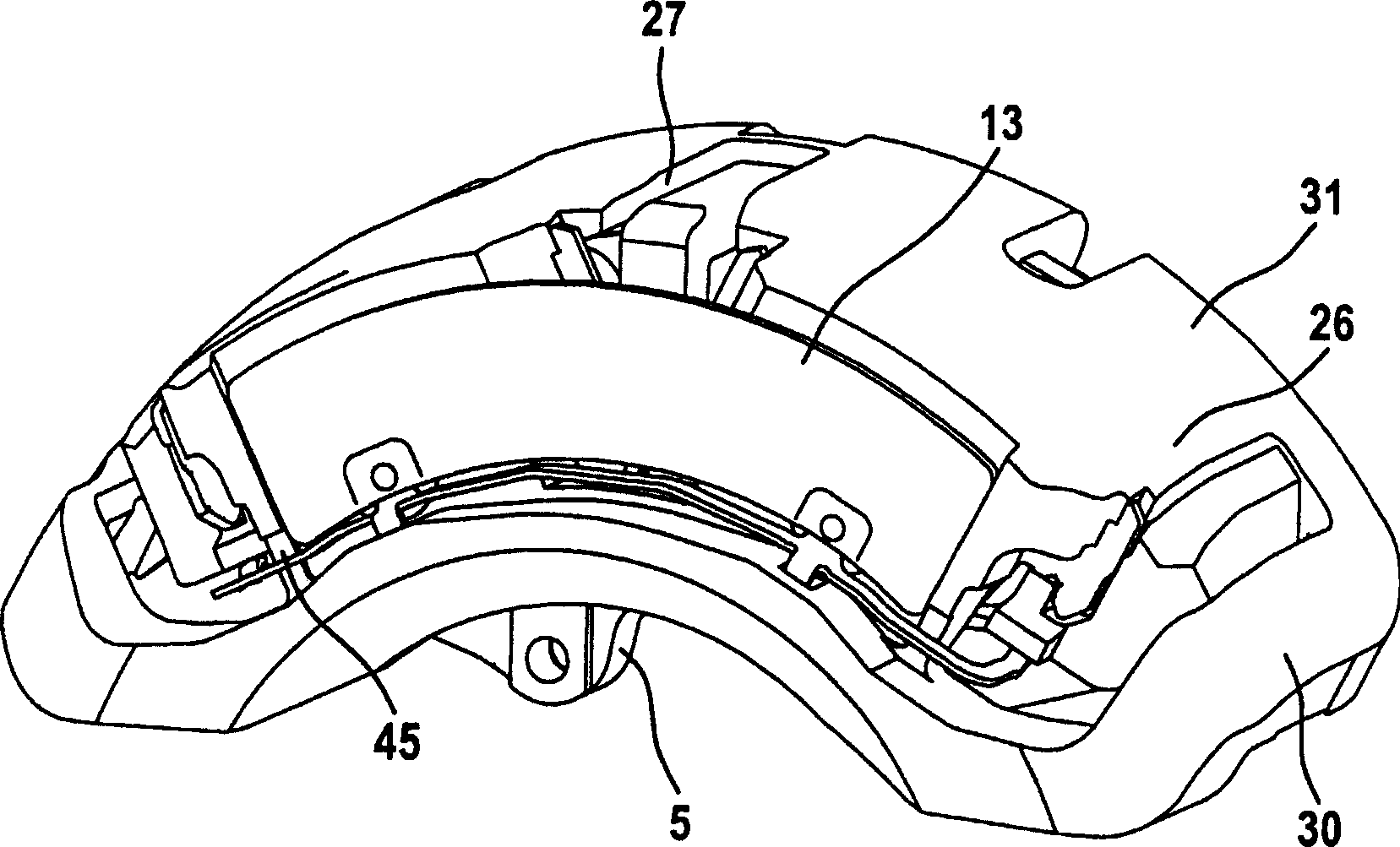

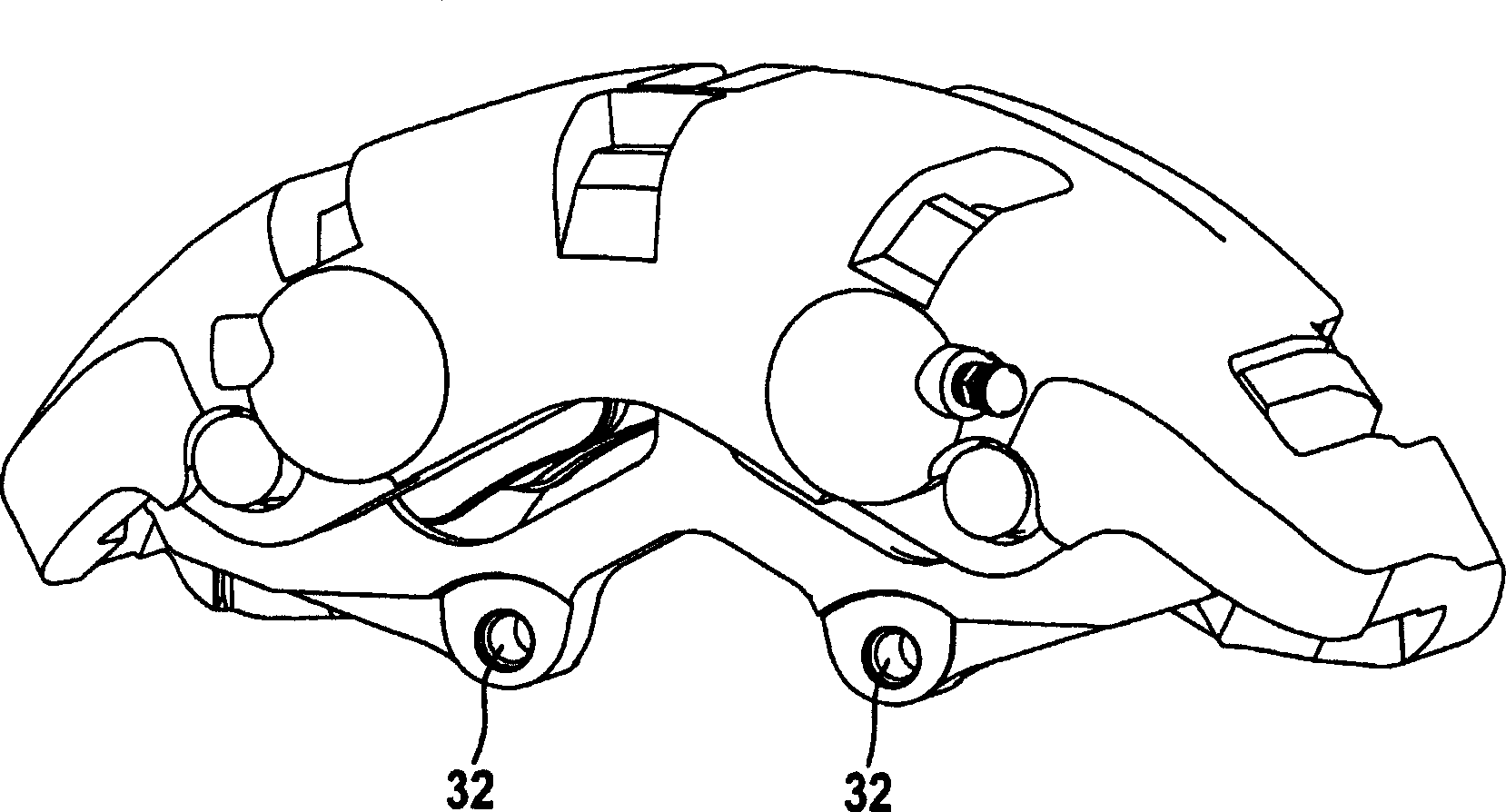

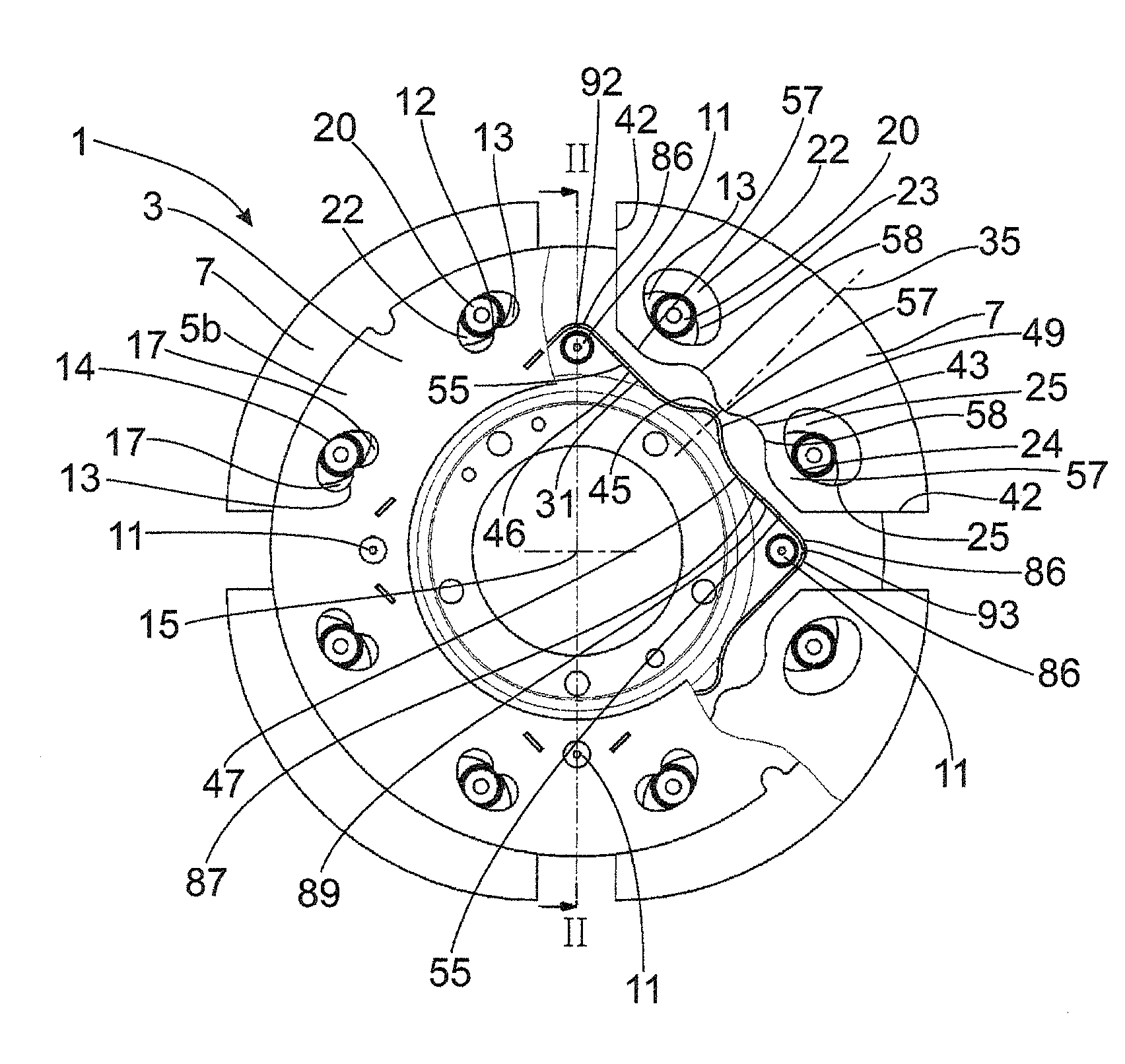

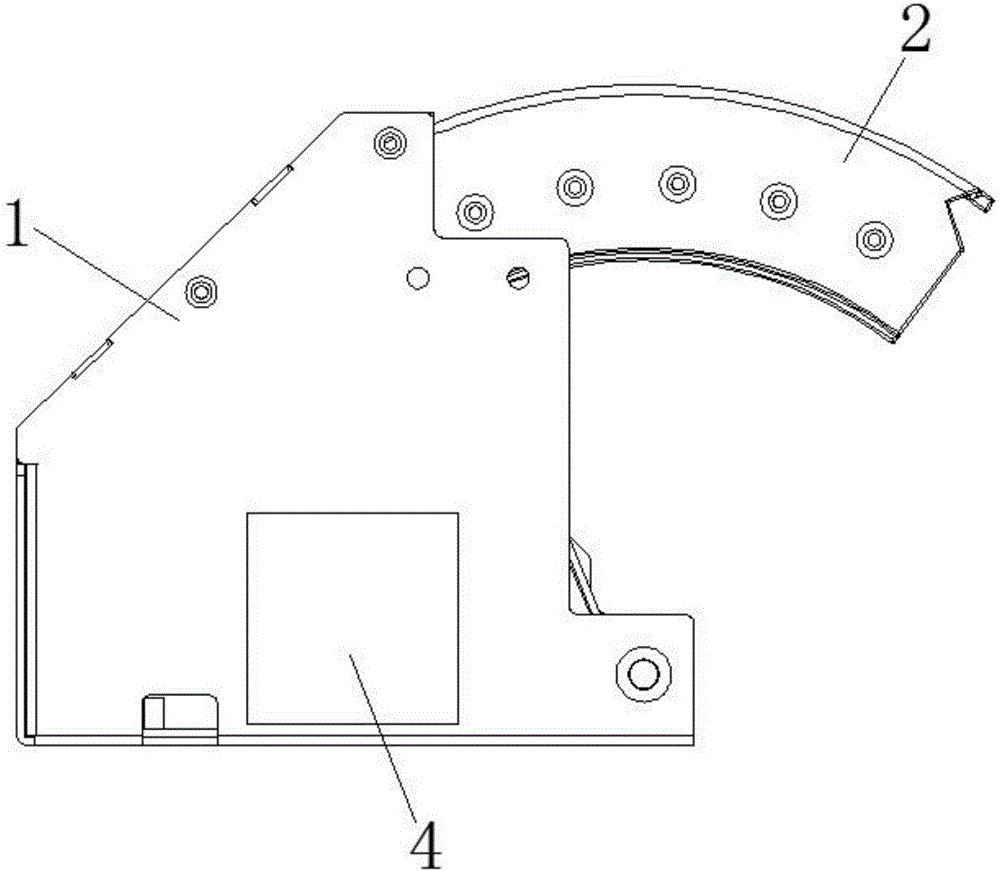

Disc brake equipped with a floating caliper and several outer brake pads directly supported on the brake anchor plate

InactiveCN1653281AAvoid knocking noiseSmall guide surfaceAxially engaging brakesBrake actuating mechanismsEngineeringCalipers

Owner:CONTINENTAL TEVES AG & CO OHG

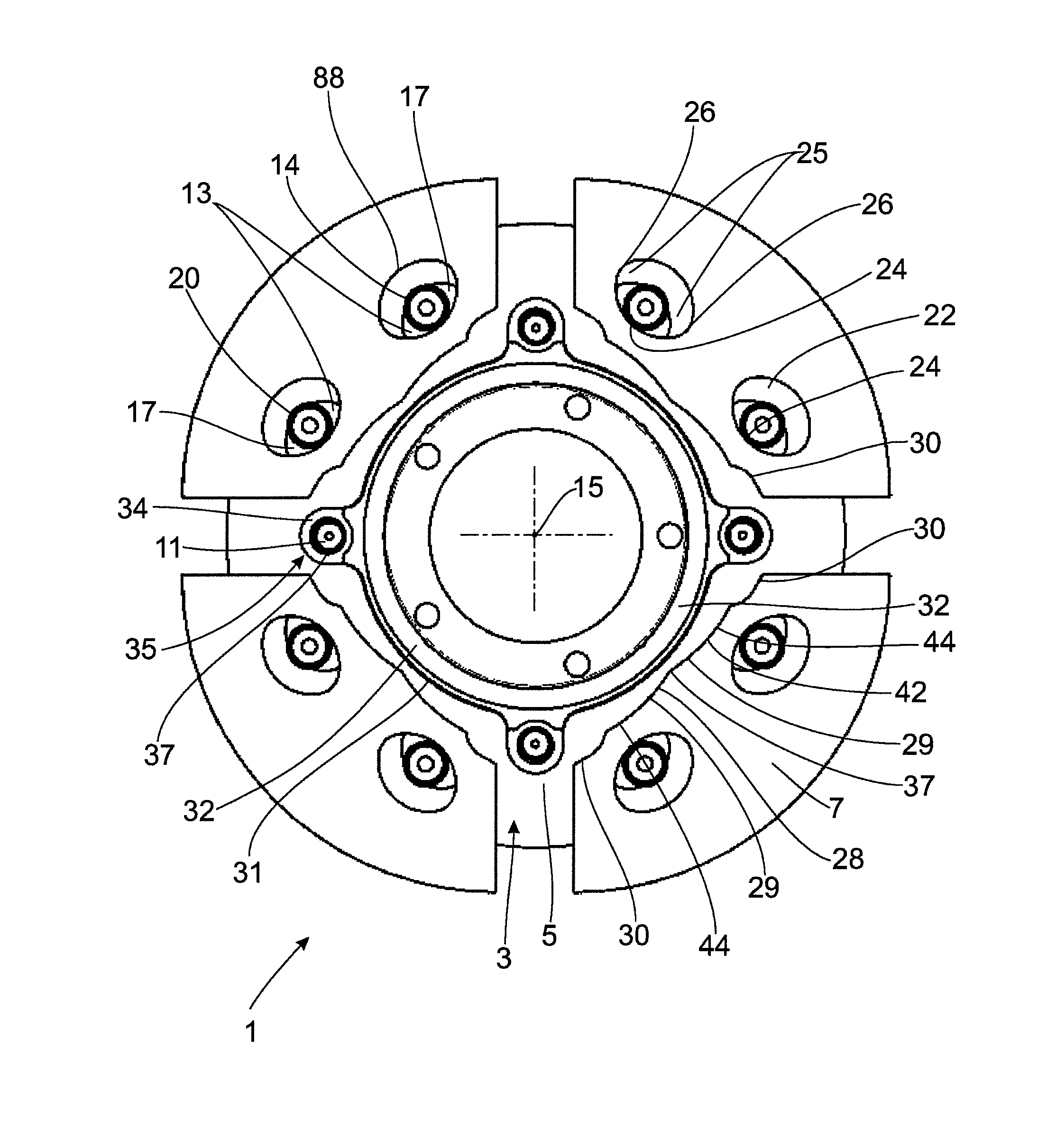

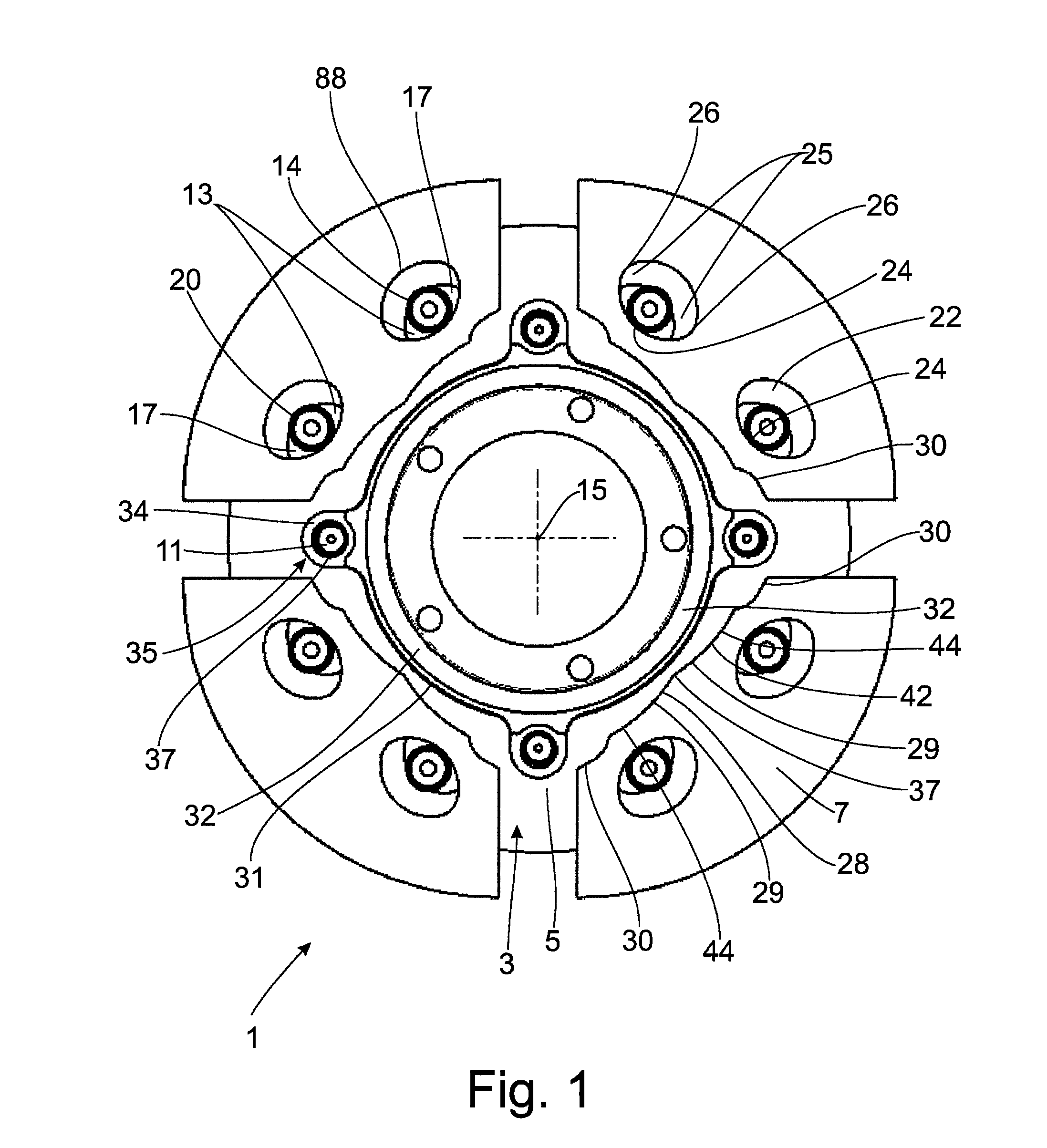

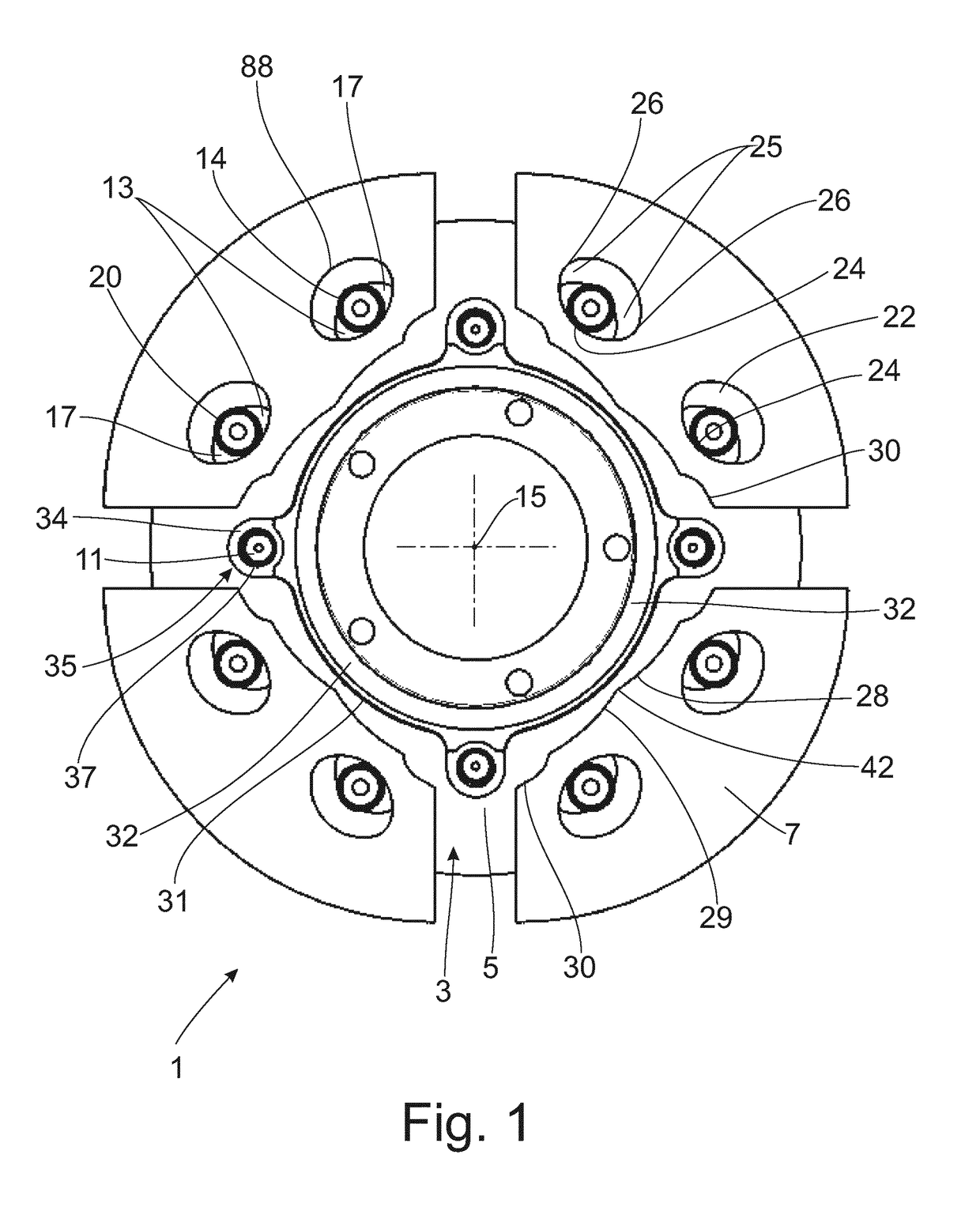

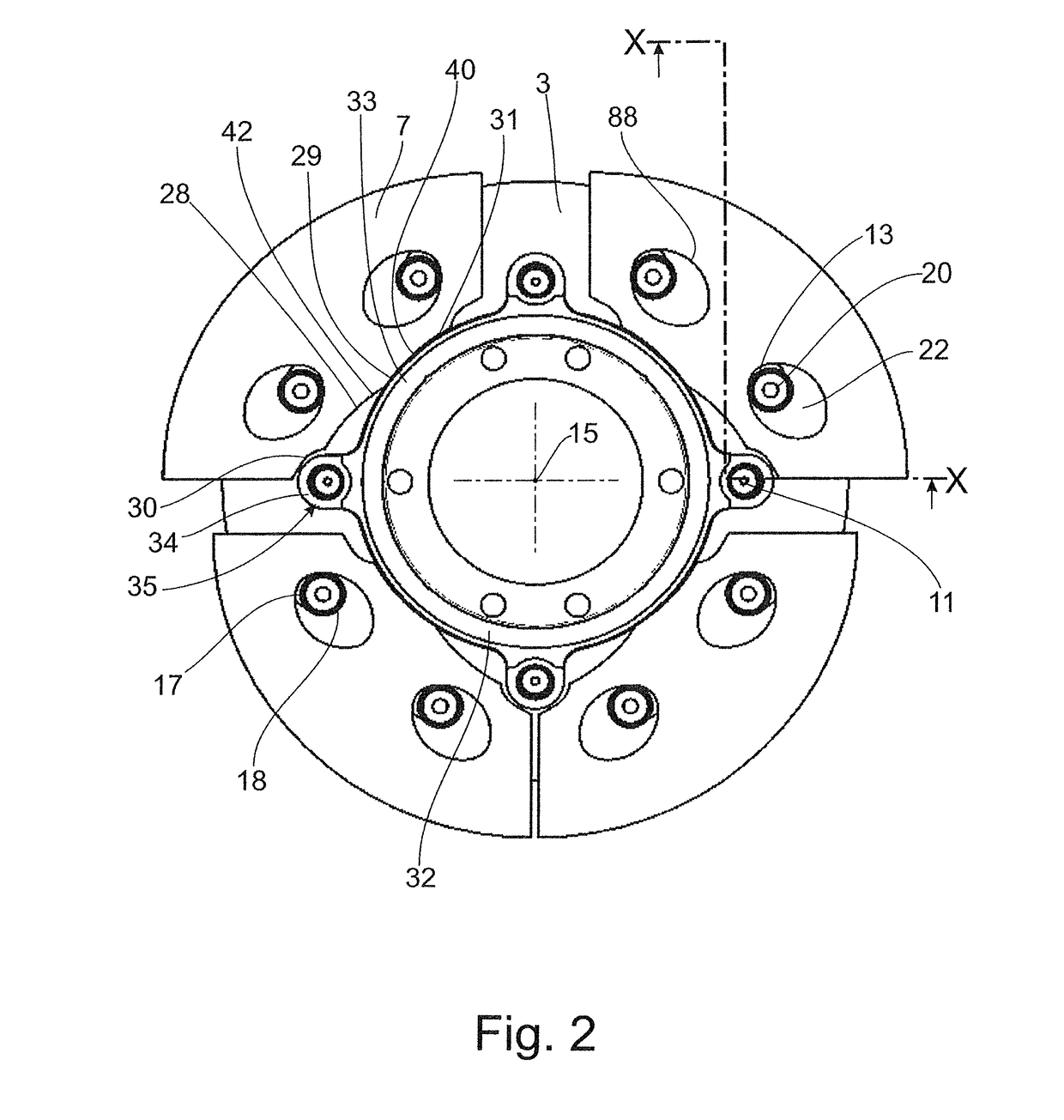

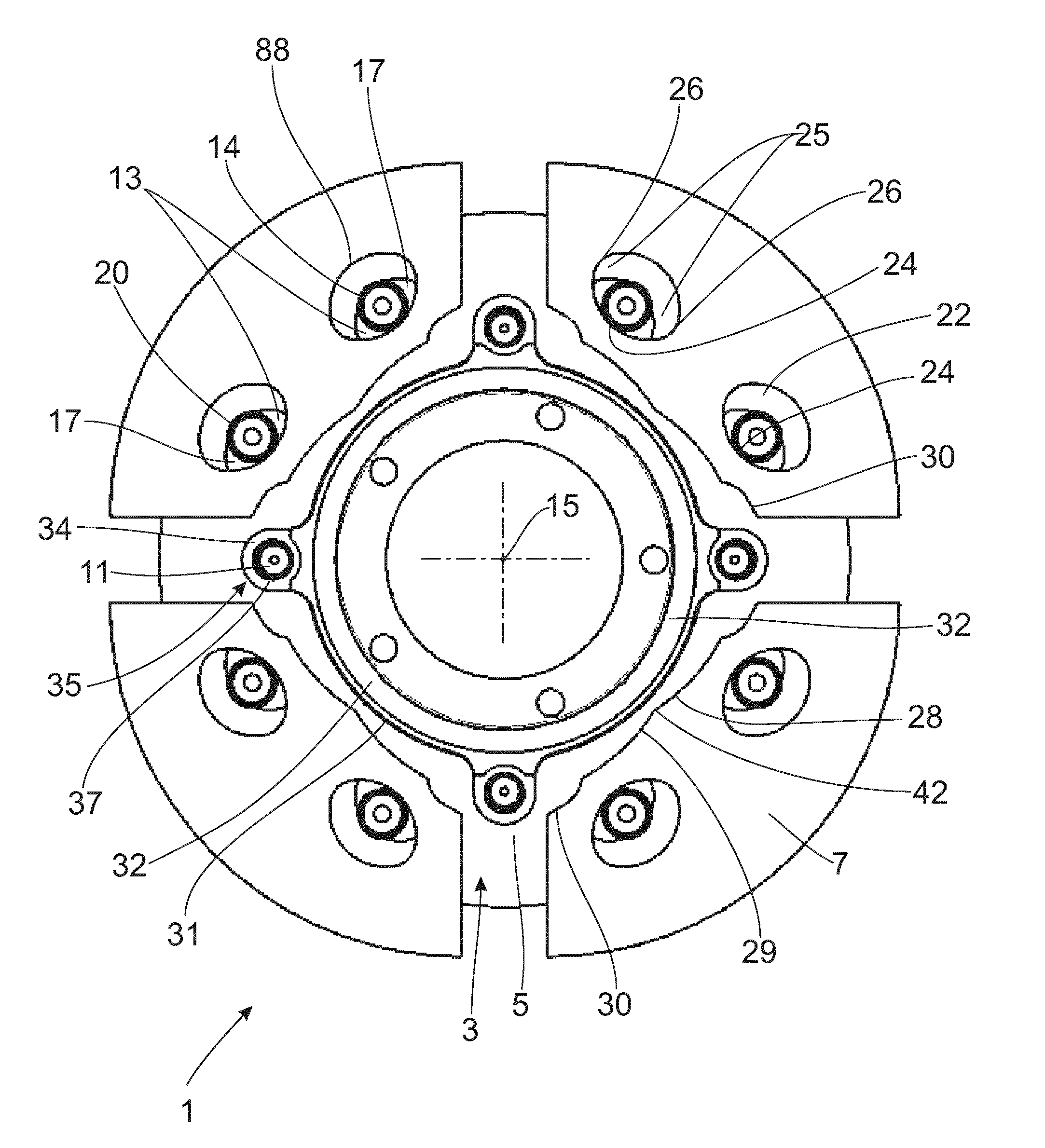

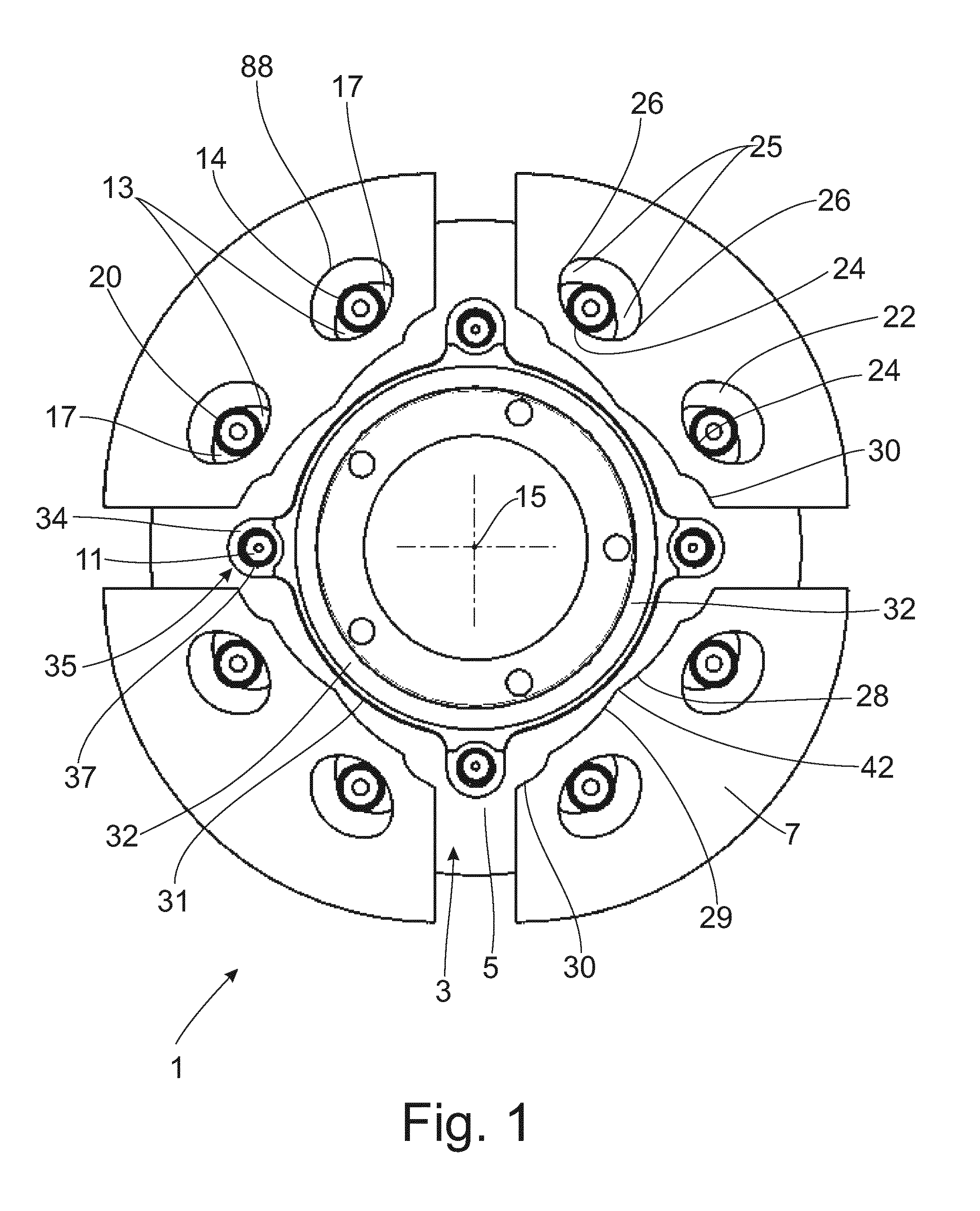

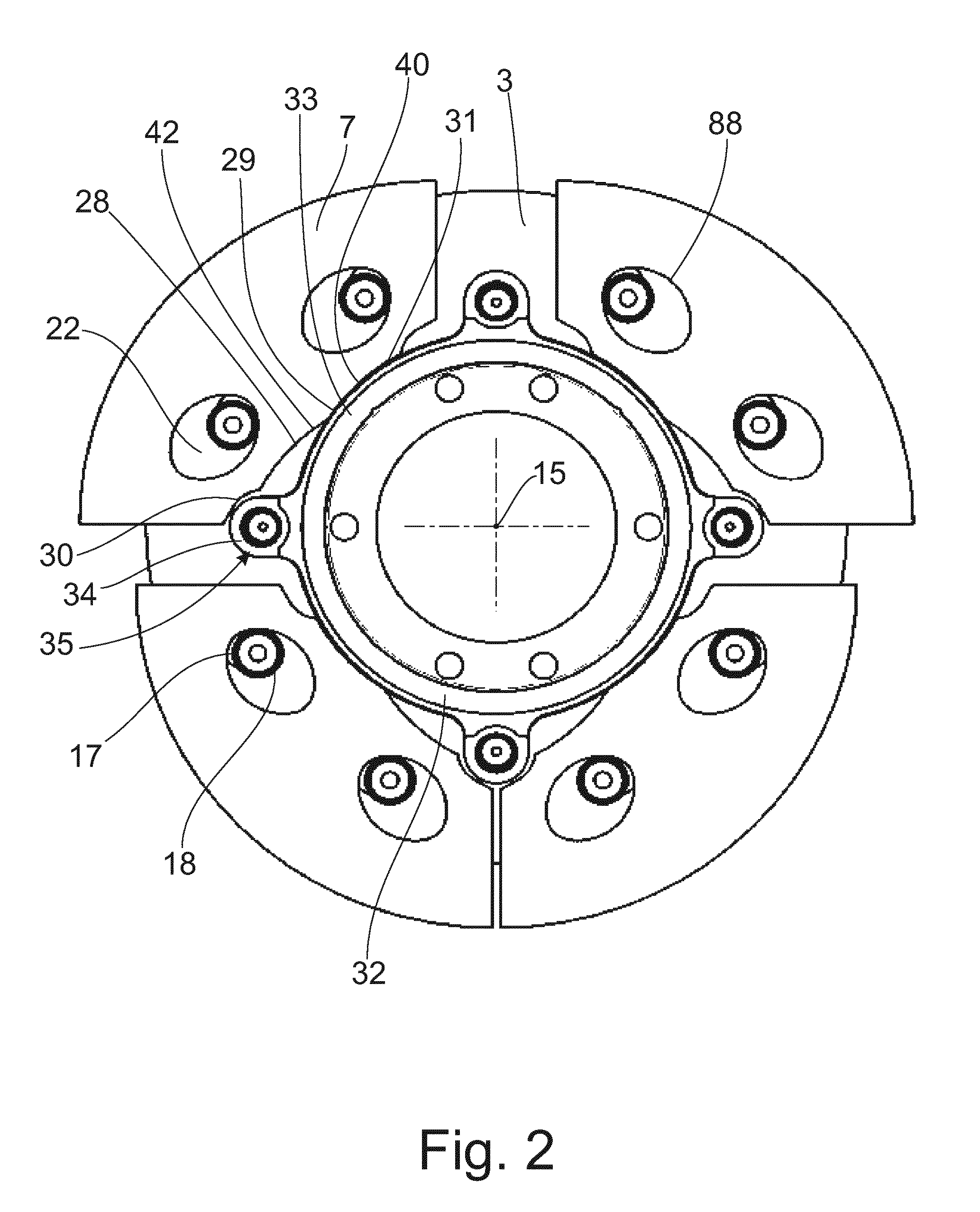

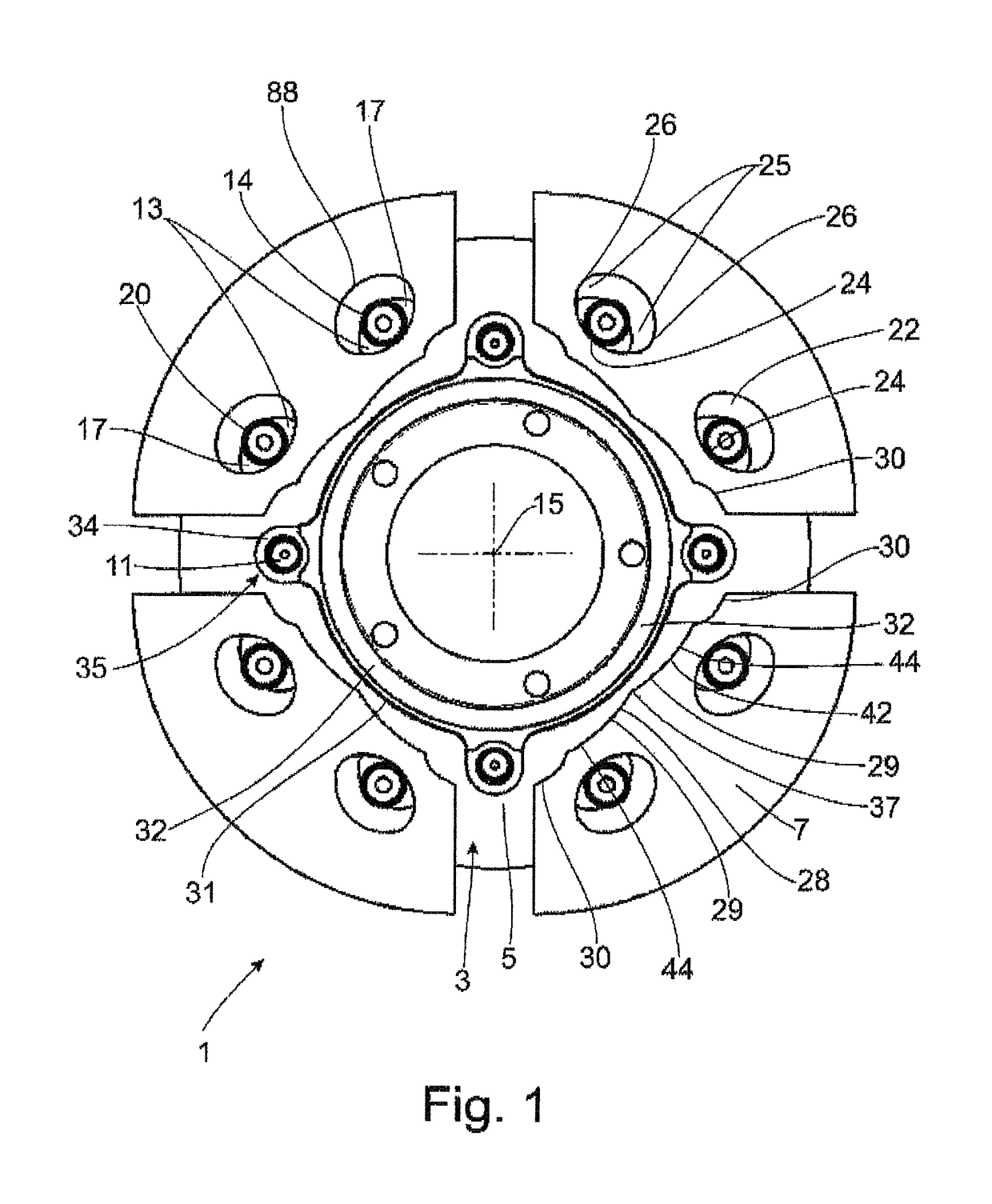

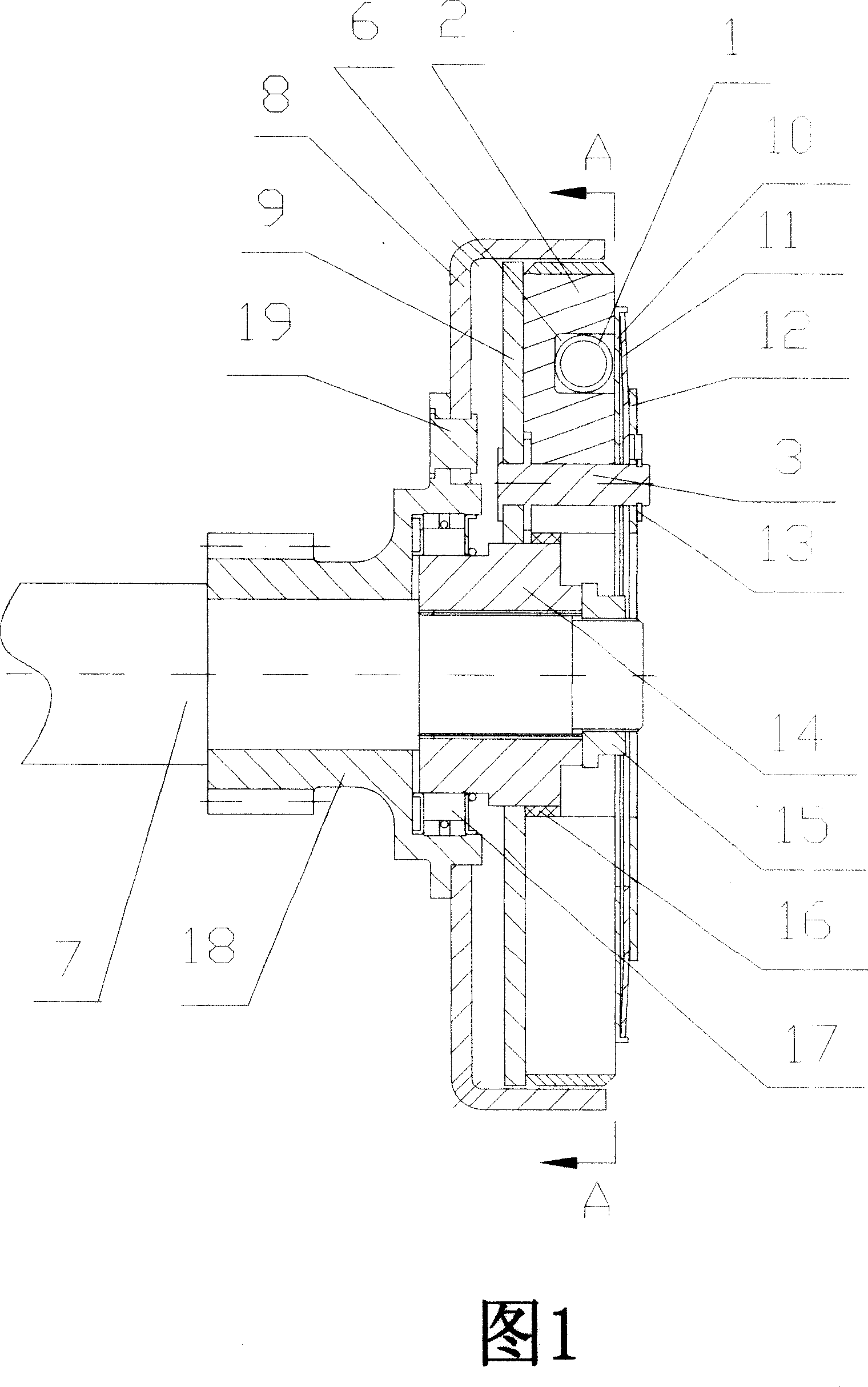

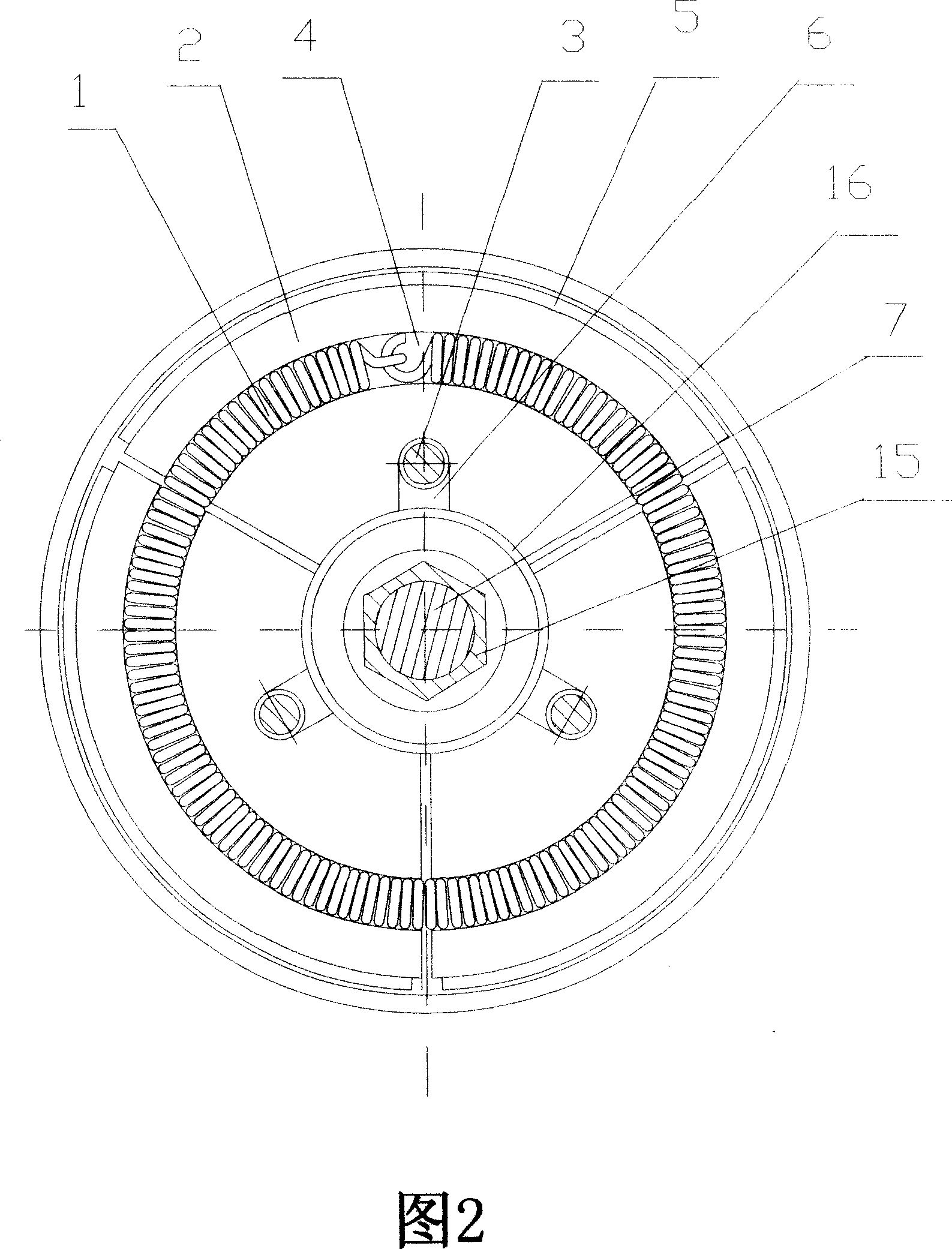

Torsional vibration damper

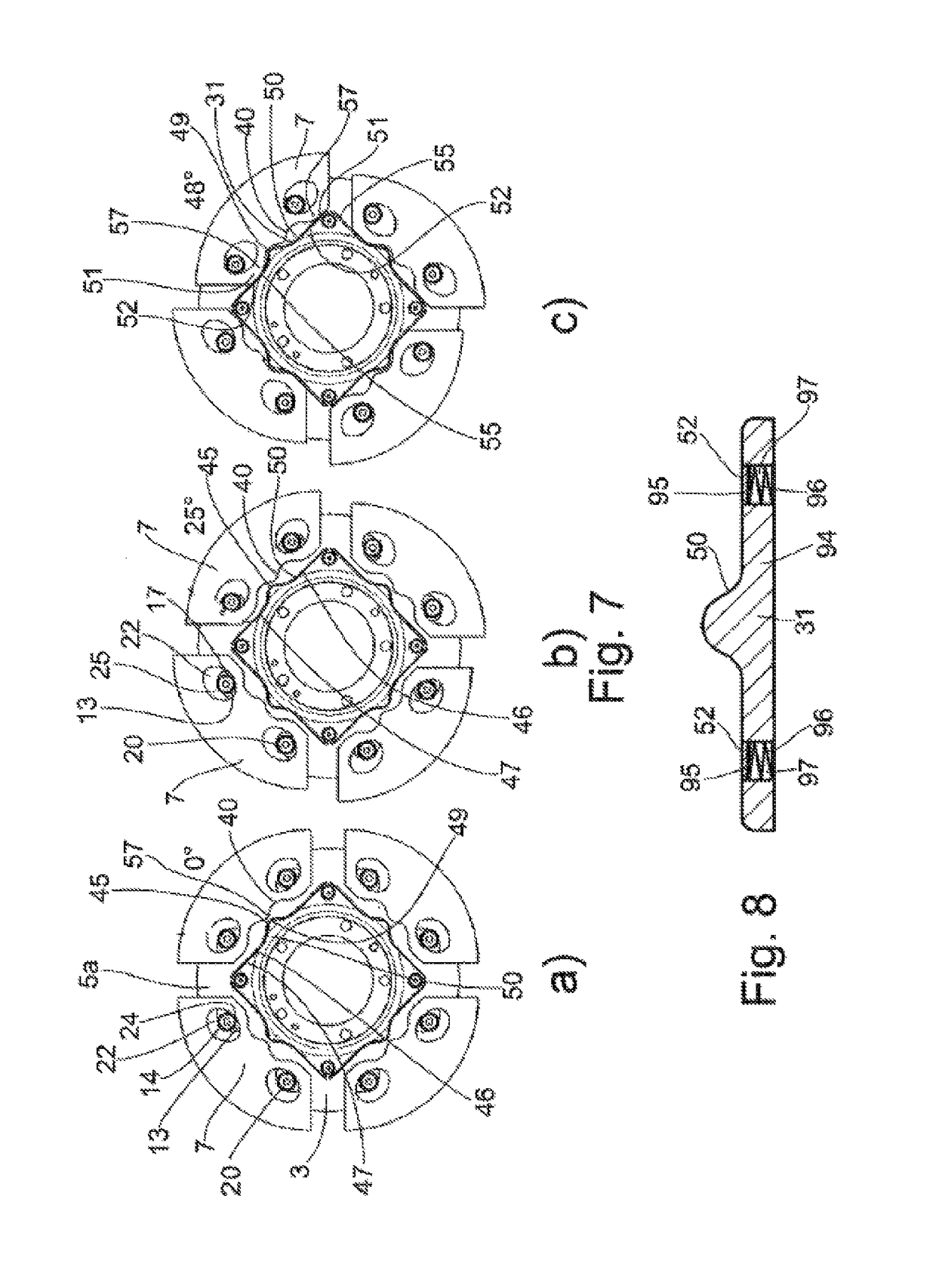

ActiveUS20150285332A1Increase elasticityAvoid knocking noiseRotating vibration suppressionTorsional vibrationControl theory

A torsional vibration damper has a damper mass carrier at which is received at least one damper mass movable relative to the damper mass carrier and with at least one stop. The at least one damper mass has a stop side with a geometric shaping. At least one stop is associated with the damper mass, and has an axial overlap with the at least one damper mass in extension direction of a central axis and a stop profile at its side facing the stop side of the damper mass. At least one stop receiver is associated with the least one stop for the at least one damper mass. The geometric shaping which is provided at the at least one damper mass has a first contact region operative at least substantially in radial direction and a second contact region operative at least substantially in tangential direction. The first contact region can be brought into operative connection with the stop, and the second contact region can be brought into operative connection with the stop receiver.

Owner:ZF FRIEDRICHSHAFEN AG

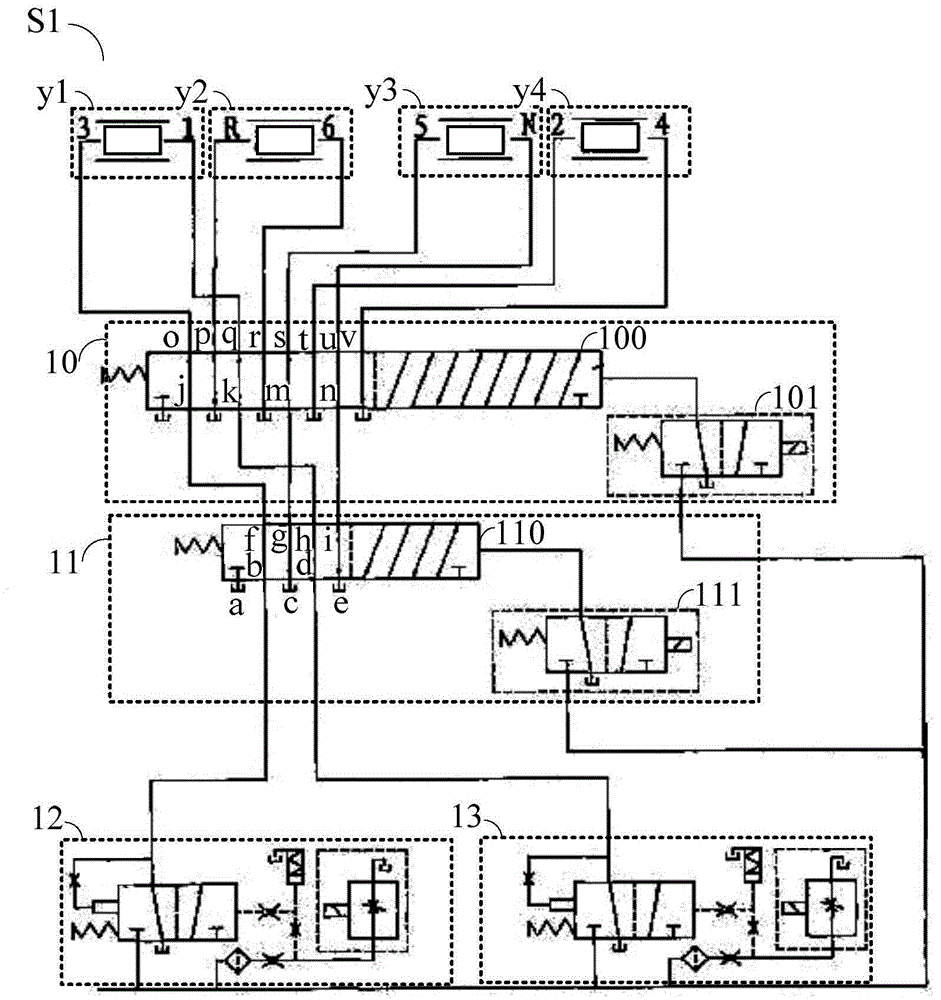

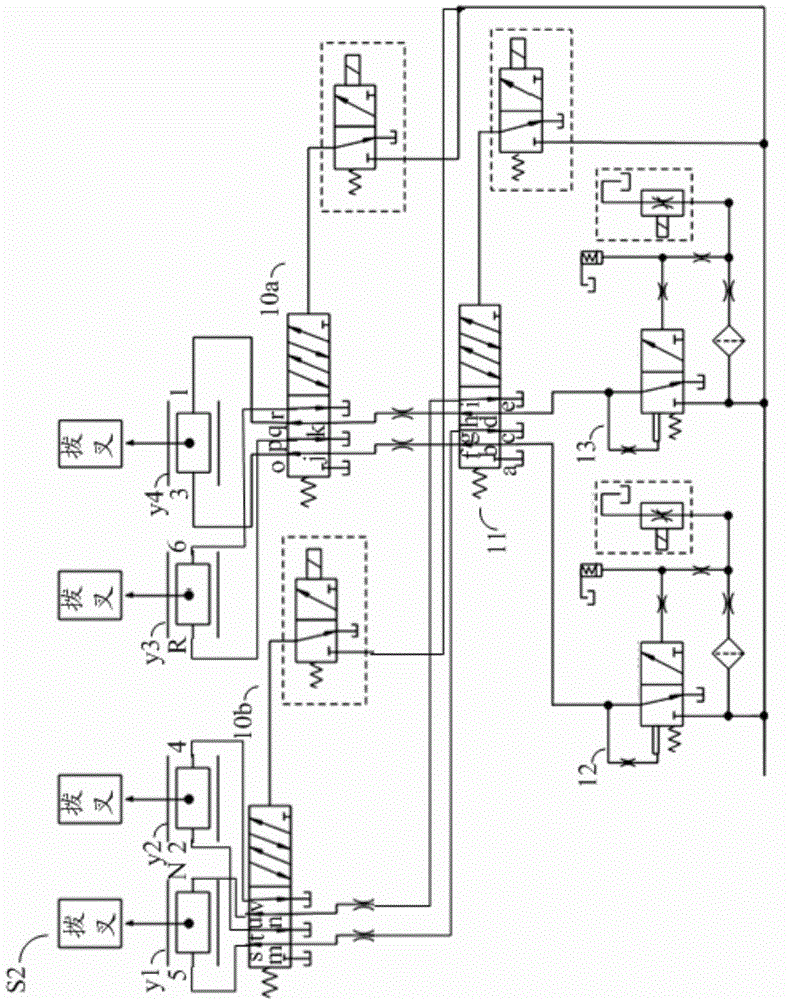

Method for controlling gear engaging and gear shifting of double-clutch transmission and hydraulic control system

ActiveCN105221739AAccurate reduction of fork movement speedReduce mechanical shock and noiseToothed gearingsGearing controlClutchMoving speed

The invention relates to a method for controlling gear engaging and gear shifting of a double-clutch transmission and a hydraulic control system. The method for controlling gear engaging of a shifting fork of the double-clutch transmission comprises the step of determining a target gear, and the step of simultaneously applying forward gear shifting force and reverse gear shifting force to the shifting fork according to the target gear so as to move the shifting fork to achieve gear engaging; the forward gear shifting force is larger than the reverse gear shifting force. Through the method for controlling gear engaging and gear shifting of the double-clutch transmission and the hydraulic control system, the moving speed of the shifting fork of the double-clutch transmission can be accurately controlled in the gear engaging process, and the noise, vibration and harshness (NVH) performance of a vehicle is improved remarkably.

Owner:SAIC MOTOR

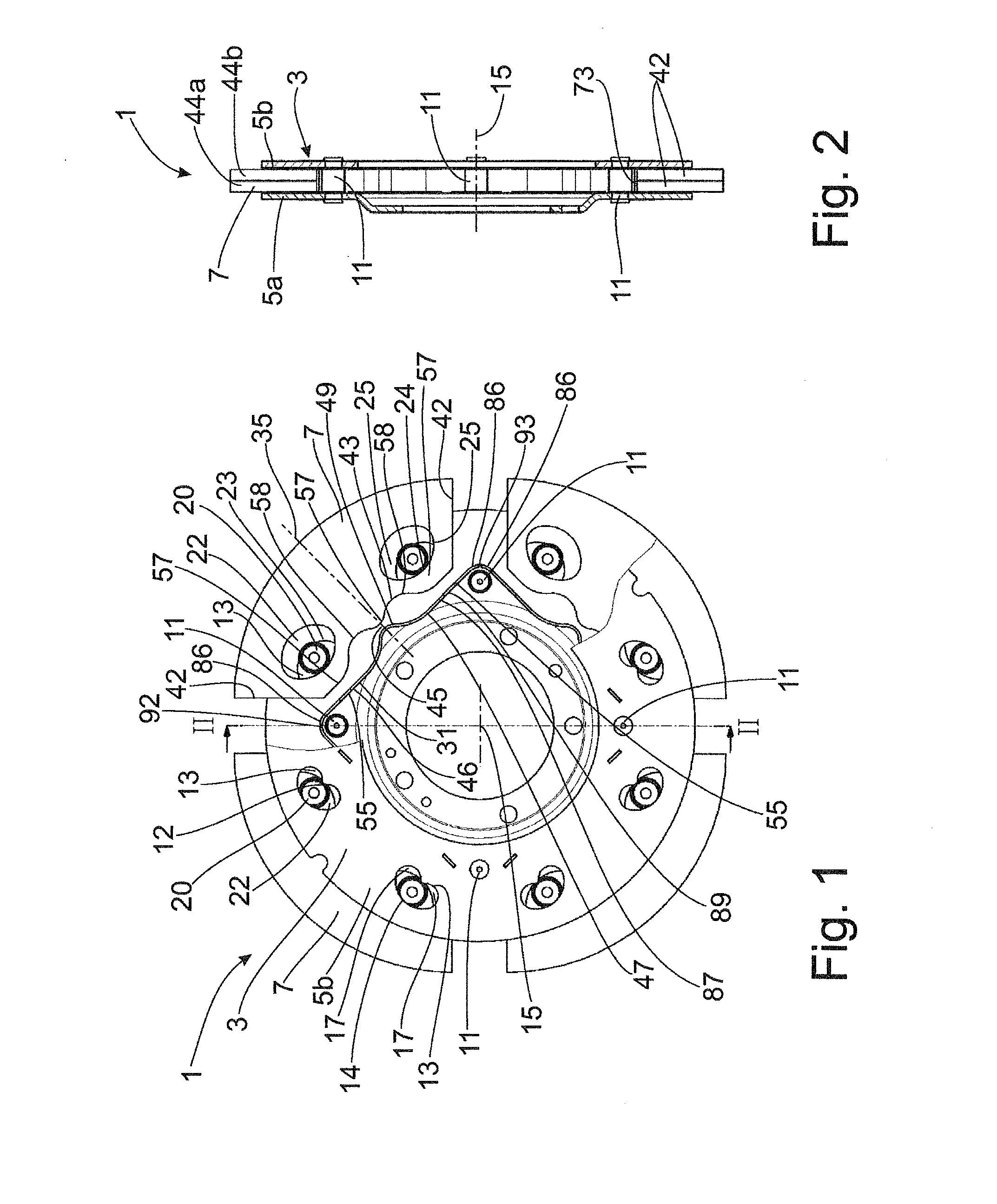

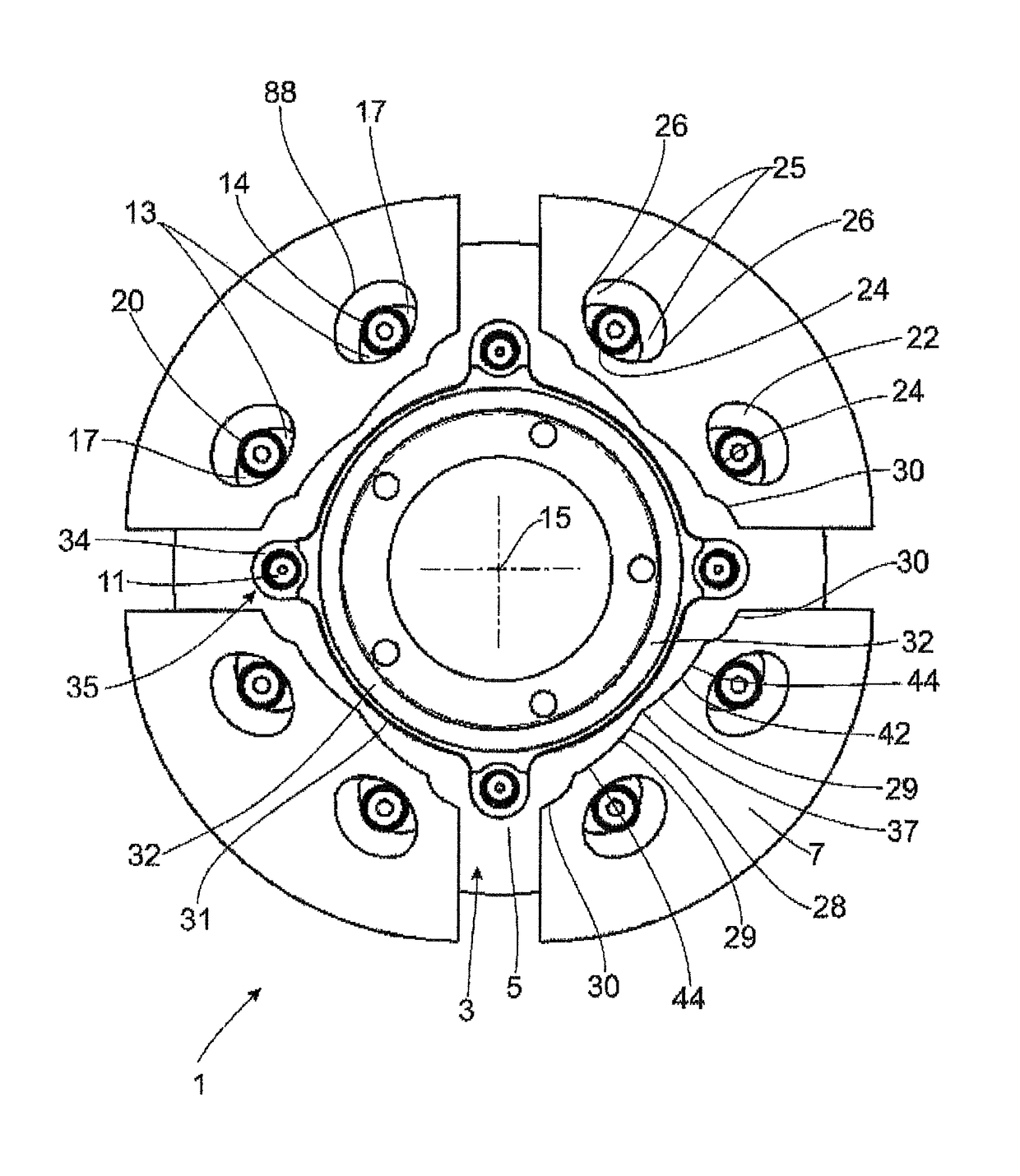

Torsional vibration damper

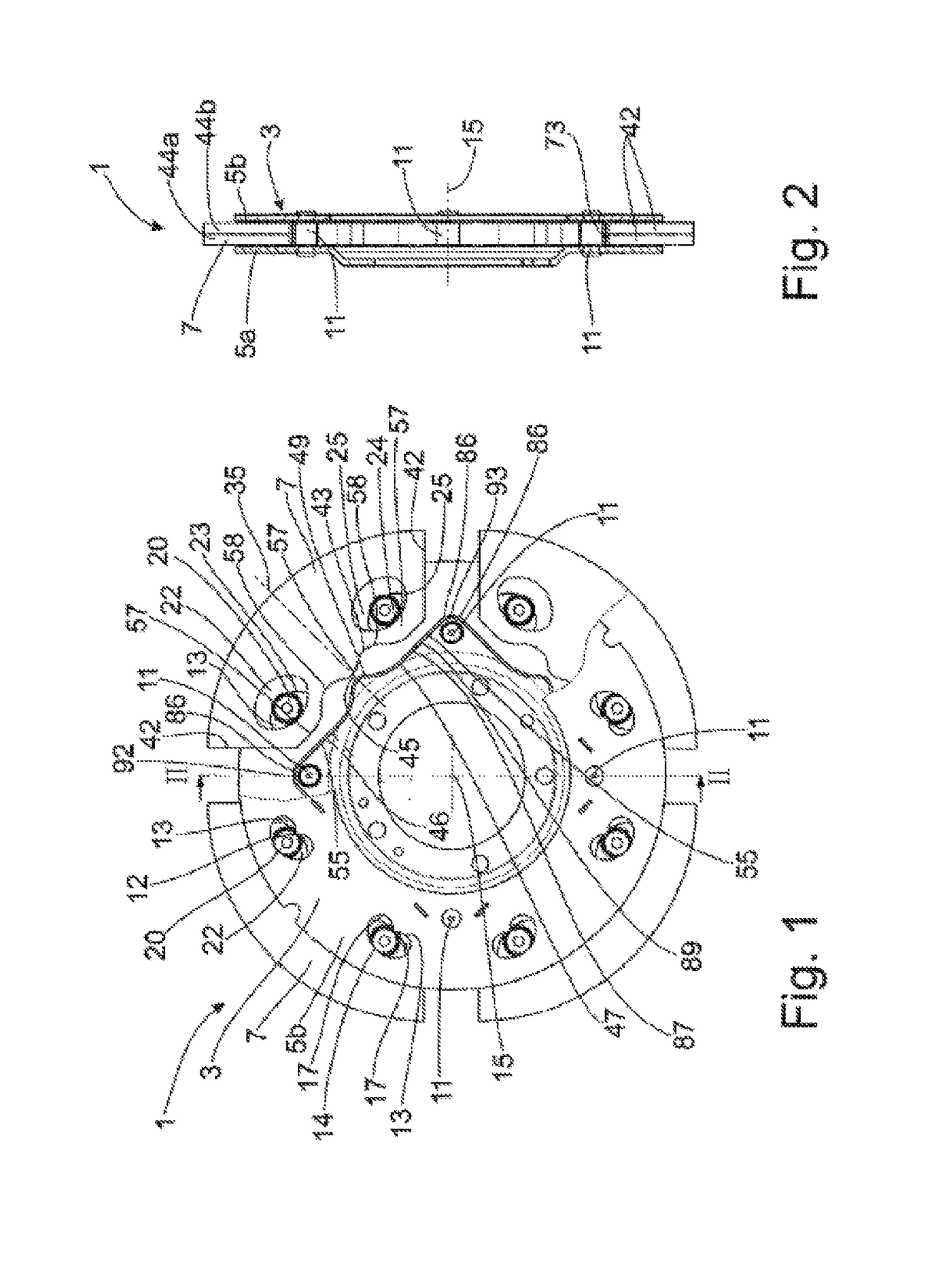

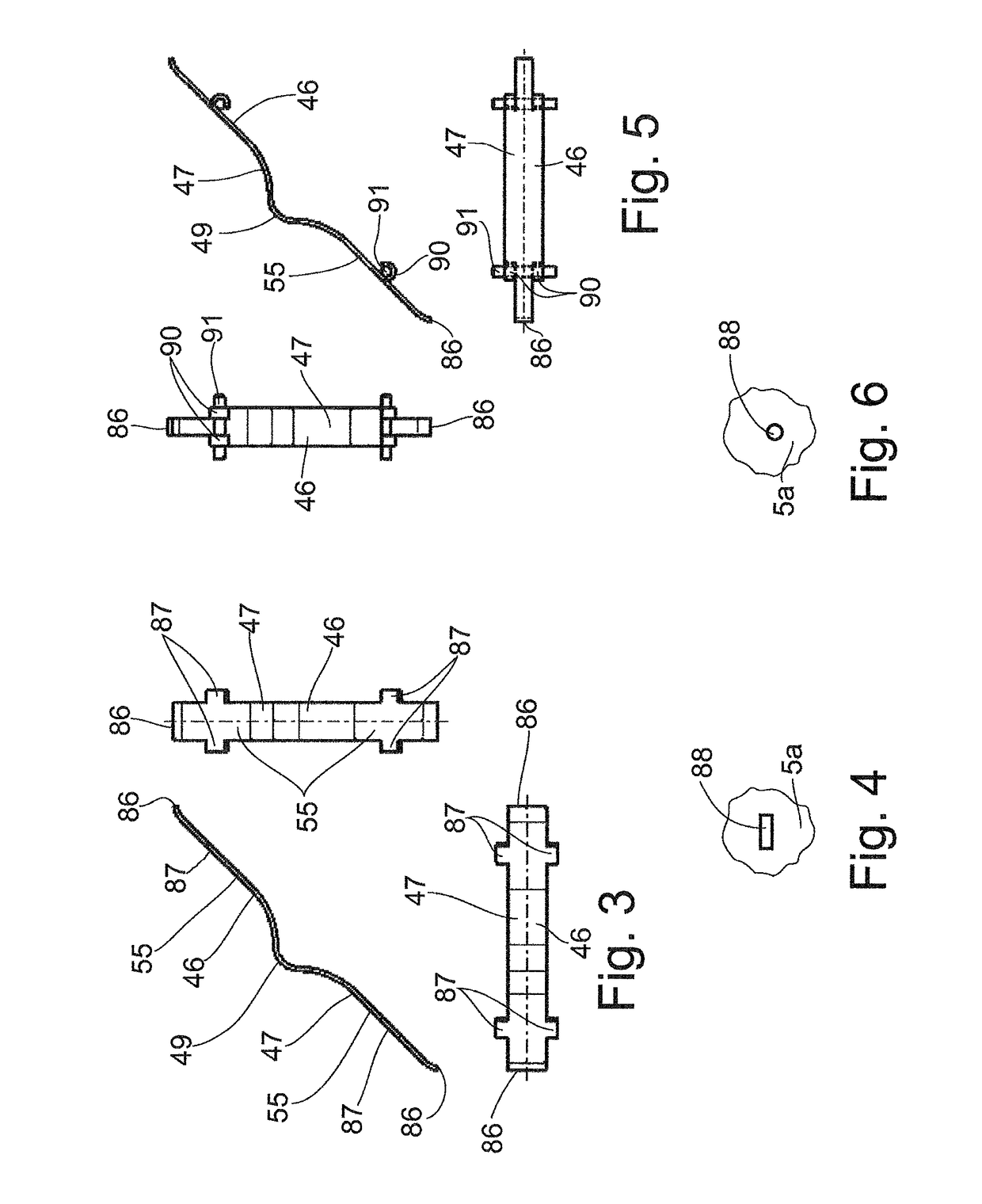

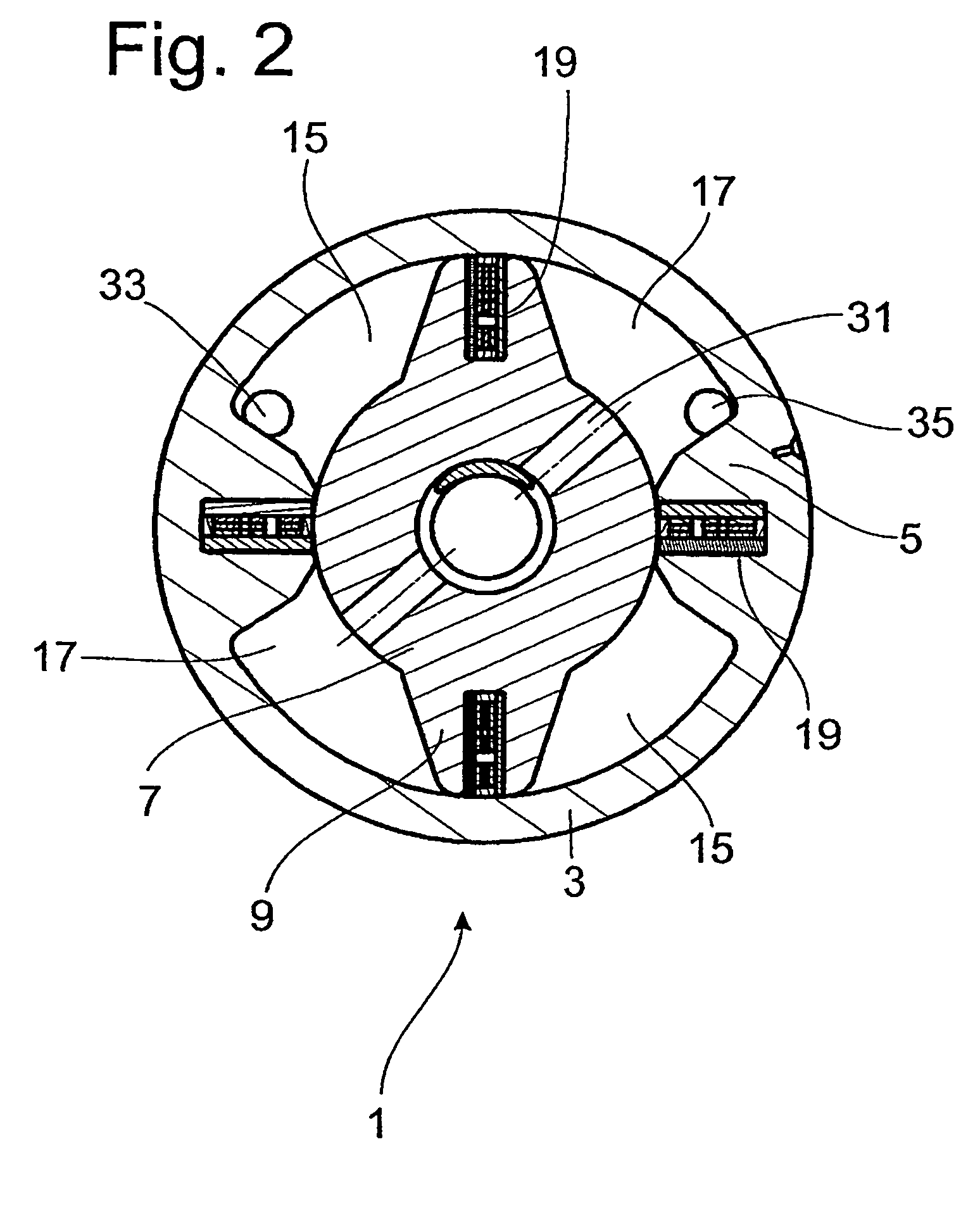

ActiveUS9638283B2Avoid knocking noiseReduce noiseRotating vibration suppressionTorsional vibrationControl theory

A torsional vibration damper is provided with a damper mass carrier at which is received at least one damper mass that is movable relative to the damper mass carrier and at least one stop. The at least one stop is associated with each stop side of the at least one damper mass. The at least one damper mass and the stop have an extension in extension direction of a central axis. The at least one damper mass has a plurality of damper mass elements in extension direction of the central axis, while the stop has in extension direction of the central axis a stop profile at its side facing the stop sides of the damper mass elements. The stop profile has different radial distances from the central axis in association with the damper mass elements.

Owner:ZF FRIEDRICHSHAFEN AG

Torsional Vibration Damper

ActiveUS20150316124A1Increase elasticityAvoid knocking noiseRotating vibration suppressionYielding couplingEngineeringTorsional vibration

A torsional vibration damper is provided with a damper mass carrier at which is received at least one damper mass that is movable relative to the damper mass carrier and at least one stop. The at least one stop is associated with each stop side of the at least one damper mass. The at least one damper mass and the stop have an extension in extension direction of a central axis. The at least one damper mass has a plurality of damper mass elements in extension direction of the central axis, while the stop has in extension direction of the central axis a stop profile at its side facing the stop sides of the damper mass elements. The stop profile has different radial distances from the central axis in association with the damper mass elements.

Owner:ZF FRIEDRICHSHAFEN AG

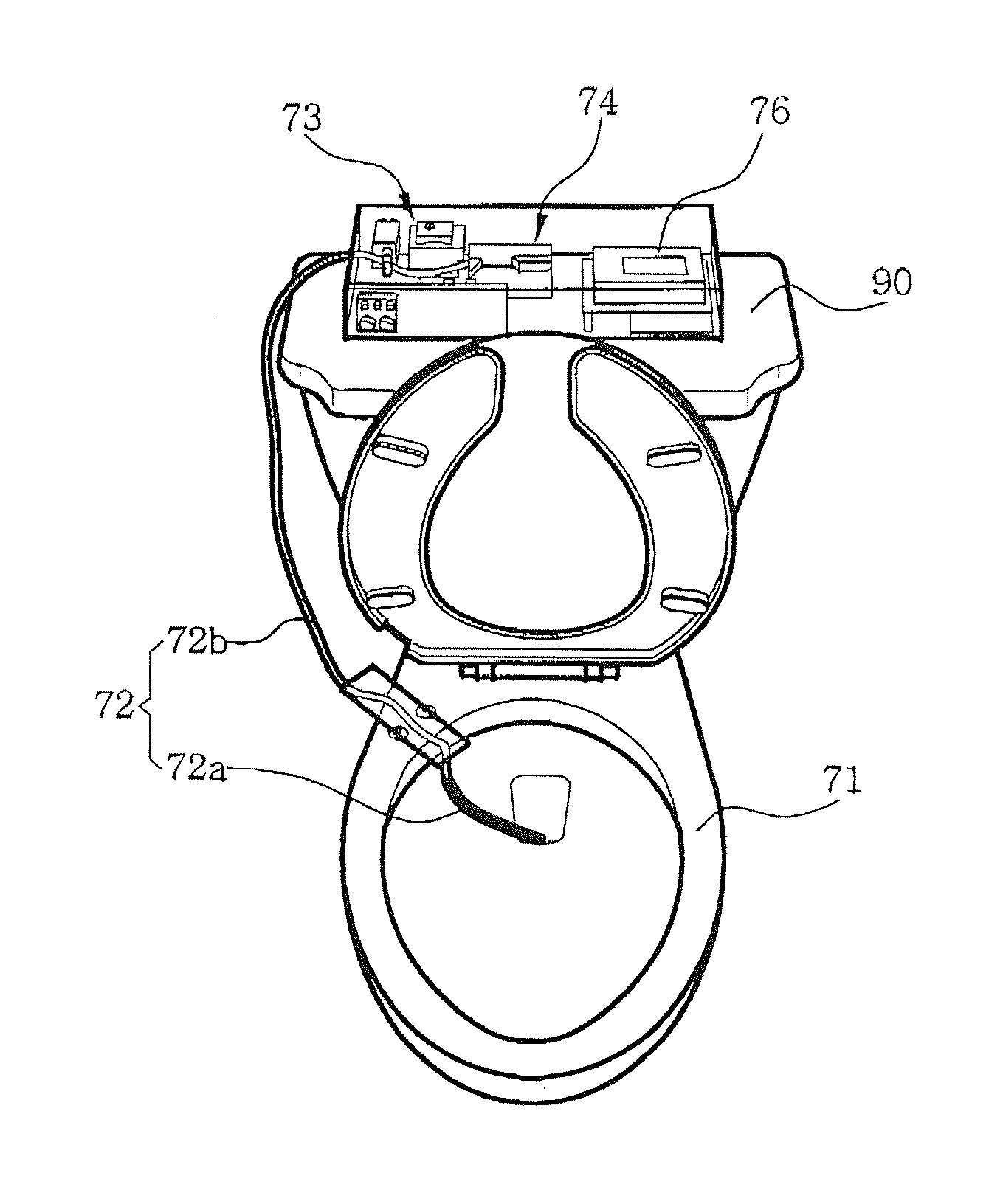

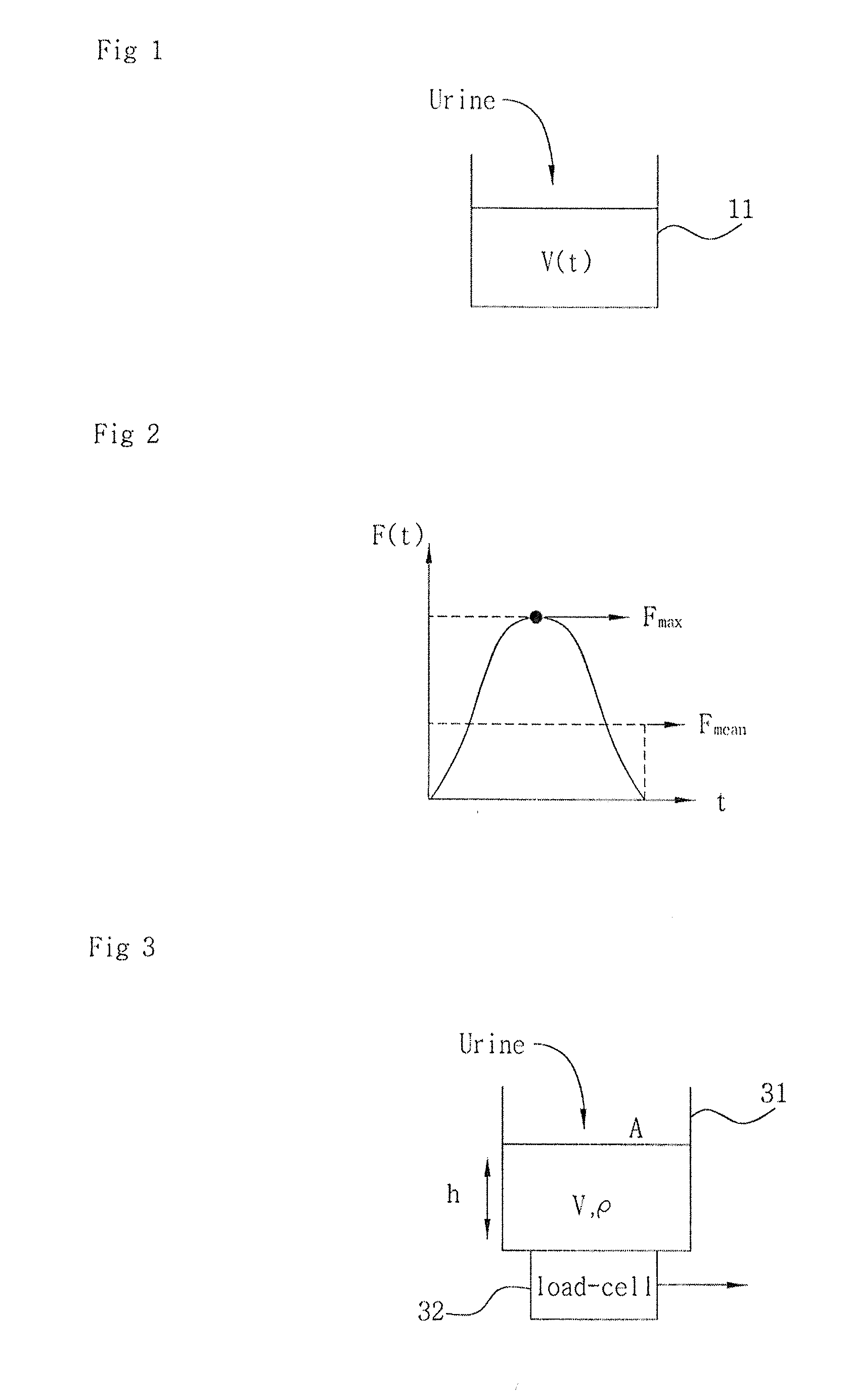

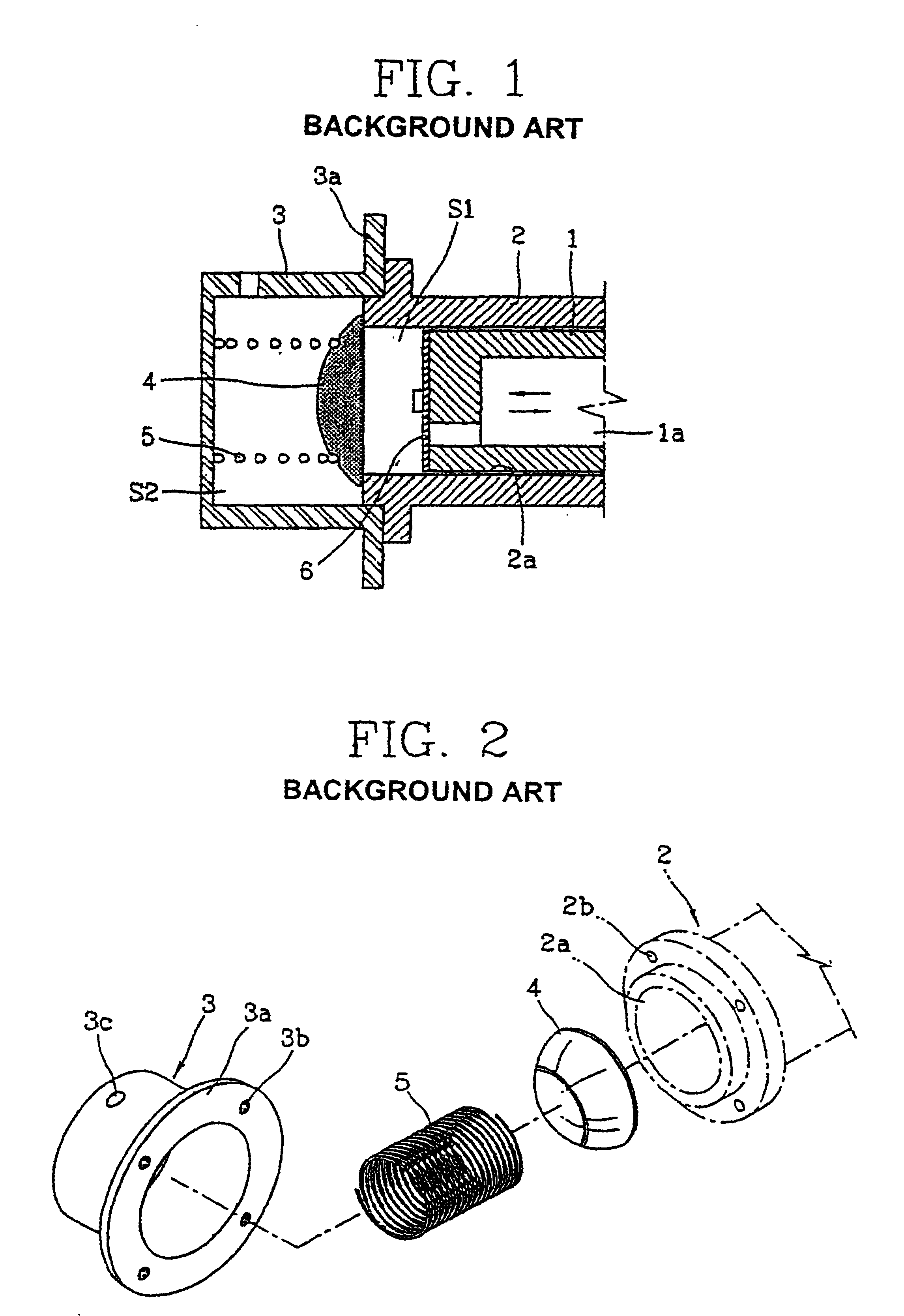

Uroflowmeter attachable to toilet

InactiveUS20110265576A1Convenient, sanitary, and installedImprove measurement reliabilityVolume/mass flow measurementFluid pressure measurement by mechanical elementsWireless transceiverEngineering

Disclosed is a uroflowmeter attachable to a toilet capable of diagnosing a BPH with high reliability and convenience in a sanitary way without the constraints of a space by checking the urinary flow rate of a patient. The uroflowmeter includes a toilet bowl for temporarily storing feces and urine, a connection tube which has one end introduced into water of the toilet bowl, a pressure measuring unit connected with an opposite end of the connection tube to measure pressure inside the toilet bowl, a signal analyzing unit for analyzing pressure signals from the pressure measuring unit to measure a urinary volume signal and a urinary flow rate signal, a display unit for displaying the urinary flow rate signal measured by the signal analyzing unit, and a wireless transceiver unit for making data communication with the signal analyzing unit in a wireless way.

Owner:CHA EUN JONG +3

Vibration Absorber System

InactiveUS20160208886A1Avoid knocking noiseReliable preventionRotating vibration suppressionFluid gearingsControl theoryShock absorber

A mass damper system is provided with a damper mass carrier with at least one damper mass movable relative to the damper mass carrier and at least one stop. The damper mass moves within a predetermined movement region when a rotational movement of the damper mass carrier exceeds a predetermined limit speed. The predetermined movement region has a first movement region portion bounded at one end by an initial position in which the damper mass is free from a deflection in circumferential direction and by a limit position in which the damper mass has undergone a deflection, and a second movement region portion is defined at one end by the limit position and at the other end by a stop position in which the damper mass has come in contact with the stop.

Owner:ZF FRIEDRICHSHAFEN AG

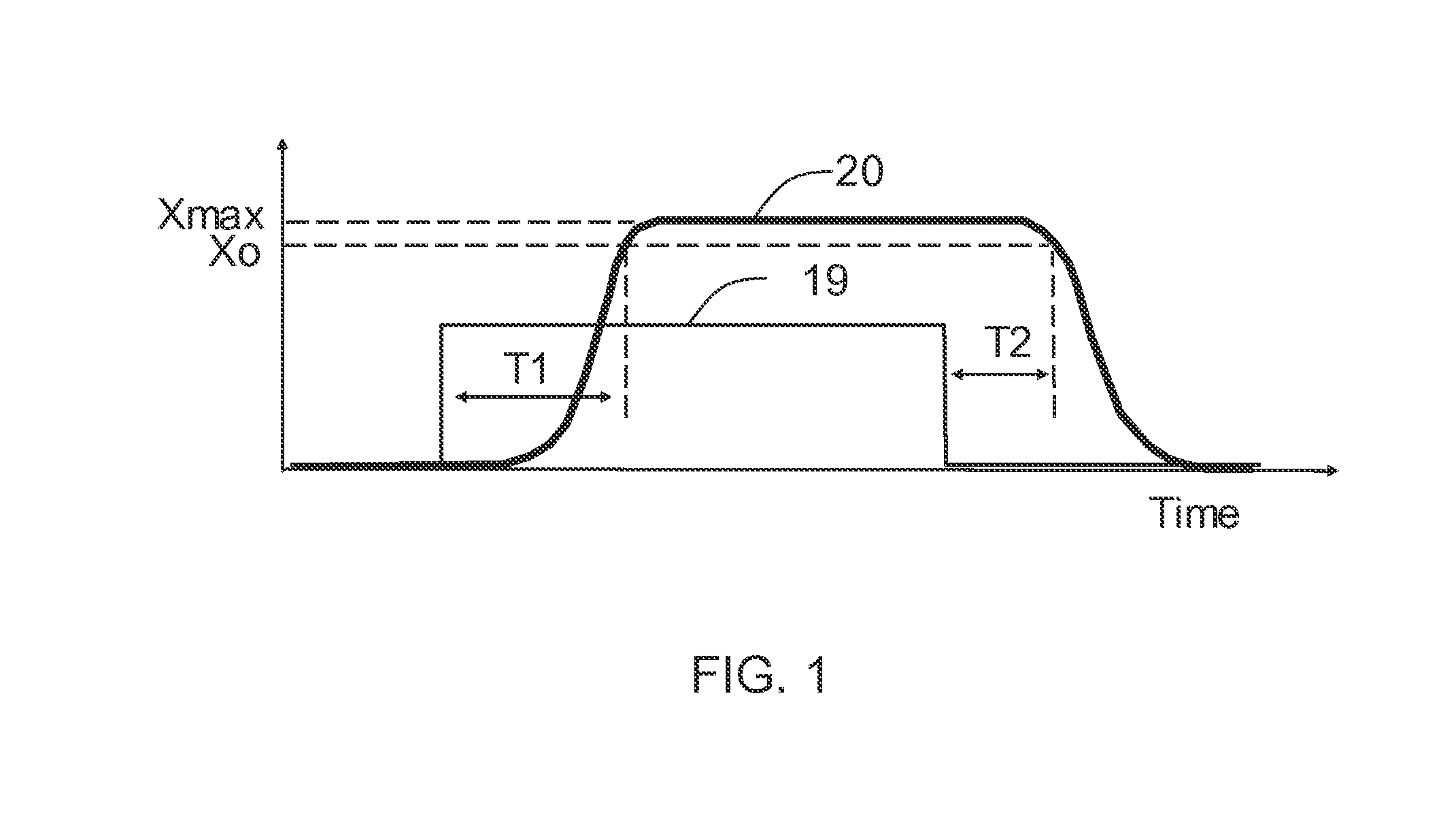

Engine valve actuation system

ActiveUS20160215661A1Good time consistencyAvoid knocking noiseOperating means/releasing devices for valvesValve drivesComputer moduleHydraulic circuit

The present disclosure provides an engine valve actuation system comprising: a camshaft, with a plurality of cams: a control shaft one; a control shaft two; and a plurality of valve actuation units, each unit further comprising: (i) at least one set of an engine valve and an engine-valve return spring; (ii) an lost-motion module, further comprising a collapsible high-pressure chamber, and operably converting the profile of the one of the cams and the collapsing motion from the high-pressure chamber to corresponding movement of the at least one engine valve; and (iii) a hydraulic circuit, further comprising: a trigger valve one and a trigger valve two, being controlled respectively by the control shaft one and the control shaft two.

Owner:NINGBO HOYEA MACHINERY MFG

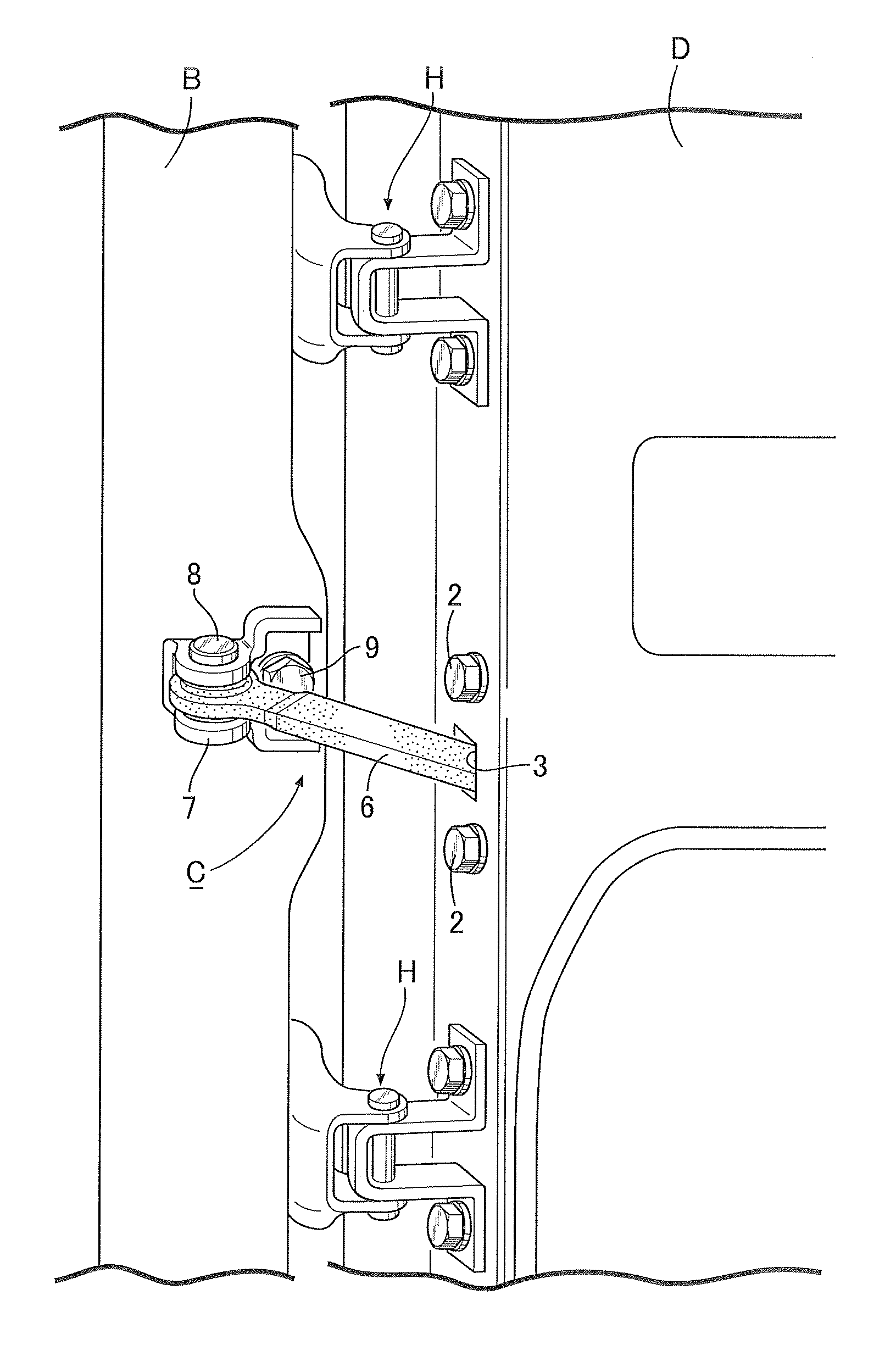

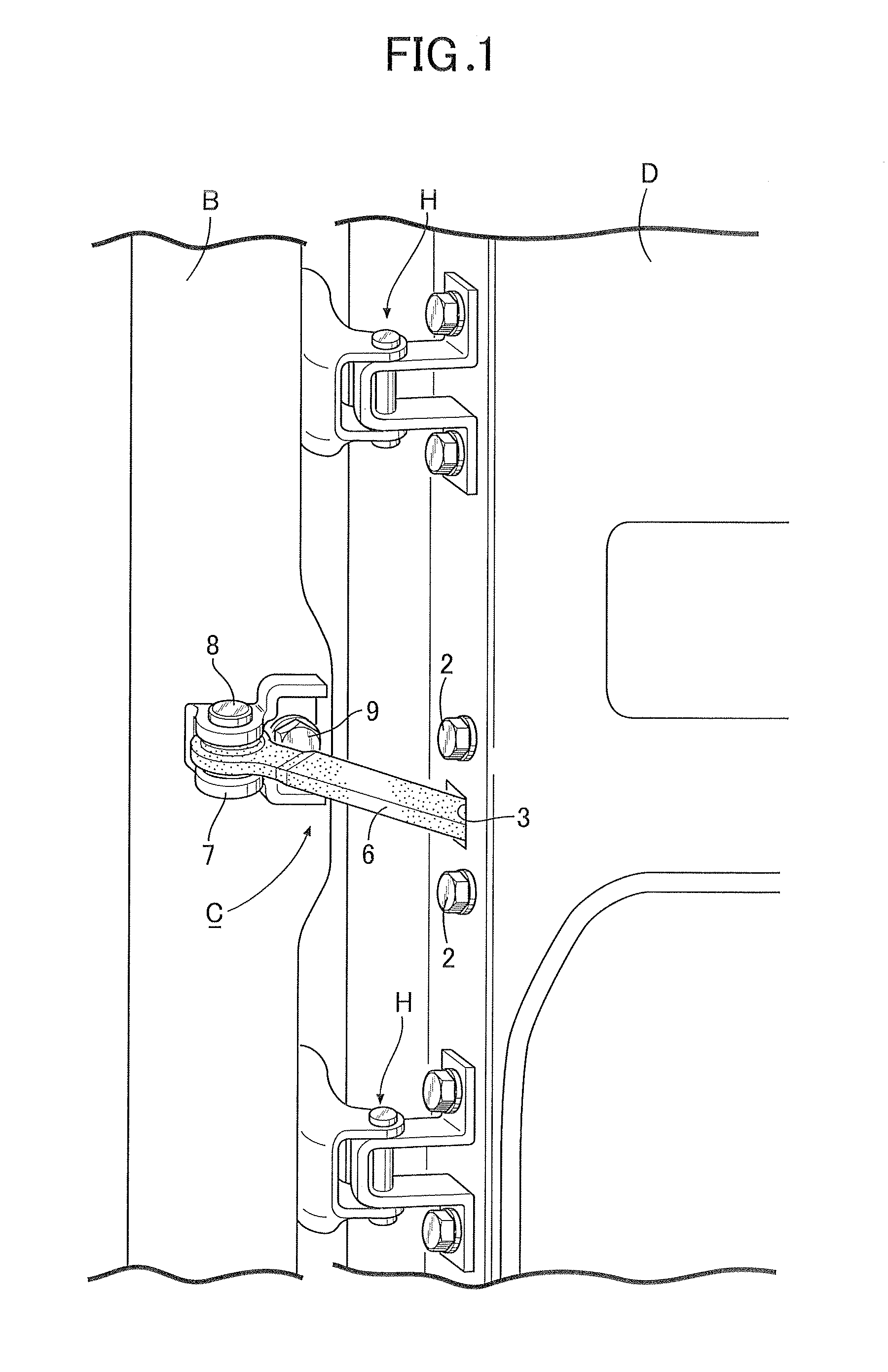

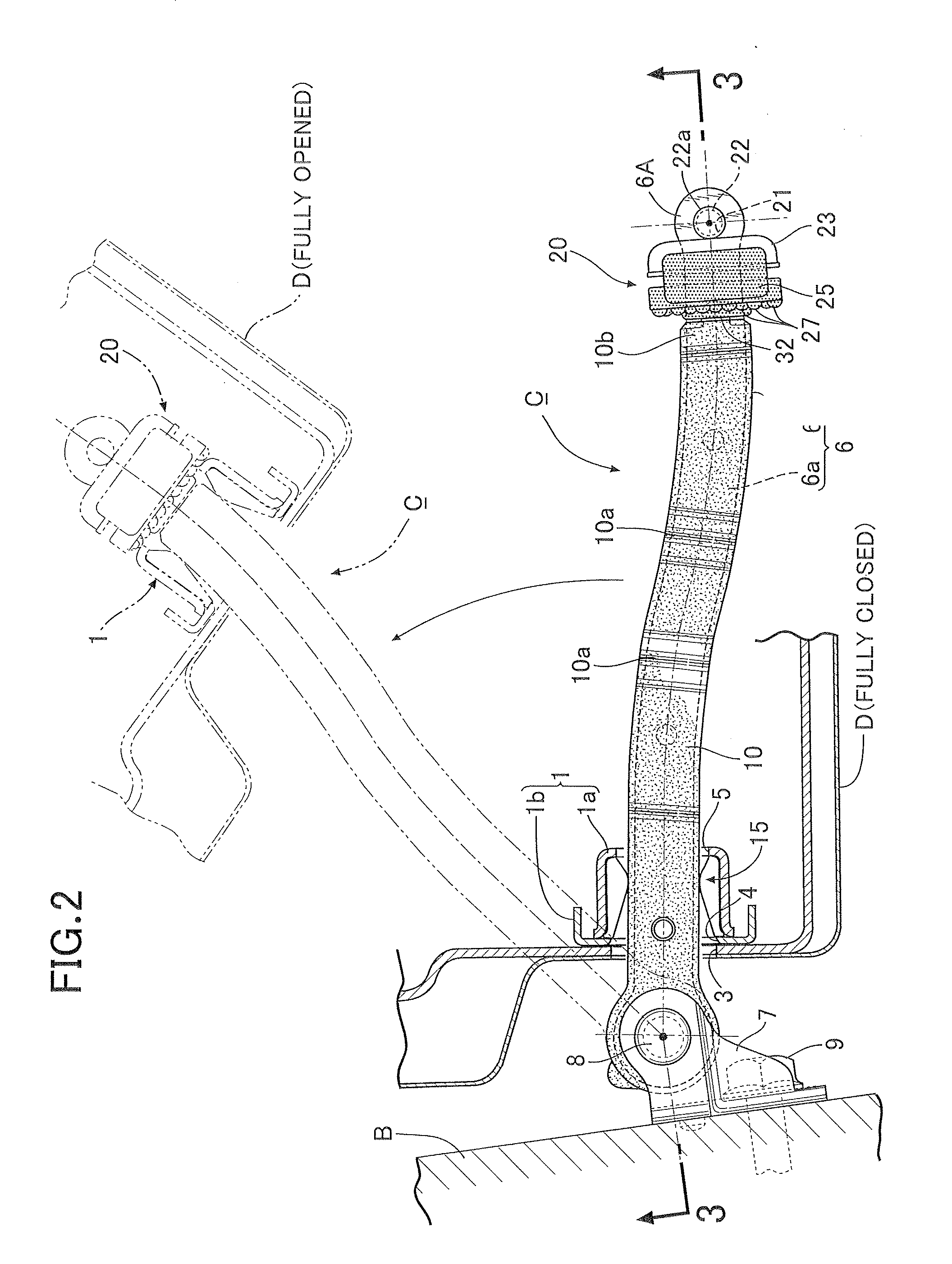

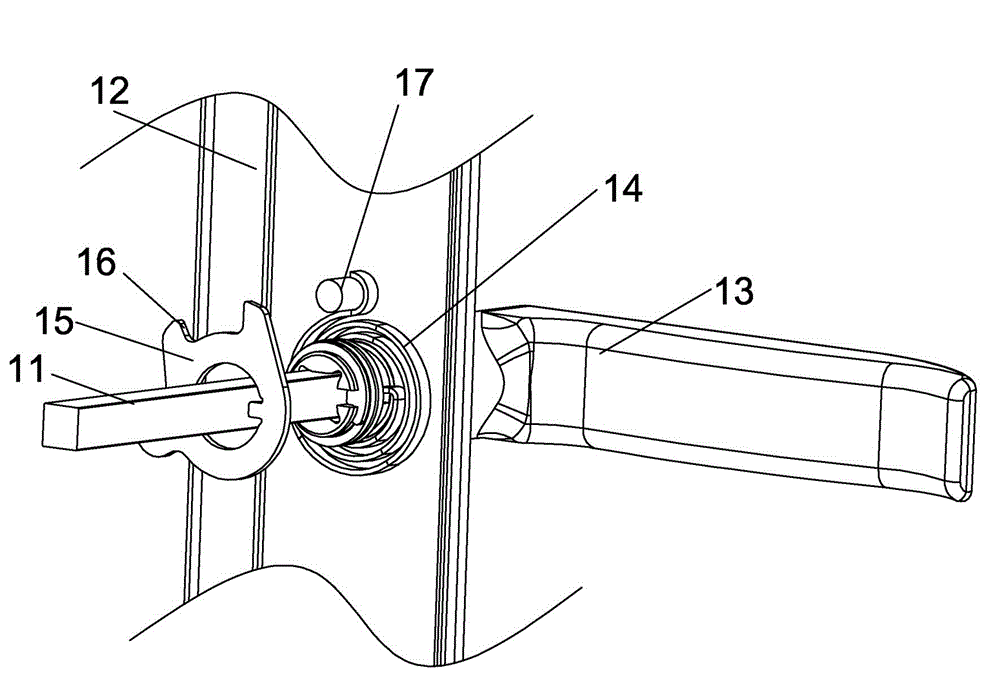

Door checker for automobile

InactiveUS20140059802A1Avoid knocking noiseEffectively absorb impact of opening of doorBuilding braking devicesWing fastenersEngineeringMechanical engineering

In a door checker for automobile which is applicable to vehicles having different full open angles of doors, and which makes no chattering noise by vibration, a free end portion of a check lever plate is provided with a core plate exposed portion where a core plate is exposed from a cover layer, a full open stopper mechanism includes: a stopper pin fitted in the core plate exposed portion, the stopper pin having anti-falling expanded portions; a stopper plate swingably supported on the stopper pin; and a cushion member supported by the stopper plate, and configured to cushion an impact of full opening of the door by receiving a case, and a pressing piece is provide integrally and continuously to the cover layer, the pressing piece configured to press the cushion member toward the stopper pin to thereby keep the stopper plate in contact with the stopper pin.

Owner:RIKEN KAKI KOGYO CO LTD

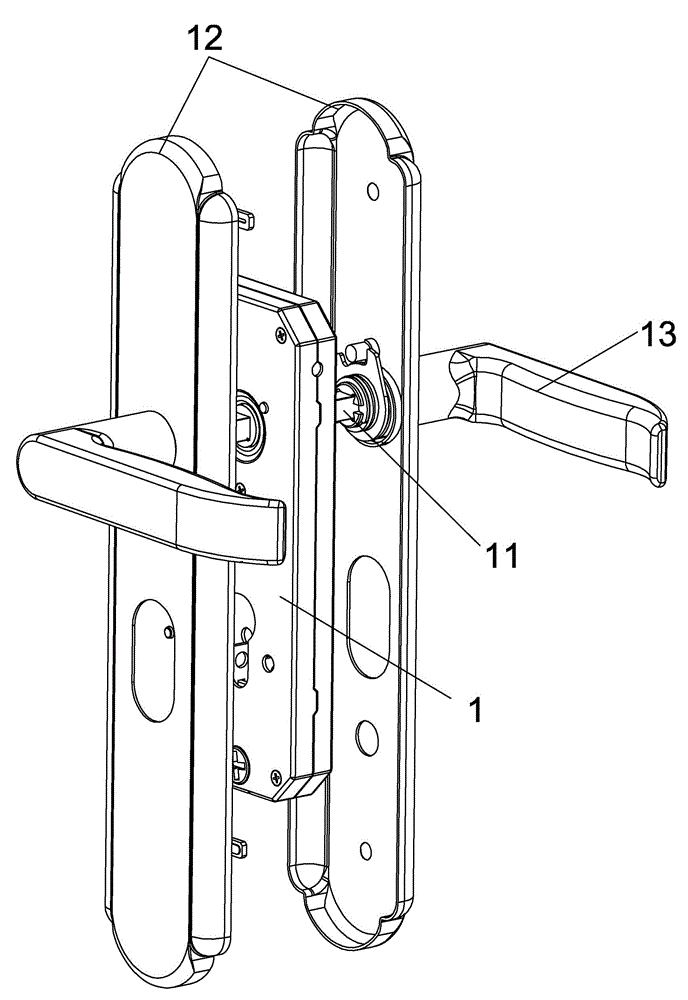

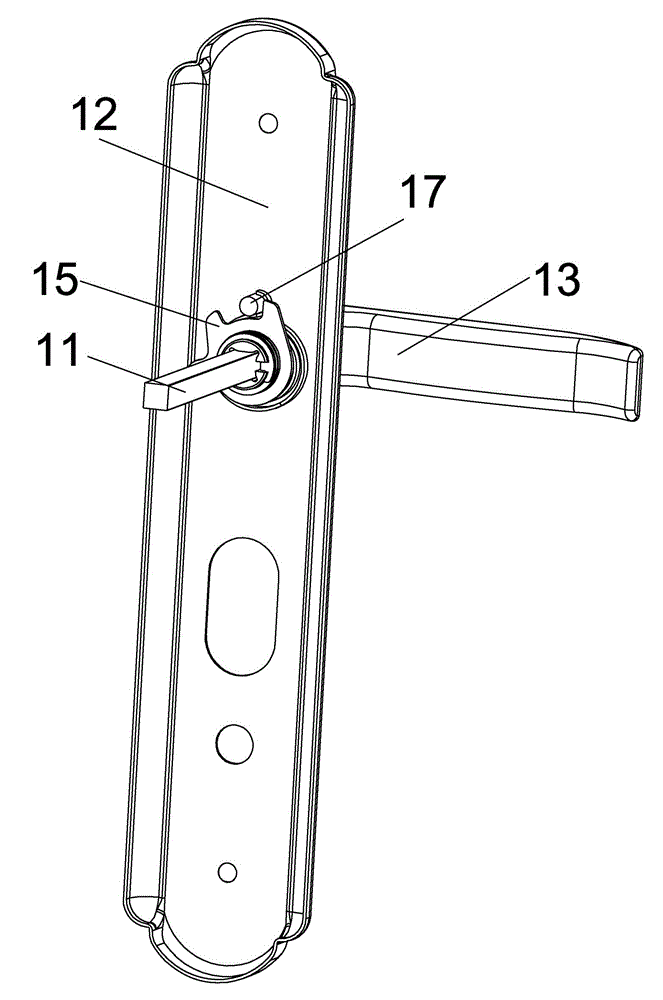

Silent mortise lock

InactiveCN104005607ASimple structureReduce manufacturing costBuilding locksHydraulic cylinderLower limit

Disclosed is a silent mortise lock. The silent mortise lock comprises a fixing plate and an upper cover plate. The side edge of the fixing plate is provided with a stopping plate with a spring bolt hole; the inside of the fixing plate is provided with an inclined spring bolt limit rack, an inclined spring bolt stopping plate, a lock rudder, an inclined spring bolt, a square spring bolt and an interlock rod, wherein the inclined spring bolt, the square spring bolt and the interlock rod are in linkage with the lock rudder; the tail end of the inclined spring bolt is provided with a slide bar, which can slide on the inclined spring bolt limit rack and the inclined spring bolt stopping plate in a penetrating mode, and the slide bar between the inclined spring bolt and the inclined spring bolt stopping plate is provided with a front pushing spring which keeps the inclined spring bolt in a spring-out state all the time. The silent mortise lock is characterized in that the tail end of the slide bar is provided with an upper limit sheet and a lower limit sheet; a poke rod fixed onto the lock rudder is arranged between two limit rods; the lock rudder is provided with a buffering hydraulic cylinder for buffer the rotating speed of the lock rudder. The silent mortise lock has the advantages of, by buffering the rotating speed of the lock rudder through the buffering hydraulic cylinder on the lock rudder, avoiding the impact noise due to rapid rebound and reset of a door opening handle and the inclined spring bolt, and meanwhile, being noiseless, reducing wearing, prolonging the service life and the like.

Owner:GUANGDONG JUSEN HARDWARE PRECISION MFG

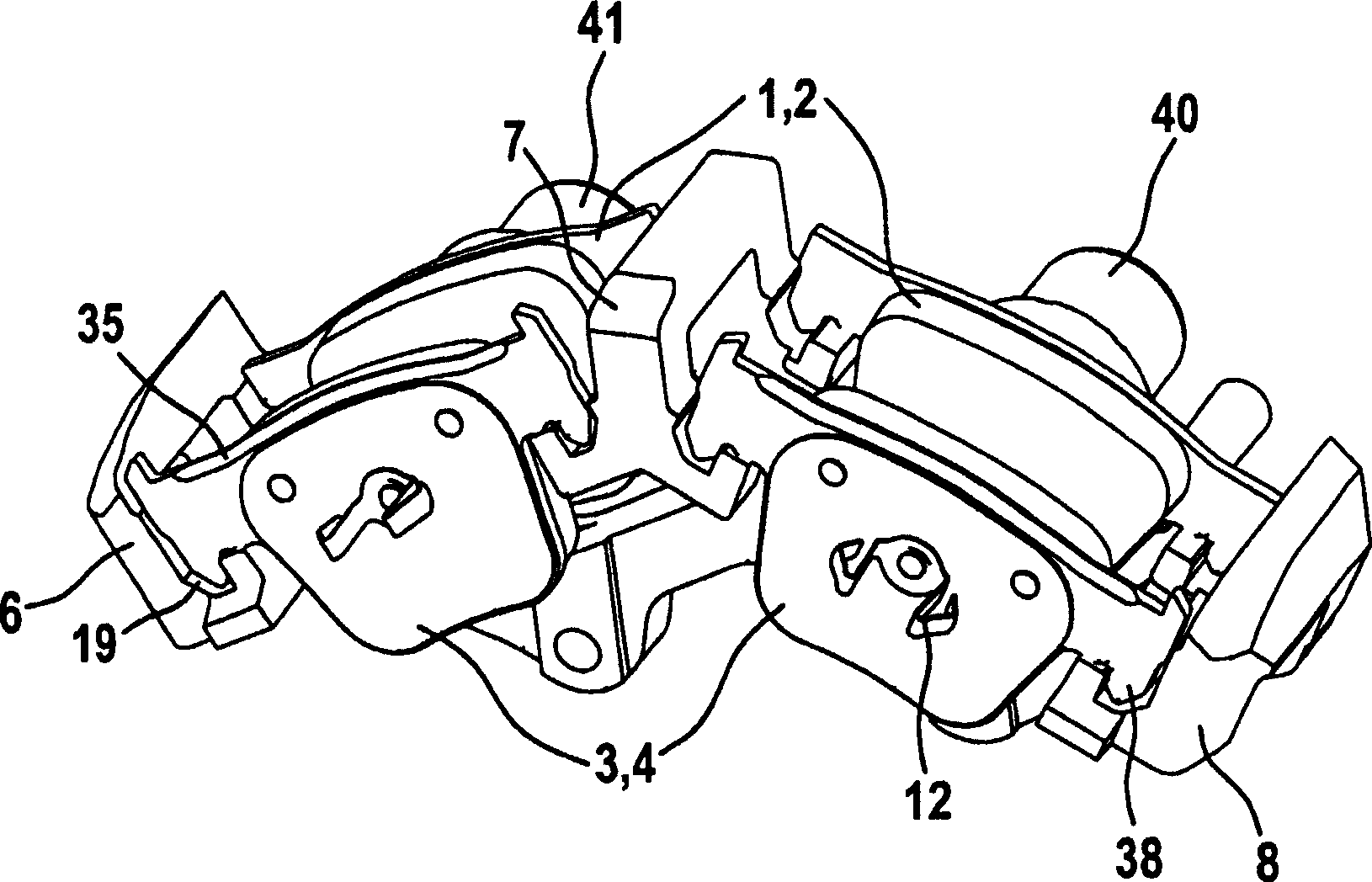

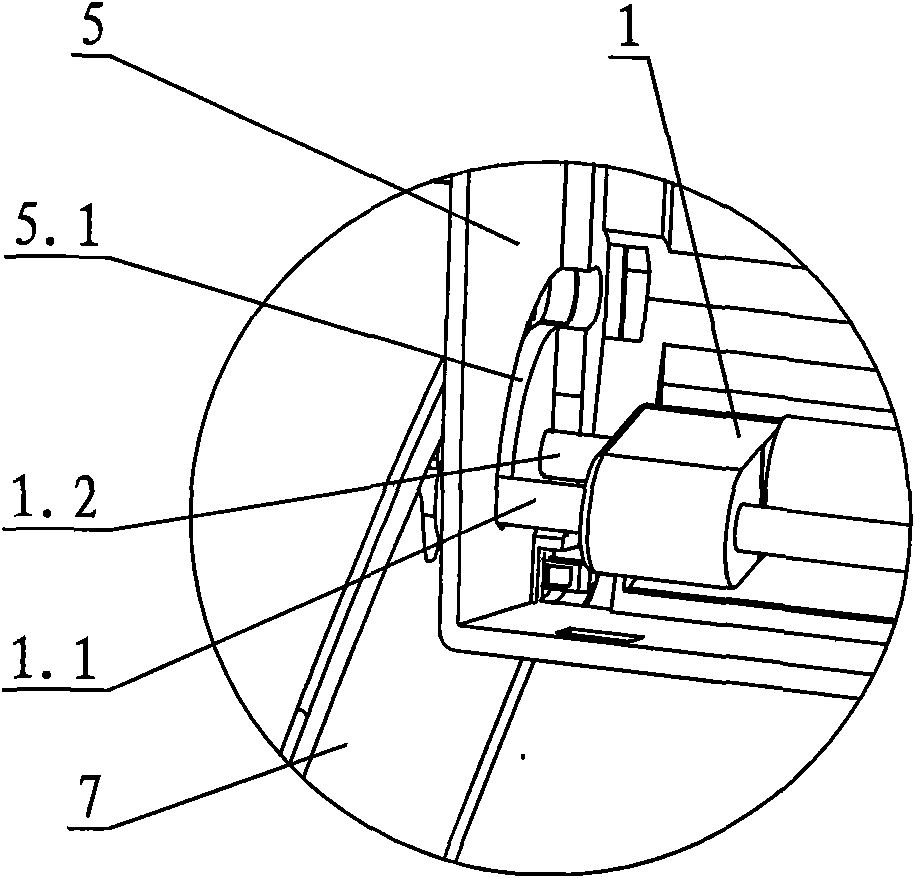

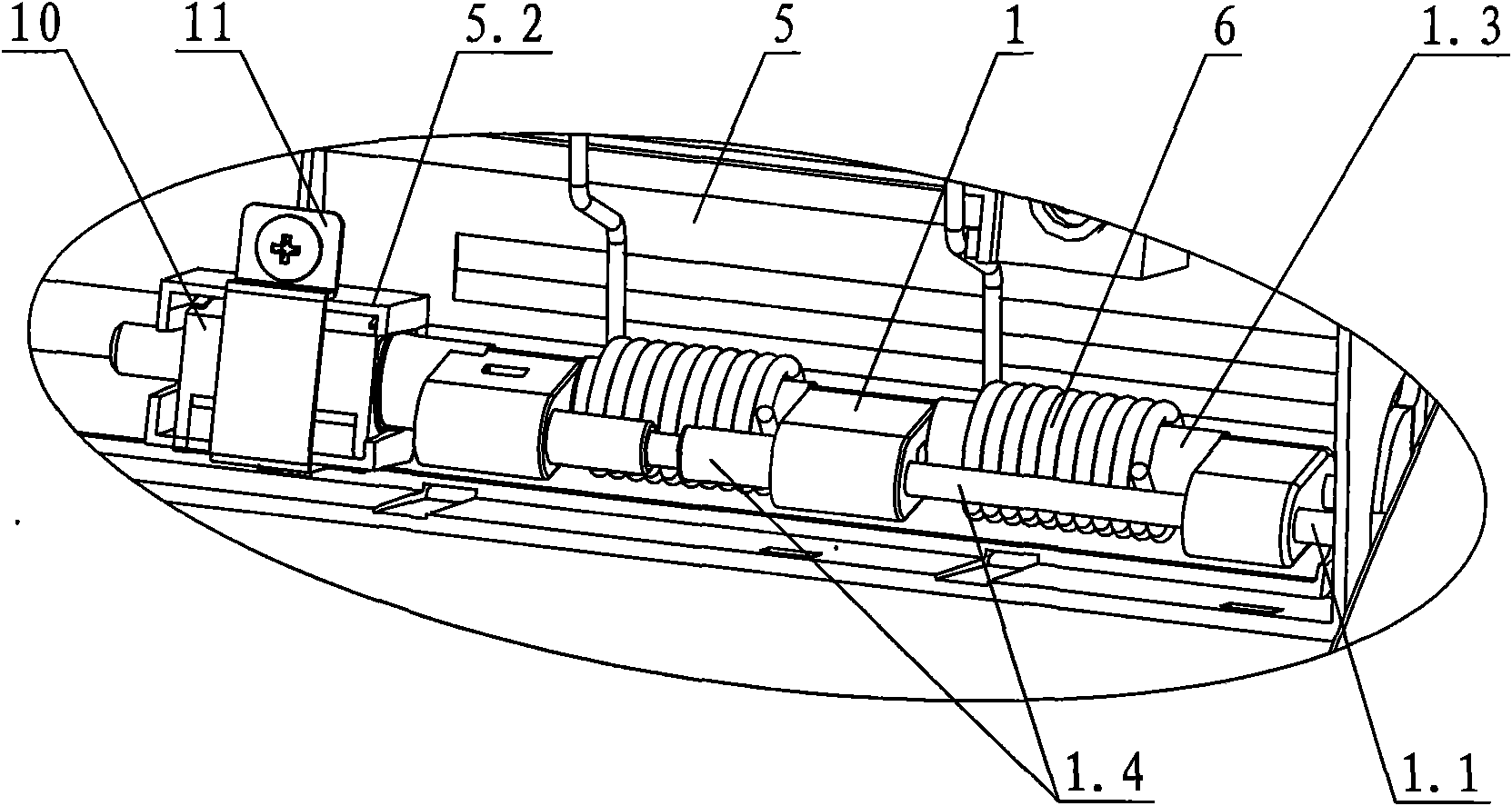

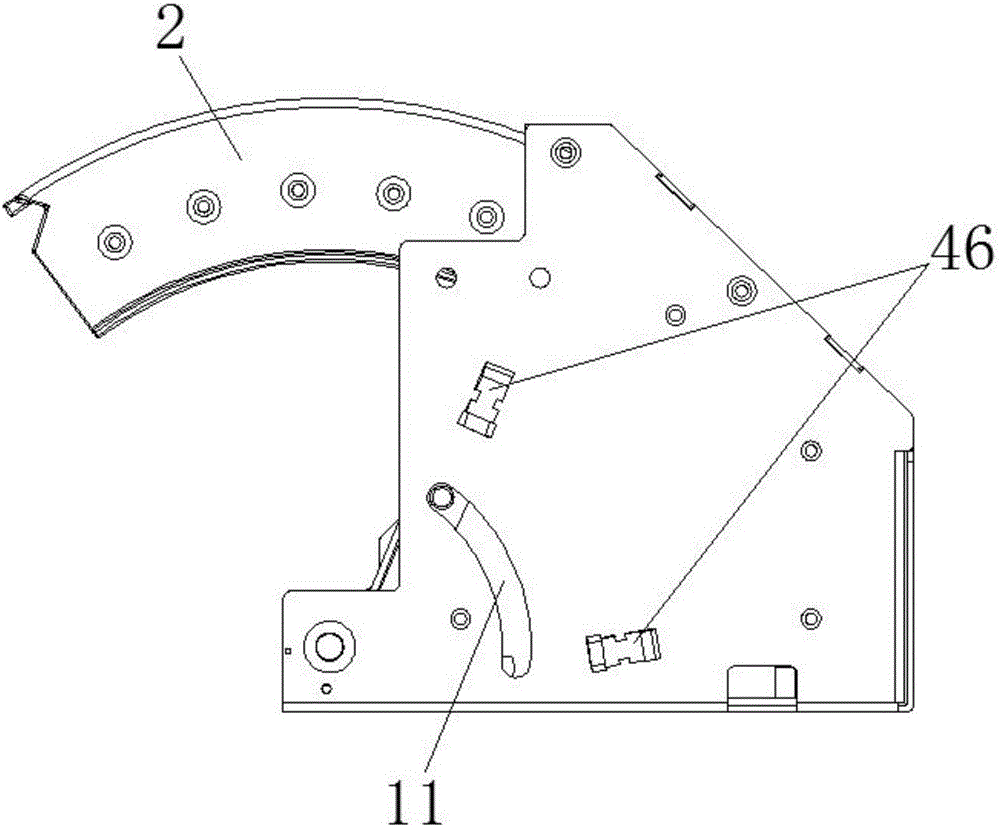

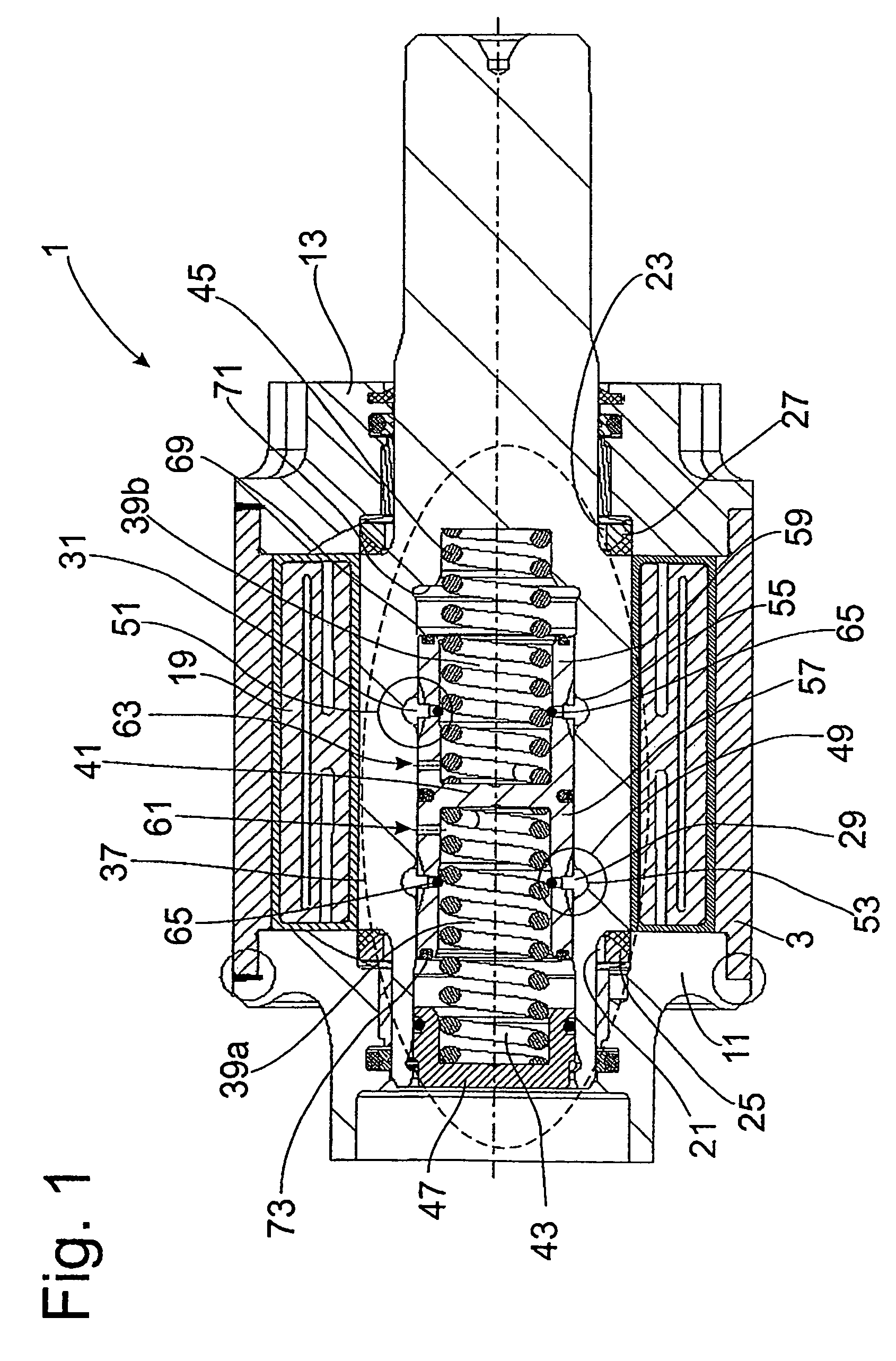

Double ratchet, double pawl vehicular latch with soft stop on reset

ActiveUS9512651B2Eliminate impact noiseAvoid knocking noiseNoise-prevention/anti-rattling lockingConstruction fastening devicesGear wheelGear train

A low release effort eccentric double ratchet, double pawl vehicle latch includes a ratchet, a primary pawl, an auxiliary ratchet and a secondary pawl. A drive mechanism including a gear cam wheel sequences movement of the secondary pawl to open and reset the latch. Upon reset, the drive mechanism actuates the auxiliary ratchet back to a closed state in a soft manner without using a hard stop; instead the latch has a cushioning spring that is used to softly stop the gear train during the reset absorbing motor energy and thus eliminating impact noise.

Owner:MAGNA CLOSURES SPA

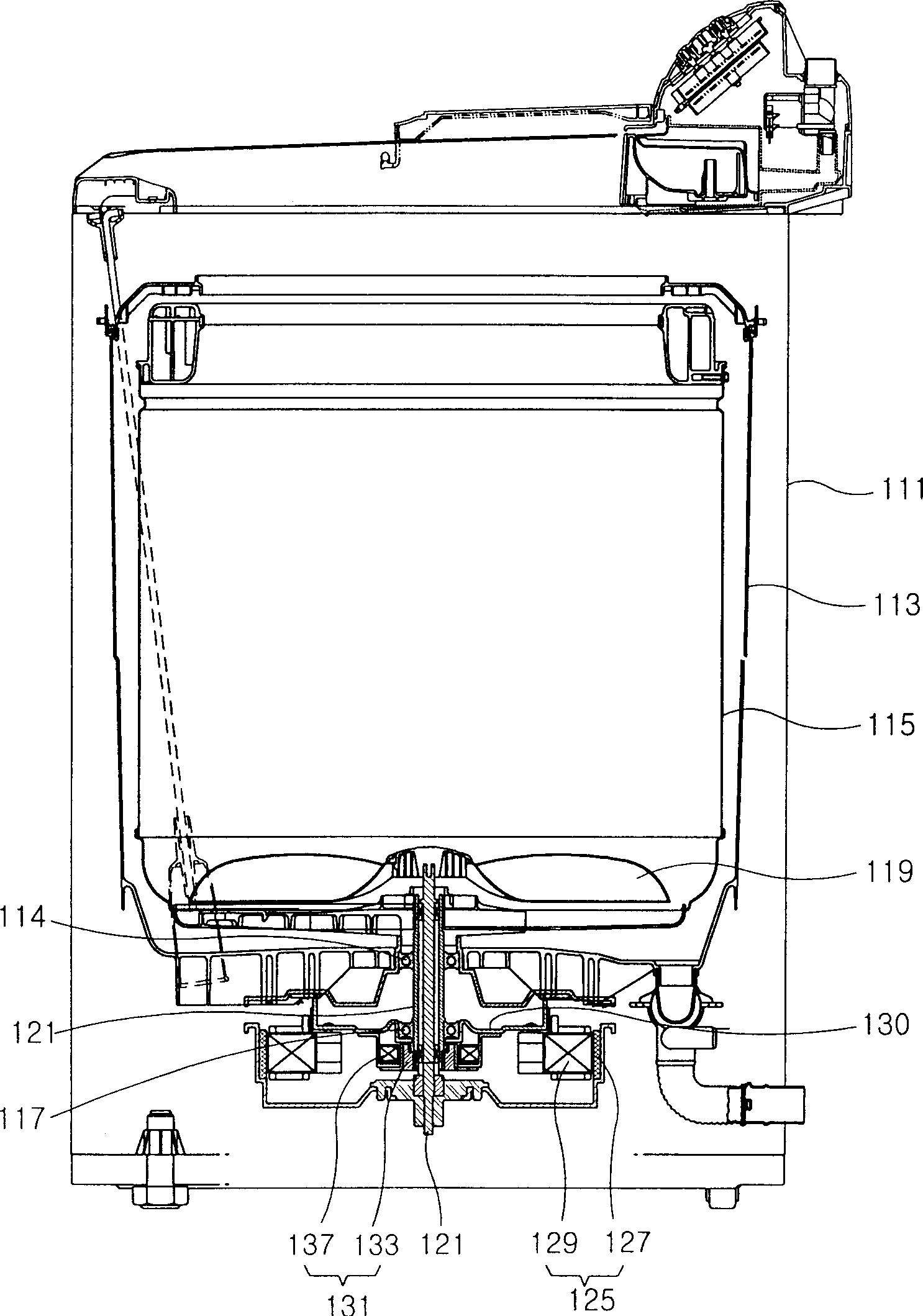

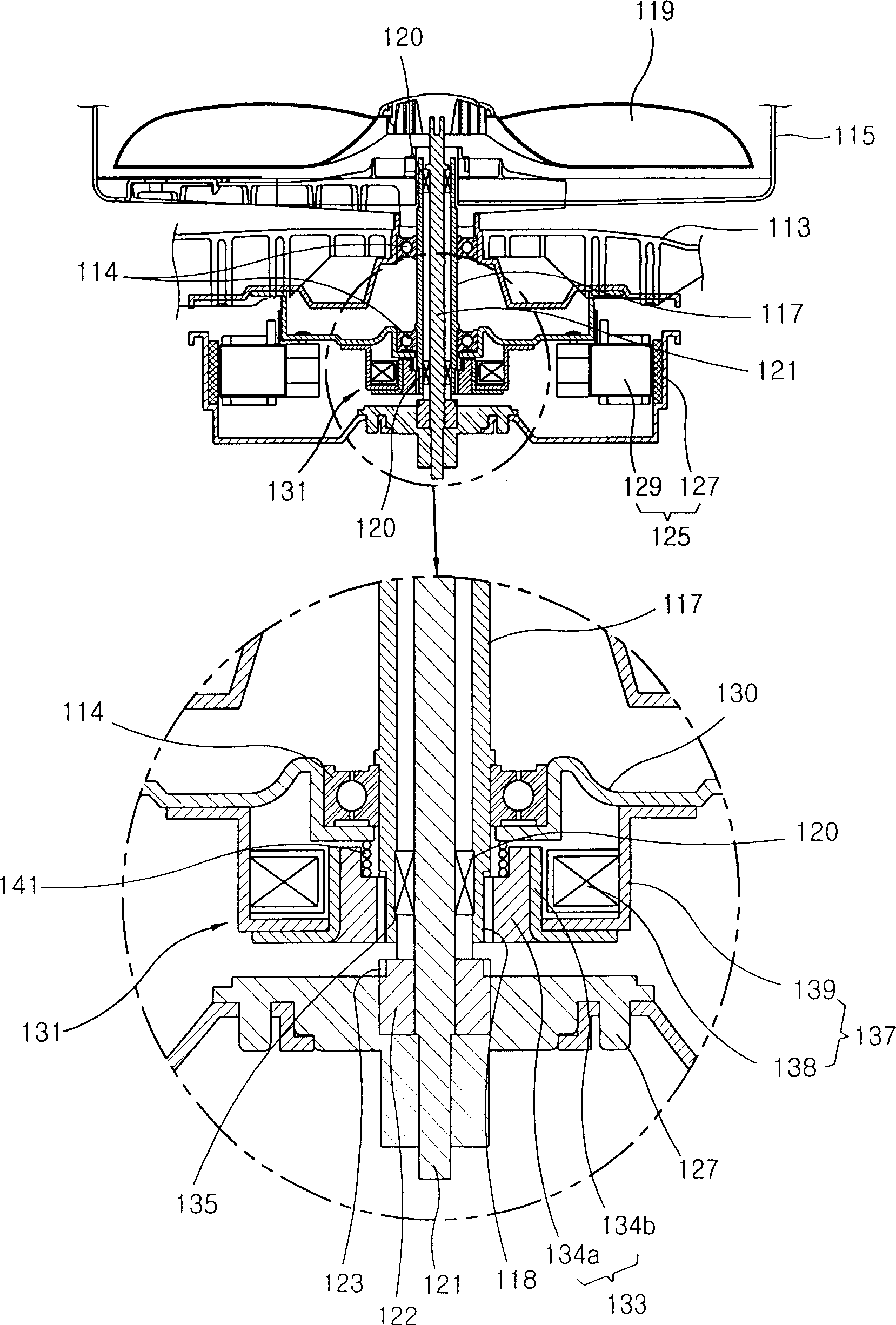

Clutch device for washing machine

InactiveCN1393591AAvoid knocking noiseReduce power consumptionOther washing machinesMagnetically actuated clutchesElectric machineDrive motor

A clutch apparatus of a washing machine is provided. The clutch apparatus includes a coupling unit comprising a magnetic unit at least in one part, combined around the basket shaft, and combined with a rotor of the driving motor in a state where the coupling unit moves downward, the coupling unit for transmitting the rotary power of the driving motor to the basket shaft and a solenoid actuator comprising a solenoid coil and fixed to the lower portion of the tub, the solenoid actuator for supplying electromagnetic repulsive force between the solenoid actuator and the coupling unit so that the coupling unit is separated from the rotor of the driving motor, to thus push the coupling unit upward. The clutch apparatus is formed to have a repulsive type structure unlike a conventional attractive type clutch apparatus. Accordingly, it is possible to collision noise generated when the coupling unit rises and to reduce the amount of consumption of power for maintaining a state where the coupling member rises.

Owner:LG ELECTRONICS INC

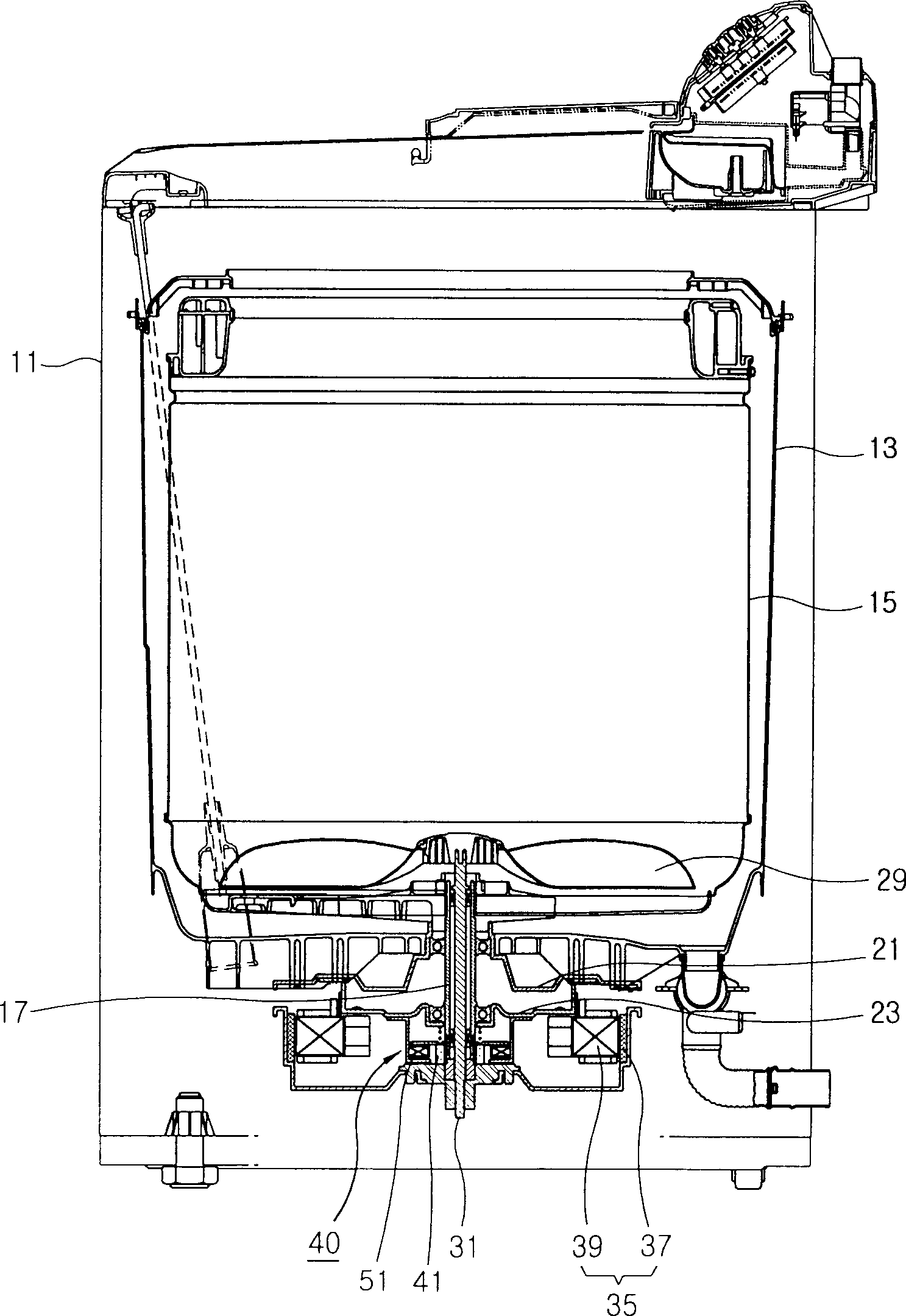

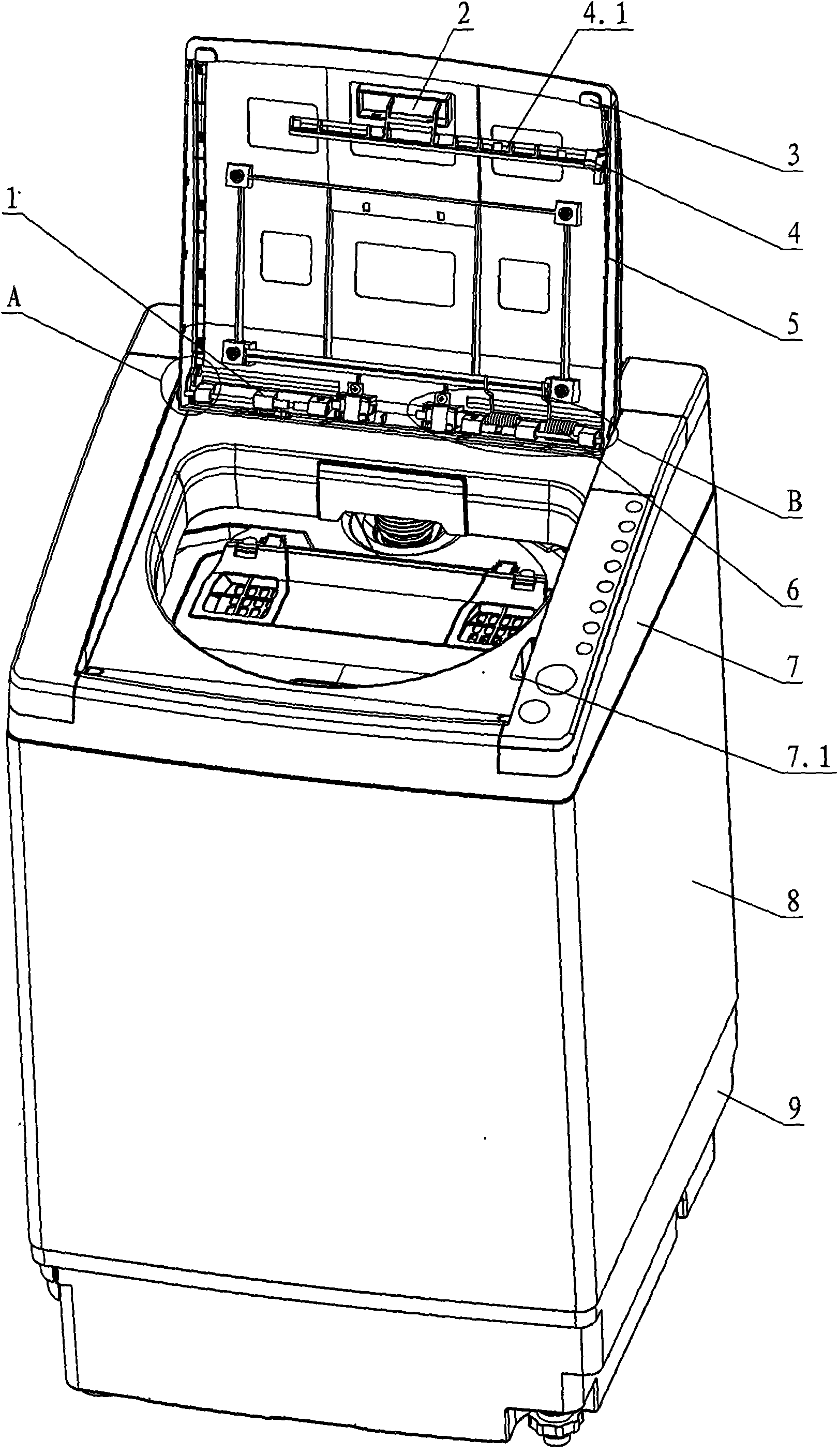

Cover structure of washing machine

ActiveCN101565891ASmooth structureThe upper and lower surfaces are flatOther washing machinesTextiles and paperLaundry washing machineButton pressing

The invention relates to a cover structure of a washing machine, which comprises a shell; a base is arranged at the bottom of the shell, an opening is correspondingly arranged in an inner bucket, a surface frame is arranged at the opening, and the surface frame and the cover are articulated through at least one articulated element; a torsion spring or an elastic piece which applies an action force on the opening direction to the cover is arranged at the articulating position; the cover and the surface frame are buckled by a locking way; a hook is arranged in the cover, and the surface frame is provided with a buckling position corresponding to the hook and connected with the hook by a buckling way; the hook is also connected with the button or a spanner, and the button or the spanner is arranged on the cover; one end of at least one articulated element are connected with the surface frame, and the other end thereof is connected with the torsion force controller and the cover; and the button is pressed or the push spanner is pushed to cause the hook and the buckling position to be separated so that the cover can be automatically and slowly opened. The middle part of the cover is an integrated structure without twice articulation, the upper surface and the lower surface of the cover are flat and neat, and easy to clean; and the button controls the cover structure to be turned up, and the button exposes on the top surface of the cover, therefore, a control circuit of the washing machine can not be influenced even if water enters a slot between the button and the cover.

Owner:GUANGDONG GALANZ GRP CO LTD

Torsional vibration damper

ActiveUS10100898B2Avoid knocking noiseLow-noise impact behaviorRotating vibration suppressionEngineeringTorsional vibration

A torsional vibration damper has a damper mass carrier at which is received at least one damper mass movable relative to the damper mass carrier and with at least one stop. The at least one damper mass has a stop side with a geometric shaping. At least one stop is associated with the damper mass, and has an axial overlap with the at least one damper mass in extension direction of a central axis and a stop profile at its side facing the stop side of the damper mass. At least one stop receiver is associated with the least one stop for the at least one damper mass. The geometric shaping which is provided at the at least one damper mass has a first contact region operative at least substantially in radial direction and a second contact region operative at least substantially in tangential direction. The first contact region can be brought into operative connection with the stop, and the second contact region can be brought into operative connection with the stop receiver.

Owner:ZF FRIEDRICHSHAFEN AG

Shoe-type automatic clutch

InactiveCN101016924ASimplify the production process and production difficultyIncrease contact areaAutomatic clutchesClutchEngineering

The invention discloses a mosque automatic clutch, wherein an active cover of the clutch frame is connected with an axial sheath with a spline hole, the active cover is arranged with at least two eccentric mosque blocks which can radial move on the active disc, the inner arc of each eccentric mosque is arranged with a radial sliding groove at middle, the sliding groove of each mosque is sliding engaged with a pin axle of the active disc, the outer arc of each mosque block is adhered with a friction block between which and the inner wall of the clutch frame a clearance space is arranged, each eccentric mosque is arranged with an arc groove while all grooves are connected to form an annular groove, two ends of a flexible spring are connected to be arranged in the annular groove, the annular groove is shaded by a baffle plate, and a baffle ring clamps a pin axle to axially position the eccentric mosque blocks. The invention can contact the arc face of the friction block completely with the clutch frame when in work, to improve torque and make friction uniform to prolong the service life of friction block.

Owner:CHONGQING JIANSHE MOTORCYCLE CO LTD

Rotary cash-out shutter

PendingCN106652178ASmall footprintLow costCoin/currency accepting devicesDrive shaftLocking mechanism

The invention discloses a rotary cash-out shutter, comprising a frame, a turnover shutter, a shutter actuator, a driving mechanism and a self-locking mechanism, wherein the turnover shutter is fixed on the shutter actuator; the driving mechanism is fixed on the frame and drives the shutter actuator to rotate; the driving mechanism comprises a driving motor, a driving shaft, a driving synchronous belt pulley, a driven synchronous belt pulley and a synchronous belt; the driving motor is fixed on the frame, two ends of the driving shaft are rotationally arranged on the frame, the driving synchronous belt pulley is fixed on an output shaft of the driving motor, the driven synchronous belt pulley is fixed on the driving shaft, and the synchronous belt encircles the driving synchronous belt pulley and the driven synchronous belt pulley; the bottom of the shutter actuator is fixed on the driving shaft; and the self-locking mechanism automatically locks the shutter actuator when the turnover shutter is closed. The rotary cash-out shutter is small in floor area, low in cost and high in reliability.

Owner:GUOGUANG ELECTRONICS INFORMATION TECH

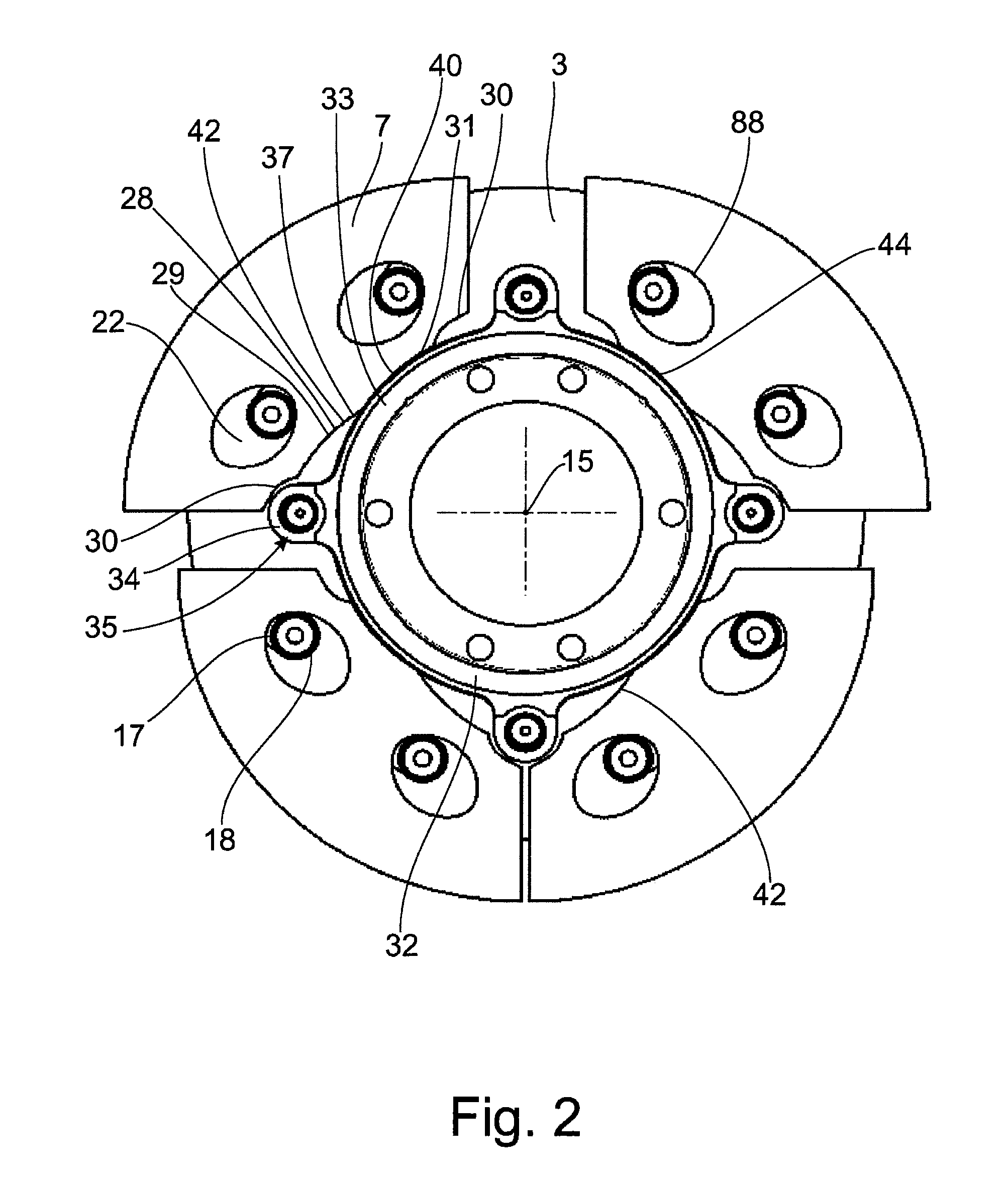

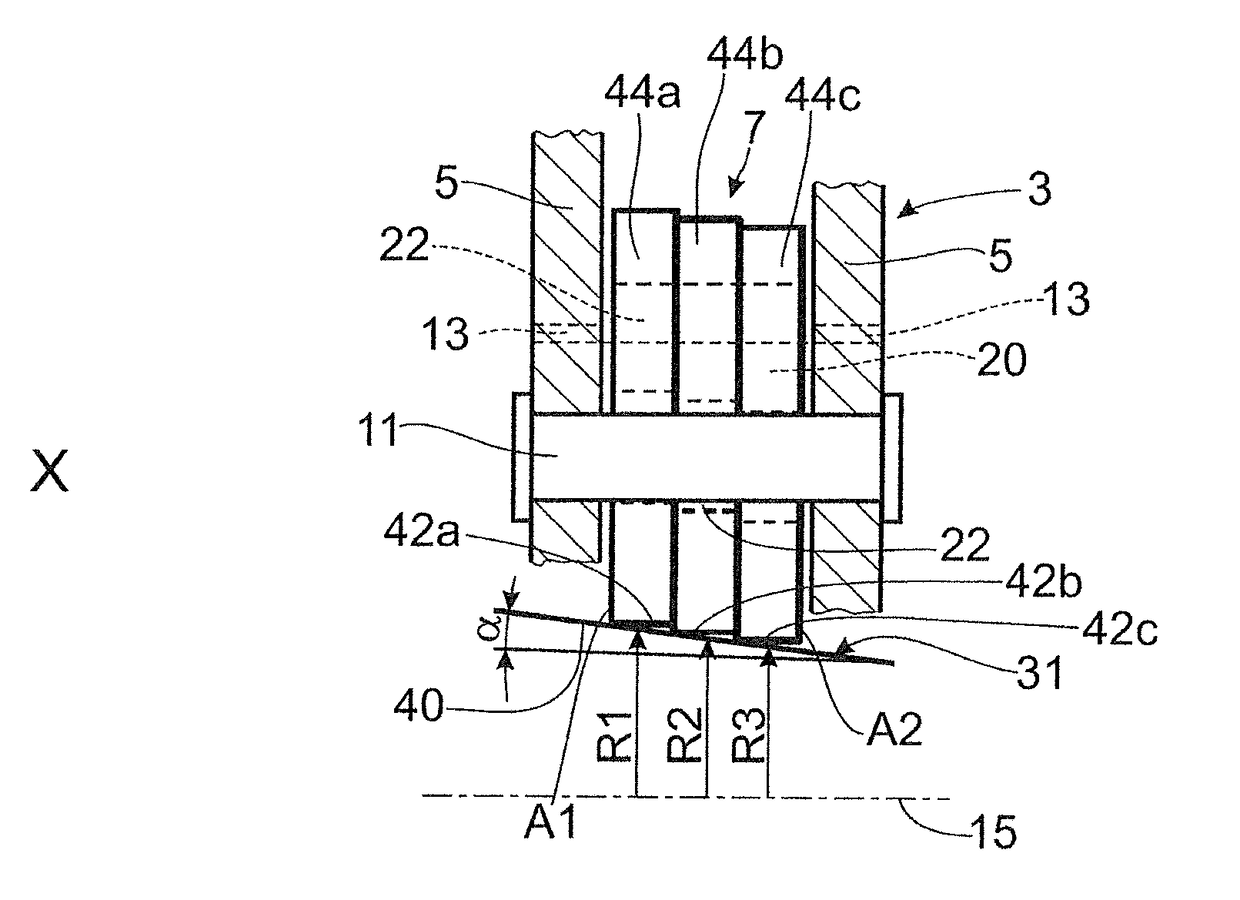

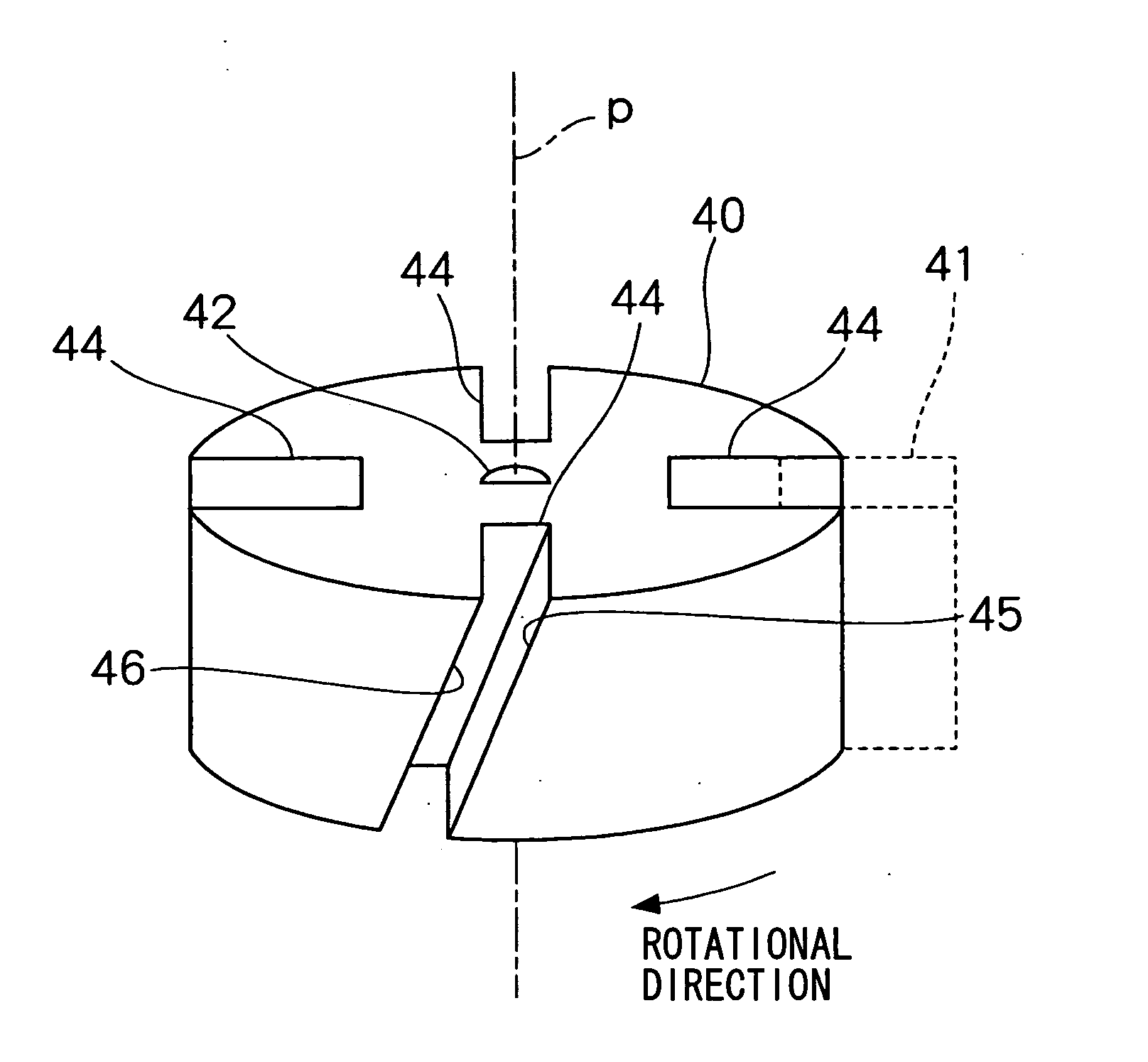

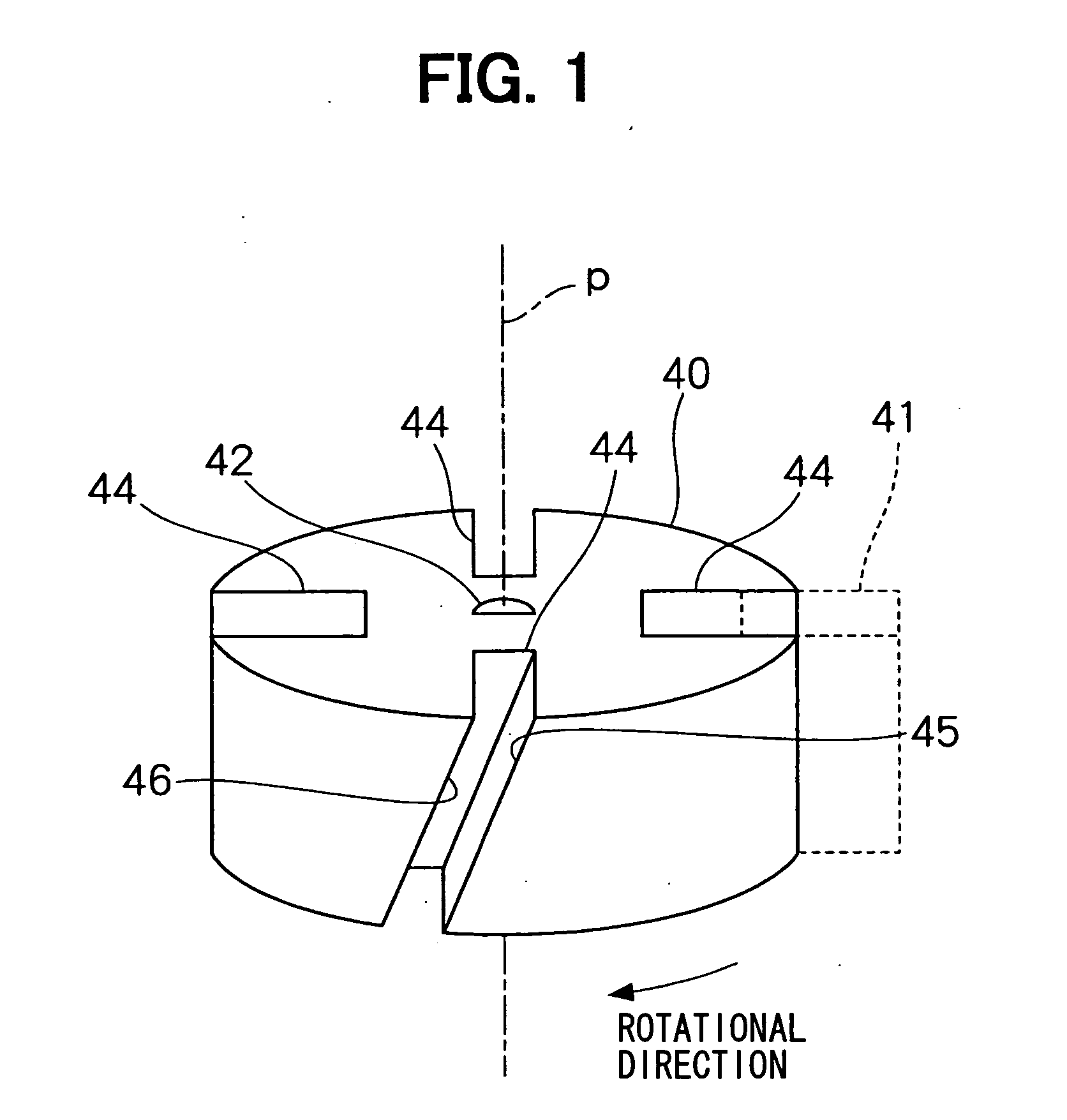

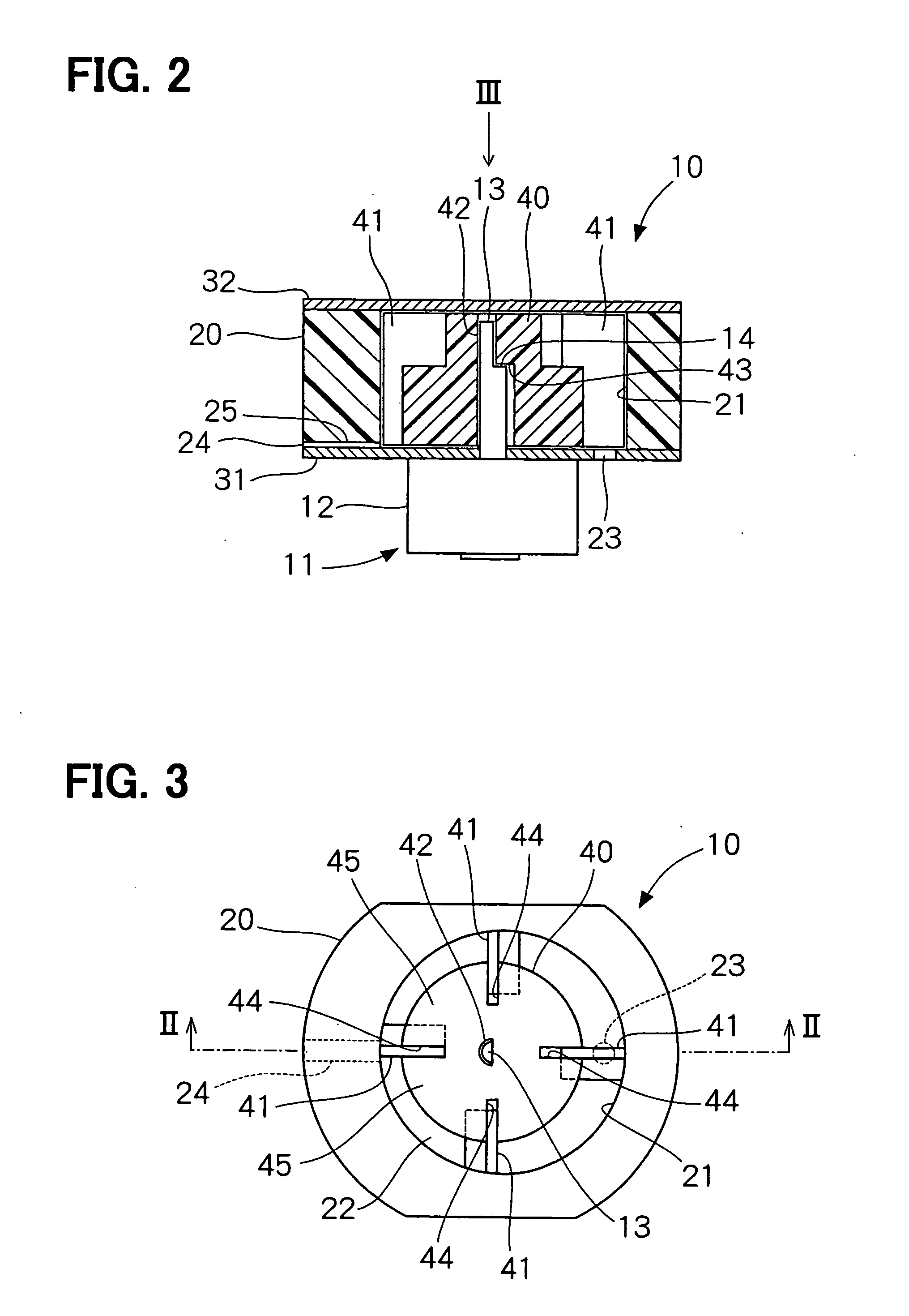

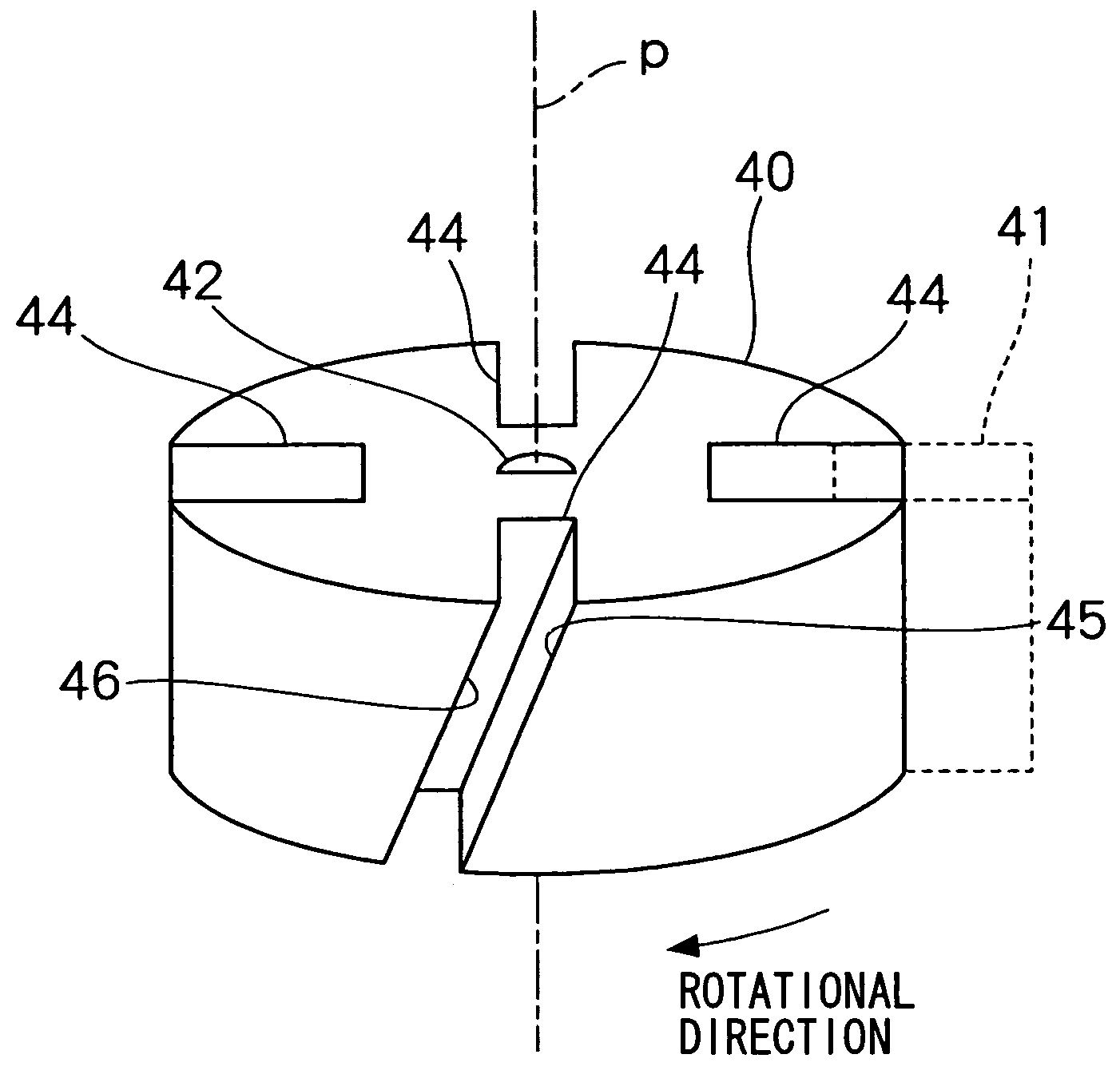

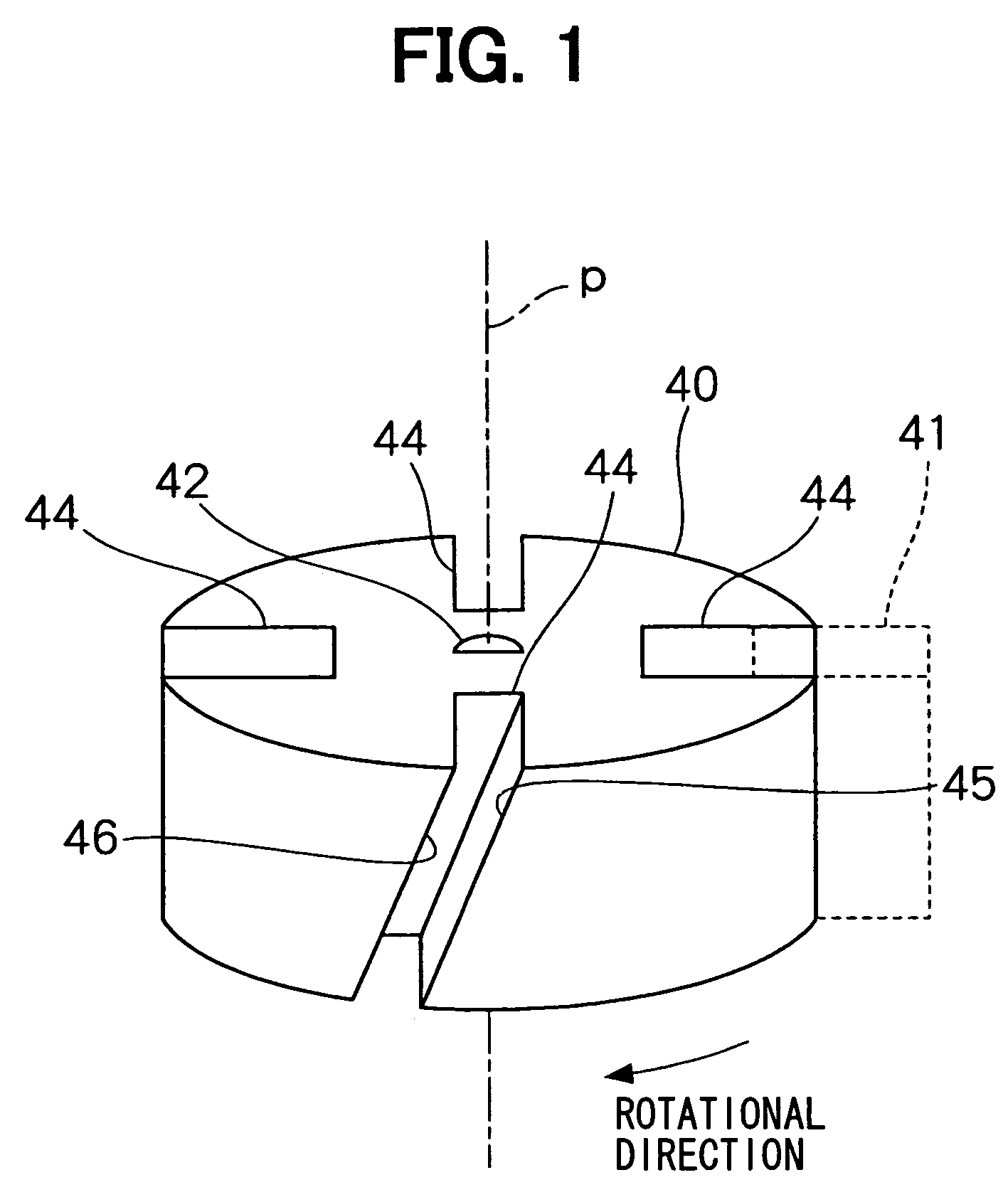

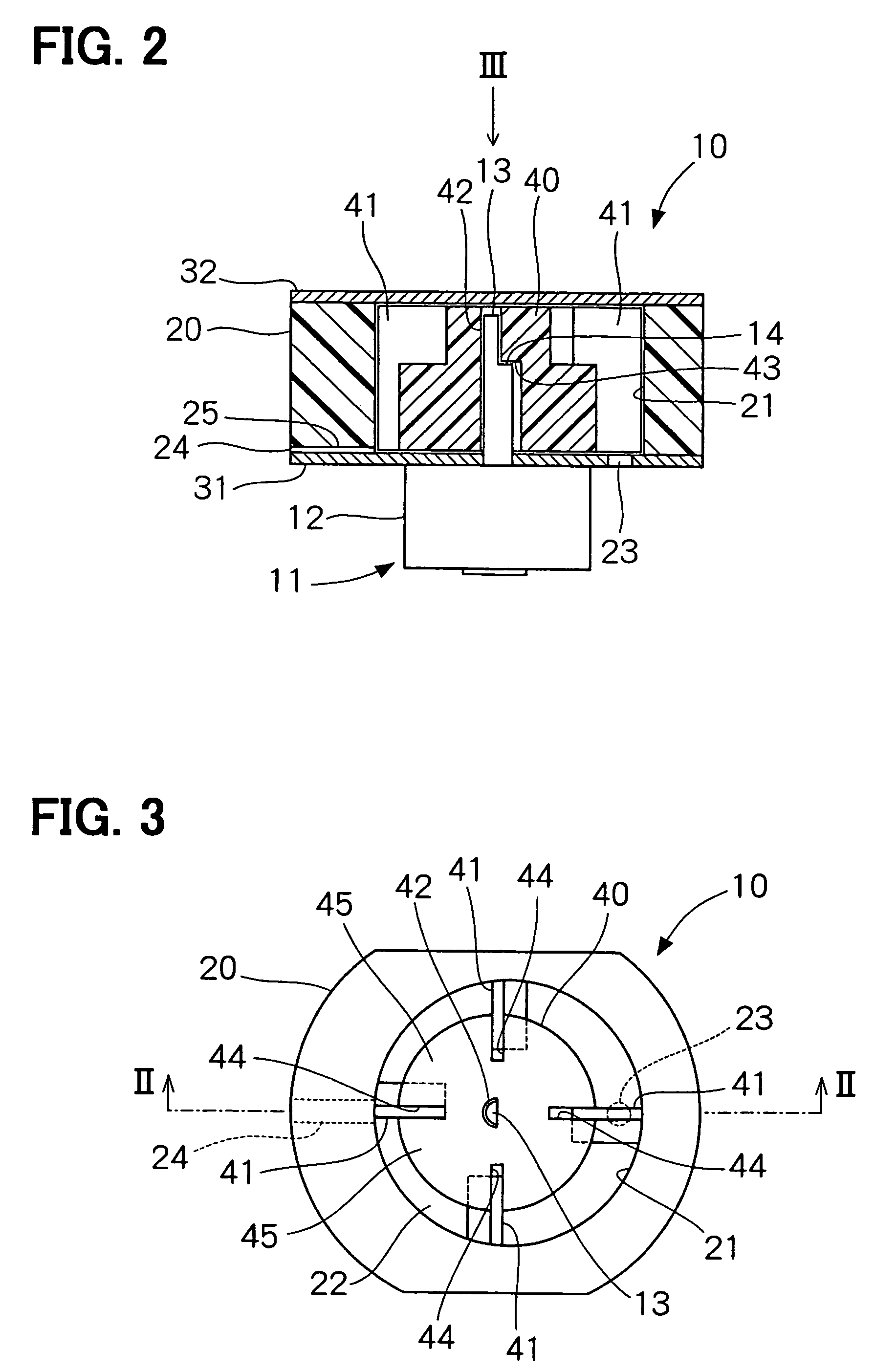

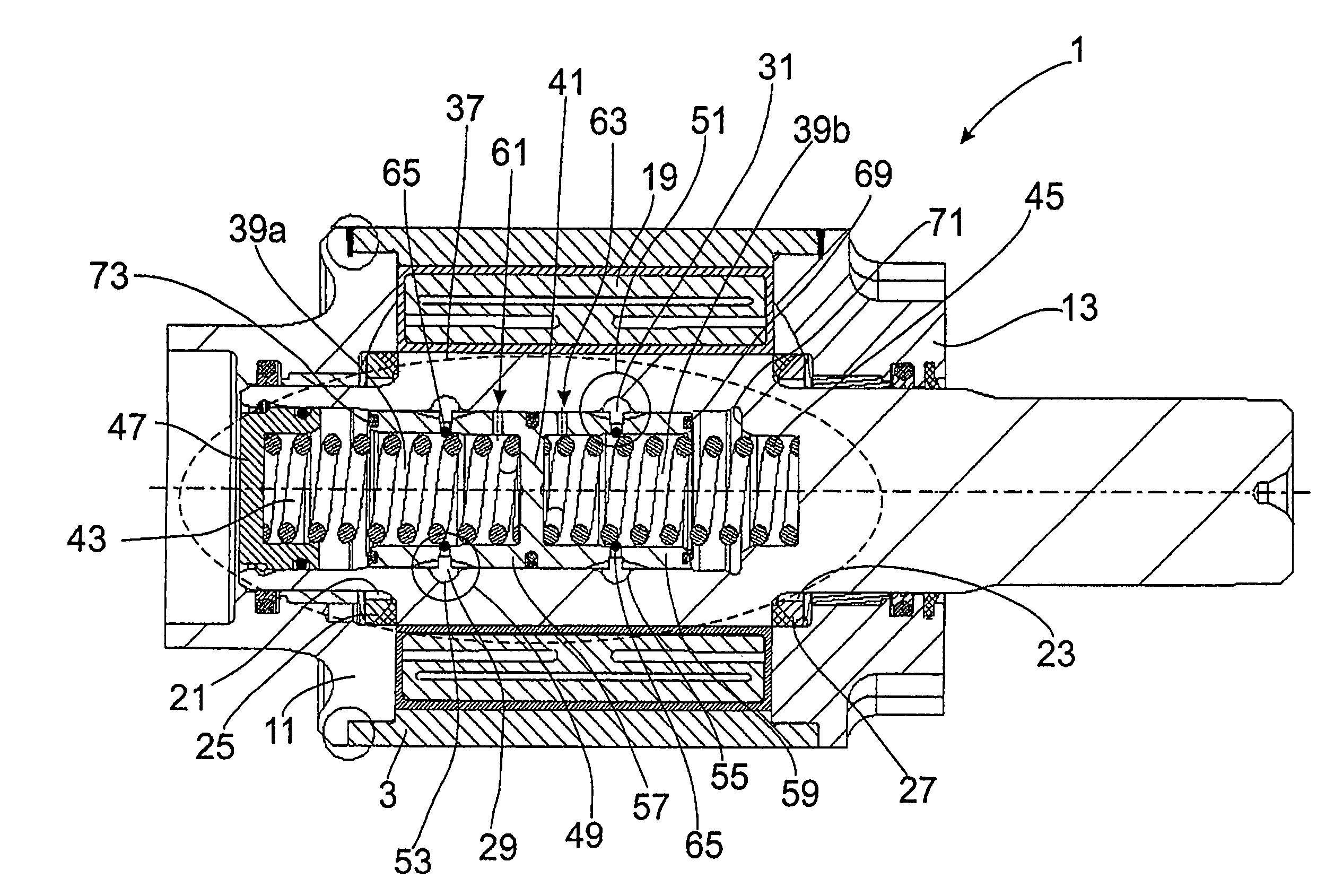

Vane pump having vanes slanted relative to rotational axis

InactiveUS20060099102A1Avoid knocking noiseInhibit wearDetection of fluid at leakage pointOscillating piston enginesRotational axisPump chamber

A vane pump is composed of a casing having a cylindrical inner bore and a rotor disposed in the inner bore with an eccentric relation to the inner bore. A circular pump chamber formed between the rotor and the inner bore is divided by vanes disposed in the rotor into plural pump chambers each changing its capacity according to rotation of the rotor. The vane is slidably disposed in a groove formed in the rotor in a slanted relation with respect to a rotational axis of the rotor. When the rotor rotates, the vane is pushed backward of the rotational direction by fluid in the pump chamber. The pushing force includes a component for pushing the vane upward toward an upper plate closing an upper opening of the inner bore. The vane is pushed against the upper plate to thereby prevent hitting noises between the vane and the upper plate.

Owner:DENSO CORP

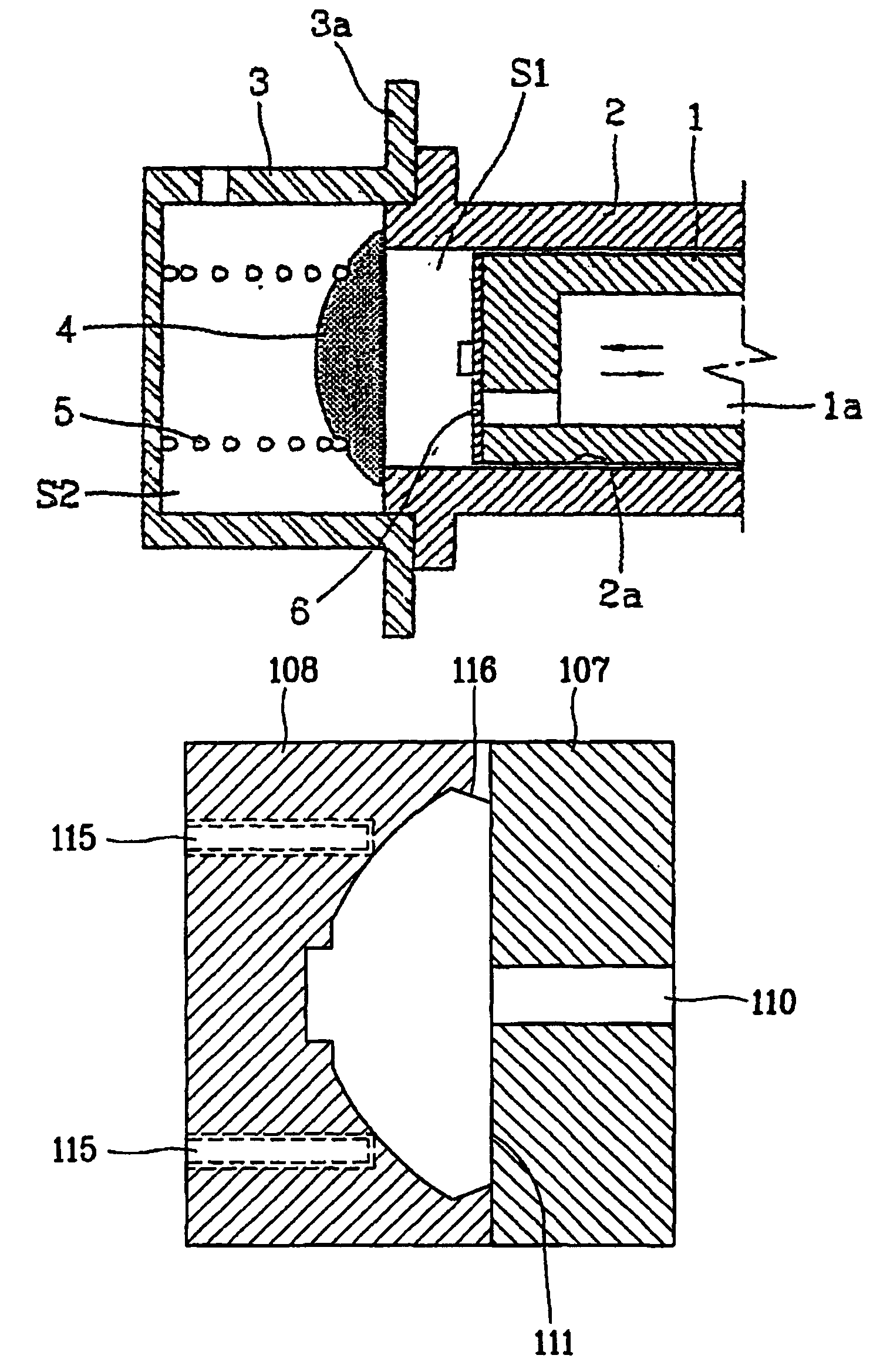

Discharge valve apparatus for reciprocating compressor

InactiveUS7056106B2Avoid knocking noiseEasy to ejectPositive displacement pump componentsCheck valvesReciprocating motionEngineering

A discharge valve apparatus for a reciprocating compressor comprises a discharge cover having built-in volume so as to cover a front end surface of the cylinder; a discharge valve disposed so as to be contacted / separated to / from the front end surface of the cylinder by a piston which undergoes a reciprocating movement inside the cylinder; and a valve spring having both ends respectively adhered to rear side of the discharge valve and to inner surface of the discharge cover so as to elastically support the rear side of the discharge valve. A rotation radius of the valve spring of a conical type is formed to be gradually reduced or increased so that impacts of a part to other parts during the compression can be prevented. Accordingly, when the valve spring is compressed in accordance with the compression and discharge strokes of the piston, the impacting noise caused by the impacts of the respective parts in the valve spring can be prevented previously.

Owner:LG ELECTRONICS INC

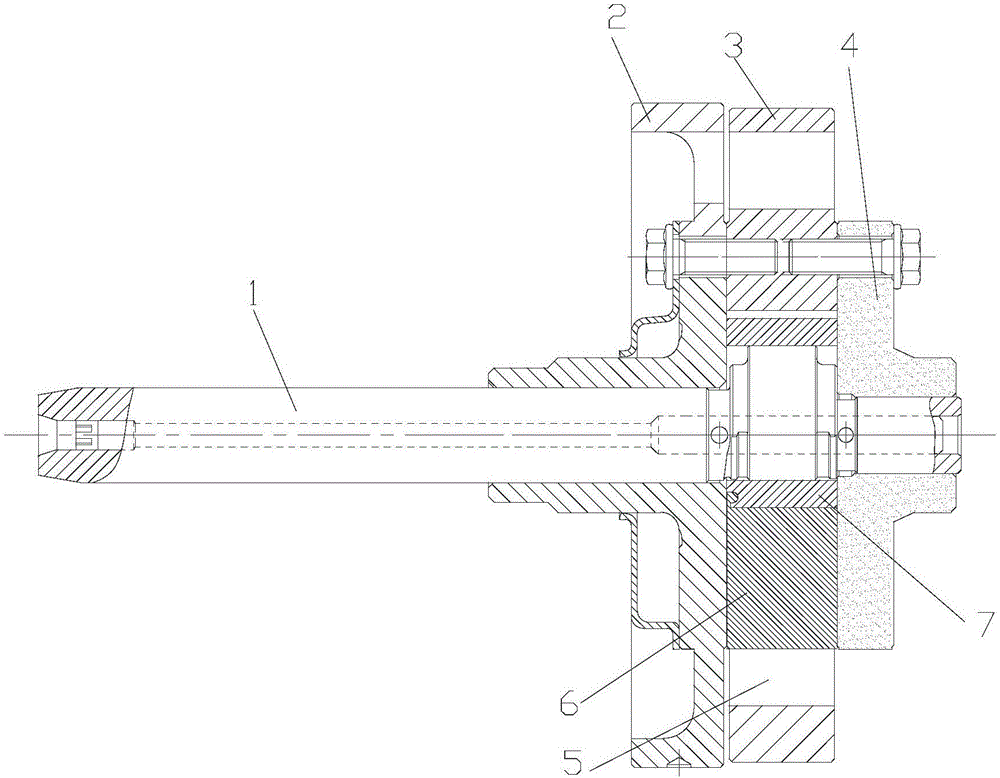

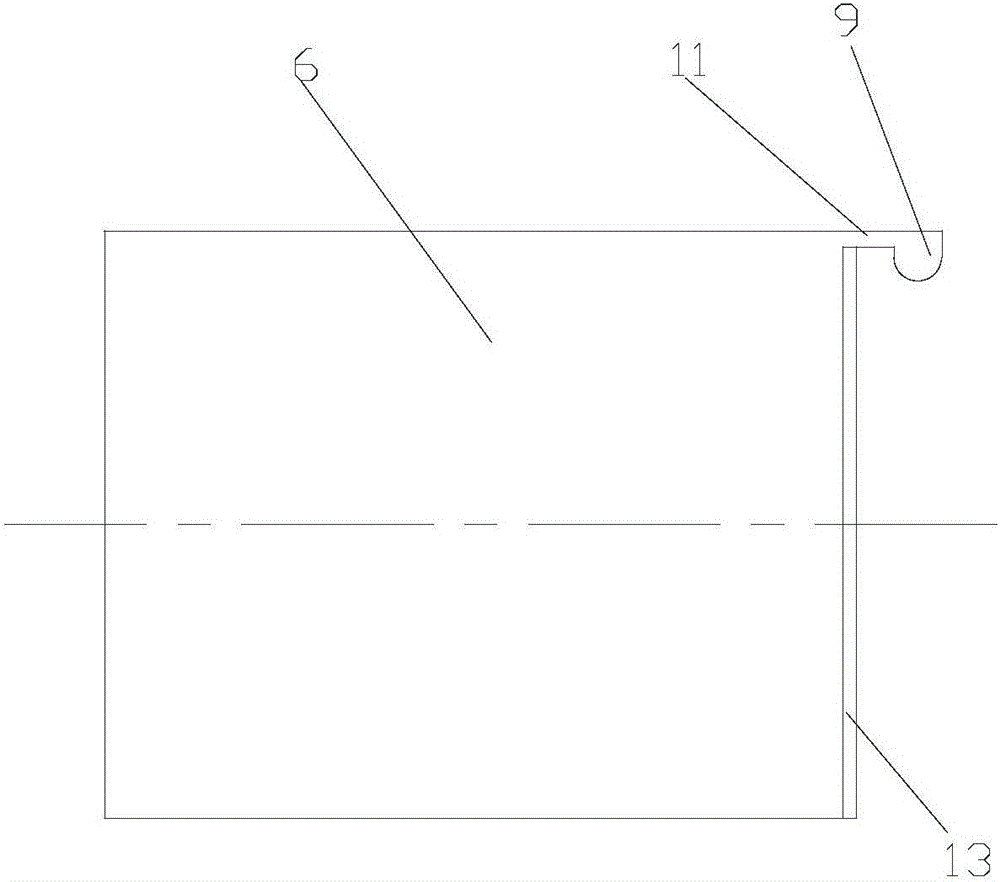

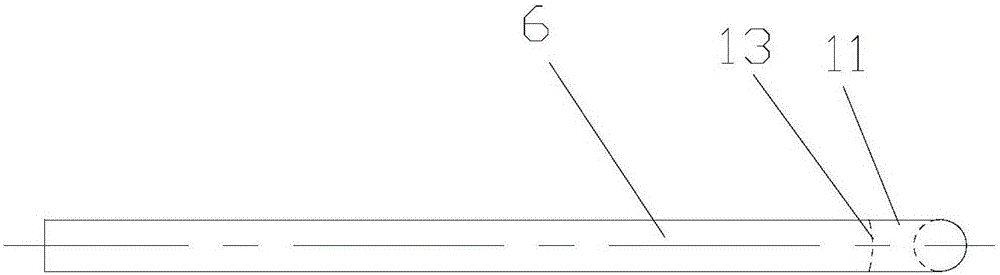

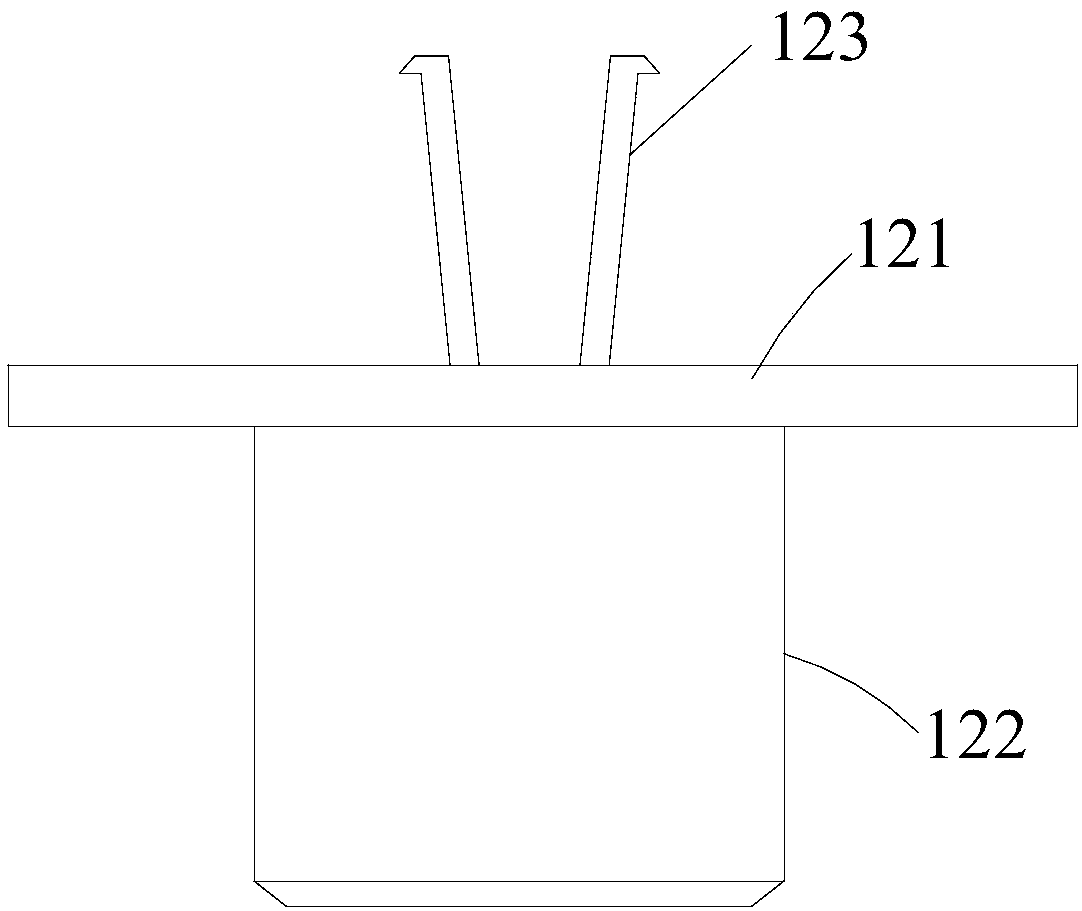

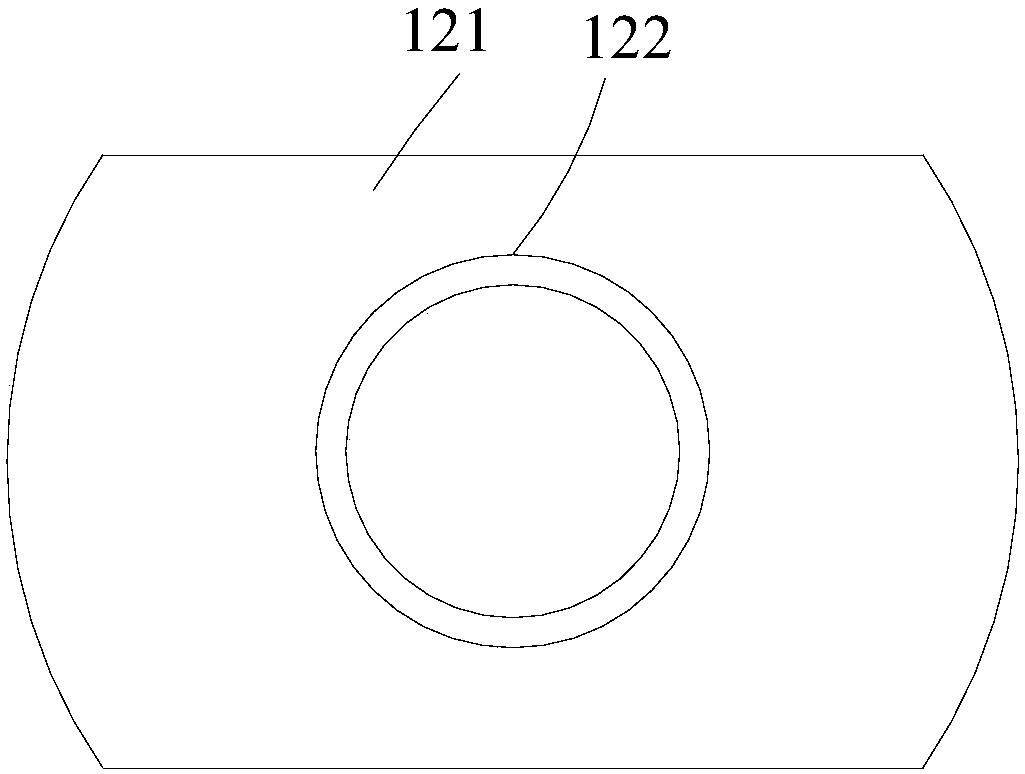

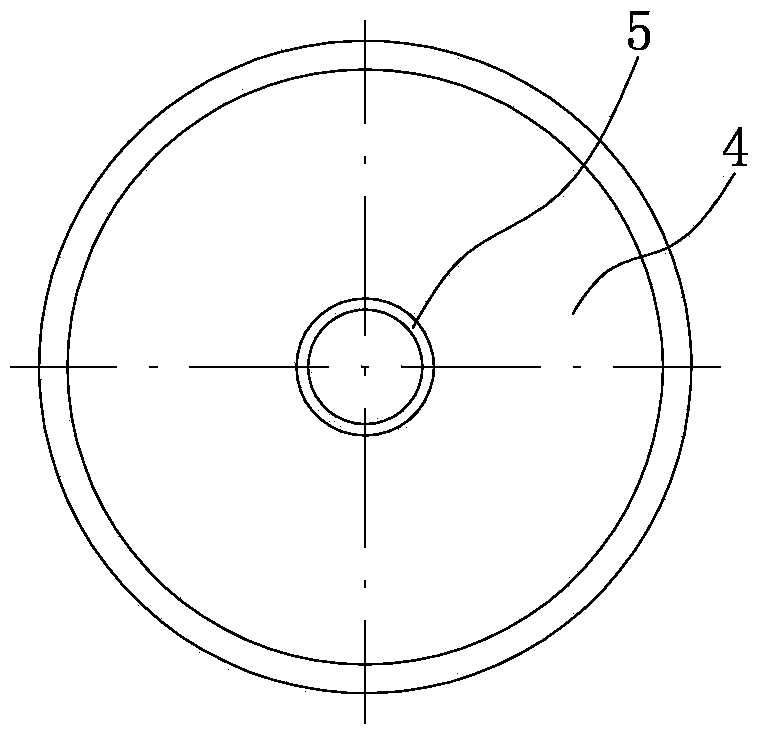

Pump body structure and compressor

ActiveCN106246542APrevent disengagementAddress the danger of disengagementRotary piston pumpsRotary piston liquid enginesEngineeringSlide plate

The invention discloses a pump body structure and a compressor. The pump body structure comprises a crankshaft (1), an upper flange (2), a cylinder (3) and a lower flange (4), wherein the upper flange (2), the cylinder (3) and the lower flange (4) are sequentially arranged along the axial direction of the crankshaft (1); a roller (7) is arranged inside the chamber body of the cylinder (3) and sleeves the outside of the crankshaft (1); the cylinder (3) is also provided with a sliding groove (5); a sliding plate (6) is arranged inside the sliding groove (5) in a sliding manner; the other end of the sliding plate (6) is rotationally connected with the roller (7). The pump body structure disclosed by the invention is capable of solving the problem that the refrigeration capacity of an air conditioner is reduced sharply because high pressure and low pressure in the cylinder body are mixed when the sliding plate and the roller are easily separated.

Owner:GREE ELECTRIC APPLIANCES INC

Display device

PendingCN114143674AIn line with the development trend of ultra-thinImprove experienceAdvertisingMagnetostrictive transducersPhysicsMagnet

The invention provides a display device which comprises a display panel, a back plate, a frame and an exciter, the exciter is located in the frame, and the exciter comprises a shell, a coil, a magnet, a magnetostrictive part and a vibration part; wherein the shell is connected with the frame or the back plate, the shell surrounds the coil, the coil is used for generating an alternating magnetic field according to a control signal, the coil is annular, the magnet and the magnetostriction piece are both located in the coil and are arranged in the axial direction of the coil, one end of the vibration piece is located in the shell, and the other end of the vibration piece extends out of the shell. The vibrating piece, the magnet and the magnetostrictive piece are tightly pressed between the frame and the shell; and the magnetostriction piece can generate telescopic deformation along the axial direction of the coil in a superposed magnetic field of the alternating magnetic field and the magnetic field generated by the magnet, and drives the frame to vibrate and produce sound. The display device provided by the invention is small in thickness and conforms to the ultrathin development trend of the display device.

Owner:HISENSE VISUAL TECH CO LTD

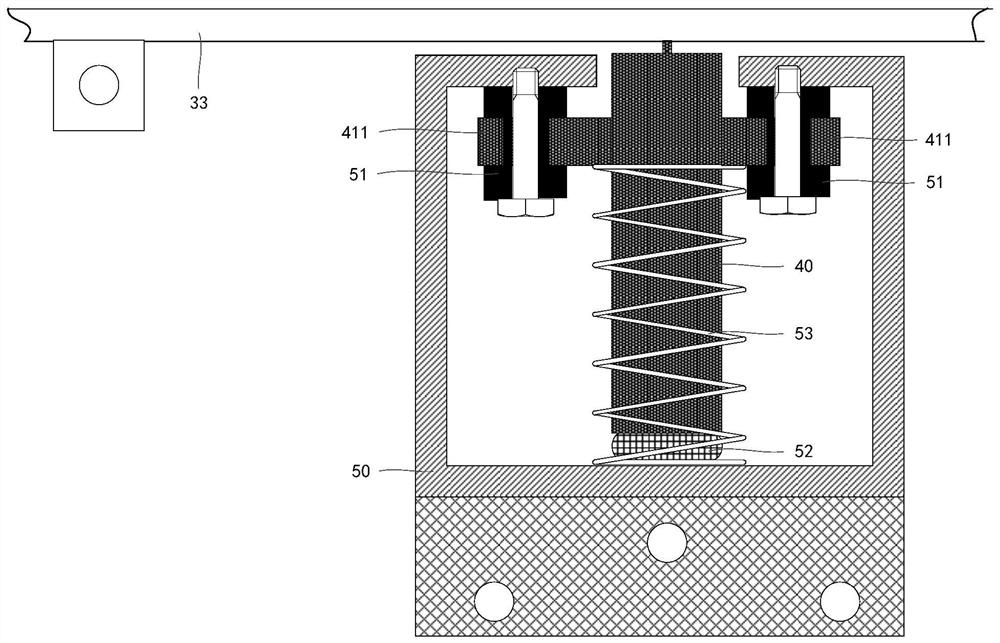

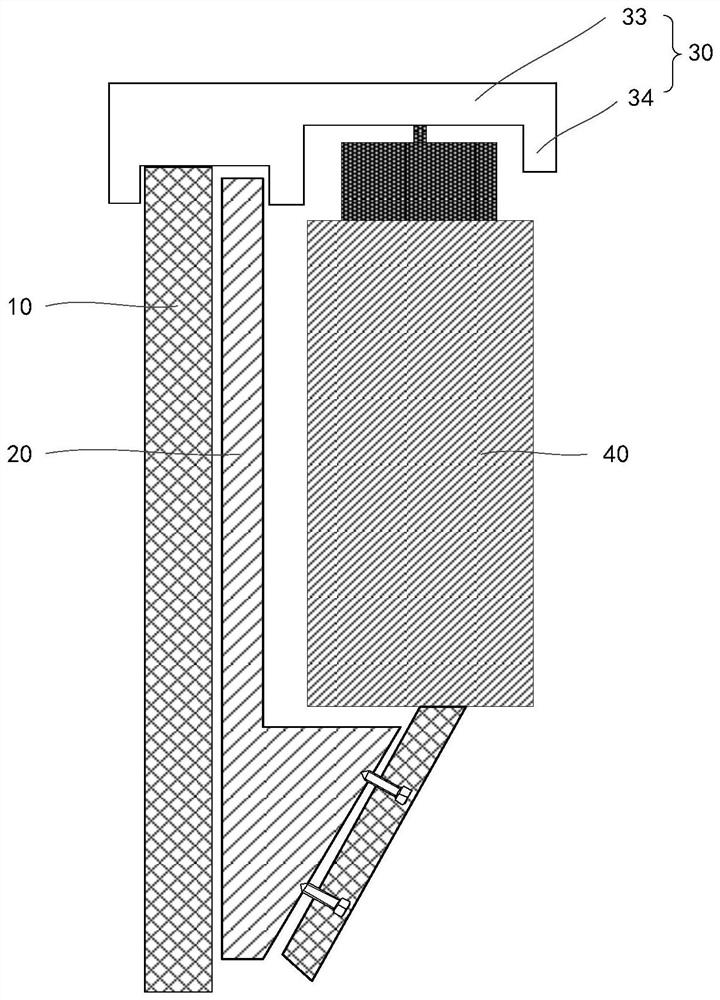

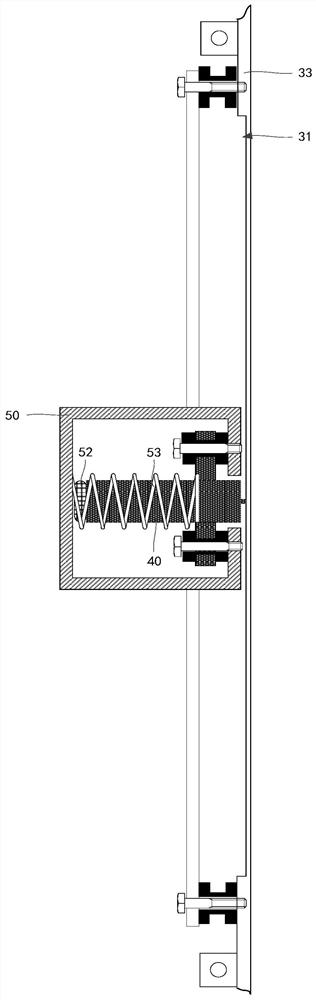

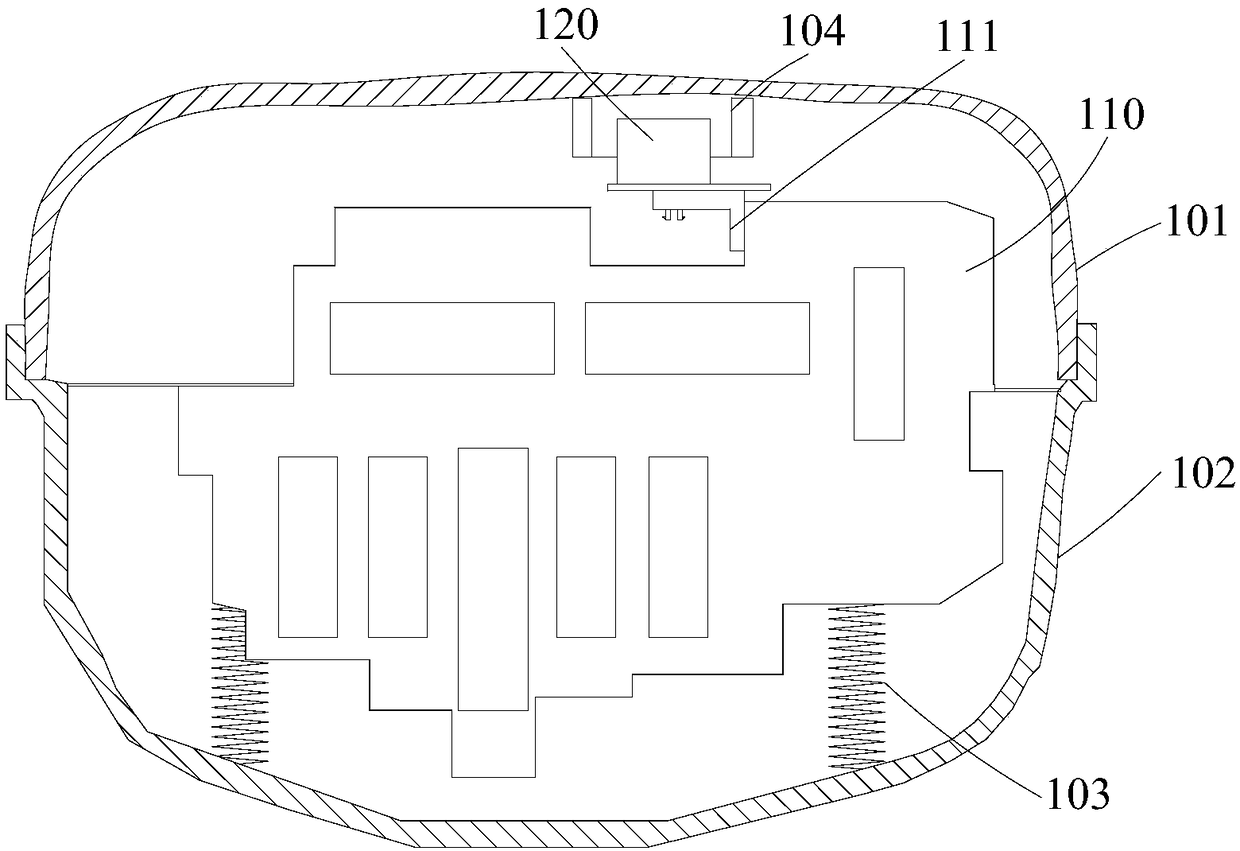

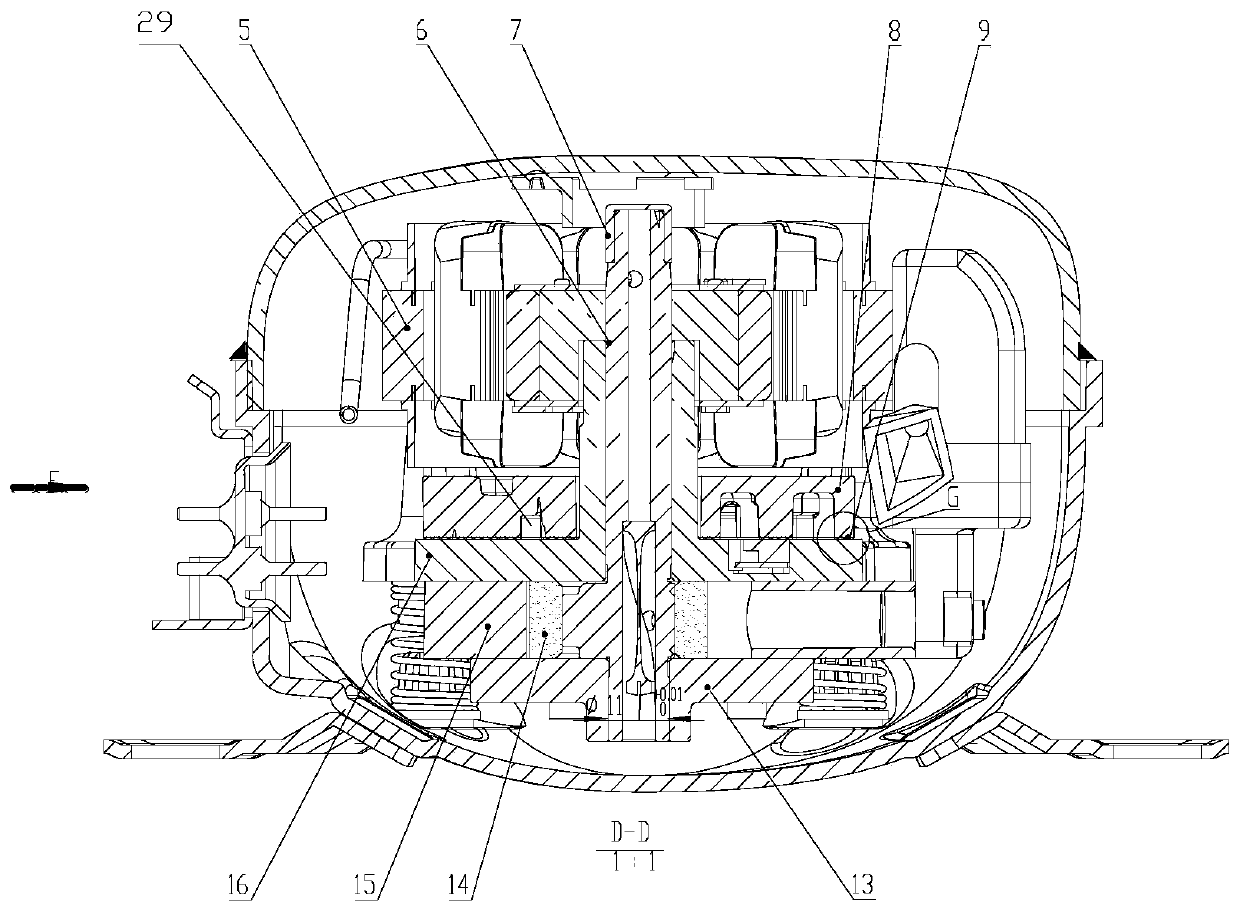

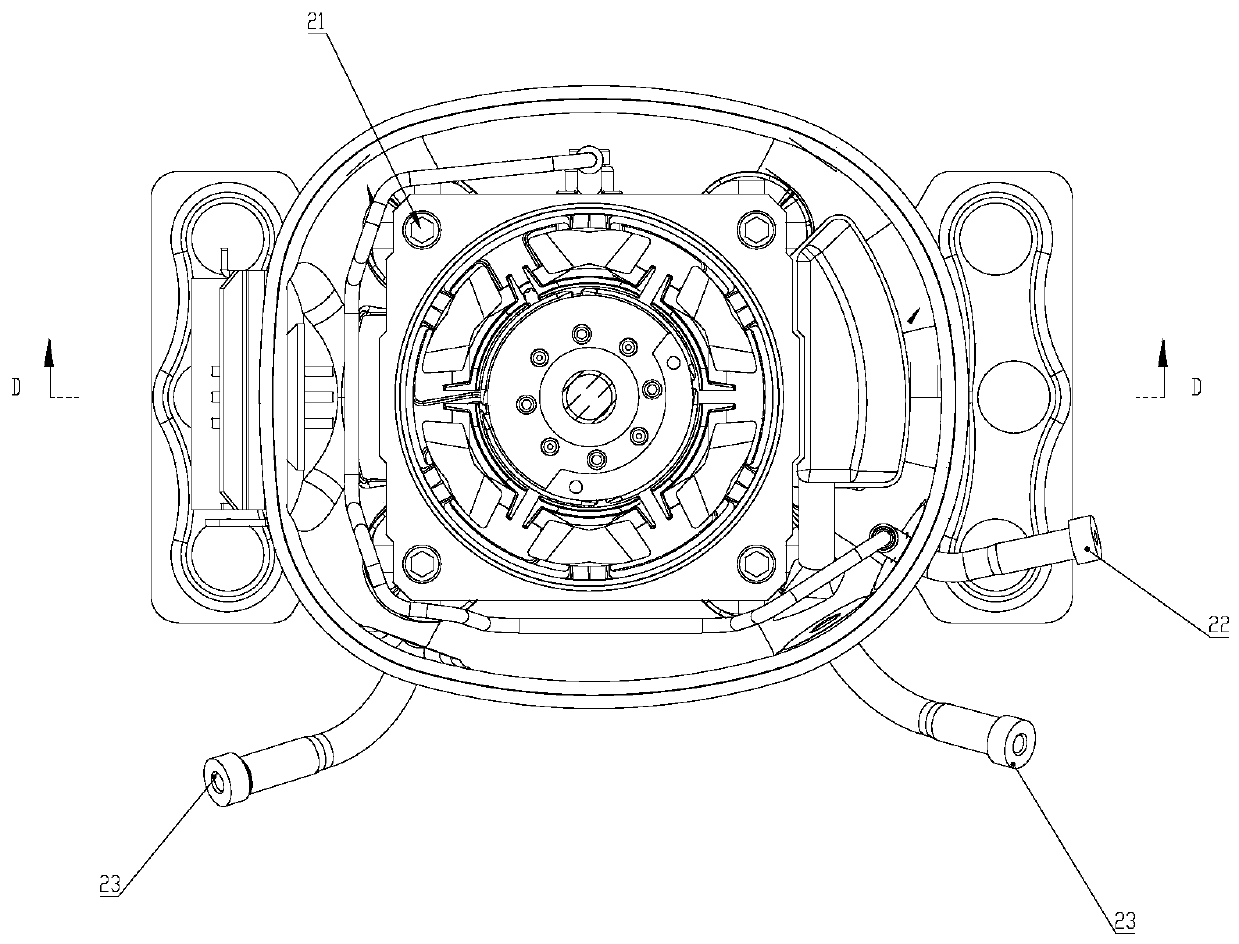

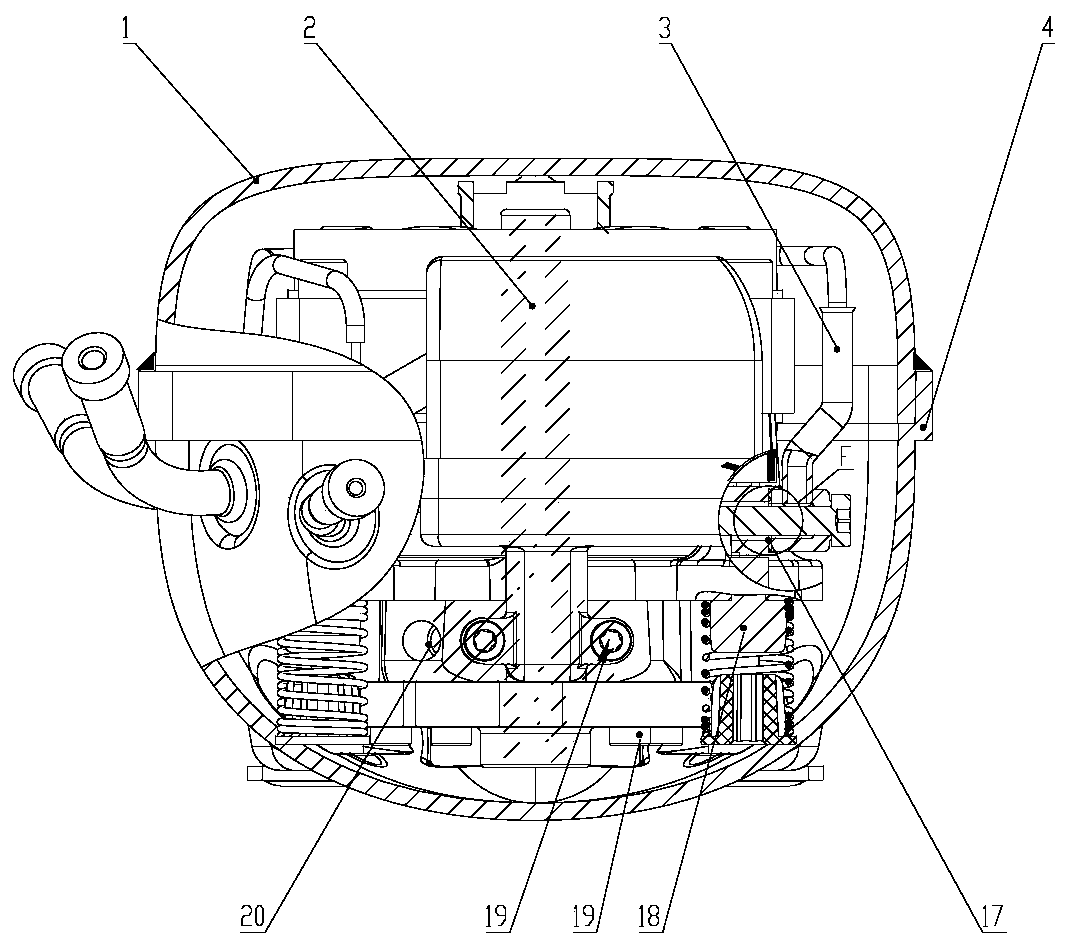

Limiting structure for compressor

PendingCN108252899APrevent trip springAvoid knocking noisePositive displacement pump componentsPositive-displacement liquid enginesRefrigeration compressorEngineering

The invention provides a limiting structure for a compressor, belonging to the field of refrigeration compressors. The limiting structure comprises a shell and a machine core located in the shell, wherein a plurality of pressure springs are arranged between the machine core and the shell, a limiting pin is further arranged on the machine core, a limiting ring is arranged on the inner side of the shell, and the limiting pin is inserted into the limiting ring. The limiting structure has an all-dimensional limiting function, the release of the springs can be prevented, and the metal impact noisecan be prevented; and the limiting structure is simple and easy to assemble.

Owner:黄石东贝压缩机有限公司

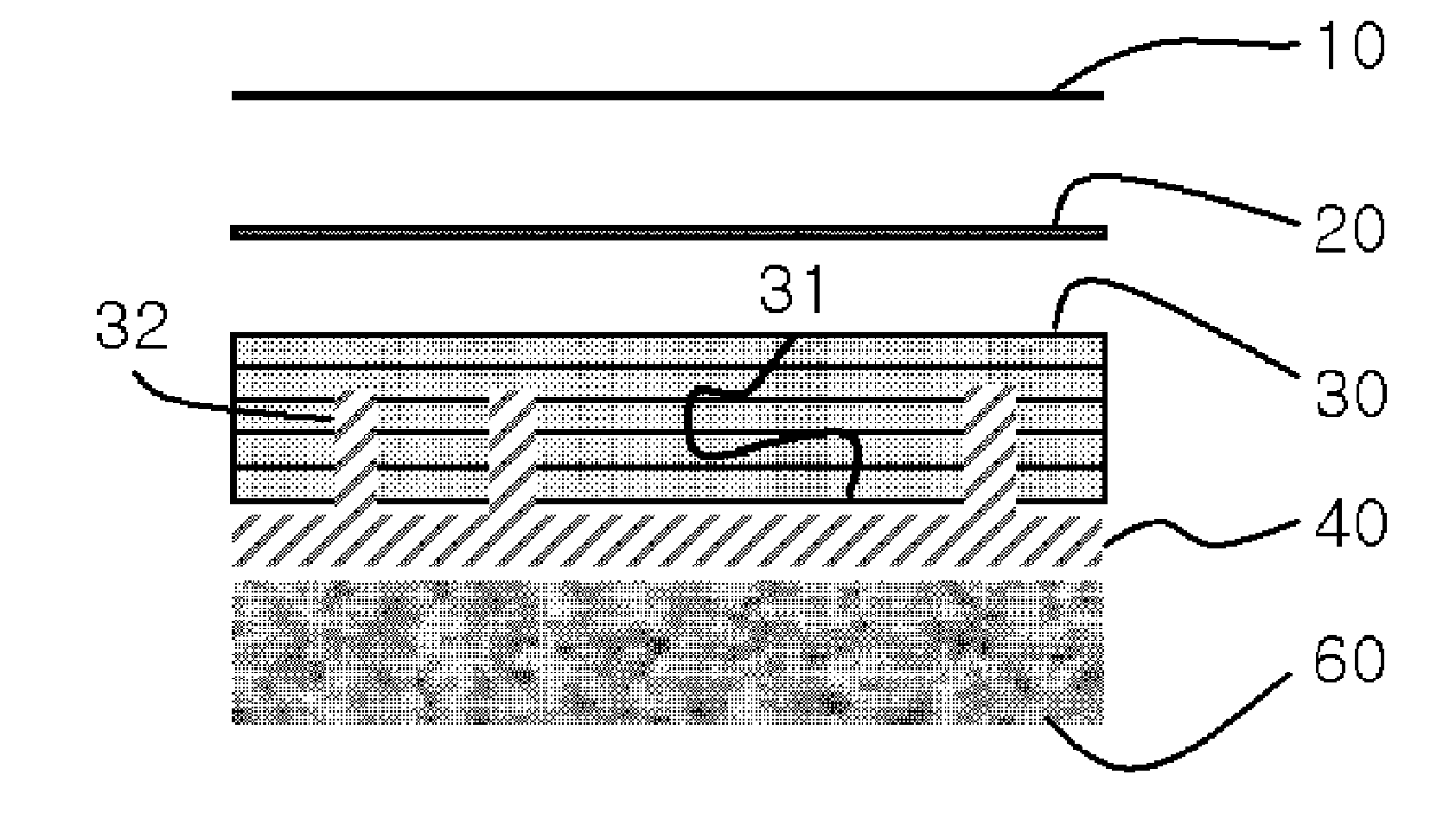

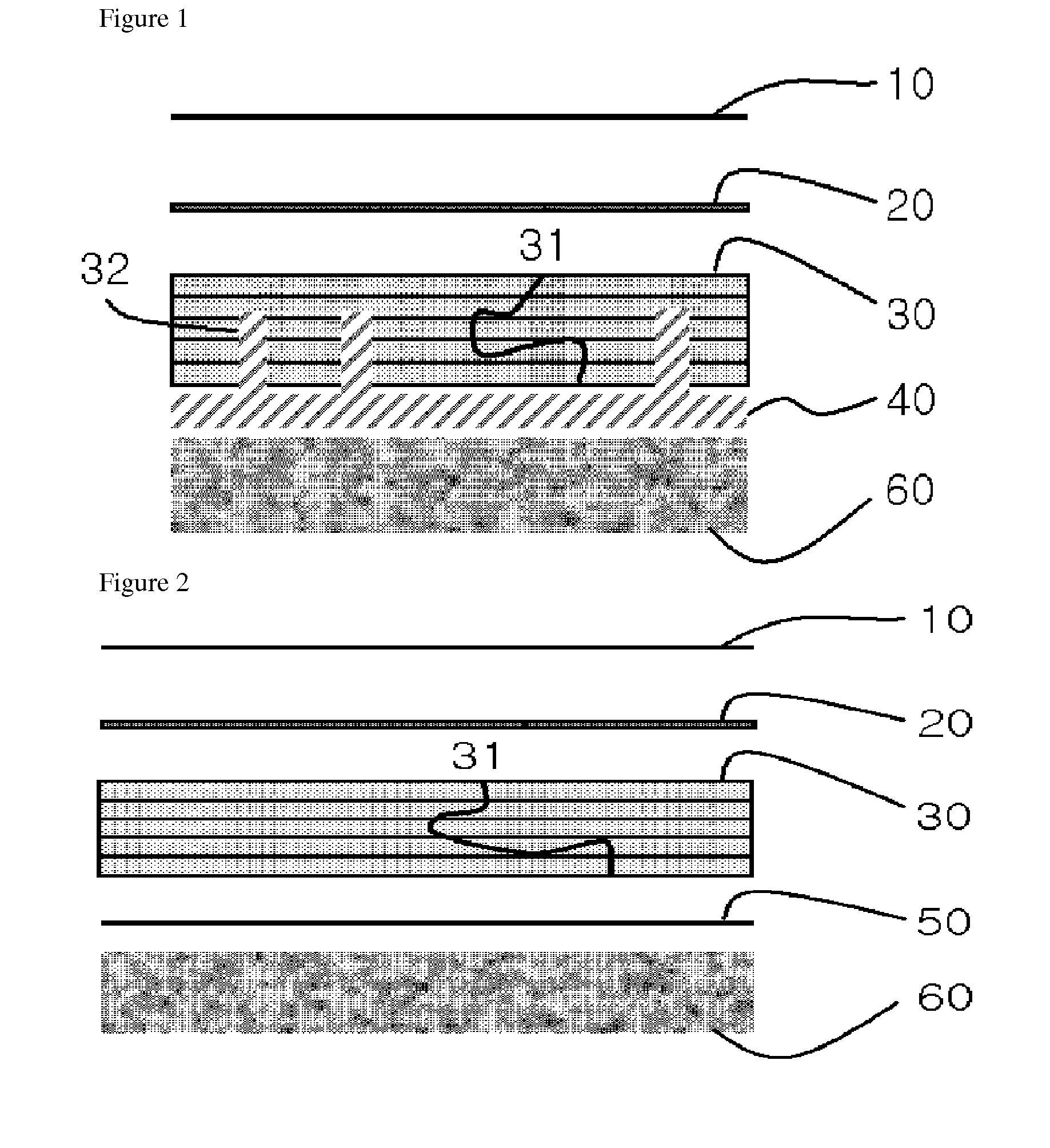

Click plywood flooring

InactiveUS8703299B2Improve surface propertiesHigh densityConstruction materialWallsSynthetic resinViscosity

A plywood flooring including a plywood as a substrate, where the plywood is heat-compressive treated in a density of 0.6 to 1.0 g / cm3 and is impregnated with a synthetic resin having a viscosity of 100 to 20,000 cp, which has both of the advantages of reinforced floorboards and the advantages of plywood floorboards.

Owner:LG HAUSYS LTD

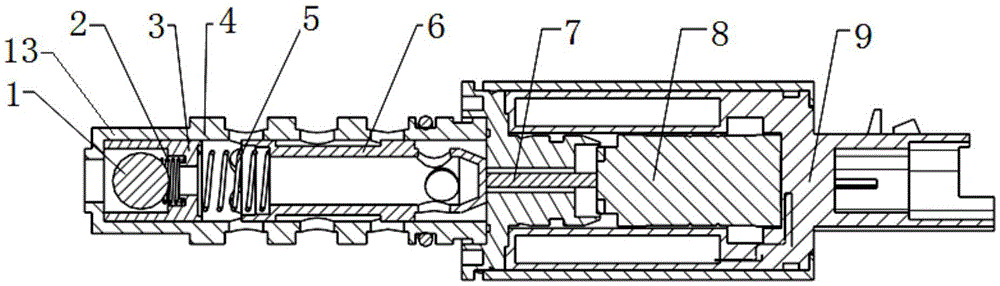

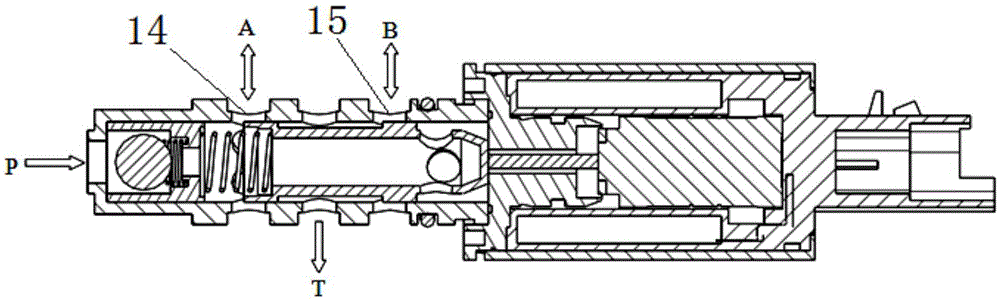

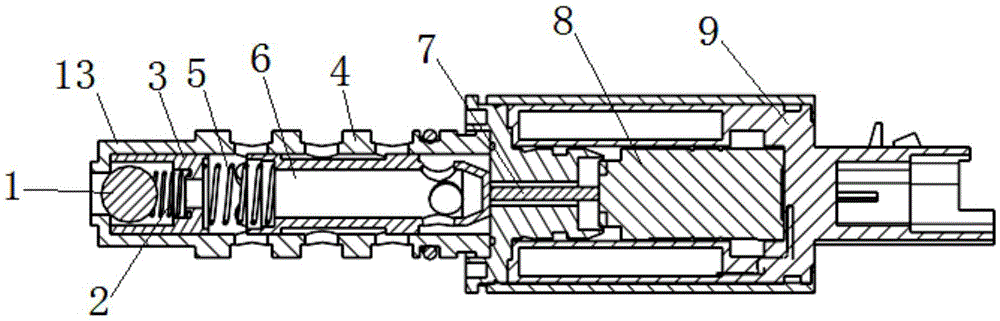

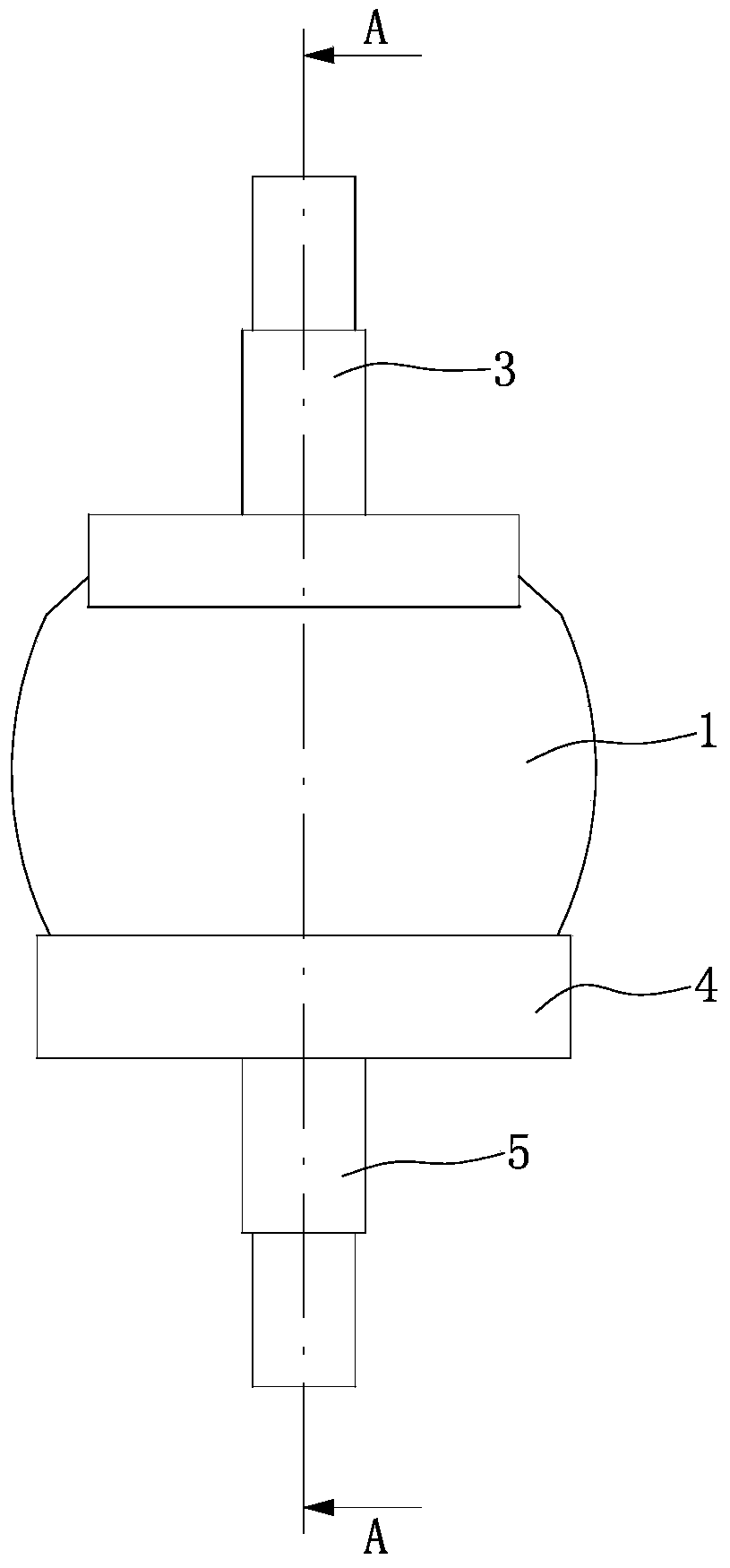

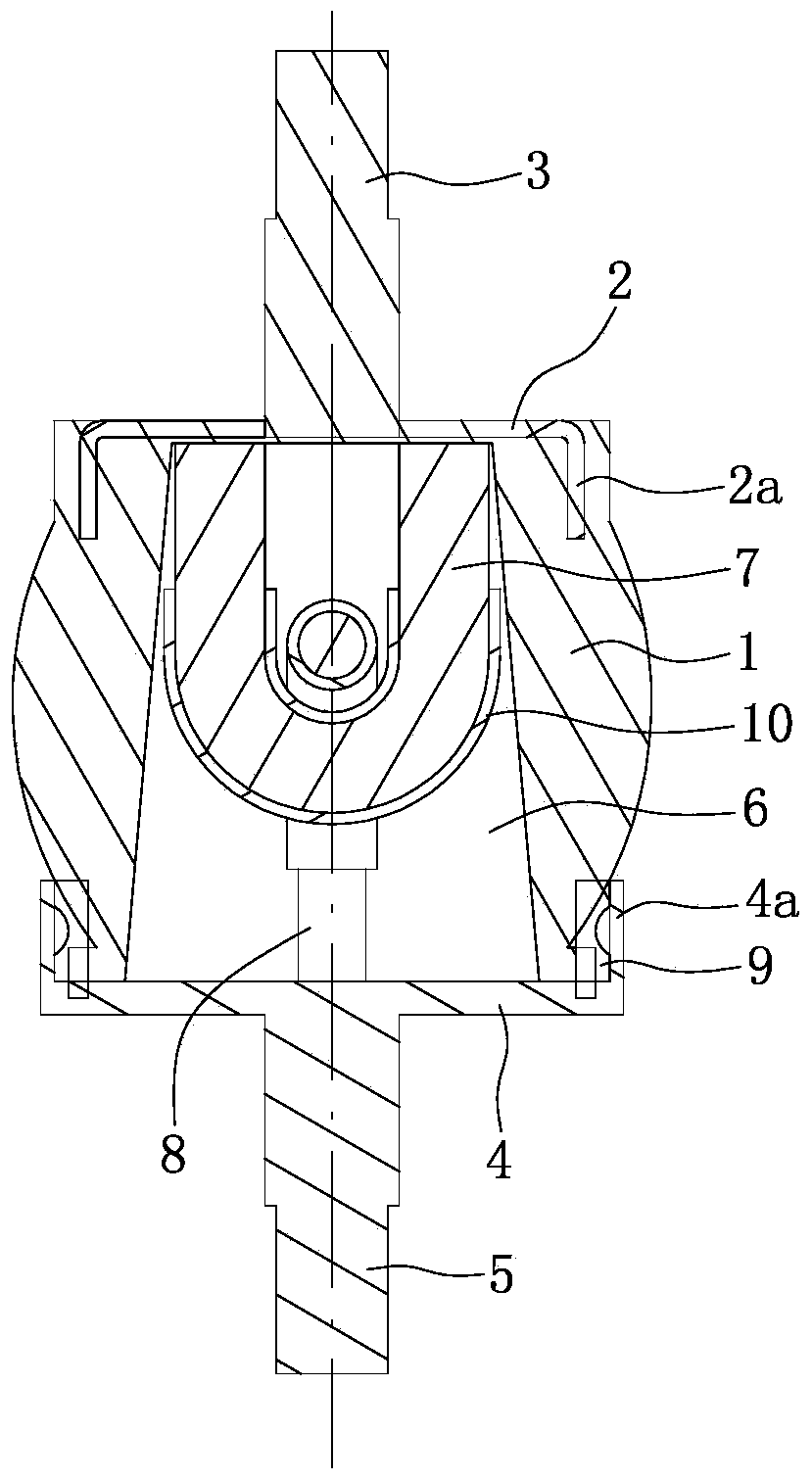

Phaser oil control valve and control method thereof

InactiveCN105484822AFast adjustmentAvoid knocking noiseValve arrangementsMachines/enginesElectric driveEngineering

The invention discloses a phaser oil control valve and a control method thereof. The control valve comprises a control valve body. A valve element spring and a valve element connected with the valve element spring are arranged in the control valve body. One end of the control valve body is connected with an electromagnetic head, and a push rod connected with the valve element and an electric drive connected with the push rod are arranged in the electromagnetic head. The other end of the control valve body extends to form a one-way valve body. A spring holder is arranged in the one-way valve body and provided with a one-way valve spring, and the one-way valve spring is connected with a one-way valve steel ball. An oil inlet communicated with the control valve body is formed in the one-way valve body. When an engine is started, a phaser is full of oil, oil pressure in the phaser can be built fast, the adjusting speed of the phaser can be increased when the engine is started, the knocking noise between a rotor and a stator is avoided, and noise risks are reduced.

Owner:CHERY AUTOMOBILE CO LTD

Shock absorber

InactiveCN104196951APlay the role of cushioning and shock absorptionImprove shock absorptionSpringsShock absorbersDrive shaftShock absorber

The invention discloses a shock absorber. The two ends of an outer rubber cover (1) are open. An upper base (2) is fixed to the upper end of the outer rubber cover (1). A lower base (4) is fixed to the lower end of the outer rubber cover (1). The two ends of the outer rubber cover (1) are sealed through the upper base (2) and the lower base (4) respectively. A closed cavity (6) is formed in the outer rubber cover (1). An upper connecting buckle (7) and a lower connecting buckle (8) which are fastened with each other are arranged in the closed cavity (6). The shock absorber is ingenious in design, simple in structure and easy to operate; the double shock absorption effect achieved through the outer rubber cover and pressure gas is good, vehicle body vibration can be effectively reduced, and riding comfort is greatly improved; meanwhile, the lateral oscillating quantity of an engine in the overload process can be reduced within 5 mm, so that a reverse gear device and a transmission shaft cross-shaped joint are effectively prevented from being damaged or a silencer is effectively prevented from being broken.

Owner:桂来强

Vane pump having vanes slanted relative to rotational axis

InactiveUS7226281B2Avoid knocking noiseInhibit wearDetection of fluid at leakage pointOscillating piston enginesRotational axisPump chamber

A vane pump is composed of a casing having a cylindrical inner bore and a rotor disposed in the inner bore with an eccentric relation to the inner bore. A circular pump chamber formed between the rotor and the inner bore is divided by vanes disposed in the rotor into plural pump chambers each changing its capacity according to rotation of the rotor. The vane is slidably disposed in a groove formed in the rotor in a slanted relation with respect to a rotational axis of the rotor. When the rotor rotates, the vane is pushed backward of the rotational direction by fluid in the pump chamber. The pushing force includes a component for pushing the vane upward toward an upper plate closing an upper opening of the inner bore. The vane is pushed against the upper plate to thereby prevent hitting noises between the vane and the upper plate.

Owner:DENSO CORP

Vibration absorber system

InactiveUS10190653B2Avoid knocking noiseReliable preventionRotating vibration suppressionFluid gearingsControl theoryDynamic Vibration Absorber

Owner:ZF FRIEDRICHSHAFEN AG

Swivel motor

InactiveUS8001884B2Avoid knocking noisePrevent the resulting destruction of the elastomer springsFlexible wall reciprocating enginesOscillating piston enginesElastomerCoil spring

A swivel motor has a plurality of work chambers and a join system between the work chambers that joins the work chambers at least by pairs. The arrangement of the joined work chambers is carried out in such a way that the work chambers which are connected to the first pressure medium connection alternate with those which are connected to the second pressure medium connection. At least two work chambers associated with different pressure medium connections are connected to a pressure compensation element, and the pressure compensation element is formed by a compensation space that is divided by a movable dividing element. A partial compensation space is connected in each instance to at least one work chamber of a pressure medium connection, and the dividing element is held in an initial position by oppositely acting springs. The spring force characteristic is formed by a spring arrangement which comprises a plurality of springs and has at least one coil spring and one elastomer spring. At least one volume compensation space is available for the elastomer spring.

Owner:ZF FRIEDRICHSHAFEN AG

Rolling rotor compressor with suction-free check valve for low backpressure

PendingCN110425136AReduce the temperatureImprove efficiencyRotary piston pumpsRotary piston liquid enginesExhaust valveEngineering

The invention discloses a rolling rotor compressor with a suction-free check valve for low backpressure. The rolling rotor compressor comprises an outer shell and a machine core, wherein the machine core is arranged inside the outer shell through a supporting piece, and the machine core comprises a motor, a crankshaft, an air cylinder assembly, a rolling rotor and a sliding block. The rolling rotor compressor is characterized in that an inner cavity of the outer shell is an air suction low-pressure end and is connected with a shell air suction pipe, an air inlet is connected with the inner cavity of the shell through an air suction silencing cavity assembly, an air outlet is connected with an inner exhaust coil assembly through an exhaust valve, and the inner exhaust coil assembly is connected with an exhaust pipe on the shell. The inner part of the shell is a low pressure cavity, so that the temperature of the motor can be reduced, so that the efficiency and the reliability of the compressor are improved, and the air suction silencing cavity and the exhaust air cylinder cover are additionally arranged, so that the noise is improved; the rolling rotor compressor is free of the airsuction check valve, so that the air suction efficiency is greatly improved, and the efficiency of the compressor can be improved. Due to the fact that the low-pressure cavity is located inside the shell, so that the rolling rotor compressor can be directly applied to a refrigerator and an ice locker with low backpressure working conditions, and the practical range is wide.

Owner:黄石东贝压缩机有限公司

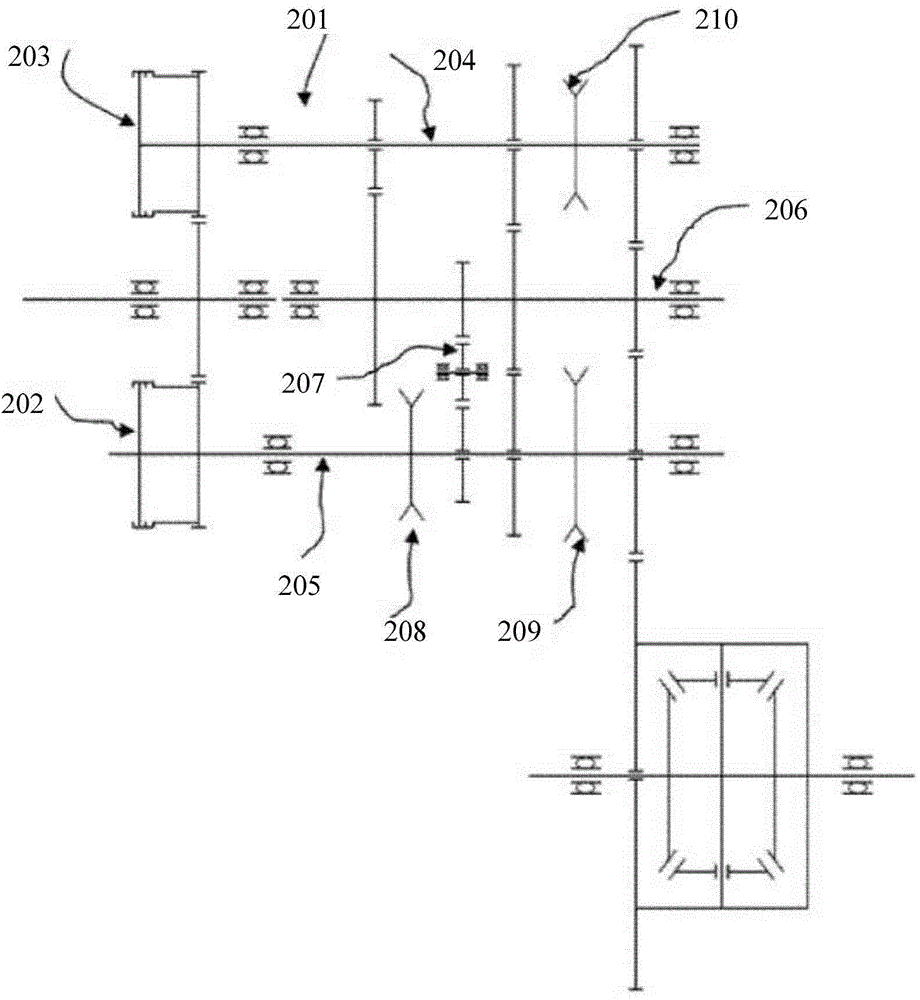

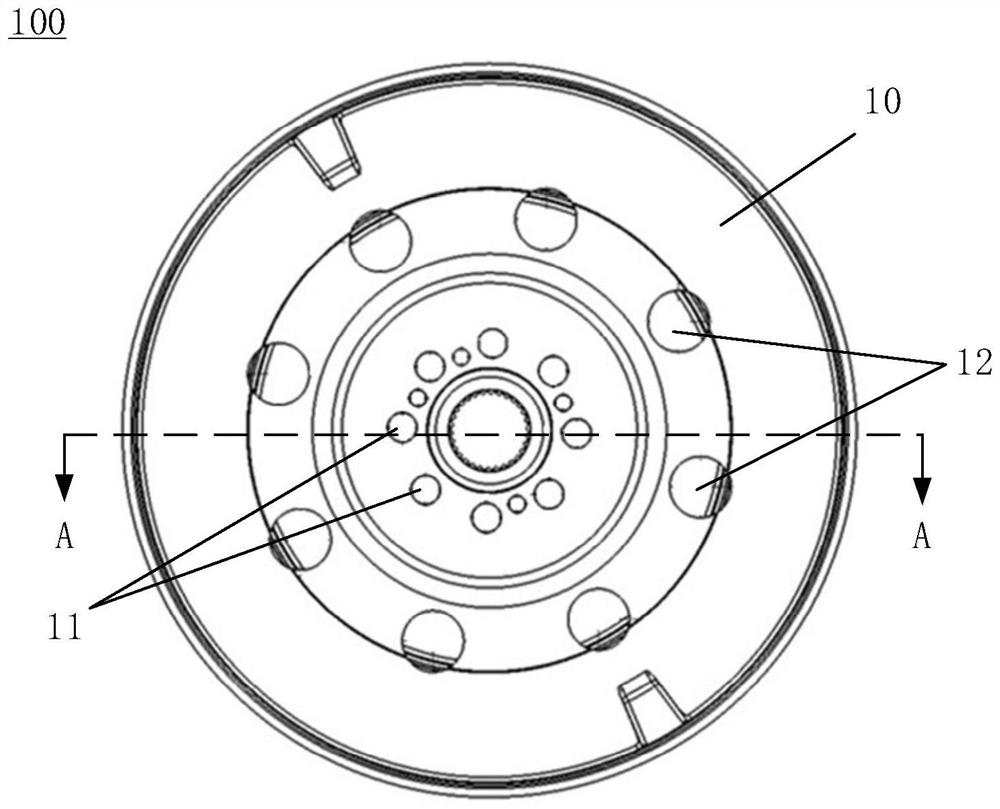

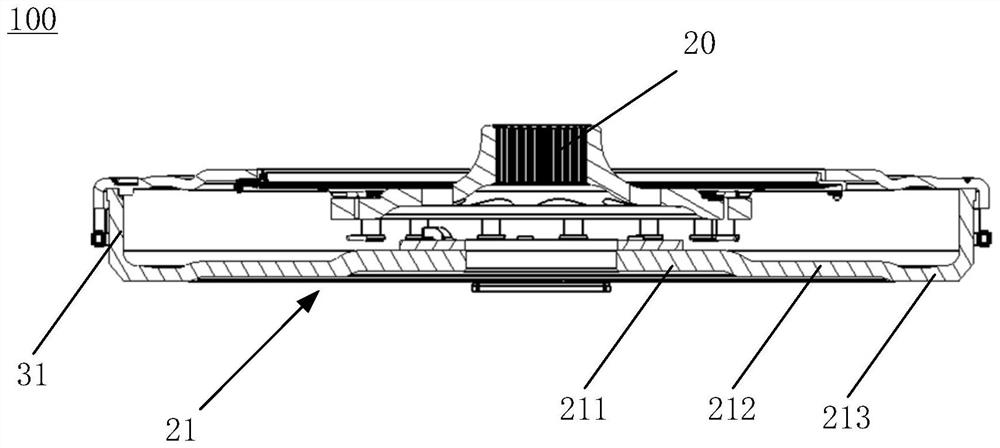

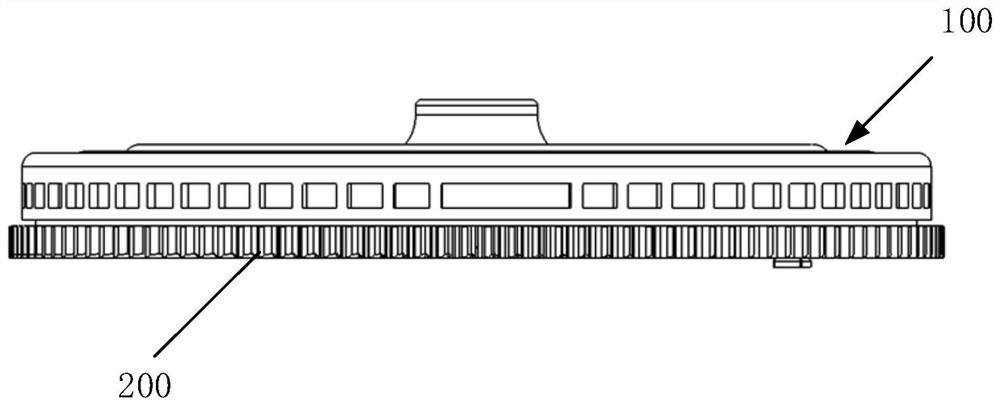

Flywheel structure of engine and engine

The invention provides a flywheel structure of an engine and the engine, and relates to the field of vehicle engines. At least one set of bolt holes used for being connected with an engine crankshaft and at least one set of through holes used for reducing the rigidity of the flywheel structure are formed in a flywheel front cover, wherein each set of bolt holes are evenly distributed in a first circular ring, each set of through holes are evenly distributed in a second circular ring, and the first circular ring and the second circular ring are concentrically arranged. Considering that the excitation of bending achieved when a crankshaft flywheel group works is not only related to combustion excitation, but also related to the rotational inertia of the flywheel structure at the rear end of the engine, the rigidity of the flywheel structure is reduced by forming the through holes, and therefore the inertia of the flywheel structure is reduced, and the frequency of the flywheel structure is changed. Therefore, the inherent frequency of the flywheel structure is kept away from the frequency of a power assembly and a whole vehicle suspension, and knocking noise generated in a vehicle is avoided.

Owner:ZHEJIANG GEELY HLDG GRP CO LTD +3

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com