Preparation method of safe anti-puncturing tyre

A tire and safety technology, applied to the reinforcement layer of pneumatic tires, tire parts, transportation and packaging, etc., can solve the problems of low production efficiency, unsatisfactory anti-puncture effect, high cost, etc., and achieve high production efficiency and tire anti-corrosion Good pricking effect and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

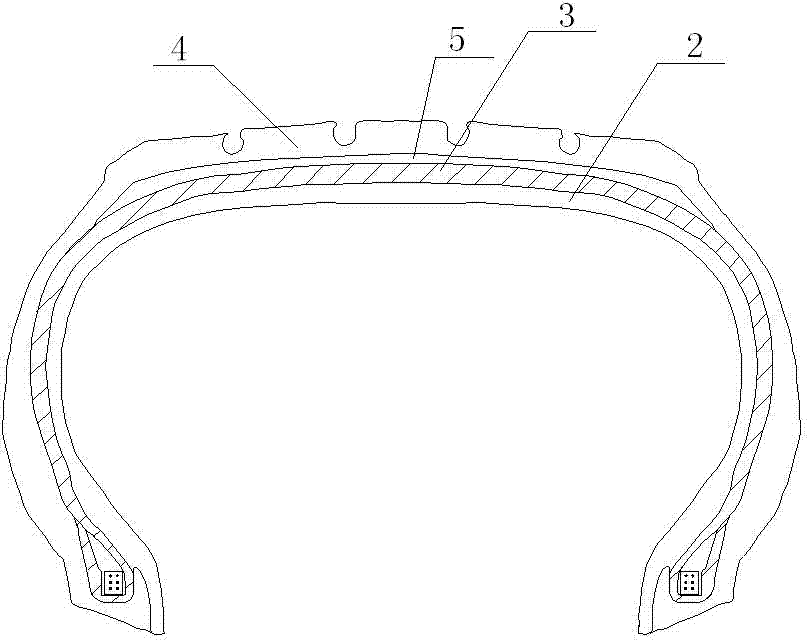

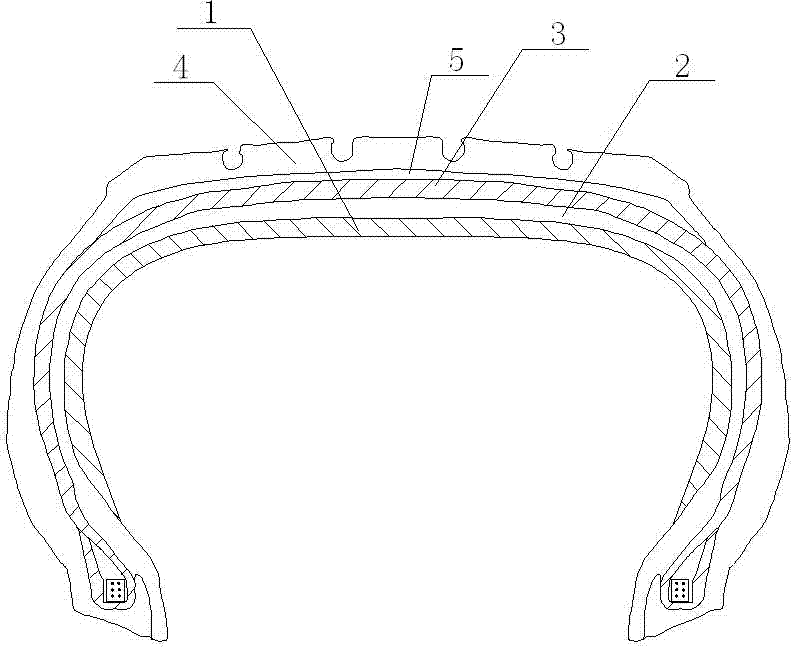

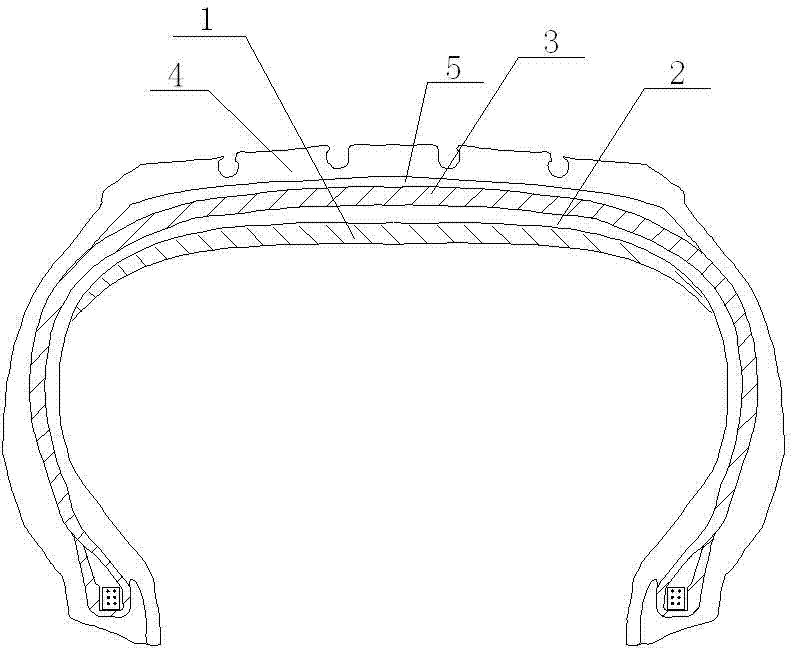

[0032] refer to figure 2 , a preparation method of a safety puncture-proof tire, the safety puncture-proof tire is provided with a self-sealing layer 1, an airtight layer 2, a carcass layer 3, a belt layer 5 and a tread 4 in sequence from the inside to the outside, and the self-sealing The thickness of the layer is 0.5mm, and the thickness of the airtight layer is 2.5mm; the self-sealing layer 1 is fully covered on the airtight layer 2 . The cord layer is a steel cord layer, and the number of layers of the steel cord layer is 3 layers. The preparation method comprises the steps of:

[0033] (1) Extrude the tread through an extruder;

[0034] (2) The adhesive is sprayed and cooled to form a self-sealing layer;

[0035] (3) Extrude the airtight layer and ply layer respectively through the calender;

[0036] (4) Bond the airtight layer and the self-sealing layer to form an inner lining layer;

[0037] (5) Forming of the belt layer; in the spindle room, the steel wire comes ...

Embodiment 2

[0045] refer to figure 2 , a preparation method of a safety puncture-proof tire, the safety puncture-proof tire is provided with a self-sealing layer 1, an airtight layer 2, a carcass layer 3, a belt layer 5 and a tread 4 in sequence from the inside to the outside, and the self-sealing The thickness of the layer is 1.1 mm, and the thickness of the airtight layer is 1.8 mm; the self-sealing layer 1 is fully covered on the airtight layer 2 . The ply is a steel ply, and the number of layers of the steel ply is one. Described tire is prepared by following method:

[0046] (1) Extrude the tread through an extruder;

[0047] (2) The adhesive is sprayed and cooled to form a self-sealing layer;

[0048] (3) Extrude the airtight layer and ply layer respectively through the calender;

[0049] (4) Bond the airtight layer and the self-sealing layer to form an inner lining layer;

[0050] (5) Belt forming;

[0051] (6) The inner liner, cord layer, belt layer and tread are integrally...

Embodiment 3

[0057] refer to figure 2 , a preparation method of a safety puncture-proof tire, the safety puncture-proof tire is provided with a self-sealing layer 1, an airtight layer 2, a carcass layer 3, a belt layer 5 and a tread 4 in sequence from the inside to the outside, and the self-sealing The thickness of the layer is 1.9 mm, and the thickness of the airtight layer is 1.0 mm; the self-sealing layer 1 is fully covered on the airtight layer 2 . The cord layer is a steel cord layer, and the number of layers of the steel cord layer is 5 layers. Described tire is prepared by following method:

[0058] (1) Extrude the tread through an extruder;

[0059] (2) The adhesive is sprayed and shaped to form a self-sealing layer;

[0060] (3) Extrude the airtight layer and ply layer respectively through the calender;

[0061] (4) Belt forming;

[0062] (5) Self-sealing layer, airtight layer, carcass layer, belt layer, and tread are integrally formed and bonded on the molding machine. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com