A kind of flexible anti-backlash gear with easy controllable stiffness

A gear and flexible technology, applied in the direction of belts/chains/gears, components with teeth, portable lifting devices, etc., can solve the problem of gear pair bearing capacity and working life reduction, the normal contact pressure is difficult to be effectively guaranteed, and the use of space Range limitation and other issues, to achieve the effect of eliminating tooth backlash, overcoming normal contact pressure, and eliminating impact noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] This embodiment 1 designs a flexible anti-backlash gear whose stiffness is easy to control. The specific structure is as follows.

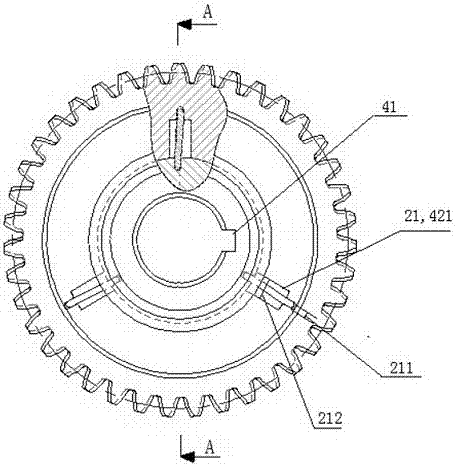

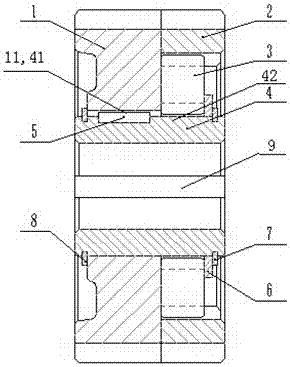

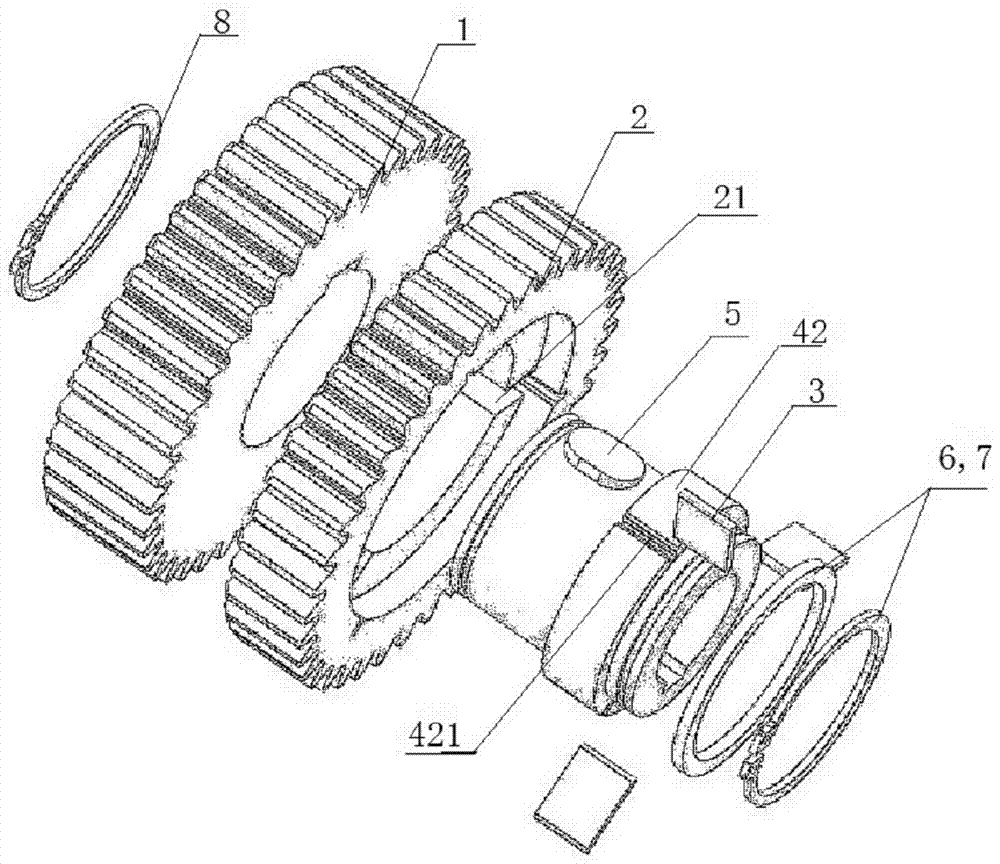

[0025] Such as figure 1 , 2 As shown in and 3, a kind of flexible anti-backlash gear whose stiffness is easy to control in this embodiment 1 includes a first misalignment gear 1 and a second misalignment gear 2 that are fitted and connected along the axial direction of the transmission shaft 9, and the first misalignment gear 1 A shaft sleeve 4 is also connected between the second misaligned gear 2 and the transmission shaft 9; the paired key grooves 41, 11 at the connection position between the shaft sleeve 4 and the first misaligned gear 1, and a key 5 is connected between the paired key grooves 41, 11 The connecting part of the shaft sleeve 4 and the second misaligned gear 2 is also provided with a boss 42, and the corresponding position of the boss 42 and the second misaligned gear 2 outside it is provided with at least a pair of pair...

Embodiment 2

[0030] Such as Figure 4 and Figure 5 As shown, the difference between the flexible anti-backlash gear with easy-to-control stiffness in embodiment 2 and the flexible anti-backlash gear with easy-to-control stiffness in embodiment 1 is that the second misalignment gear is the first misalignment gear, the leaf spring and the The axial fixed connection arrangement between the shaft sleeves, that is, the arrangement positions of the adjusting gasket and the second side elastic ring are different, and the structure of the boss of the shaft sleeve is different.

[0031] In this embodiment, the boss on the shaft sleeve is stepped, and the diameter of the end is larger, so as to position the second misaligned gear in the axial direction; the second side circlip is installed in the circlip groove in the spoke of the second misaligned gear In order to fix the leaf spring axially.

[0032] The flexible anti-backlash gear with easy-to-control stiffness in this embodiment has the same ...

Embodiment 3

[0034] Such as Figure 6 and Figure 7 The flexible anti-backlash gear with easy-to-control stiffness in Example 3 differs from the flexible anti-backlash gear with easy-to-control stiffness in Example 1 and Example 2 in that the structures of the second misalignment gear and the bushing are slightly different. , in this embodiment, the second misalignment gear is symmetrical to the left and right along the axial direction, and the sleeve is slightly longer.

[0035] In this embodiment, the second misalignment gear is symmetrical to the left and right along the axial direction, the shaft sleeve is slightly longer but the structure remains the same, so as to leave the hook groove of the circlip, and the assembly method is the same as that of Embodiment 1.

[0036] In the flexible anti-backlash gear with easy-to-control stiffness in this embodiment, the second misalignment gear can adjust the assembly direction so as to meet the requirement for flexible anti-backlash in another...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com