Shock absorber

A shock absorber and rubber technology, applied in the field of shock absorption, can solve the problems that affect the appearance of the three-wheeled motorcycle, cannot resist the left and right swing of the engine, and the left and right swing of the engine is large, and achieves good effects, ingenious design, and production. Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

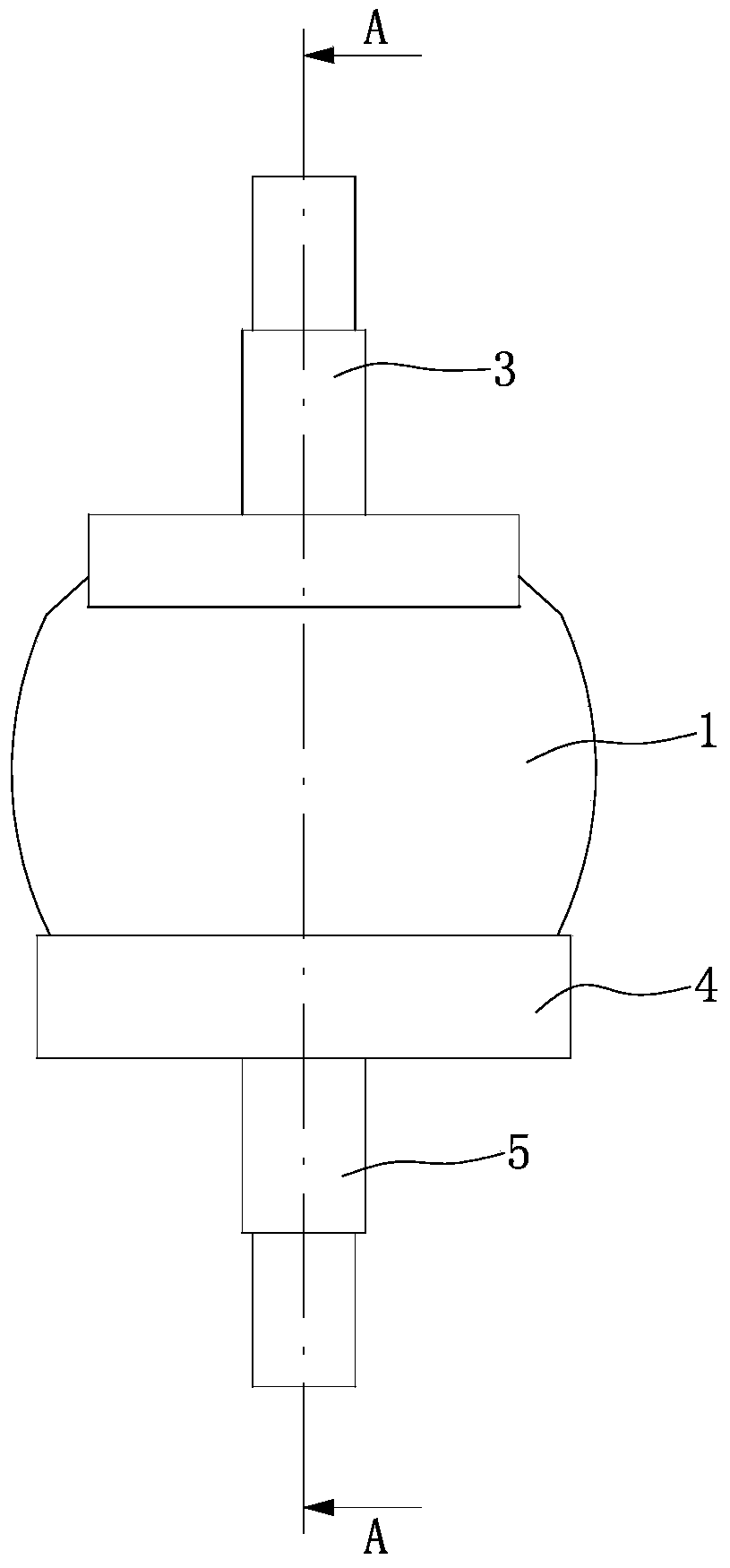

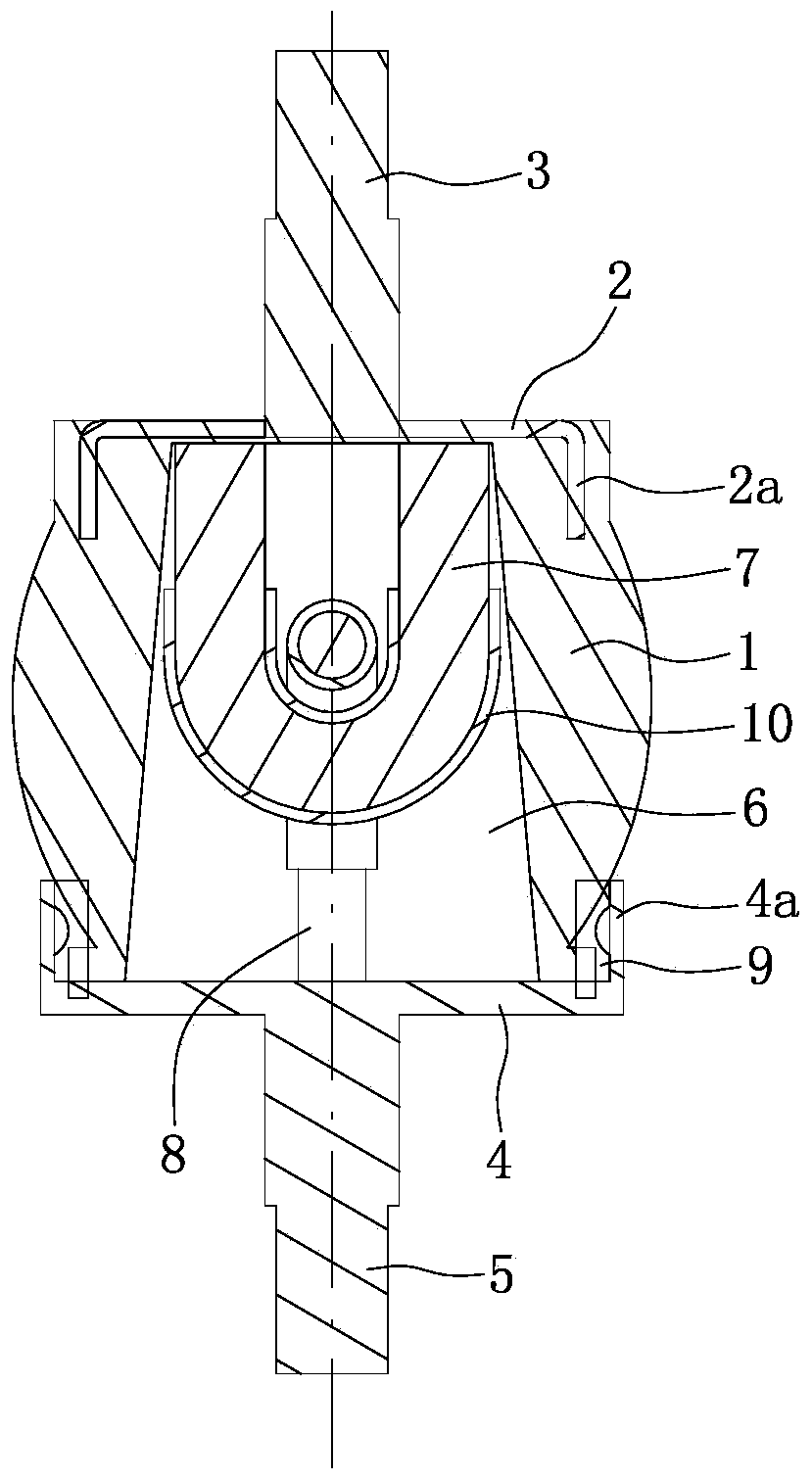

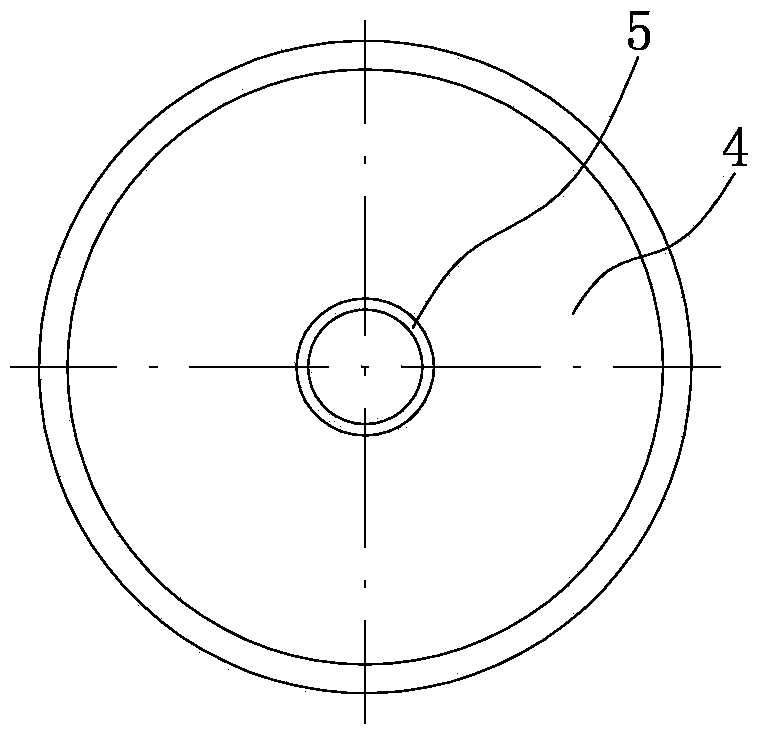

[0024] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the present embodiment is made of rubber cover 1, upper base 2, upper screw rod 3, lower base 4, lower screw rod 5, upper connecting buckle 7, lower connecting buckle 8, metal inlaid ring 9 and rubber sleeve 10, etc. Wherein, the rubber cover 1 has holes along the axis line, and the upper and lower ends of the rubber cover 1 are open. An upper base 2 is arranged on the upper end of the rubber cover 1, and the upper base 2 is circular, and is fixed with the rubber cover 1 through vulcanization molding. The edge of the upper base 2 is flanged downwards to form an upper skirt 2a, and the upper skirt 2a is wrapped in the rubber outer cover 1 . The upper screw rod 3 is arranged at the central position of the upper base 2, and the upper screw rod 3 is perpendicular to the upper base 2, and the lower end of the upper screw rod 3 is fixed with the upper base 2. The upper base 2 seals the upper port of the rubber...

Embodiment 2

[0031] In this embodiment, the airtight chamber 6 is provided with air whose pressure is equal to that of the external atmosphere. The rest of the structure of this embodiment is the same as that of Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com