Cationic waterborne polyurethane resin for wallpaper glue

A water-based polyurethane and cationic technology, applied in the field of compositions, can solve problems such as being unsuitable for large-scale industrial production, complex production processes, and great human injury, and achieve the effects of excellent physical and chemical properties, simple construction process, and reduced construction procedures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

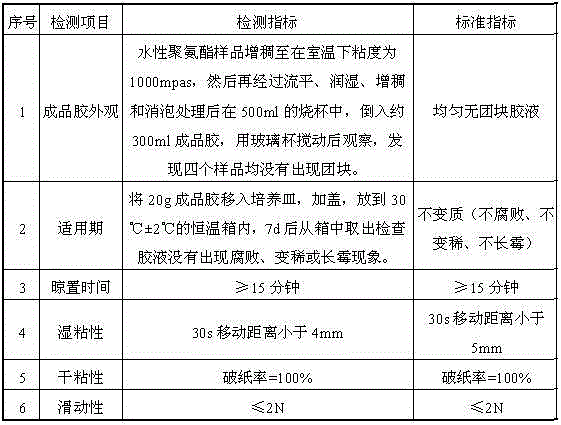

Image

Examples

Embodiment 1

[0026] Embodiment 1 A cationic water-based polyurethane resin for wallpaper glue, the water-based polyurethane resin includes the following raw materials in parts by weight: polyol 70g; polyisocyanate 50g; first chain extender 10g; second chain extender 3g; salt forming Dose 2.5g.

[0027] Among them: polyol refers to polycaprolactone polyol with a molecular weight of 1000~3000. The polyisocyanate is toluene diisocyanate. The first chain extender refers to ethylene glycol. The second chain extender refers to diethanolamine. The salt forming agent refers to lactic acid.

[0028] The preparation method of the cationic water-based polyurethane resin for wallpaper glue, comprises the following steps:

[0029] (1) Weighing according to the proportion;

[0030] ⑵Heat the polyol to 100℃~110℃ for dehydration for 0.5~1.5h, then cool down to 45~55℃, then add polyisocyanate, raise the temperature to 85~95℃, and keep it warm at this temperature for 1.5~2.5h; after that Cool down to ...

Embodiment 2

[0033] Embodiment 2 A cationic water-based polyurethane resin for wallpaper glue, the water-based polyurethane resin includes the following raw materials in parts by weight: polyol 100g; polyisocyanate 90g; first chain extender 30g; second chain extender 18g; salt forming Dose 7.26g.

[0034] Among them: polyol refers to polycarbonate polyol with a molecular weight of 1000~3000. Polyisocyanate refers to isophorone diisocyanate. The first chain extender refers to diethylene glycol. The second chain extender refers to triethanolamine. The salt-forming agent refers to glacial acetic acid.

[0035] The preparation method of the cationic water-based polyurethane resin for wallpaper glue is the same as in Example 1.

Embodiment 3

[0036] Embodiment 3 A cationic water-based polyurethane resin for wallpaper glue, the water-based polyurethane resin includes the following raw materials in parts by weight: polyol 85g; polyisocyanate 70g; first chain extender 15g; second chain extender 10.5g; Salt 6.5g.

[0037] Among them: polyol refers to polytetrahydrofuran ether polyol with a molecular weight of 1000~3000. Polyisocyanate refers to diphenylmethane diisocyanate. The first chain extender refers to 1,4-butanediol. The second chain extender refers to N-methyldiethanolamine. The salt forming agent refers to glycolic acid.

[0038] The preparation method of the cationic water-based polyurethane resin for wallpaper glue is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com