Synchronous draining pump capable of realizing unidirectional draining

A drainage pump, one-way technology, applied in the direction of radial flow pumps, pumps, non-variable pumps, etc., can solve the problems of noise pump failure, poor start, high impact frequency, etc., to increase the idling angle and avoid boss breakage problem effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

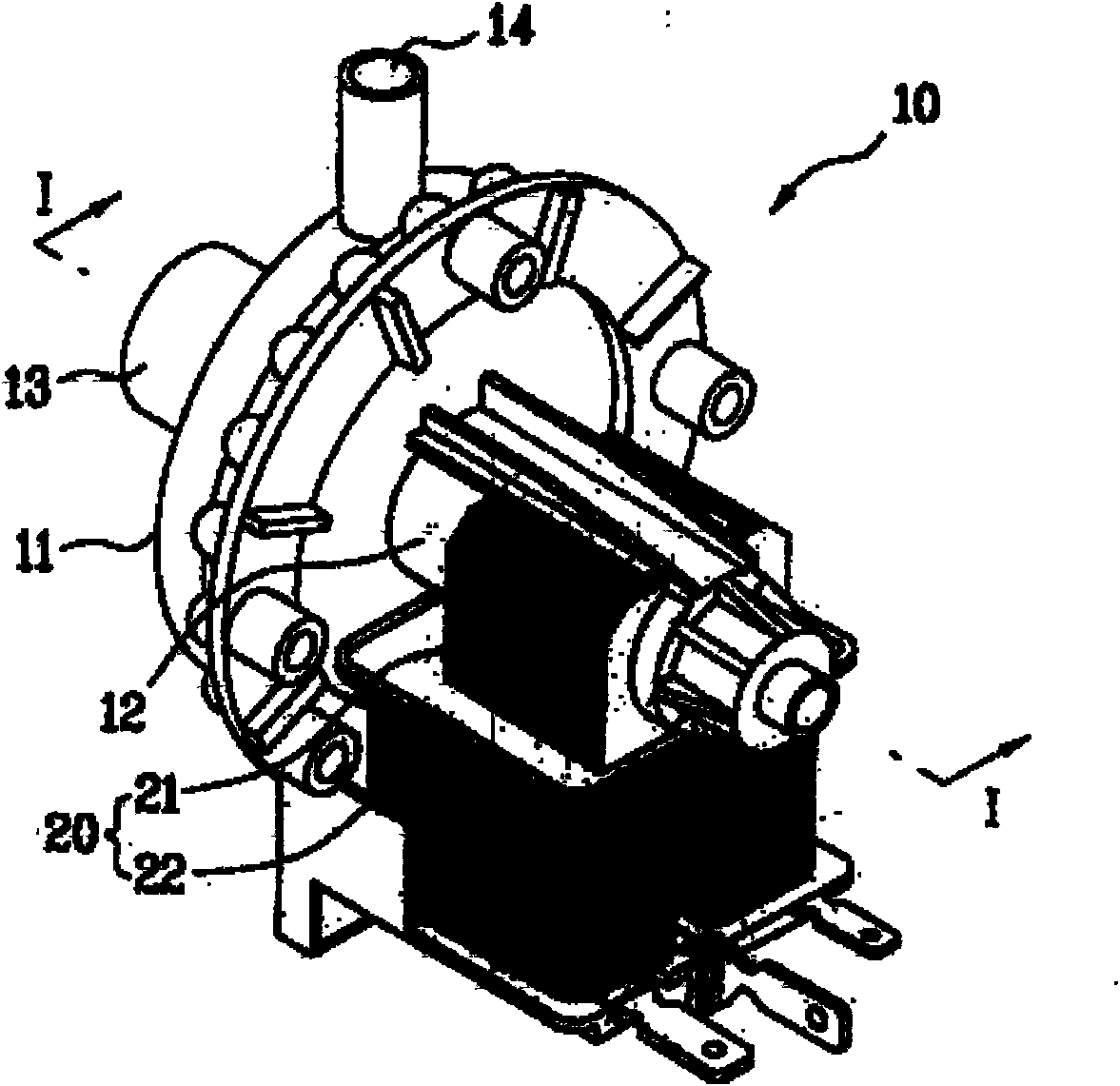

[0048] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0049] exist Figure 7 The shown embodiment of the one-way synchronous water pump according to the present invention includes the following components: a stator assembly 200 , a rotor assembly 300 , and a pump body assembly 400 . Among them, the stator assembly 200 includes parts such as a lower bearing 210 for supporting the rotor assembly 200, a motor cover 220, and an unmarked stator core, a wire package, and a terminal that provide an exciting alternating magnetic field; the rotor assembly 300 includes a permanent magnet rotor 310, a motor Shaft 320, impeller upper retaining ring 330, closed one-way impeller 340 and impeller lower retaining ring 350 and other parts; pump body assembly 400 includes water pump body 410, water retaining ring 420, water pump back cover 430 and other parts.

[0050] First, when the water pump is energ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com