Disc brake equipped with a floating caliper and several outer brake pads directly supported on the brake anchor plate

A technology of brake calipers and brakes, which is applied in the direction of brake components, brake types, axial brakes, etc., and can solve complex and high-weight problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

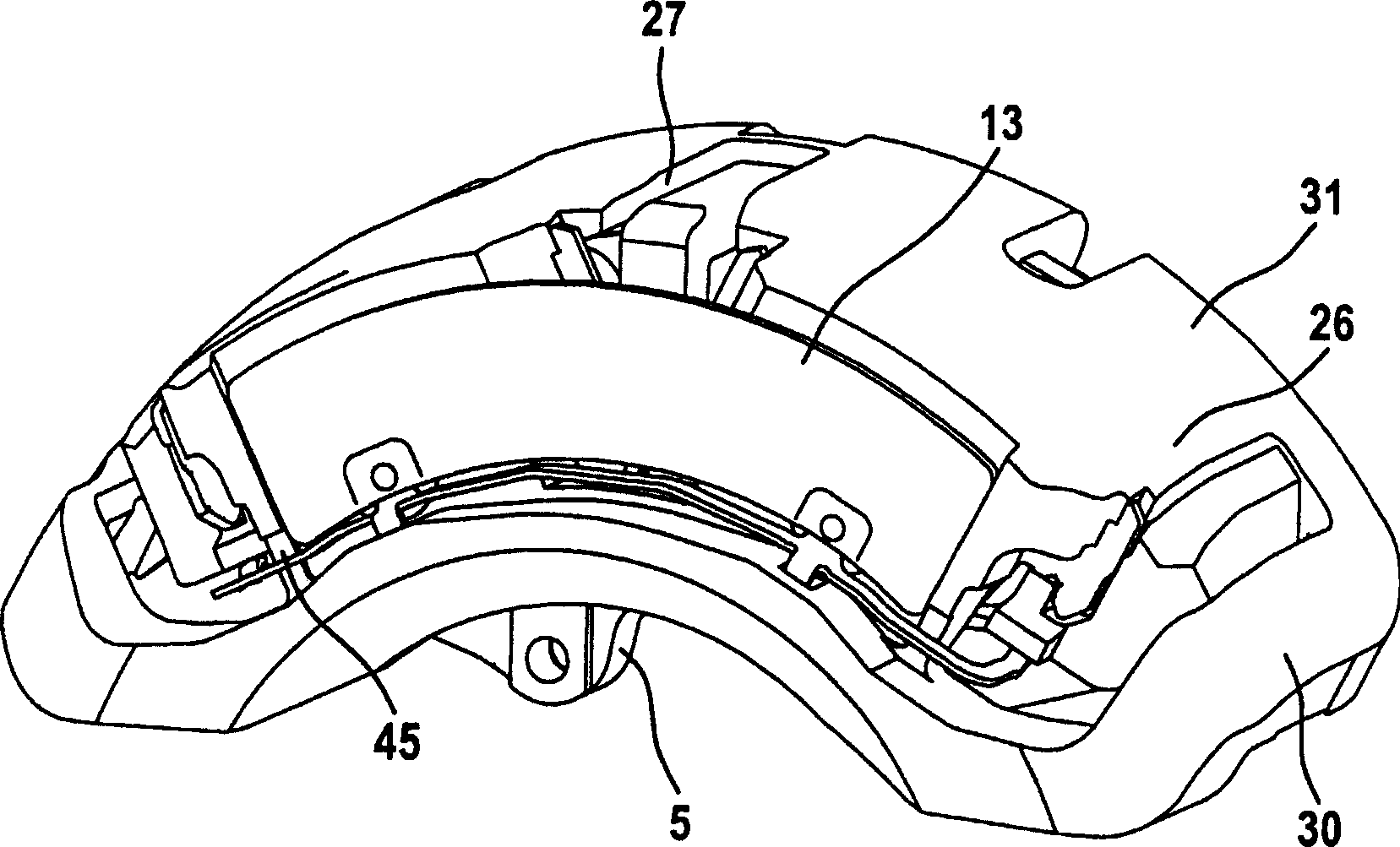

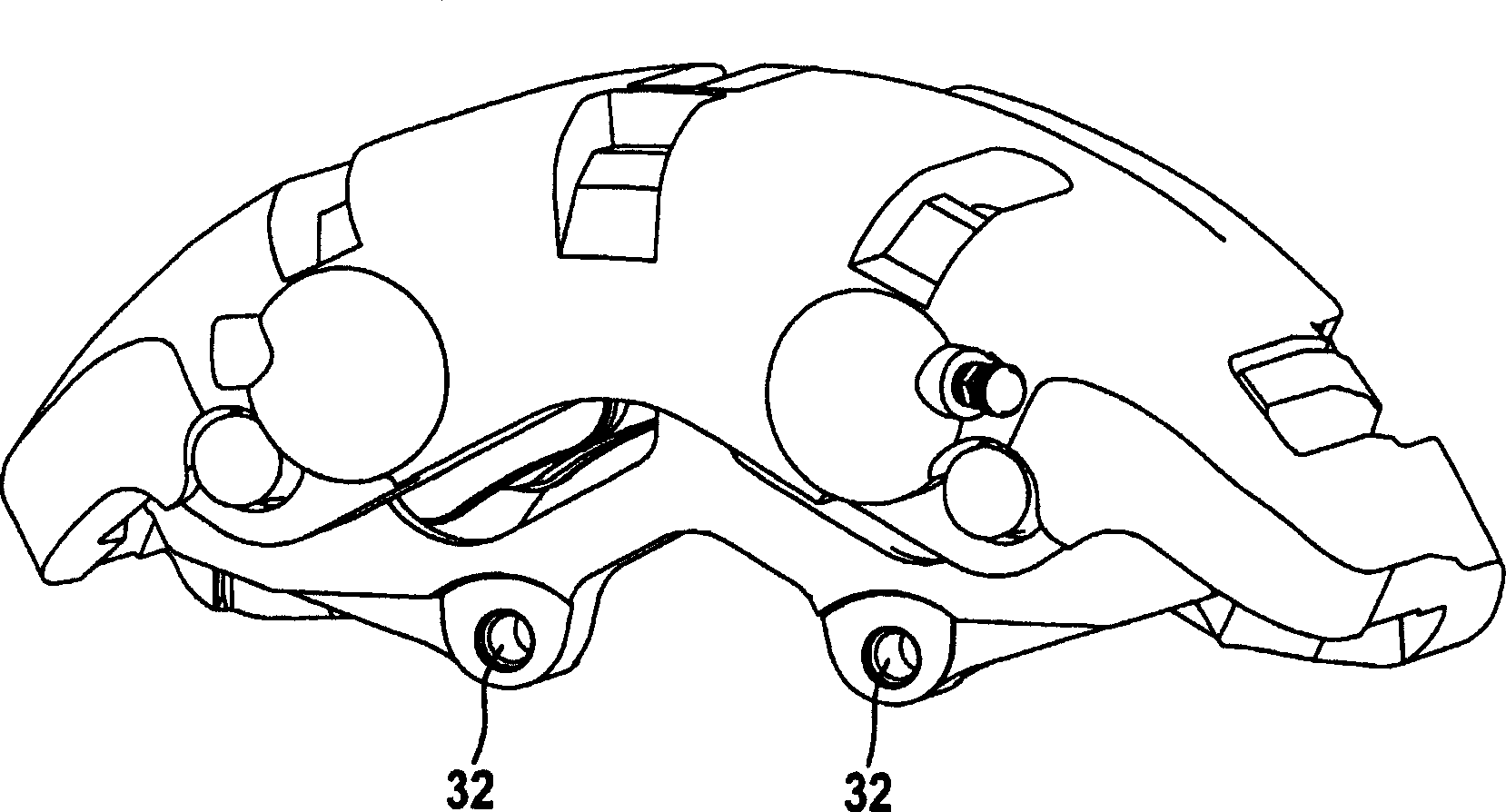

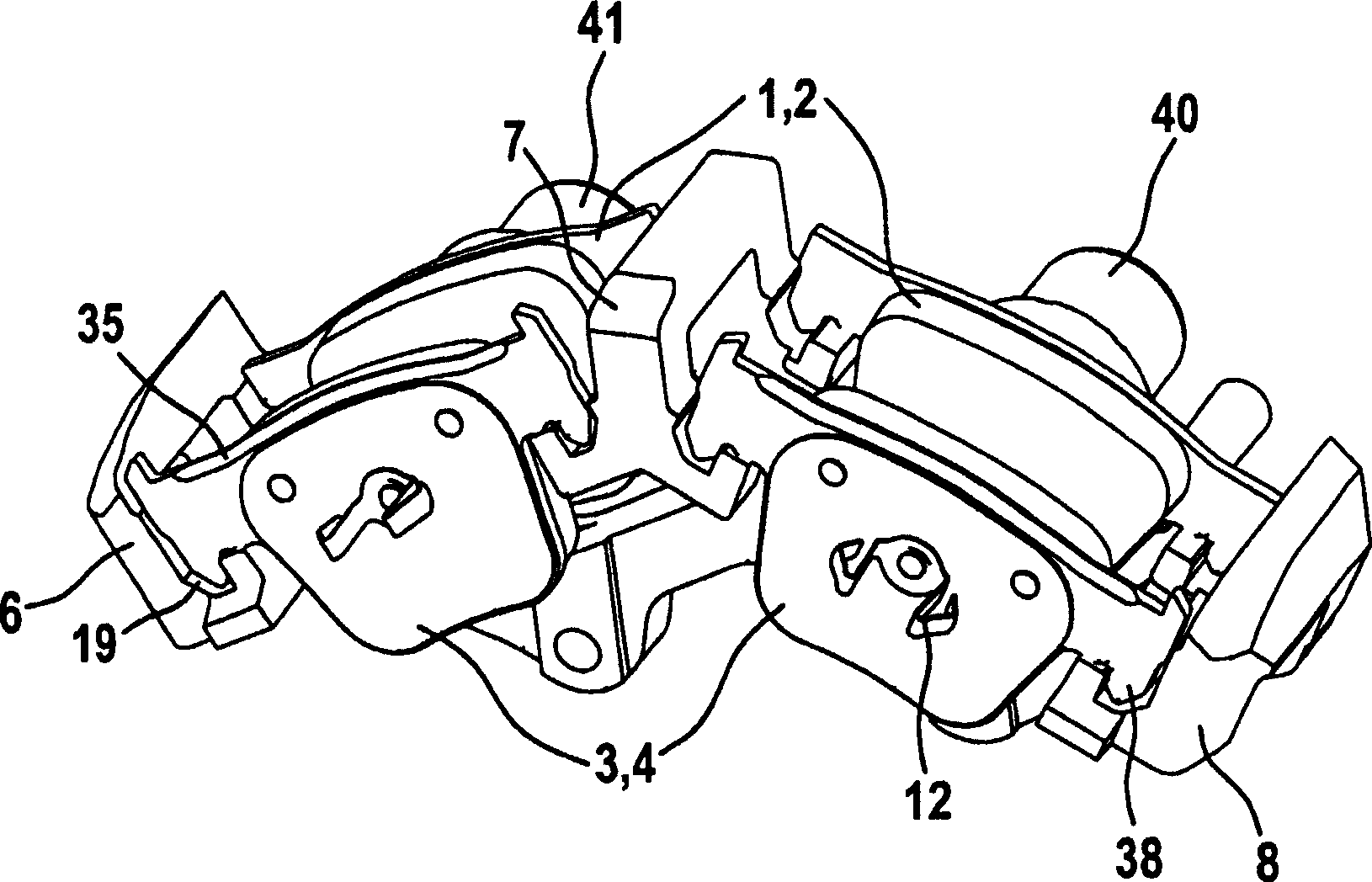

[0051]FIG. 1 shows a fist brake caliper 31 provided with a frame 30 and guided displaceably on a support 5 . The brake carrier 5 can be fastened to a steering knuckle of a vehicle by means of fastening holes 32 . Guide pins 33 , 34 on the carrier 5 serve to guide the brake caliper 31 on the carrier 5 , wherein the brake caliper 30 can additionally also be supported on a rear plate 35 of the outer brake pads 3 , 4 . The carrier arms 6 , 7 and 8 of the carrier 5 projecting axially from the fastening plate 36 are substantially U-shaped and act astride a brake disc, not shown. The arms 6 , 7 , 8 have at the free ends of their respective branches a groove 19 (referred to several times below as a broached formation) against which the radially downwardly directed hooks 38 of the brake pads 1 to 4 act. Inside. The tension and also the pressure exerted by the brake pads 1 to 4 can thus be transmitted to the corresponding walls of the groove 19 (this so-called compression / tension prin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com