Pressing block of linear guide shaft

A technology of linear guide and compression block, which is applied in the direction of linear motion bearings, rigid supports of bearing components, bearings, etc., and can solve the problems of surface roughness of the outer diameter of easily damaged linear bearings, excessive energy consumption, and increased inner diameter clearance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Specific embodiments of the present invention will be further described in detail below. It should be understood that the description of the embodiments of the present invention here is not intended to limit the protection scope of the present invention.

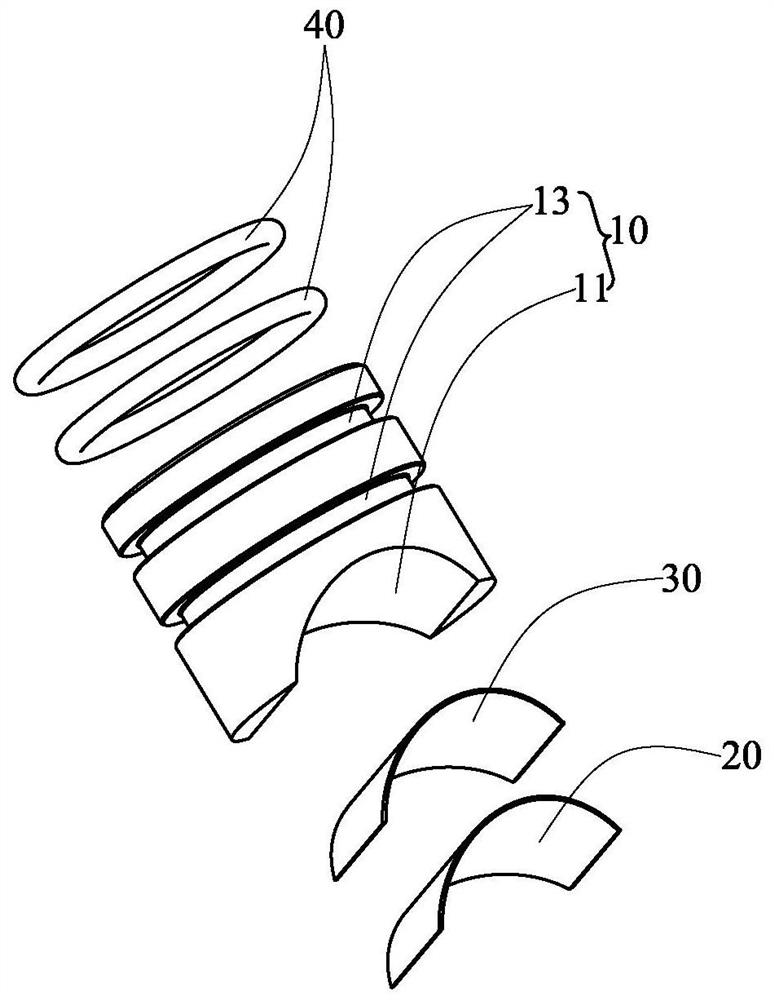

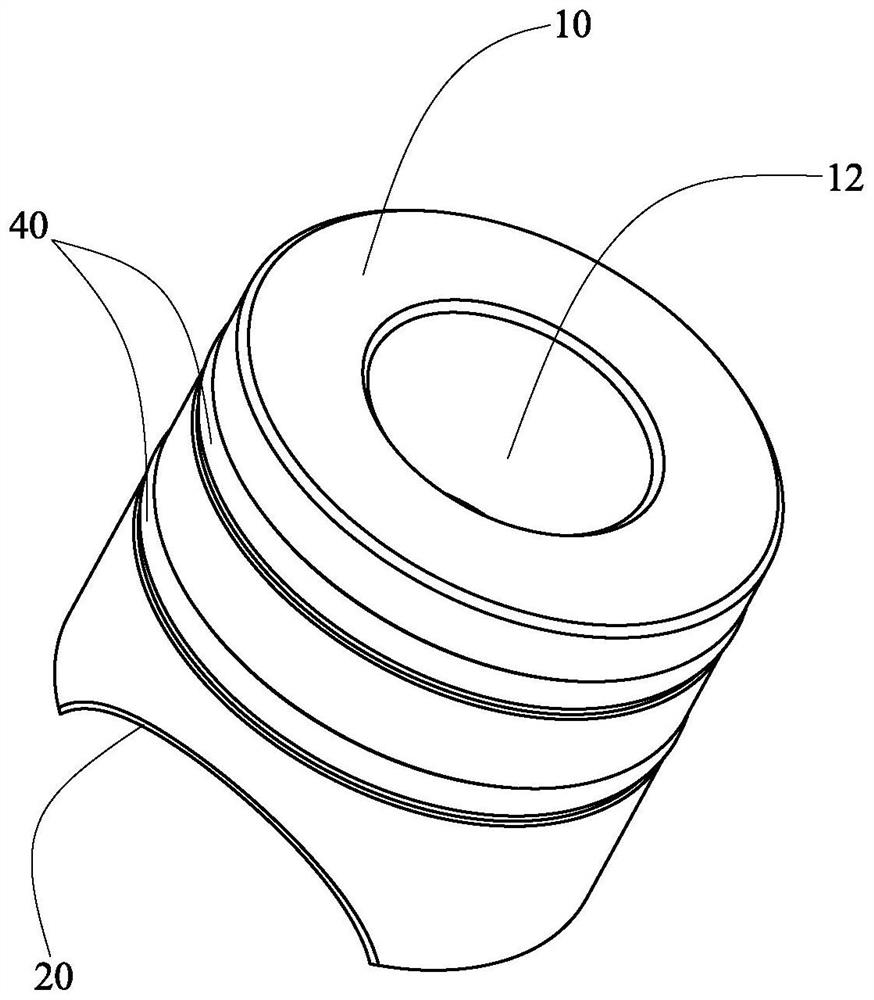

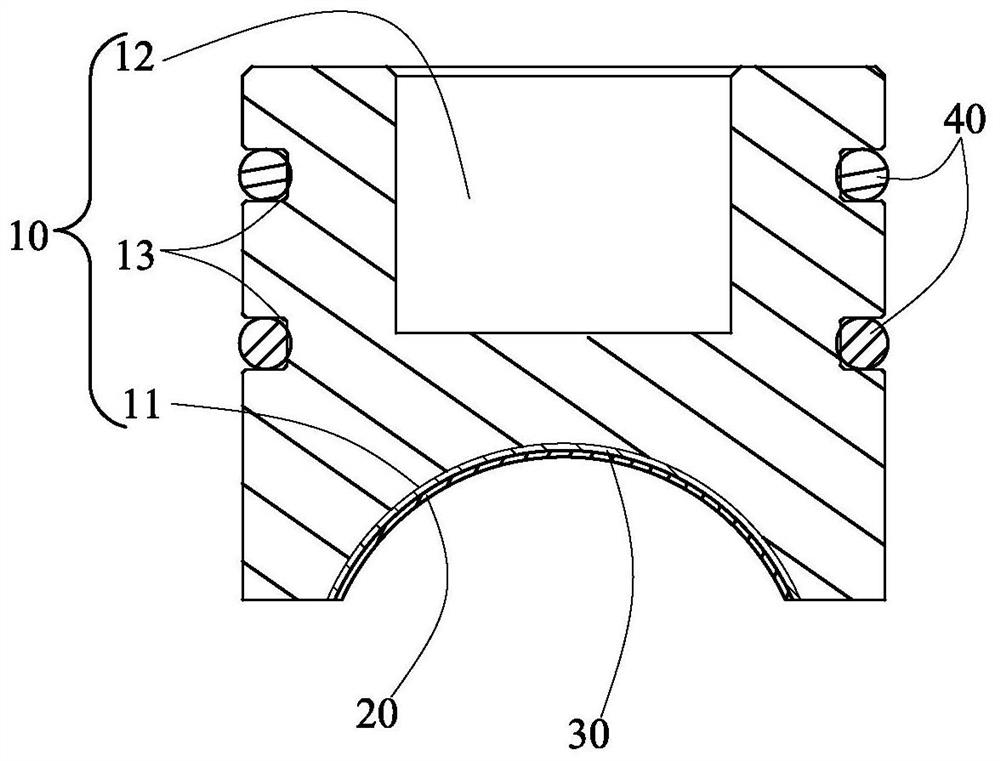

[0019] like Figure 1 to Figure 3 As shown, it is a structural schematic diagram of the compression block of the linear guide shaft provided by the present invention. The compression block of the linear guide shaft includes a body 10, a wear-resistant layer 20 arranged on the body 10, and a layer of glue for bonding between the body 10 and the wear-resistant layer 20. Layer 30, and at least one elastic ring 40 disposed on said body 10. It is conceivable that the pressing block of the linear guide shaft is assembled in an installation housing, and the installation housing is also provided with a matching seat hole for accommodating the body 10, which is not in the figure 1 Not shown, but it should be the prior art, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Peel strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com