Rolling rotor compressor with suction-free check valve for low backpressure

A rolling rotor type and rolling rotor technology, applied in the direction of rotary piston machinery, machine/engine, rotary piston pump, etc., can solve the problems of reduced compressor efficiency, large compressor vibration, and reduced reliability, and achieve noise improvement , Reduce vibration noise and prevent metal impact noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

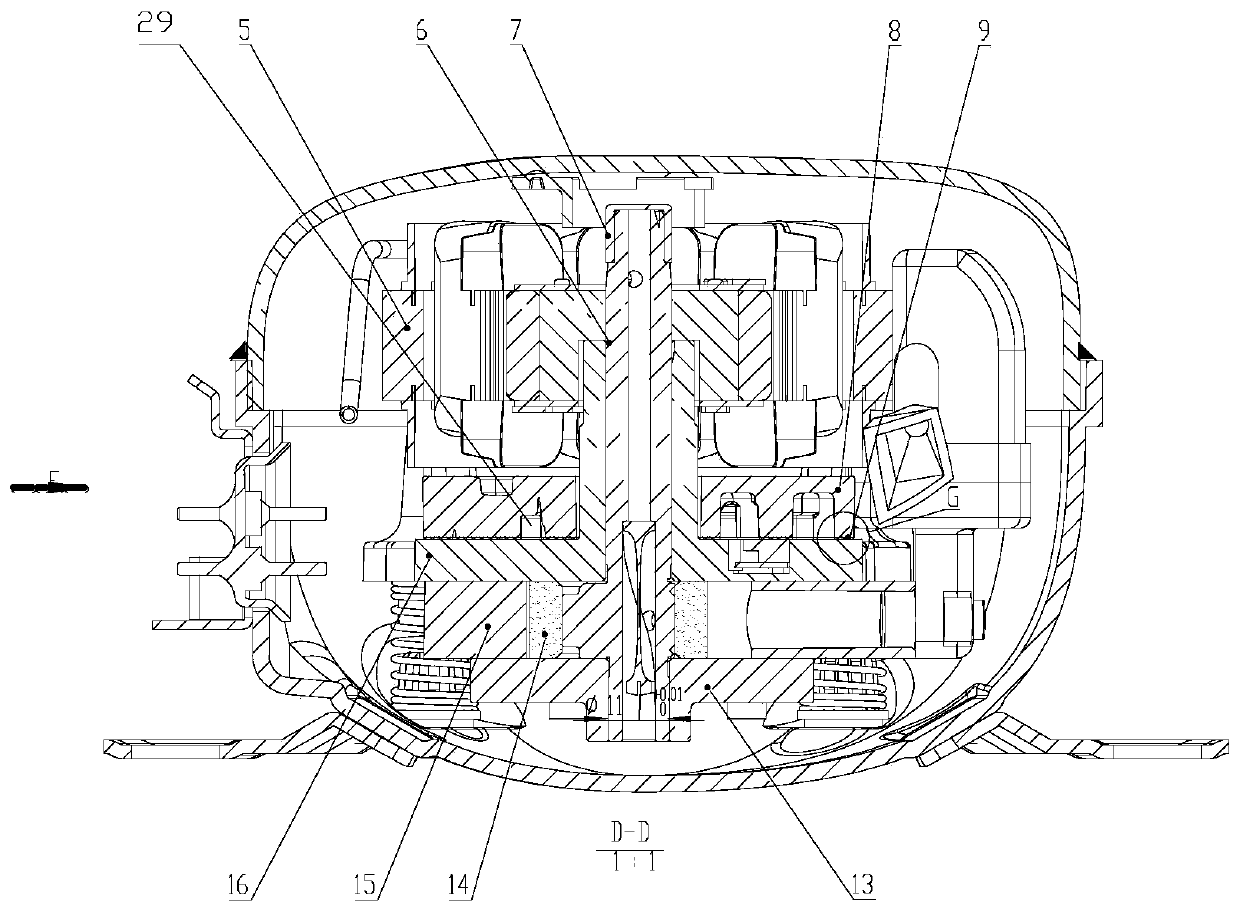

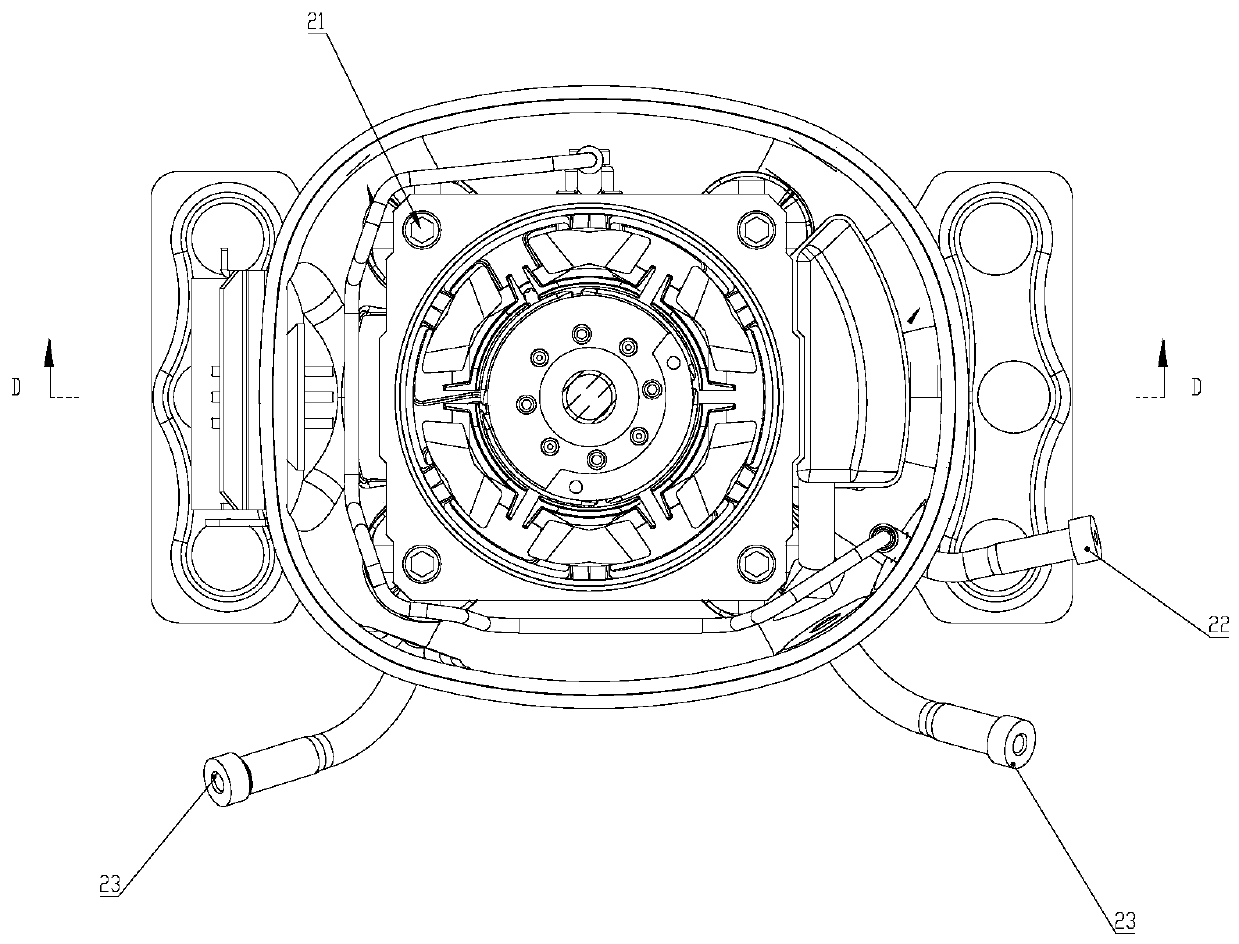

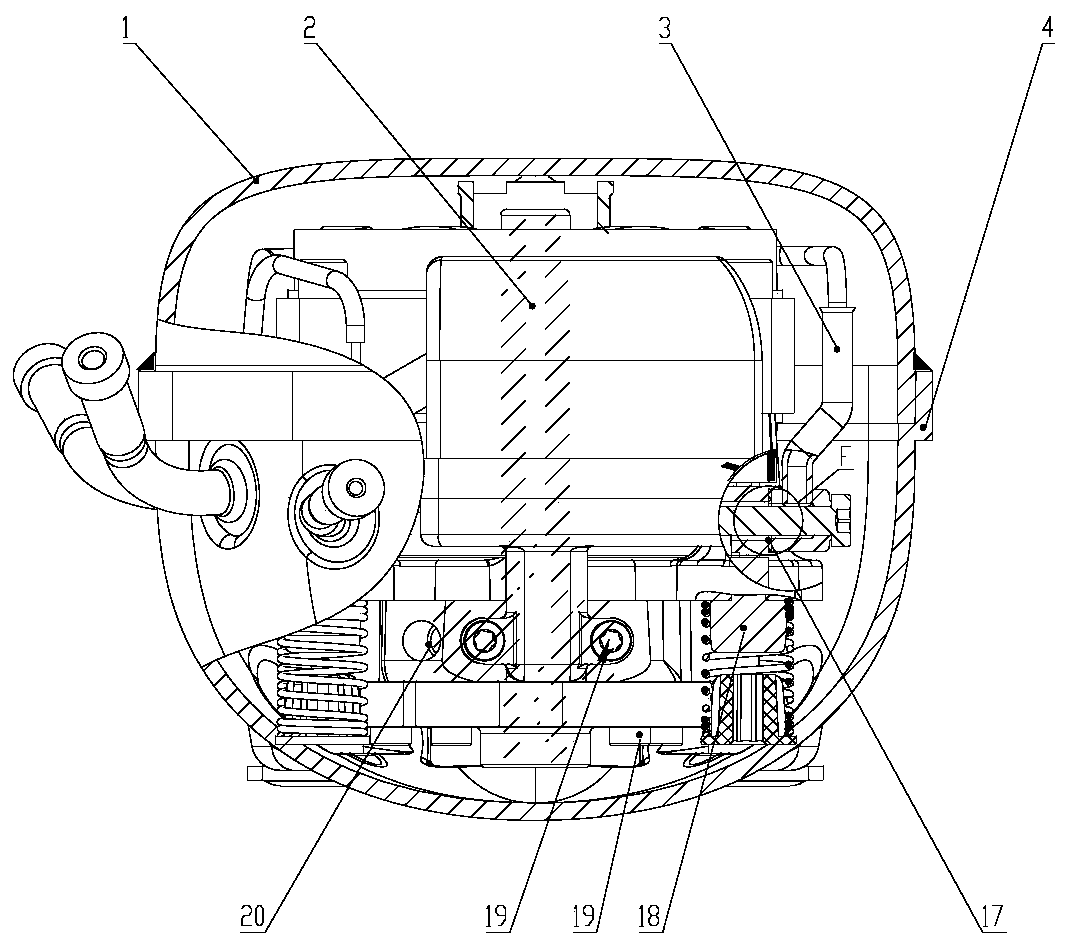

[0041] The present invention will be further described below in conjunction with the drawings.

[0042] Such as Figure 1-4 As shown, this embodiment provides a low back pressure rolling rotor compressor without suction check valve, which includes an outer casing and a movement. The movement is placed in the casing through a support, and the movement It includes a motor 5, a crankshaft 6, a cylinder assembly, a rolling rotor 14, and a slider 24. One end of the crankshaft 6 is matched with the motor, and the other end is connected with the rolling rotor 14. The motor 5 drives the crankshaft 6 to rotate, and the crankshaft 6 drives the rolling 14 rotor to operate. The cylinder assembly and the rolling rotor 14 enclose a closed cavity, The position of the sealed cavity changes with the rotation of the rolling rotor 14. The sliding block 24 divides the sealed cavity into a low pressure cavity and a high pressure cavity. The cylinder assembly is provided with an air inlet and an exhau...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com