Continuous wall forming machine of underground cement soil impermeable wall

A technology of anti-seepage wall and wall forming machine, applied in the direction of earth mover/shovel, construction, etc., can solve the anti-seepage effect and the reduction of wall strength, uneven surface, uneven density, unable to guarantee the quality of the wall, etc. problems, to achieve the effect of improving the degree of freedom and cutting ability, quality balance, and equipment mobility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

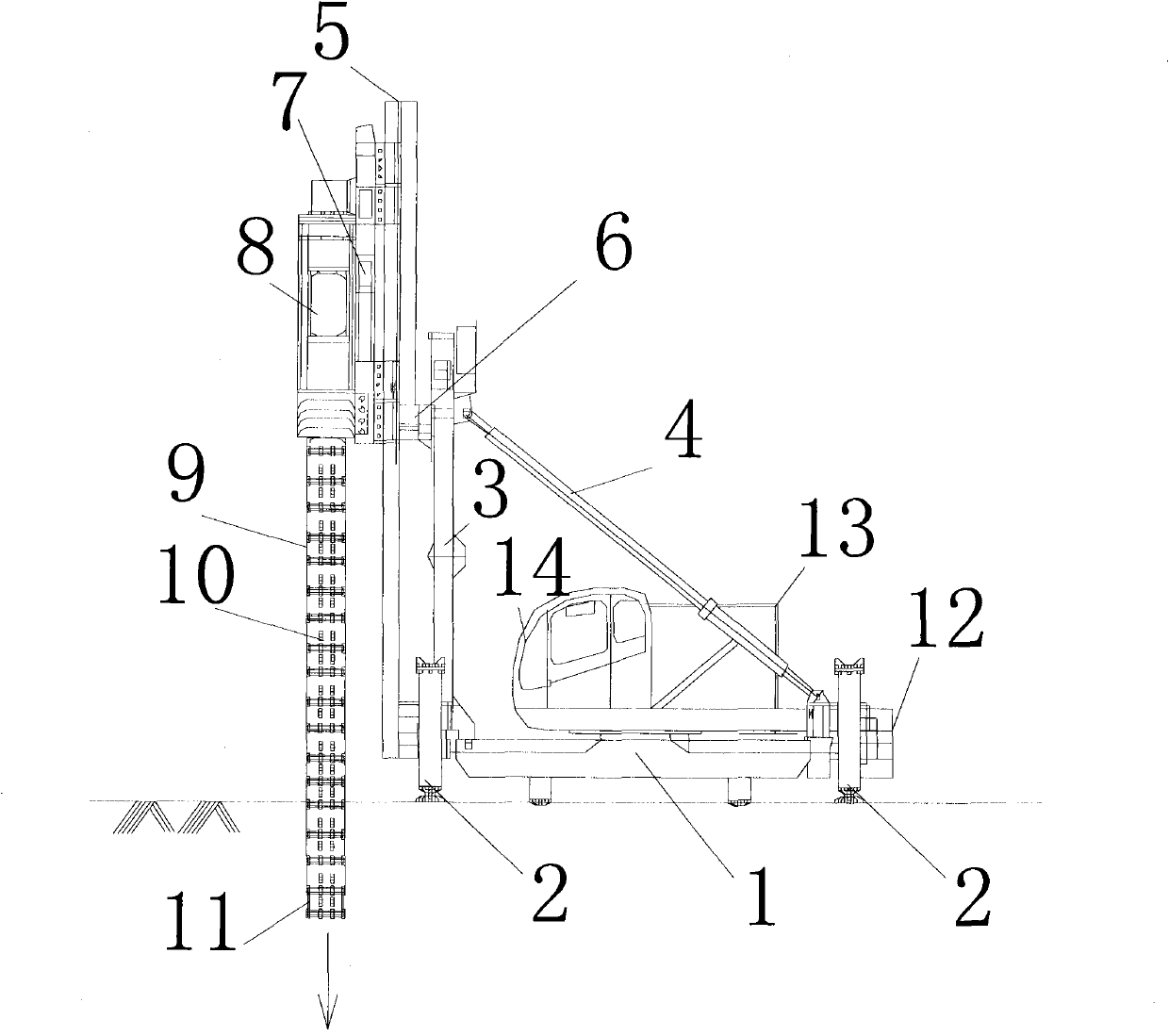

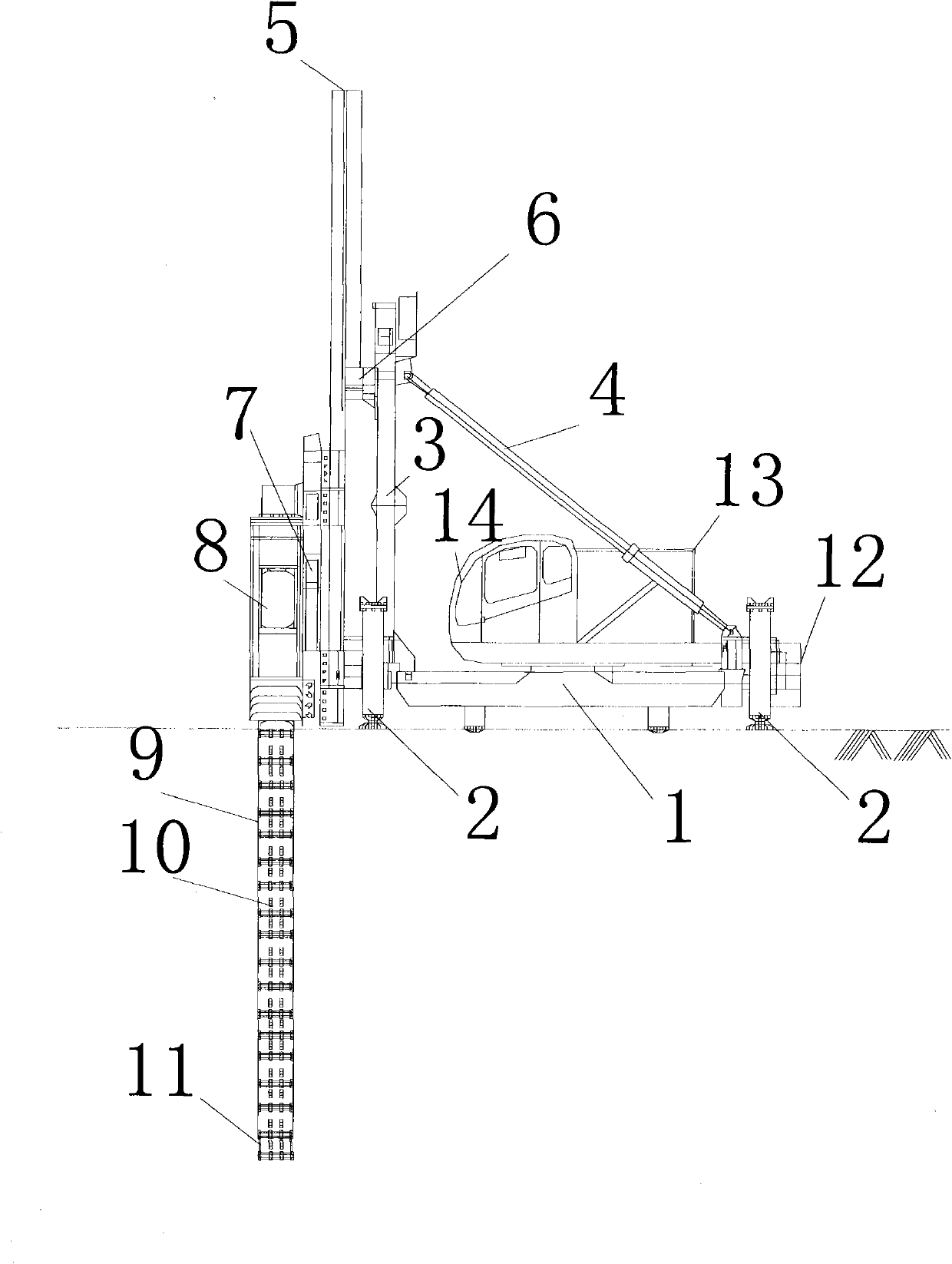

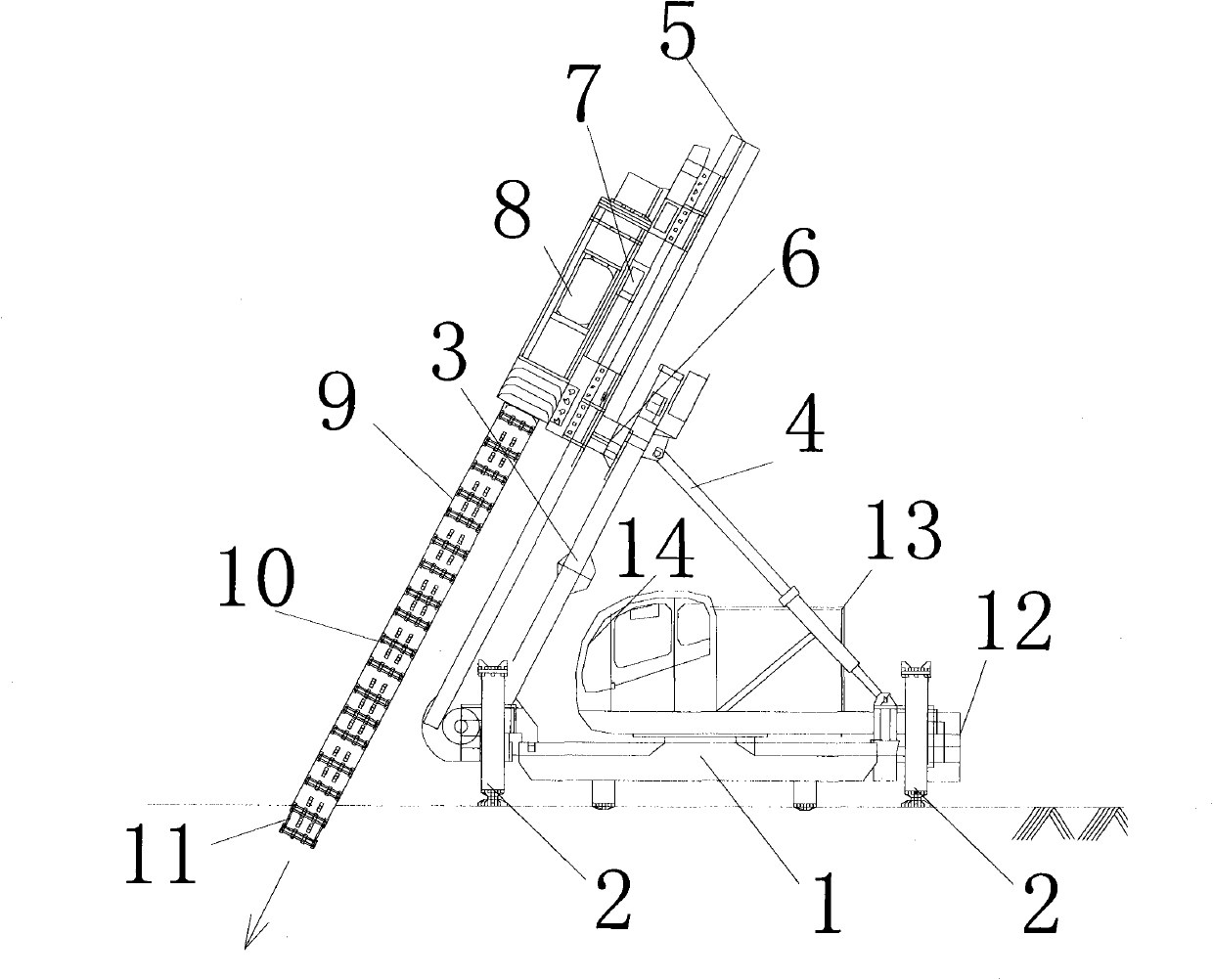

[0021] exist figure 1 Among them, the mechanical chassis (1) and the hydraulic support (2) constitute a walking-type moving mechanism, the frame (3) and the tilt adjustment rod (4) are installed on the mechanical chassis (1), and the frame (3) passes through the tilt adjustment rod (4) To achieve a vertical or inclined state, install a vertical guide rod (5) and a horizontal drive cylinder (6) on the frame (3), and make the vertical guide rod (5) horizontal on the frame (3) through the horizontal drive cylinder (6). Movement, vertical drive cylinder (7) and cutter drive mechanism (8) are installed on the vertical guide rod (5), cutter drive mechanism (8) and cutter combination box (9) and cutter combination chain (10) and cutter head ( 11) are connected, and move up and down on the vertical guide rod (5) through the vertical drive cylinder (7), and the tool combination chain (10) surrounding the tool combination box (9) on both sides is in the tool drive mechanism ( 8) and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com