High-efficiency axial flow synchronous draining pump

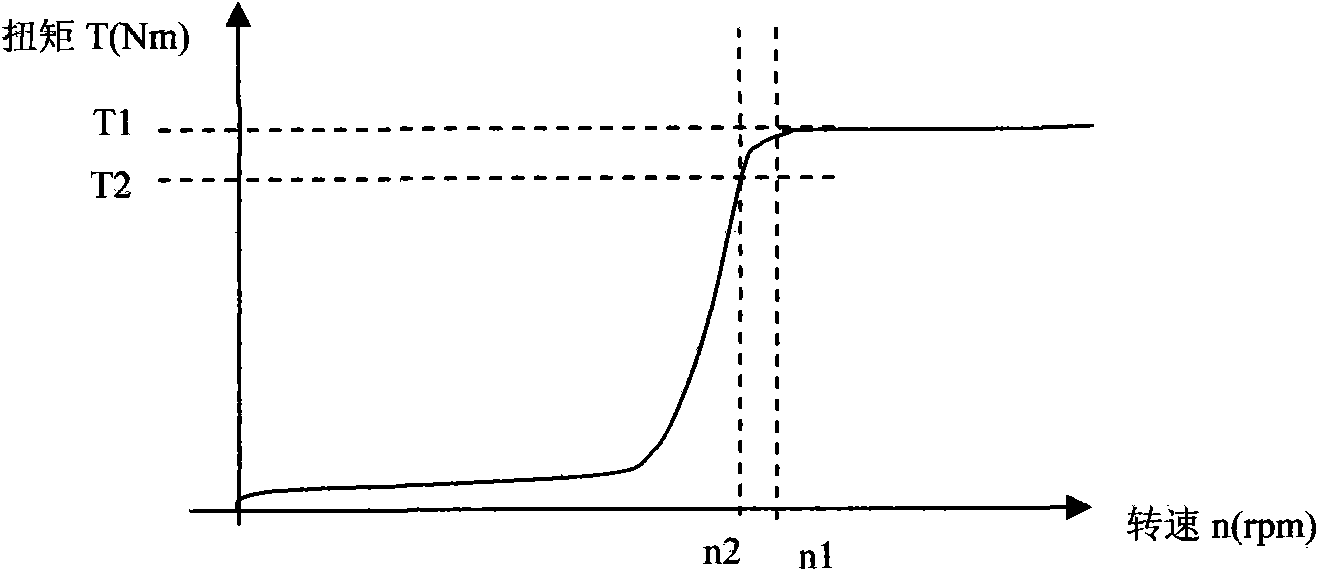

An axial flow, drainage pump technology, applied in the field of synchronous water pump and axial flow synchronous pump on household appliances and other similar products, can solve the problems of low efficiency of centrifugal impeller, loss of pump efficiency, complicated manufacturing process, etc., to improve reliability performance and service life, increased head and displacement, and ease of design and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0071] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

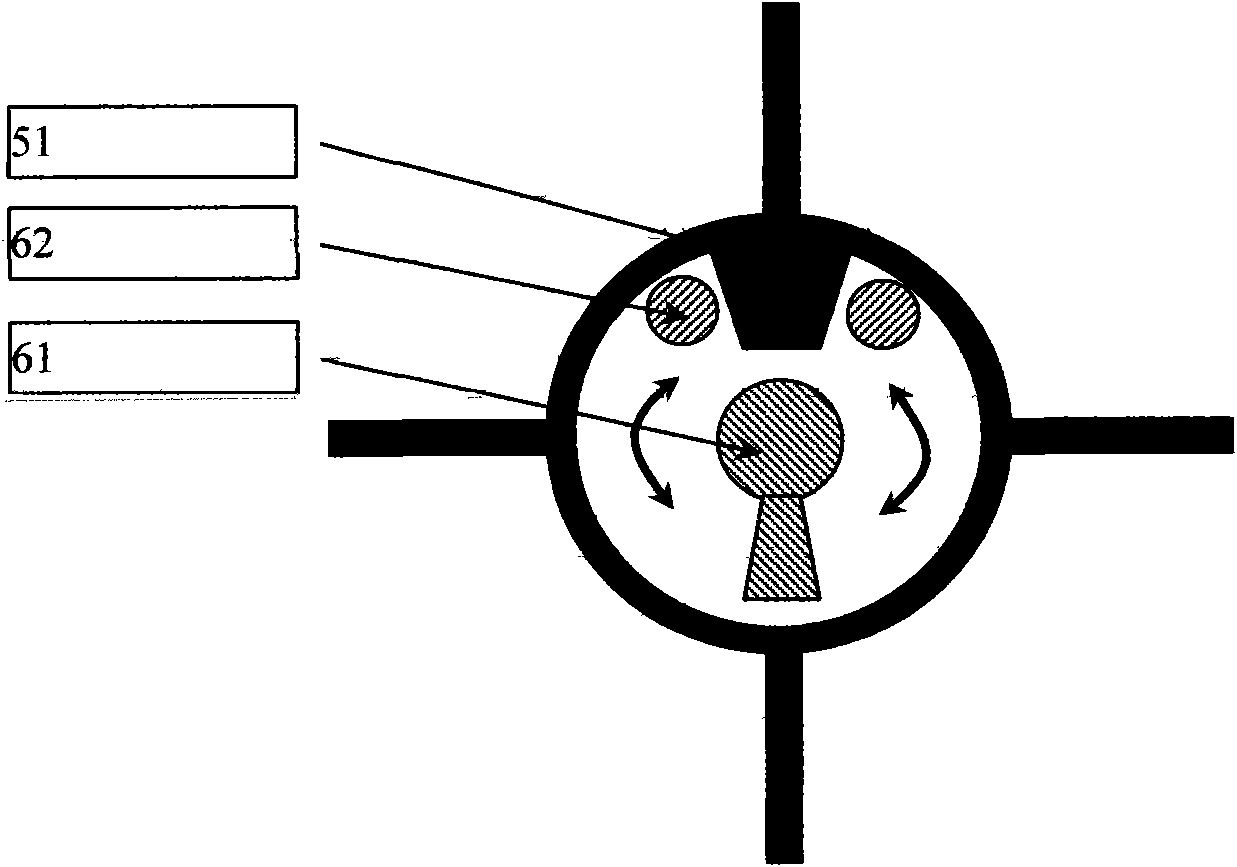

[0072] The first structural type of high-efficiency axial-flow synchronous water pump is a special-shaped cam drive structure. Examples of this structure are as follows:

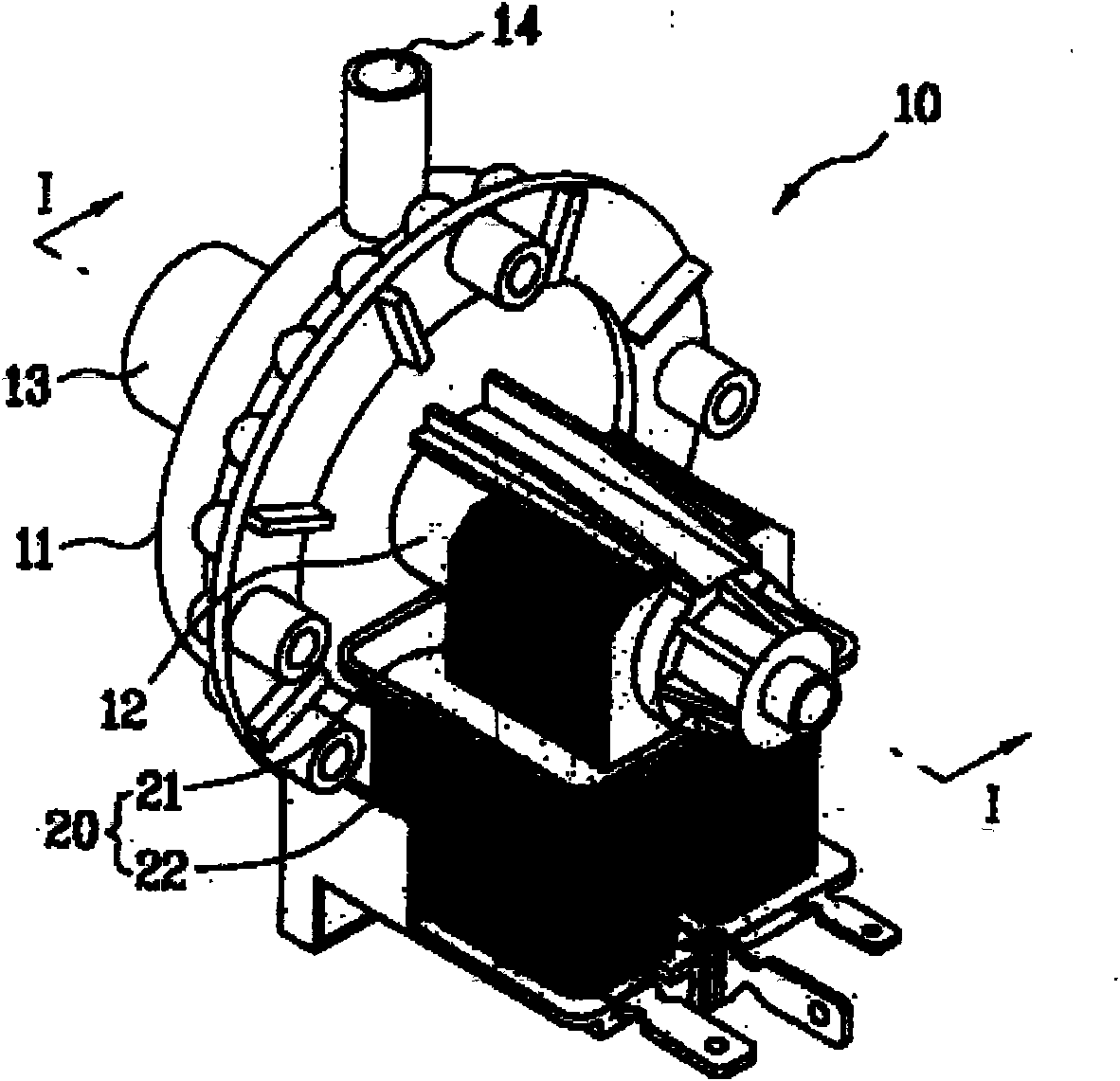

[0073] exist Figure 7 , Figure 8 , Figure 9 and Figure 10 In the shown embodiment of the high-efficiency synchronous axial flow water pump according to the present invention, when viewed from the water inlet 231 toward the inside of the water pump, the impeller 310 must rotate counterclockwise to pump water toward the water outlet 211 . The water pump consists of the following parts: a stator assembly 200 and a rotor assembly 300 . The stator assembly 300 includes a water pump lower cover 210 and a water pump upper cover 230, which together provide support and shell insulation protection for the stator core 240, wire package 260 and wire package sheath 250 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com