Vertical low-temperature container

A low-temperature container and vertical technology, which is applied to pressure vessels, container filling methods, and outer walls of container structures, etc. It can solve problems such as high process and manufacturing requirements, no glass fiber reinforced plastic positioning and fastening devices for upper supports, and permanent contact. , to achieve the effect of ensuring vacuum insulation performance, reducing static evaporation rate, and small heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

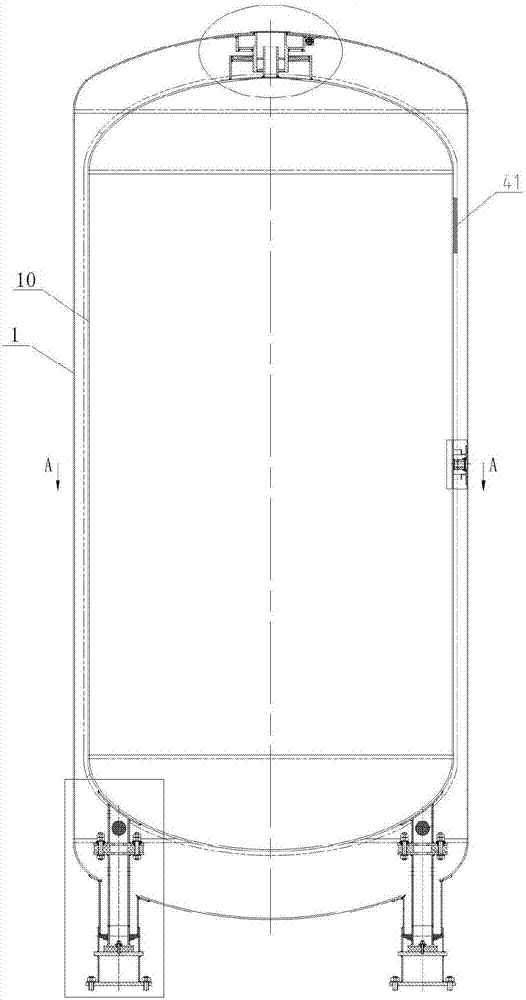

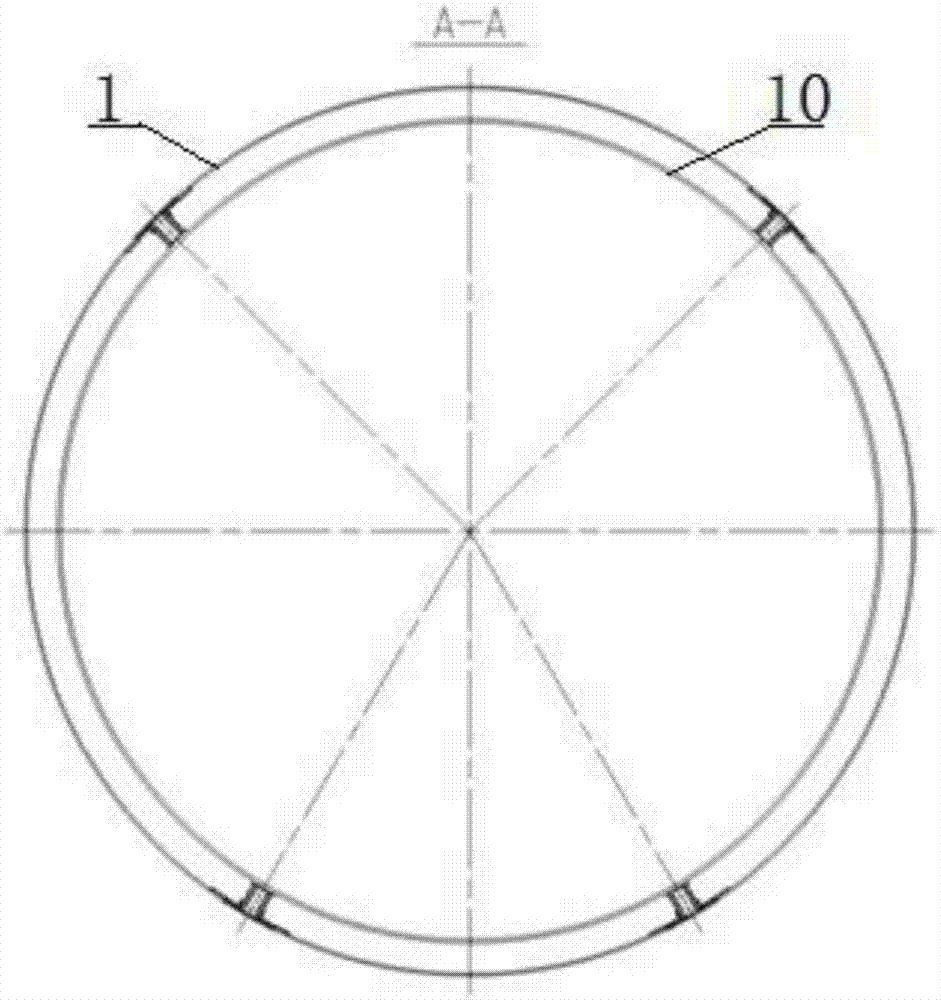

[0043] Such as figure 1 As shown, a vertical cryogenic container includes an inner tank 10 and an outer shell 1, and an axial support of a head is provided between the top outside of the inner tank 10 and the inner top of the outer shell 1, and the outer bottom of the inner tank 10 is connected to the outer shell 1. A steel pipe fiberglass support is provided between the outside of the bottom of the shell 1, and the inner tank 10 is provided with a heat insulating interlayer 41 made of a heat insulating material;

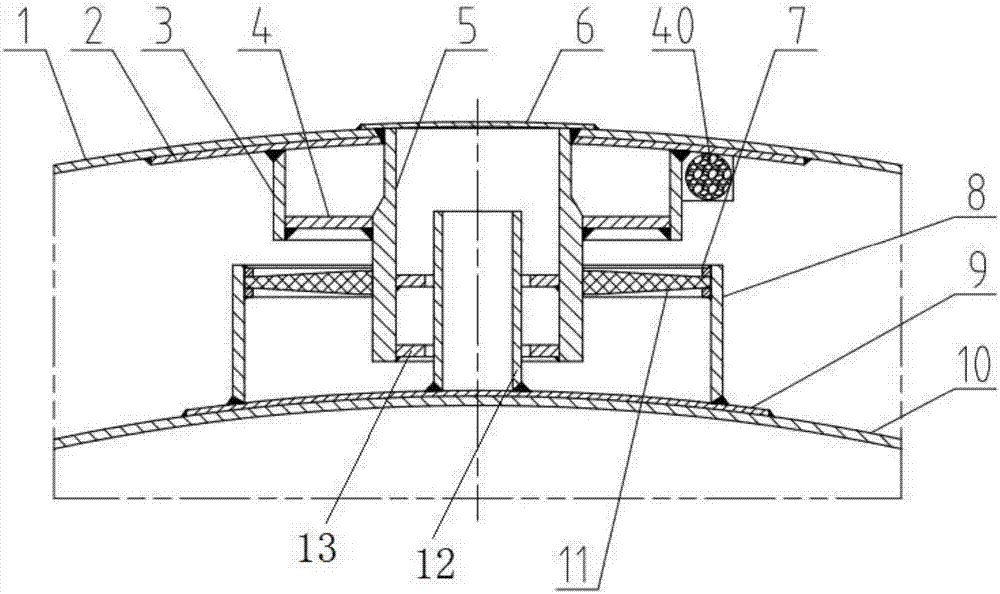

[0044] Such as figure 2 As shown, the axial support of the head includes an upper assembly and a lower assembly, and the lower assembly includes a backing plate 9 fixed on the outside of the top of the liner 10, and a supporting steel pipe 8 is connected to the backing plate 9, so Two fixing rings 7 are arranged up and down on the inner side of the supporting steel pipe 8, and an annular glass fiber reinforced plastic 11 is clamped between the two fixing rings 7; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com