Tube-type glass bottle bottom firing process and bottle bottom firing device thereof

A technology for controlling glass bottles and glass bottles, applied in glass cutting devices, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of explosive and fragile bottles, and achieve the effects of reasonable thickness, improved bearing capacity, and reduced damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the technical purpose, technical solution and beneficial effect of the present invention clearer, the technical solution of the present invention will be further described below in conjunction with the drawings and specific embodiments.

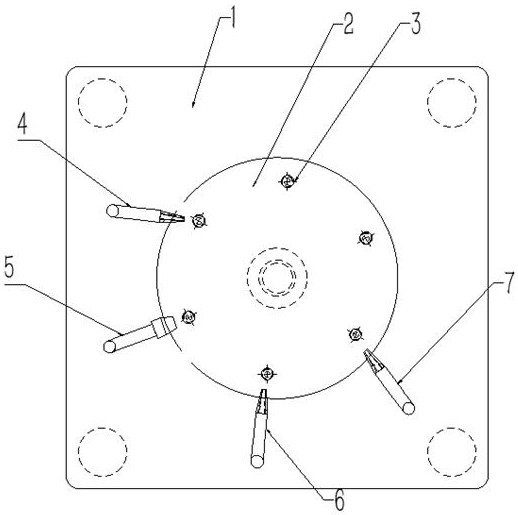

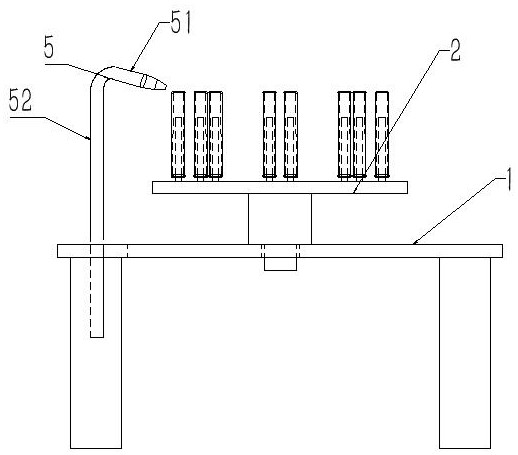

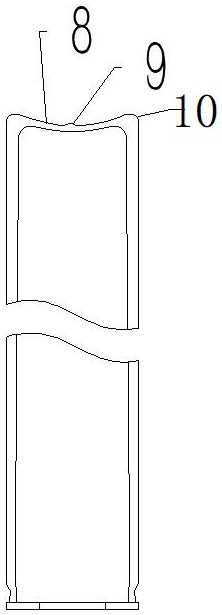

[0019] In a specific embodiment of the bottle bottom firing device for controlled glass bottles involved in the present invention, the bottle making machine is mainly composed of A part and B part, wherein A part has 12 stations, and B part has 6 stations. There are a total of 18 stations. Part A is mainly for the manufacture of the bottle mouth. Through thermal processing and secondary molding at different positions, the processing of the bottle mouth is completed; while part B is mainly for the production and molding of the bottom of the bottle, and finally forms a complete Glass bottle products enter the annealing furnace. And in the application, improve mainly at B part, that is to say that the B part equipment con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com