Patents

Literature

57 results about "Cobaltite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cobaltite is a sulfide mineral composed of cobalt, arsenic, and sulfur, CoAsS. Its impurities may contains up to 10% iron and variable amounts of nickel. Structurally, it resembles pyrite (FeS₂) with one of the sulfur atoms replaced by an arsenic atom.

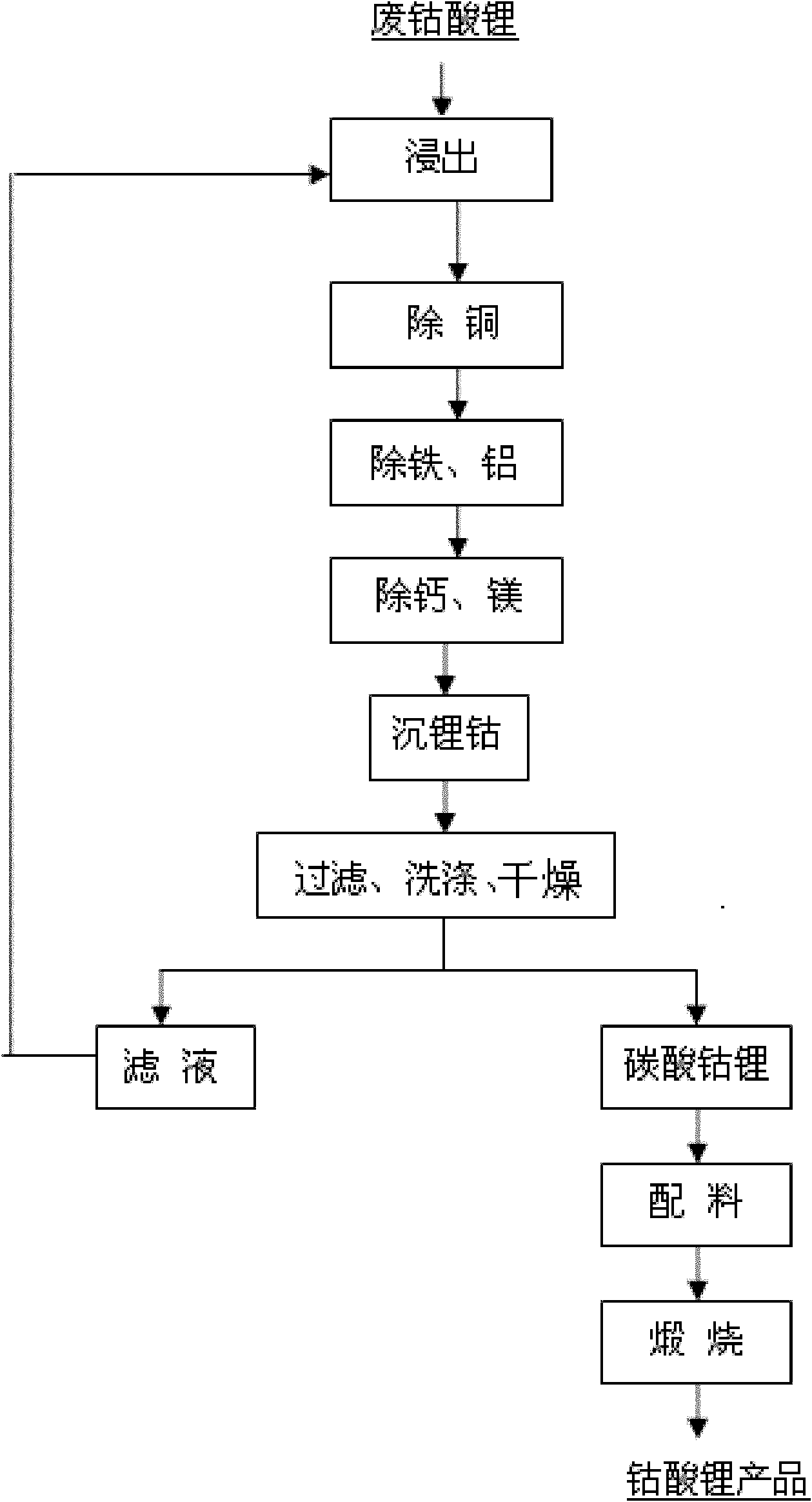

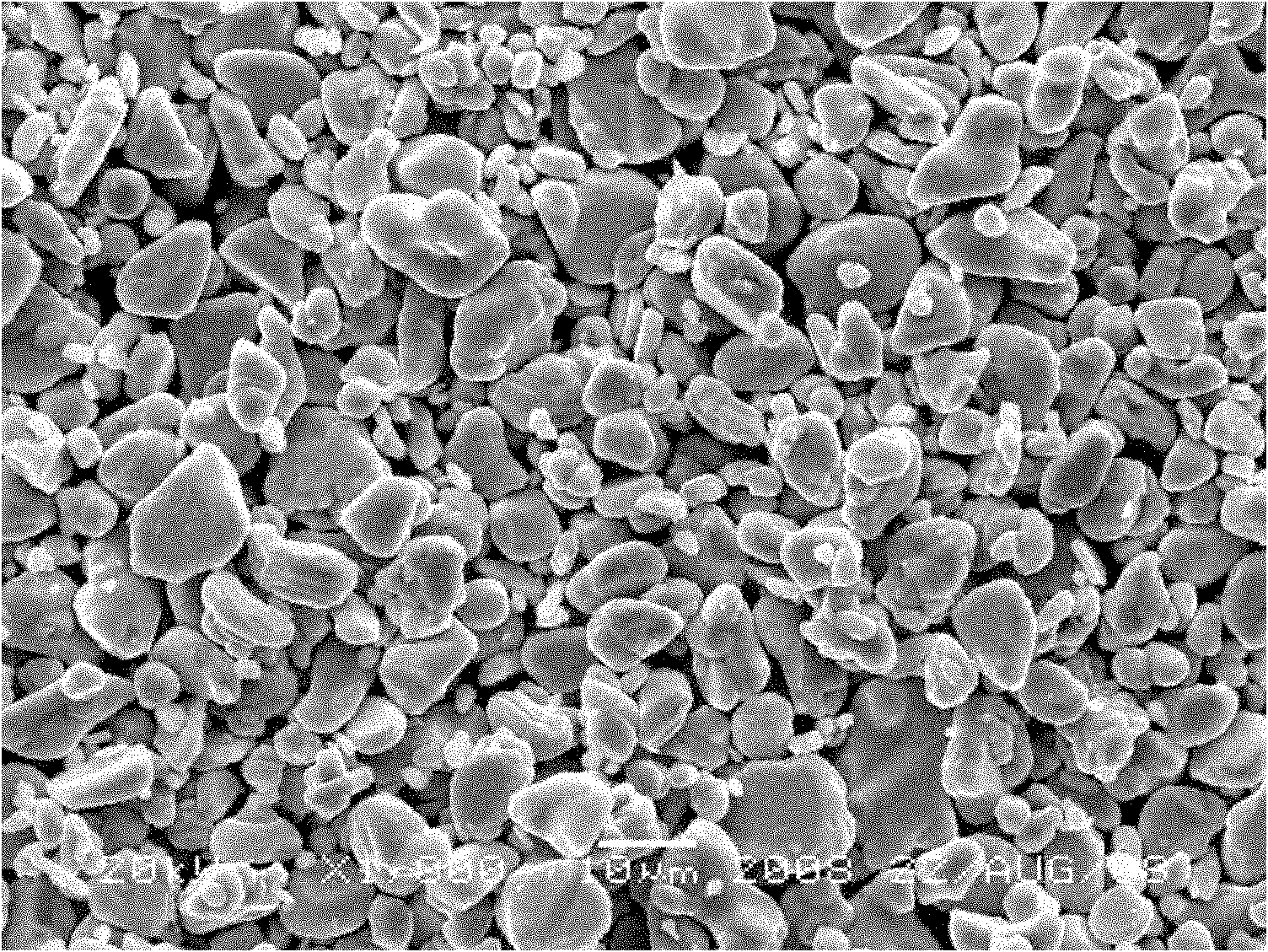

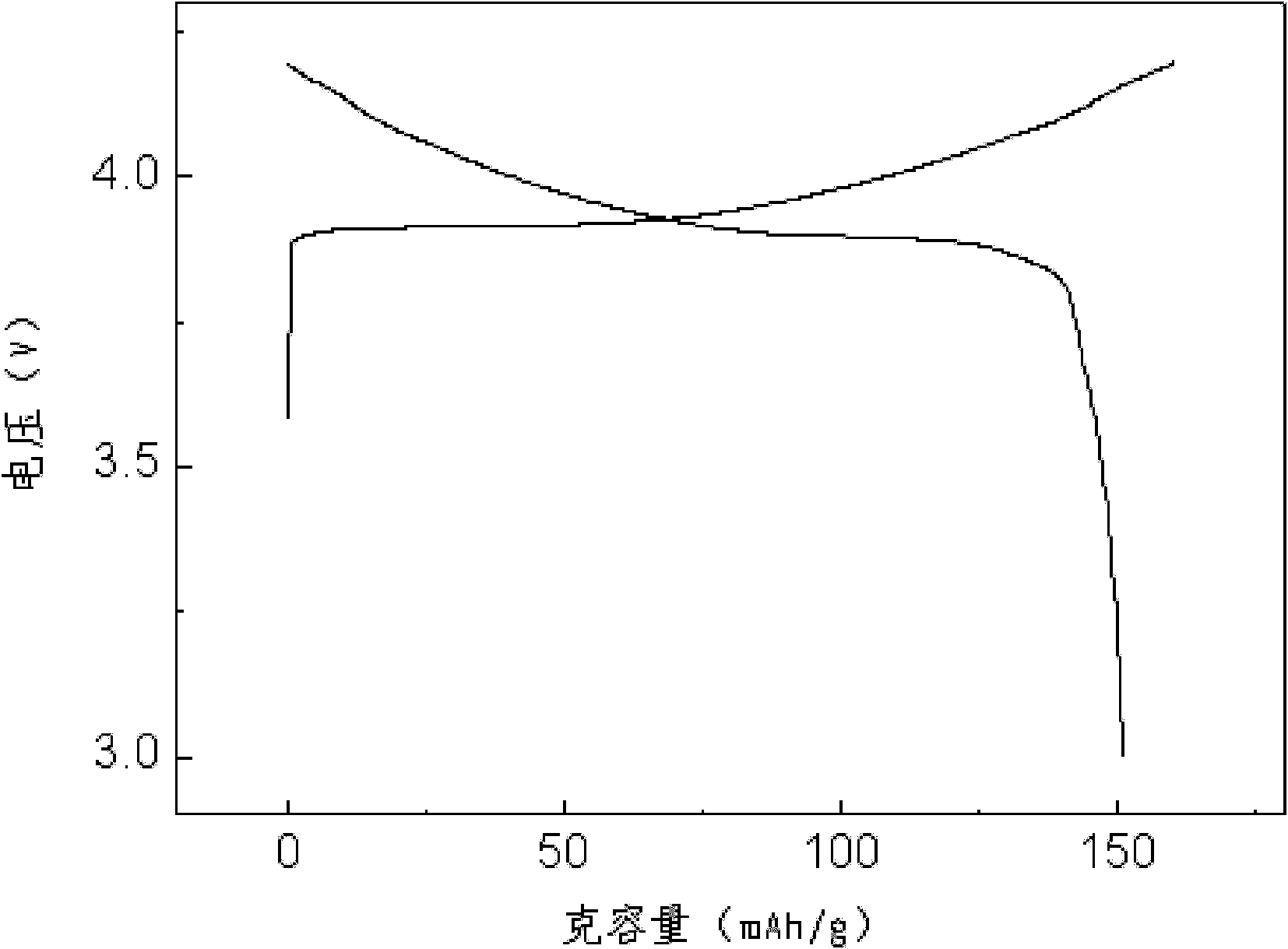

Method for recovering cobalt and lithium from waste lithium cobaltite and preparing lithium cobaltite

InactiveCN102101701AReduce consumptionSimple processWaste accumulators reclaimingCobalt compoundsLithium carbonateEconomic benefits

The invention discloses a method for recovering cobalt and lithium from waste lithium cobaltite and preparing lithium cobaltite. The method comprises the following steps: (1) leaching out the cobalt and lithium in the waste lithium cobaltite by using acid and a reducing agent, so as to obtain lixivium; (2) removing copper, iron, aluminum, calcium and magnesium in the lixivium by using a chemical method; (3) precipitating the cobalt and lithium in a solution without impurities with carbonate; (4) drying the cobalt lithium carbonate, and blending corresponding cobalt salt and / or lithium salt according to cobalt-lithium ratio; and (5) calcining so as to obtain lithium cobaltite product. The lithium cobaltite obtained by the method is good in property, cobalt and lithium recoveries are above 99% and above 96% respectively. The method has the advantages of simple process, low cost and high economic benefits, and is easy to carry out industrial production.

Owner:HUNAN BRUNP RECYCLING TECH

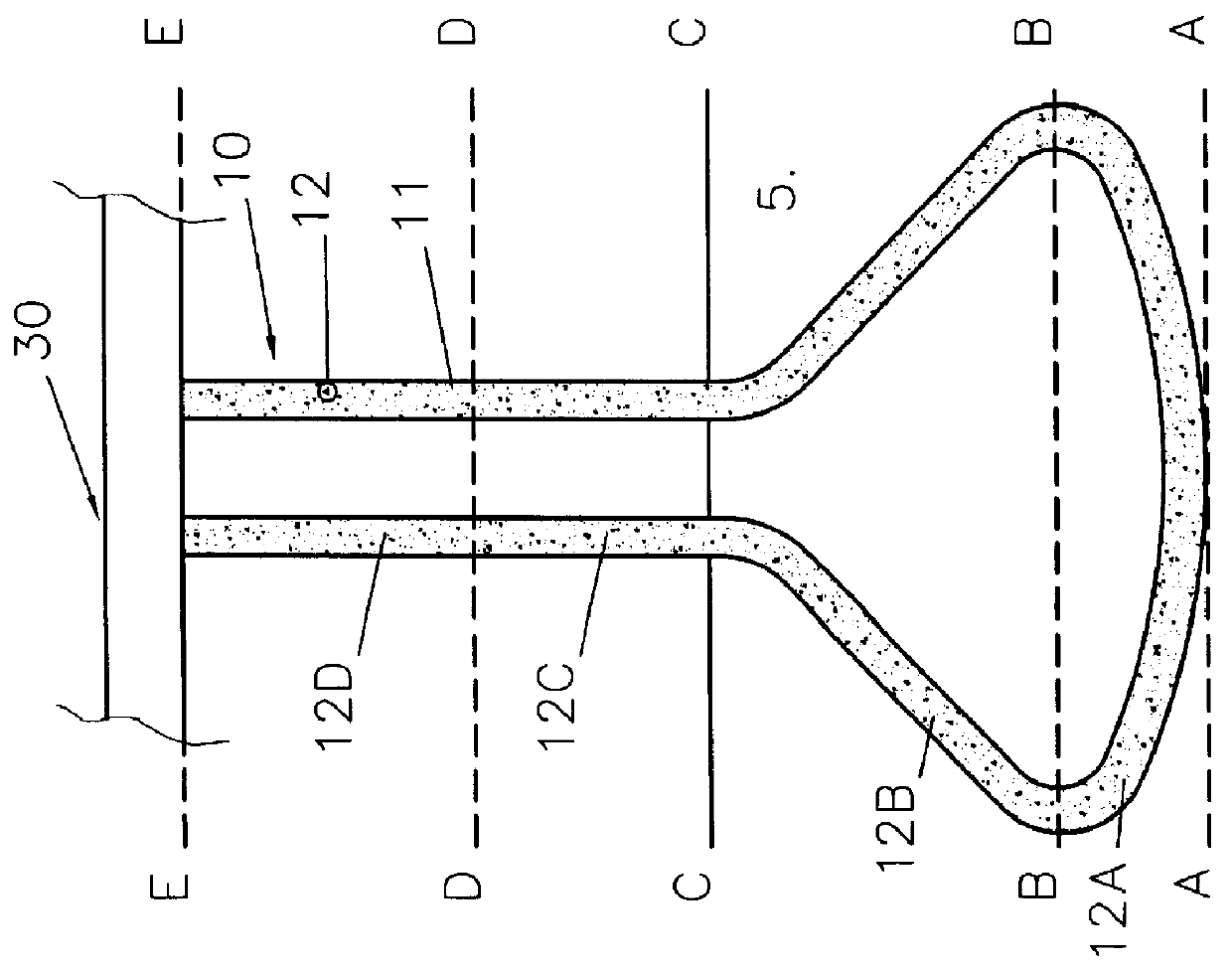

Porous non-carbon metal-based anodes for aluminium production cells

InactiveUS6113758AEliminate carbon-generated pollutionReduces high cell operating costMachining electrodesElectrical-based machining electrodesFiberCuprate

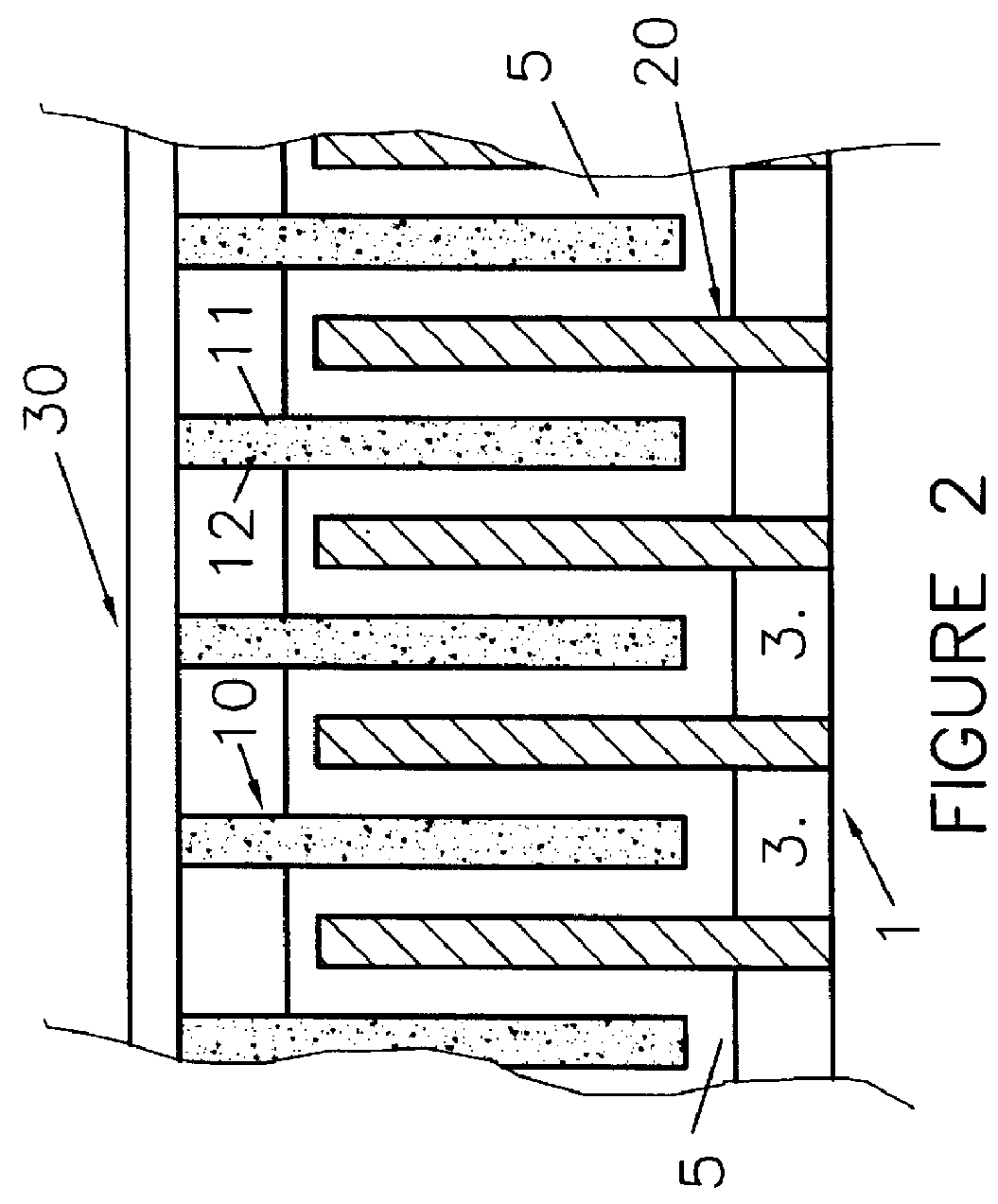

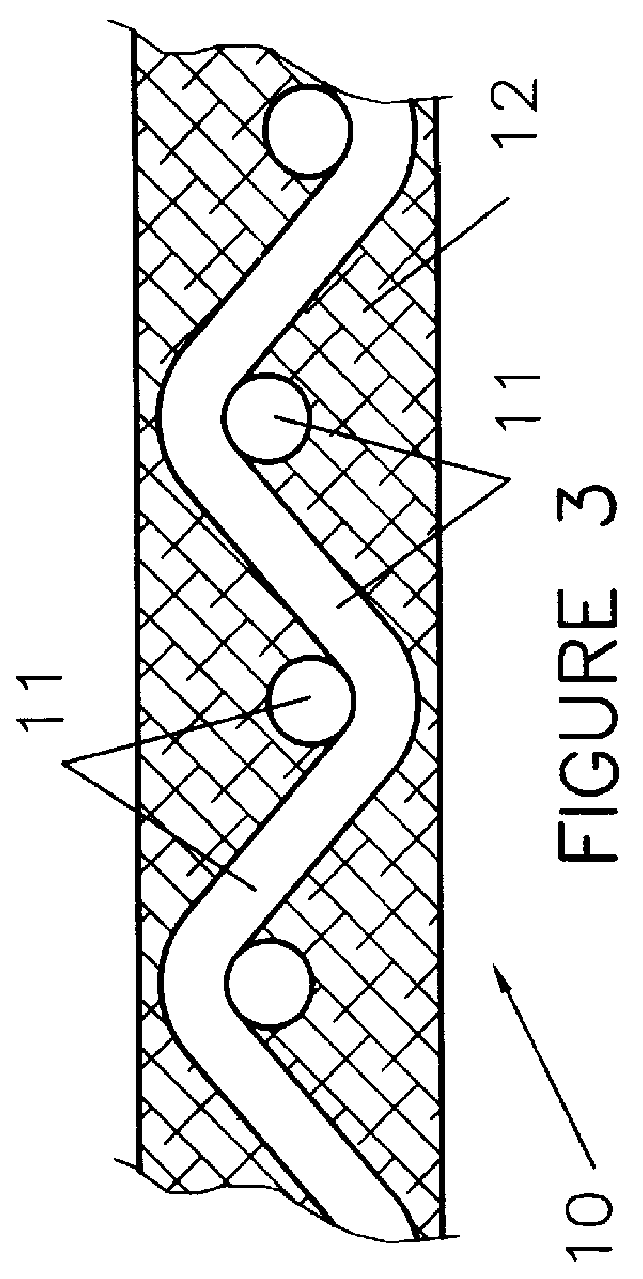

A non-carbon, metal-based anode (10) of a cell for the electrowinning of aluminium, comprising an electrically conductive, high temperature resistant and oxidation resistant metal structure (11) in the form of a wire mesh or net, a foraminate sheet, a fibrous network, a reticulated skeletal structure, or a porous structure having voids, recesses and / or pores which are filled or partly filled with an electrochemically active filling (12), such as oxides, oxyfluorides, phosphides, carbides, cobaltites and cuprates making the surface of the anode (10) conductive and electrochemically active for the oxidation of oxygen ions present at the anode surface / electrolyte (5) interface.

Owner:MOLTECH INVENT

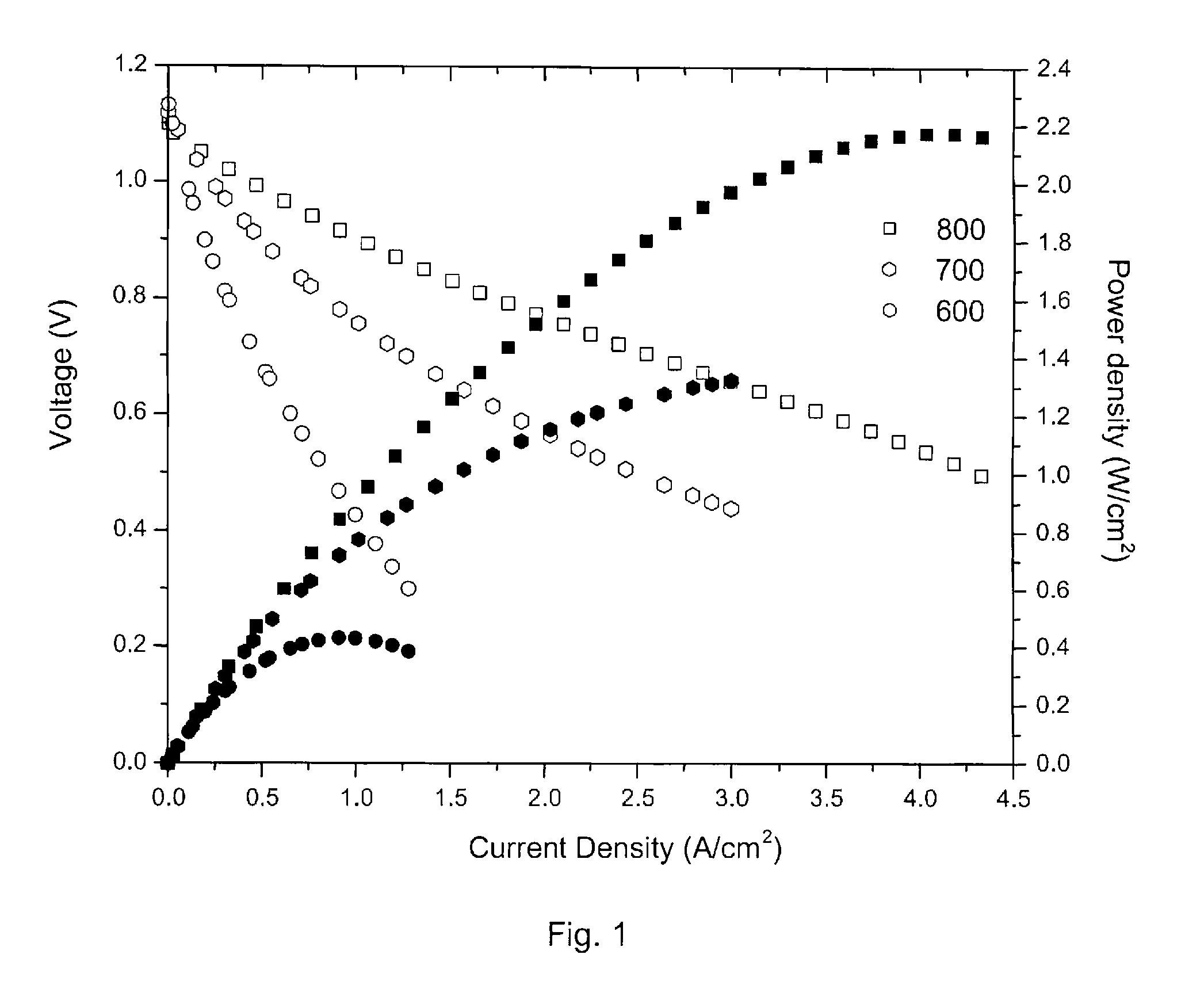

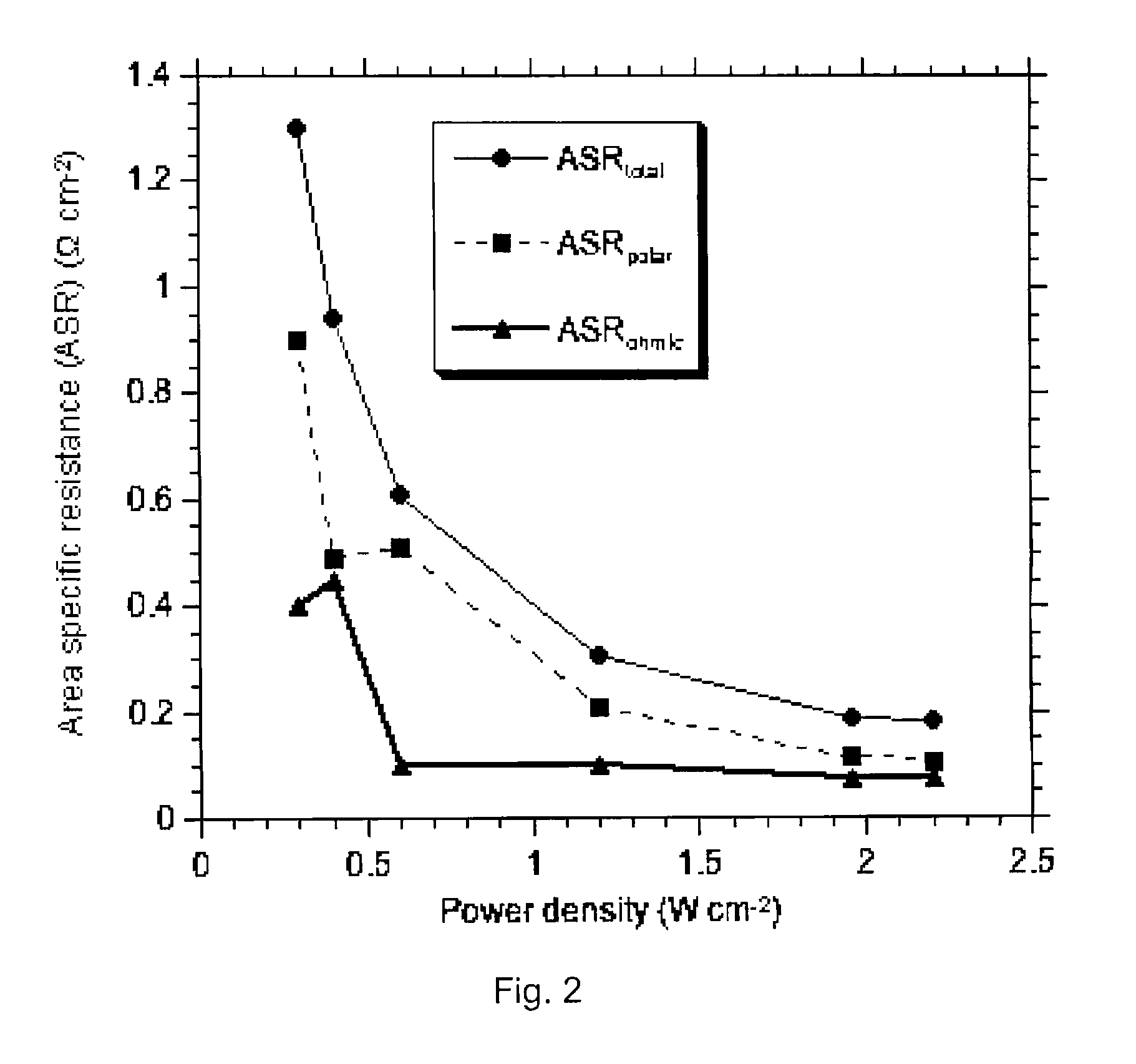

Solid oxide fuel cell cathode comprising lanthanum nickelate

A solid mixture of La2NiO4+δ and an ionic conductive material. A solid oxide fuel cell having a cathode interlayer having a La2NiO4+δ layer and a doped ceria layer, a lanthanum strontium cobaltite or lanthanum strontium manganate cathode current collector, an anode; and an ionic conductive electrolyte between and in contact with the cathode interlayer and the anode.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

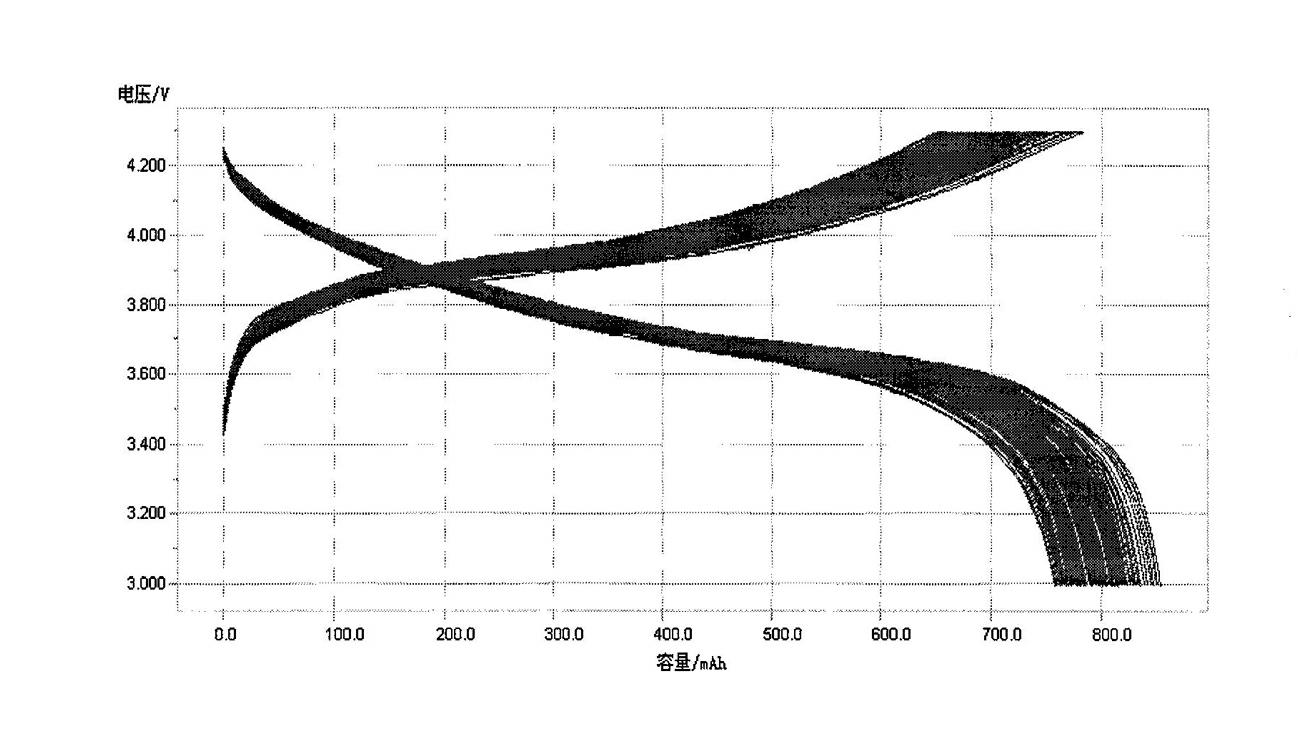

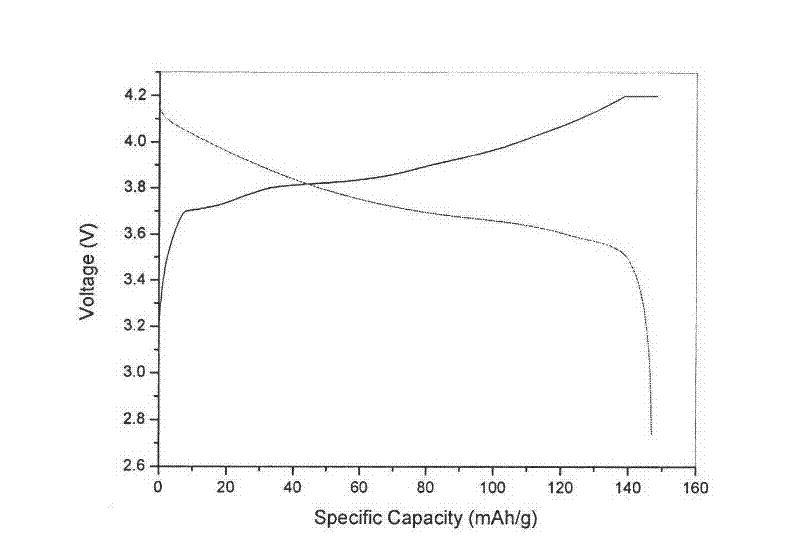

Method for preparing high-compaction high-voltage lithium cobaltite cathode material

InactiveCN102122712AImprove cycle performancePromote circulationCell electrodesCobalt(II,III) oxidePhysical chemistry

The invention relates to a method for preparing a high-compaction high-voltage lithium cobaltite cathode material. The method comprises the following concrete steps and implementation manners: by using a coprecipitation method, coating an NixMny(OH)z layer on the surface of a cobaltosic oxide in the preparation method to obtain a precursor of a gradient material [NixMny(OH)z]n.(Co3O4)1-n, wherein x is more than or equal to 0.1 and less than or equal to 0.75, y is more than or equal to 0.3 and less than or equal to 1.5, n is more than or equal to 0 and less than or equal to 0.35, and z is 2 or 4; tempering and sintering at a certain temperature to form an oxide in a gradient structure of [NixMnyOz]n.(Co3O4)1-n; and adding lithium and carrying out secondary sintering, thus obtaining the high-compaction high-voltage gradient cathode material. The lithium cobaltite cathode material has good cycle performance at high voltage, the product process is simple and is easy to control, and the cathode material is applicable to batch production.

Owner:NINGBO JINHE NEW MATERIALS

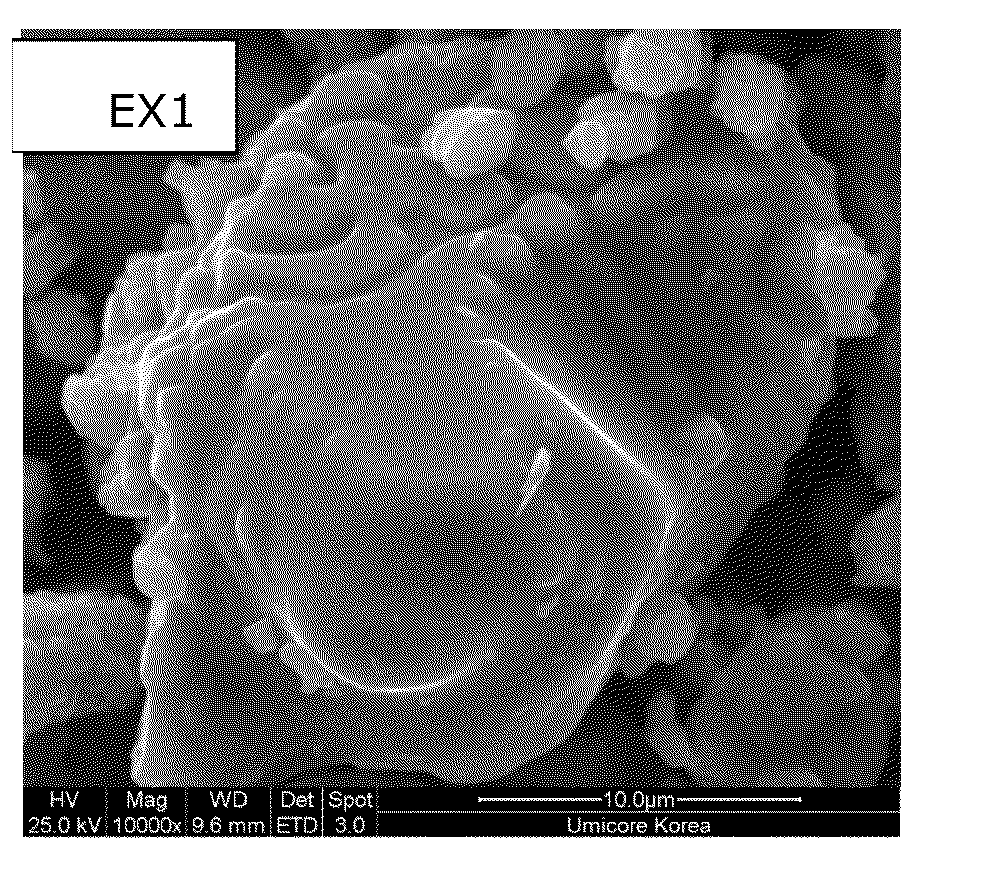

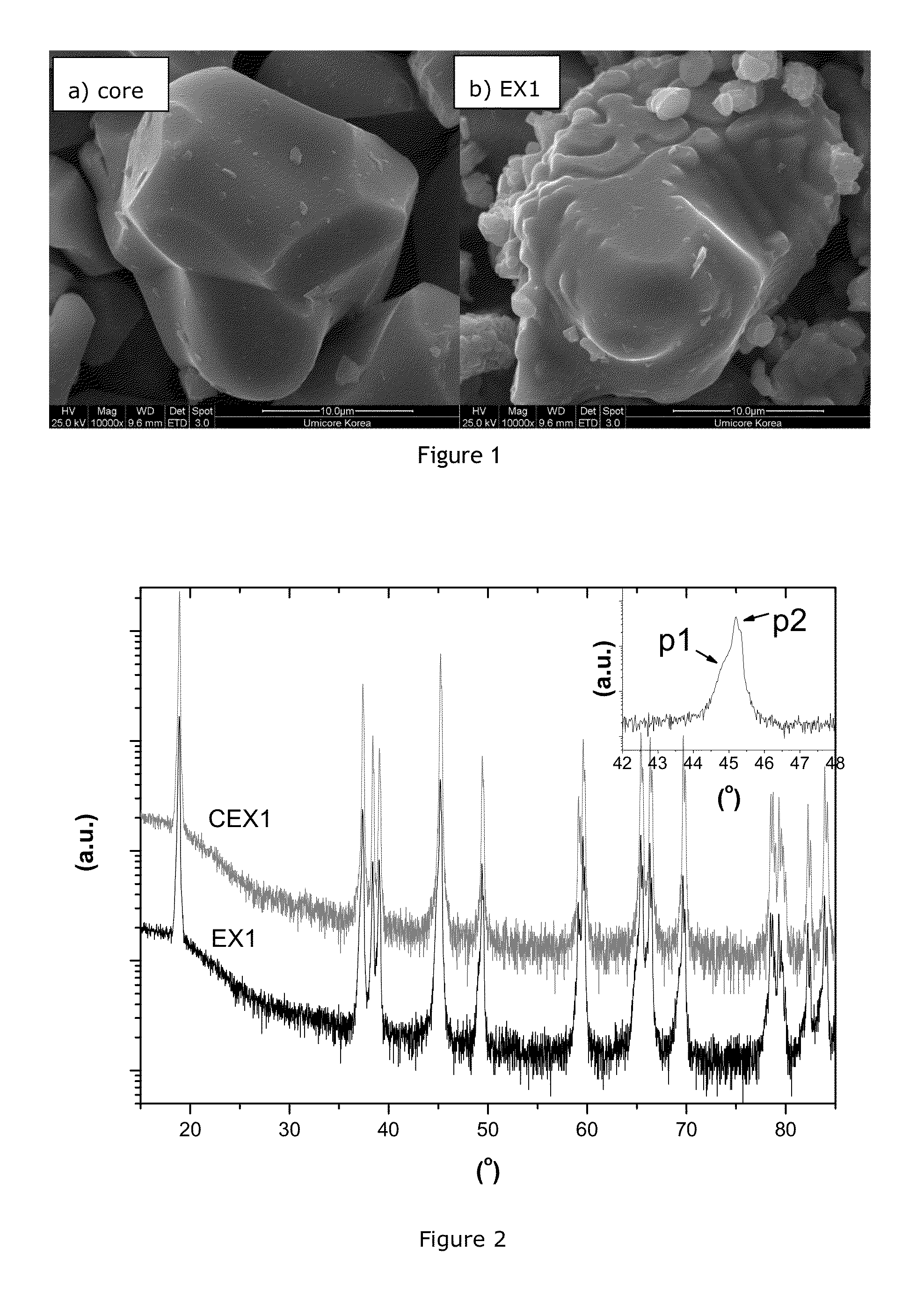

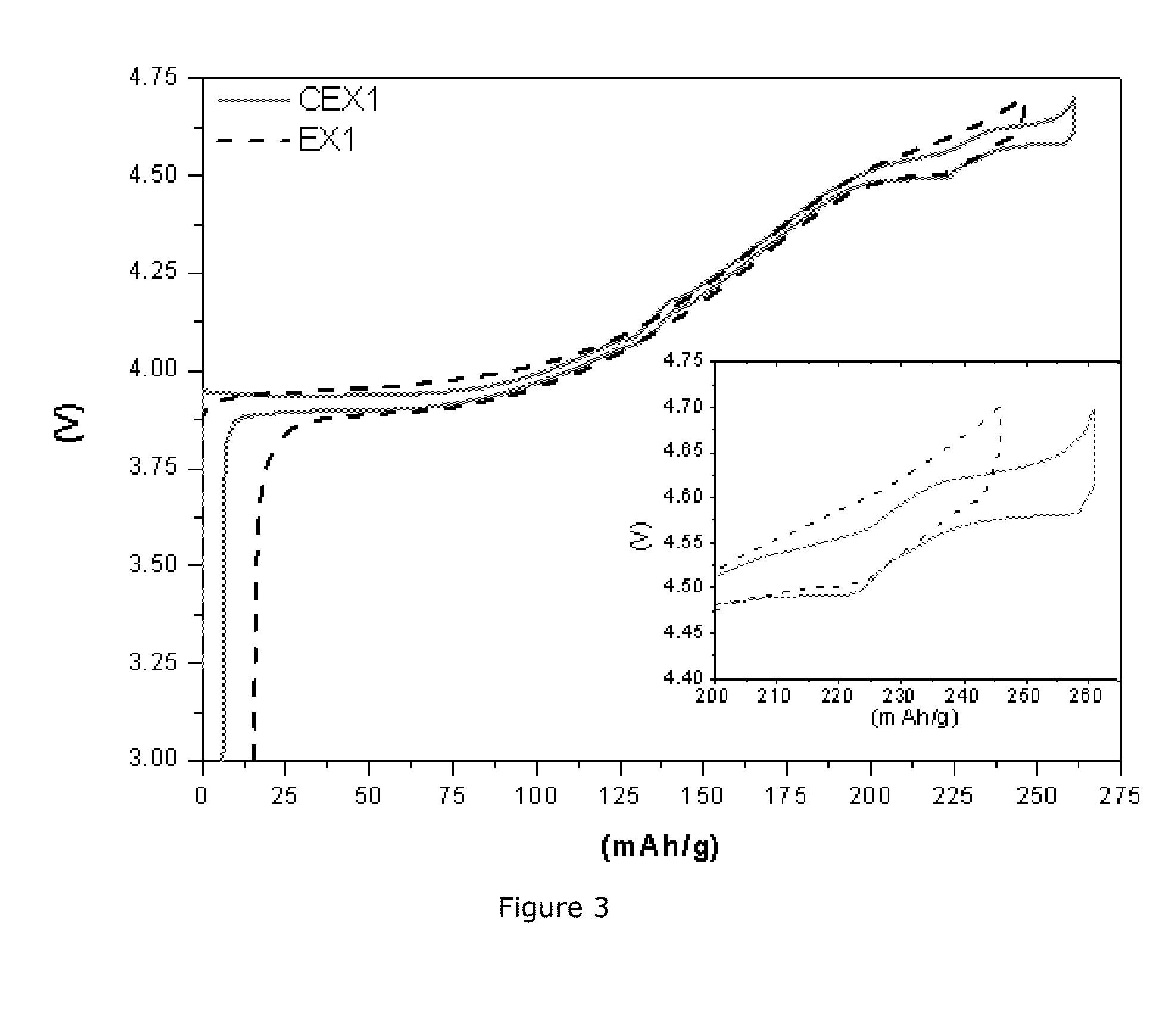

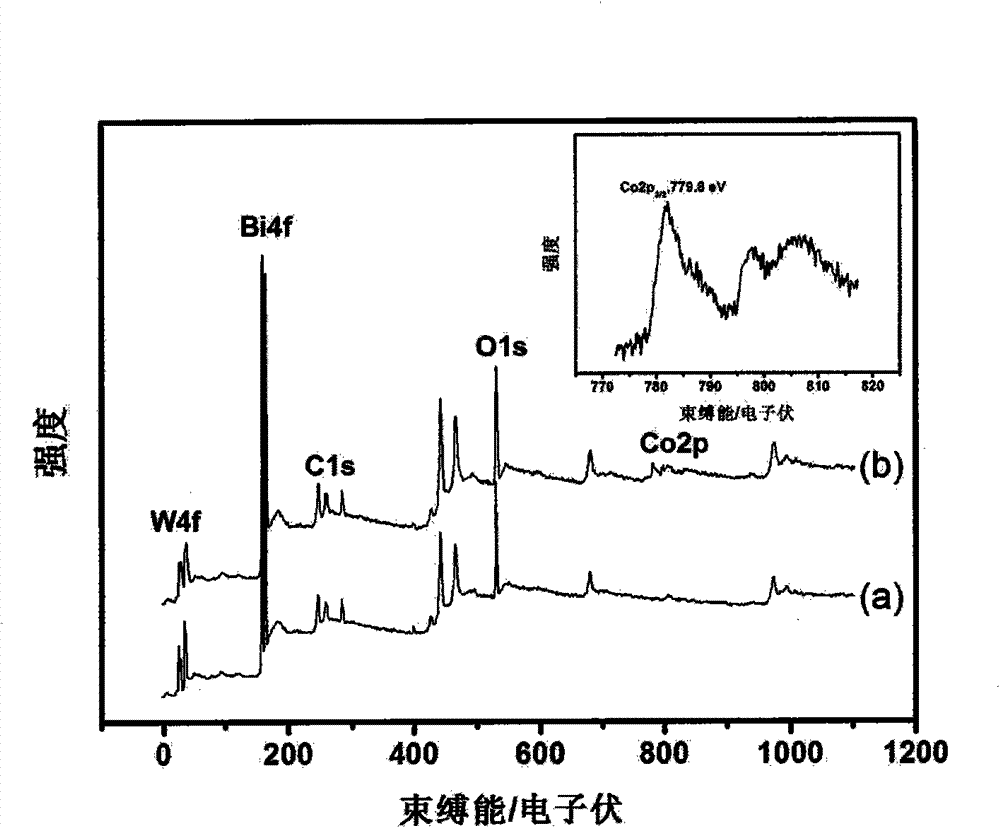

Doped and Island-Covered Lithium Cobaltite Oxides

Disclosed is a cathode active material and a method to produce the same at low cost. The cathode powder comprises modified LiCoO2, and possibly a second phase which is LiM′O2 where M′ is Mn, Ni, Co with a stoichiometric ratio Ni:Mn≧1. The modified LiCoO2 is Ni and Mn bearing and has regions of low and high manganese content, where regions with high manganese content are located in islands on the surface. The cathode material has high cycling stability, a very high rate performance and good high temperature storage properties.

Owner:UMICORE AG & CO KG

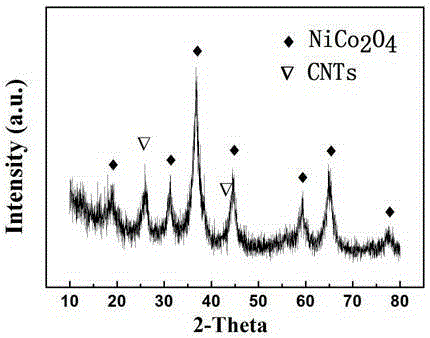

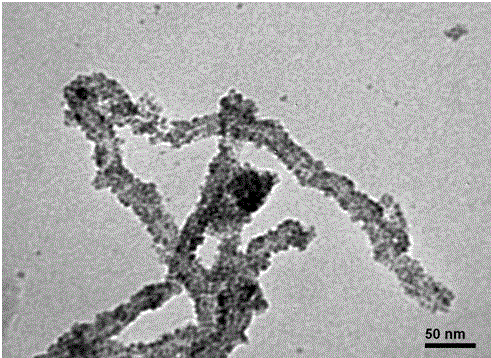

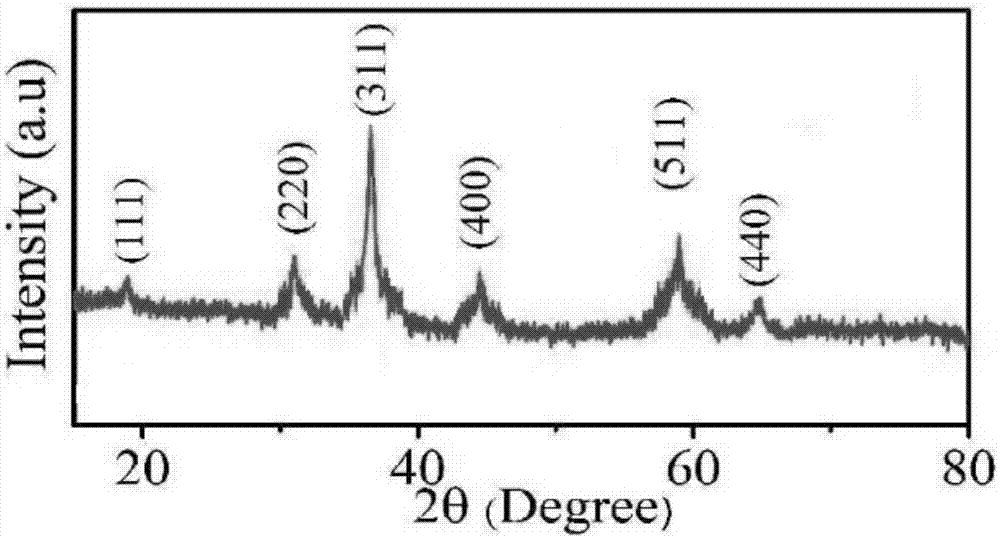

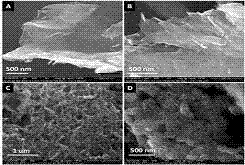

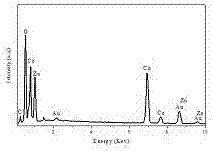

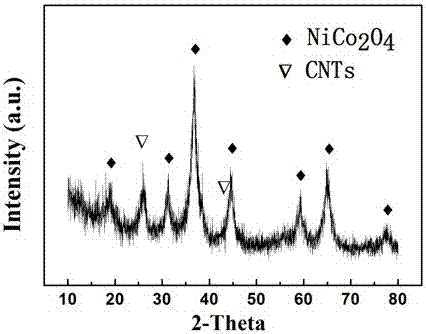

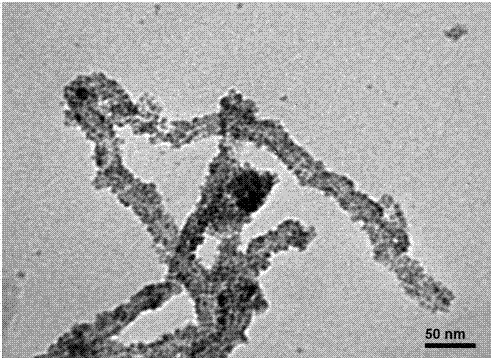

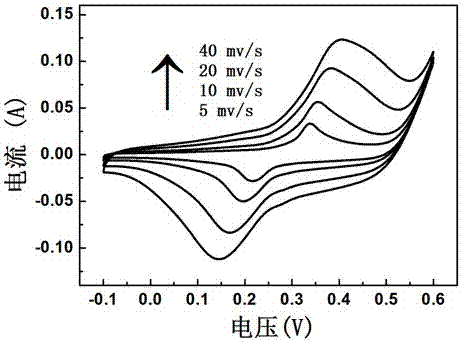

Method of preparing nickel cobaltite/carbon nanotube composite materials

InactiveCN105161313AHigh specific capacitanceImprove electrochemical stabilityMaterial nanotechnologyHybrid capacitor electrodesCapacitanceCarbon nanotube

The invention discloses a method of preparing nickel cobaltite / carbon nanotube composite materials. The invention further relates to a method of preparing a carbon nanotube loaded with nano-particles nickel cobaltite. The method comprises the following steps of dissolving Ni(NO3)2.6H2O and Co(NO3)2.6H2O in diglycol to prepare a mixed metal solution A containing Ni2+ / Co2+ with a mol ratio being 1:2; dissolving NaOH and a carbon nanotube in the diglycol and performing ultrasonic dispersion to form a solution B; making the solution B added in the solution A drop by drop to acquire a mixed solution; fully and uniformly stirring the mixed solution in a condition with a temperature of 80 DEG C, moving the solution to a reaction vessel and further replacing CO2, and after the replacement, adjusting the pressure intensity of the CO2 to be 10MPa; putting the reaction vessel in an oil bath pan, setting the stirring rate to be 400r / min, the temperature to be 140-220 DEG C, and the reaction time to be 4-10h; cleaning the acquired product by ethanol and distilled water to be neutral and further performing centrifugation and 80 DEC C drying to acquire nickel cobaltite / carbon nanotube composite materials. The method which hardly damages the structure of the carbon nanotube has the characteristics of simple operation and environment friendliness. By means of the method, products can be directly acquired in the solution without calcining. The acquired nickel cobaltite / carbon nanotube composite materials have relatively high specific capacitance and good electrochemistry performance stability when applied to super capacitor electrodes.

Owner:CHINA JILIANG UNIV

Method for producing lithium cobaltite by preparing hydroxyl trivalent cobalt oxide through wet chemical reaction

The invention discloses a method for producing lithium cobaltite by preparing hydroxyl trivalent cobalt oxide through wet chemical reaction. The method comprises the following steps of: preparing cobalt salt solution and sodium hydroxide solution; adding ammonia water serving as a complexing agent and stirring to generate cobaltous hydroxide slurry; adding sodium hypochlorite solution to oxidize the cobaltous hydroxide slurry; filtering, washing and drying to obtain a hydroxyl trivalent cobalt oxide precursor; uniformly mixing the precursor and lithium carbonate and then sintering to obtain a lithium cobaltite product; crushing the lithium cobaltite, then adding oxides of Ti, Mg and Al, serving as additives, into a muffle furnace and then sintering to perform doping treatment; and crushing and grading to obtain a product. By adopting the method, the need of a high-temperature oxidation step in the conventional synthesis process of the lithium cobaltite from the bivalent cobalt compound is avoided, air or oxygen is not required to be introduced in a sintering process, and influence of oxygen diffusion on reaction is avoided; and the method has the advantages of quick sintering reaction, low energy consumption, high capacity and high product quality.

Owner:DAXIN MANGANESE MINE BRANCH OF CITIC DAMENG MINING IND

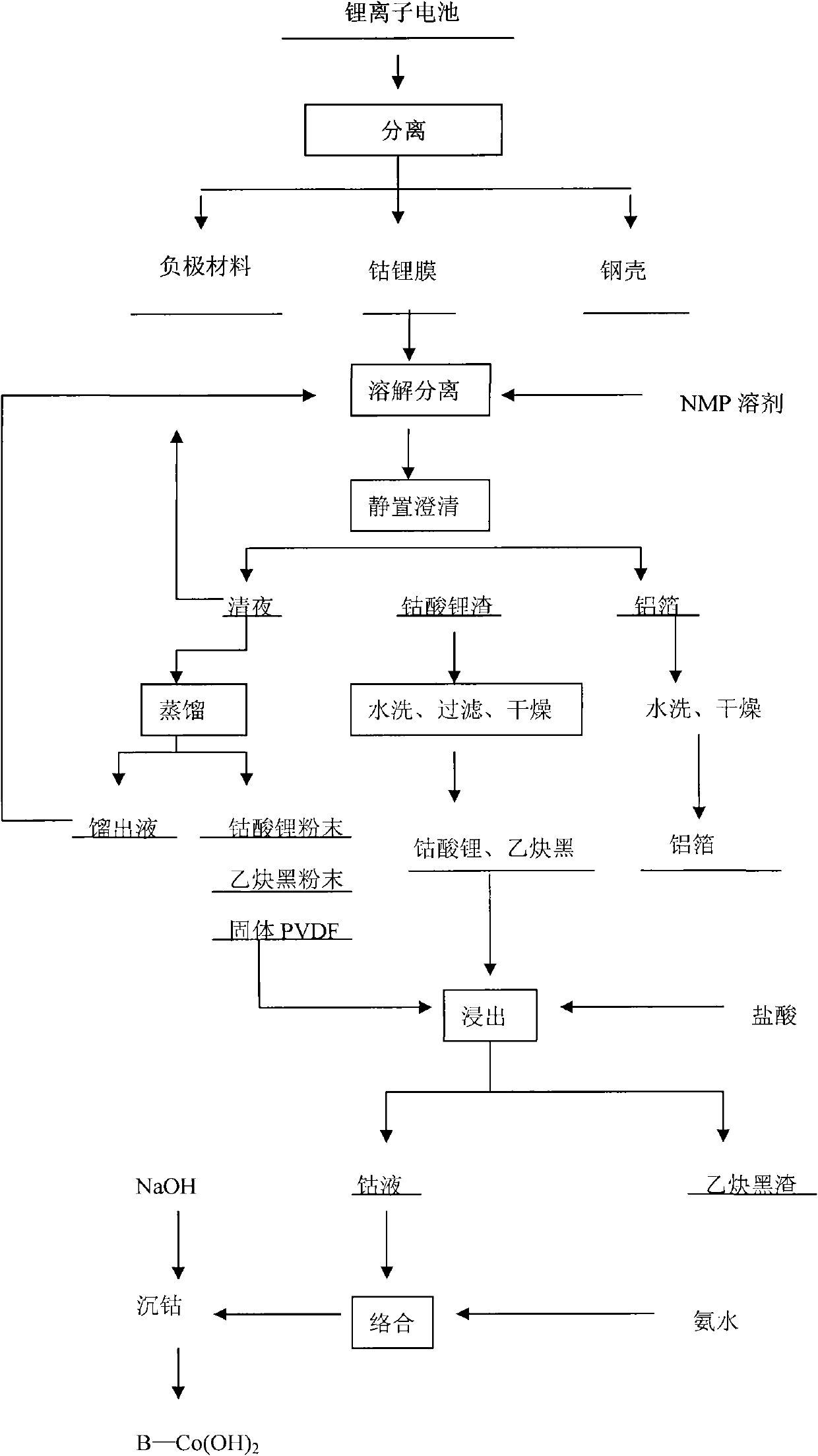

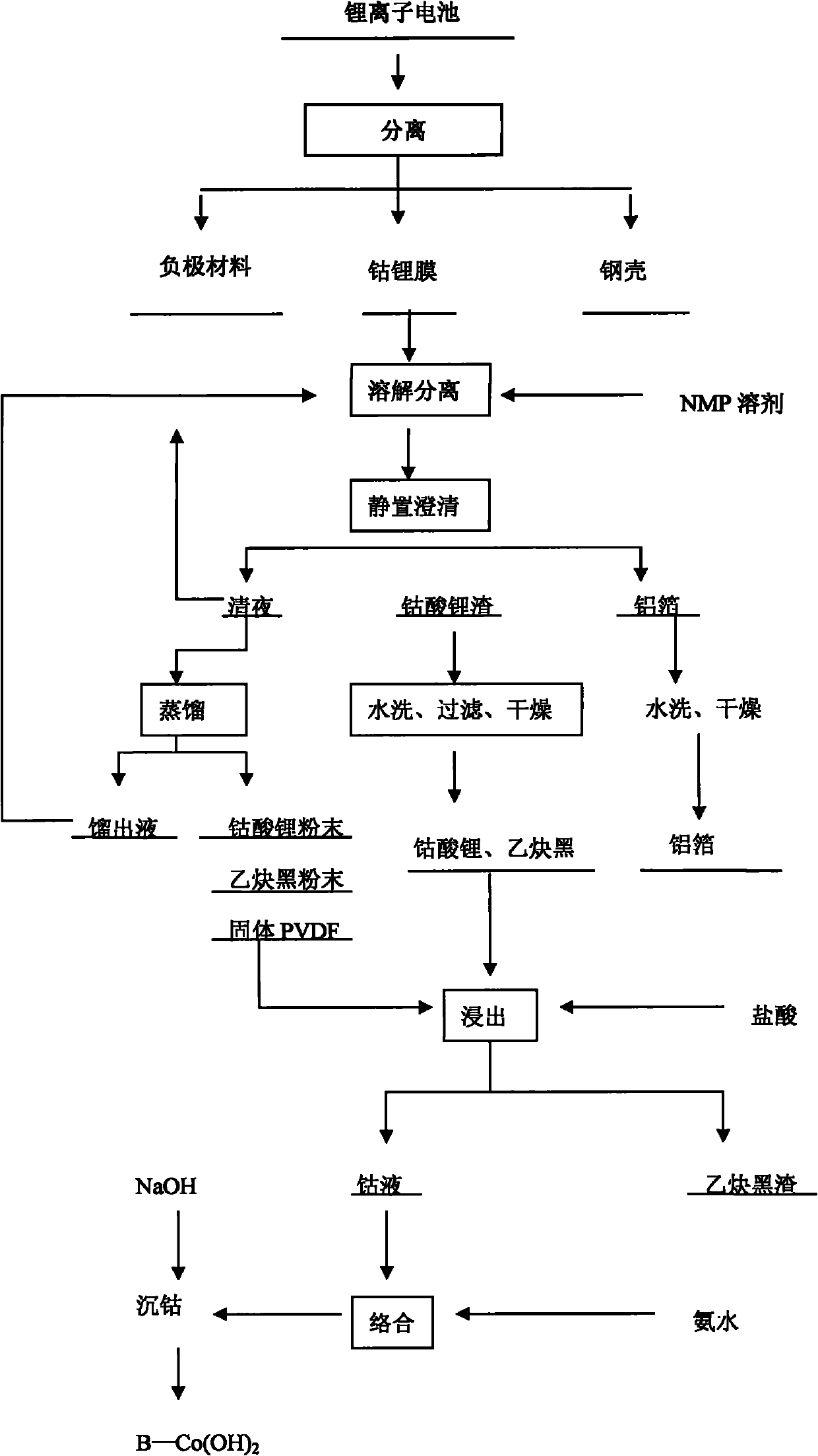

Process for treating wasted lithium cells

InactiveCN102005625ASimple recycling processIncrease recycled productsWaste accumulators reclaimingBattery recyclingSlagCobalt

The invention discloses a process for treating wasted lithium cells, comprising the following steps of: (1) separating recycled wasted cells, wherein negative electrode materials and steel shells are directly recycled and packed to be used raw materials for sale; (2) dissolving cobalt-lithium membranes obtained from separation with an NMP (N-methyl-2-pyrrolidone) solvent, clarifying, redissolving clear liquid, and washing separated aluminum foils with water and drying for sale; (3) carrying out water washing, filtering, drying and leaching on lithium cobaltite slag to obtain a cobalt solution; and (4) further complexing and precipitating the cobalt solution to obtain B-Co(OH)2. The invention has the advantages that the inorganic solvent is adopted for dissolving a binder PVDF (Polyvinylidene Fluoride) of the lithium cobaltite to enable the lithium cobaltite to fall off from the aluminum foil, and the elementary aluminum foils are directly recycled without the performing of cobalt-aluminum separation in the traditional lithium cell recycling process, therefore, the whole recycling process of wasted lithium cells is simplified and recycled products are increased.

Owner:苏州群瑞环保科技有限公司

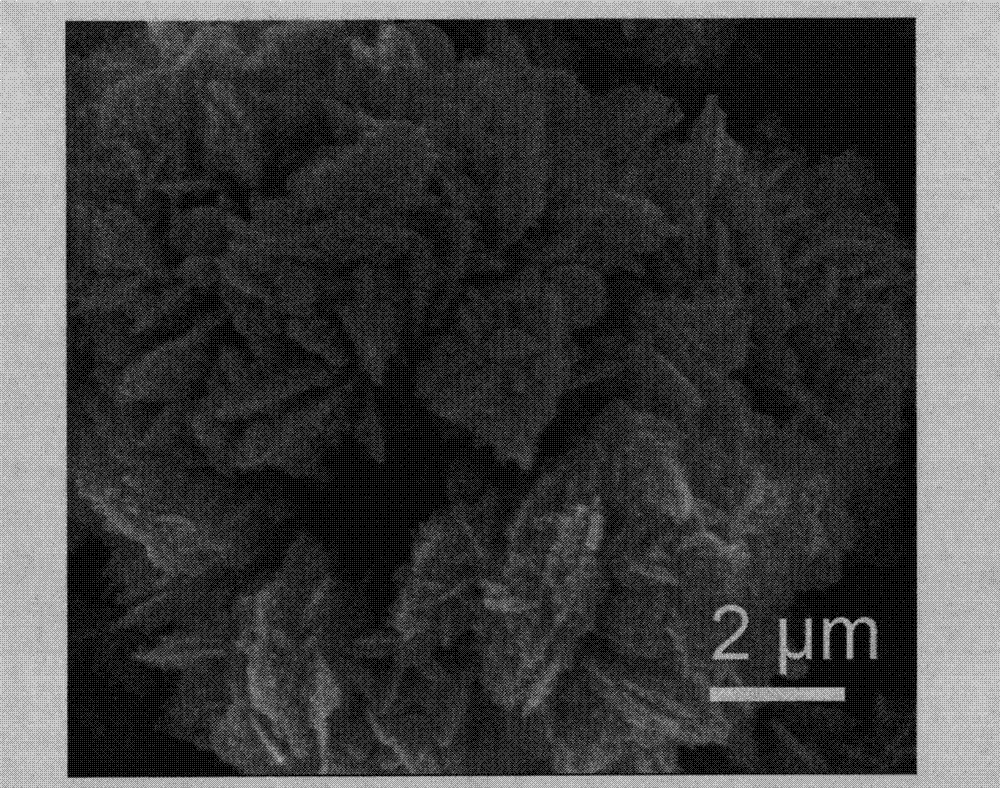

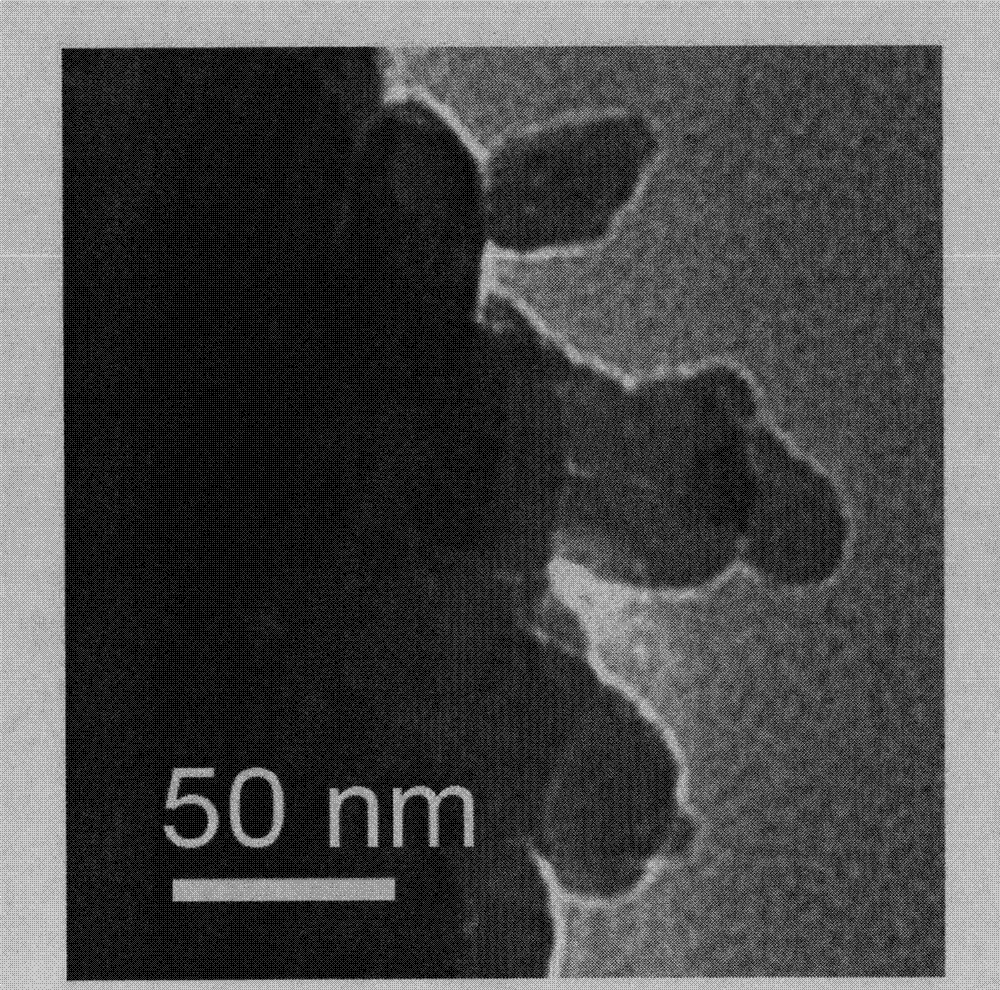

Cobalt-modified bismuth tungstate composite photocatalyst, its preparation method and application thereof

InactiveCN102764659ALarge specific surface areaImprove stabilityWater/sewage treatment by irradiationMetal/metal-oxides/metal-hydroxide catalystsTungstateSodium tungstate

The invention discloses a cobalt-modified bismuth tungstate composite photocatalyst, its preparation method and an application thereof. Bismuth tungstate in the catalyst is granules with the particle size being 0.5-3 microns and the catalyst is composed of bismuth tungstate pieces, the length of which is 30-100 nm and the thickness of which is 5-10 nm. Cobalt oxide granules with the particle size being 10-100 nm are modified on the bismuth tungstate pieces. The specific surface area of the catalyst is 5-20m<2> / g. The preparation method comprises the following steps of: respectively adding bismuth nitrate into a nitric acid solution with stirring to obtain a bismuth nitrate solution and adding cetyl trimethyl ammonium bromide into a sodium tungstate solution with stirring to obtain a mixed solution, adding the bismuth nitrate solution into the mixed solution, placing in an enclosed state, keeping warm at 160-180 DEG C for 20-24 h, centrifuging, washing, drying to obtain a bismuth tungstate powder, adding the bismuth tungstate powder into a cobaltite solution, stirring, drying, grinding into a powder, and roasting the powder to prepare the target product. The product can be used in water polluted by organic matters or heavy metal ions to perform visible light photodegradation.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

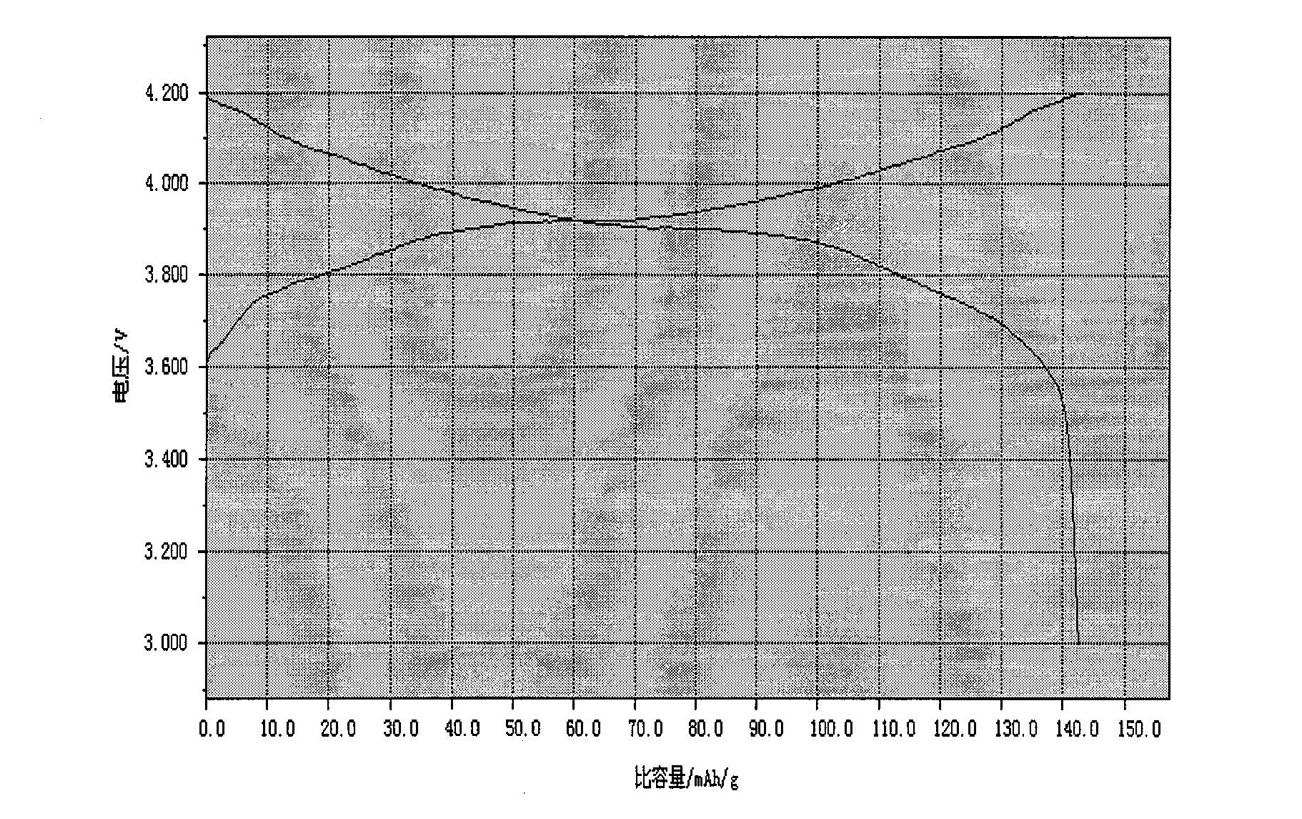

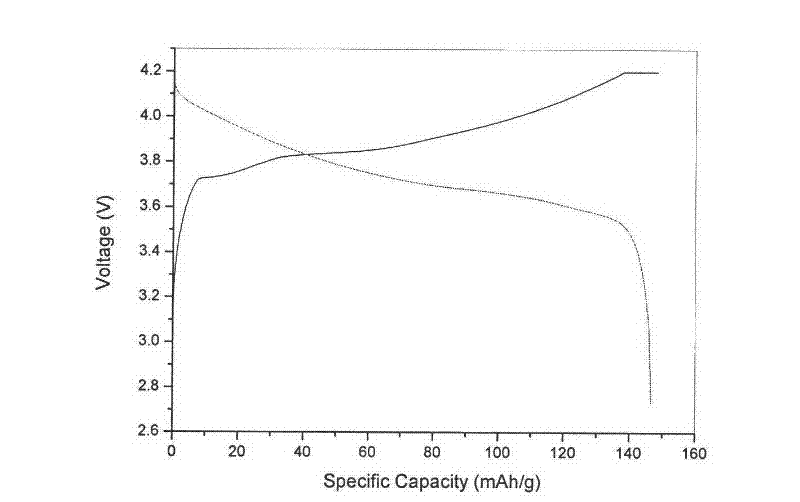

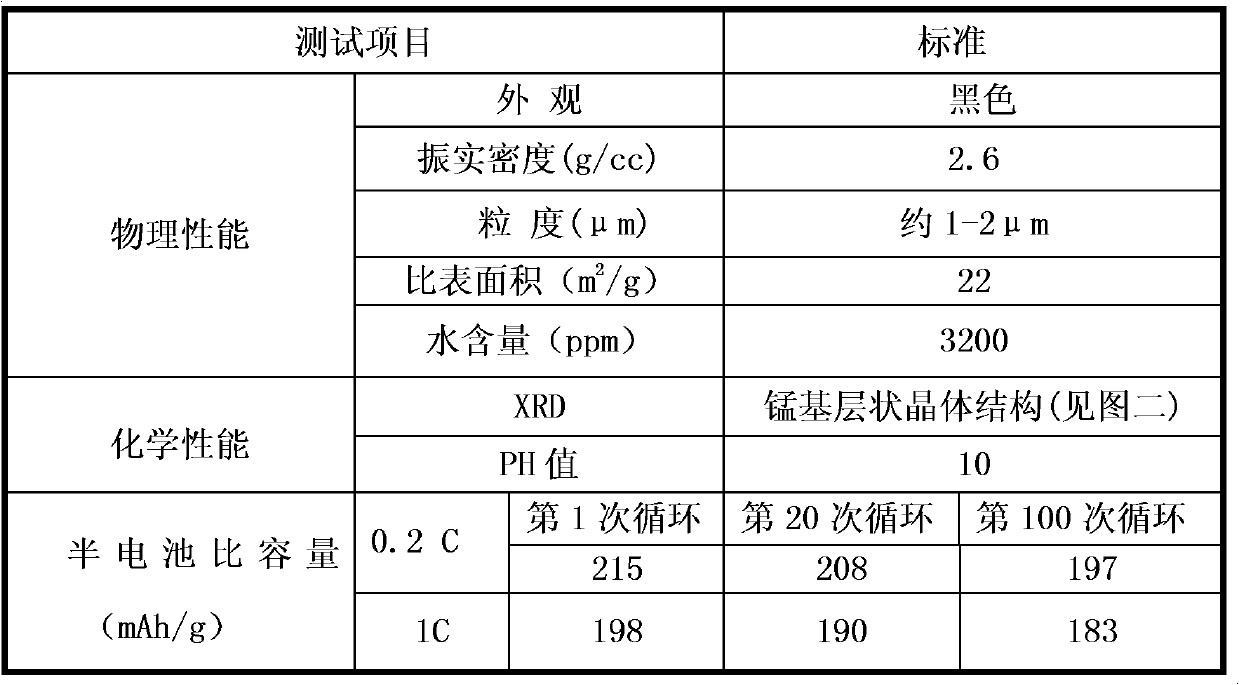

Lithium cell cathode material with manganese-based laminated crystal structure and preparation method thereof

The invention relates to a manufacture technology of lithium cells, in particular to a preparation method of a lithium cell cathode material with a manganese-based laminated crystal structure, which comprises the steps of: 1, preparing a precursor of LI[Li0.20Ni0.133Co0.133Mn0.534]O2 by adopting a mechanical activating method; 2, pelleting by adopting a closed cycle spraying drying method; and 3,preparing a laminated crystal structure Li[Li0.20Ni0.133Co0.133Mn0.534]O2 by adopting a high-temperature solid phase method. In the material and the method, most of cobalt in lithium cobaltite is replaced with cheap metal manganese, cost of raw materials is lower, the preparation process is simple, and micron-level powder particles can show excellent cell properties. Through detection, capacity of the cathode material reaches 236mAh / g and is about 60 percent higher than that of lithium cobaltite and lithium iron phosphate, and the cathode material has excellent safety property.

Owner:宁夏科捷锂电池股份有限公司

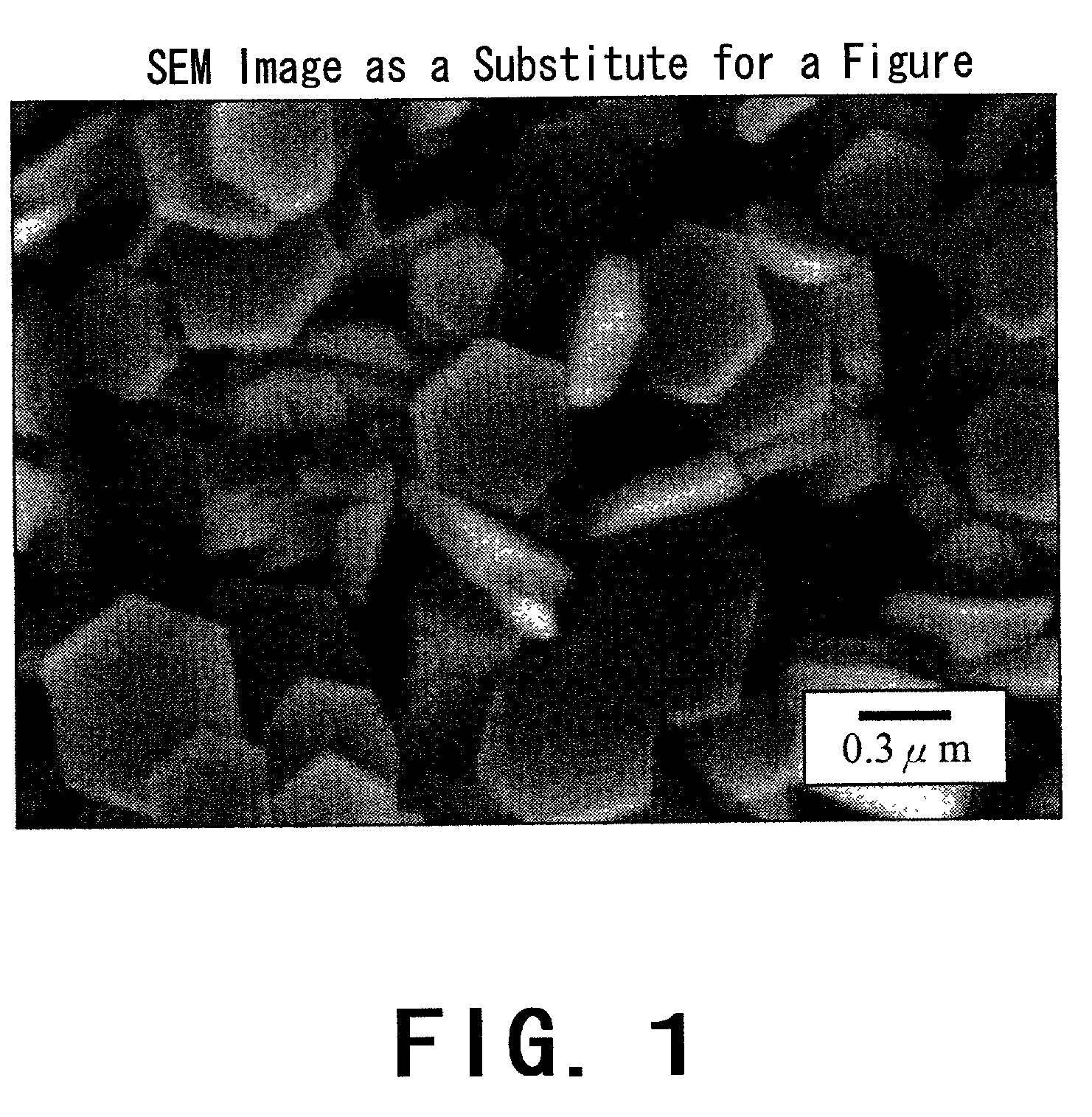

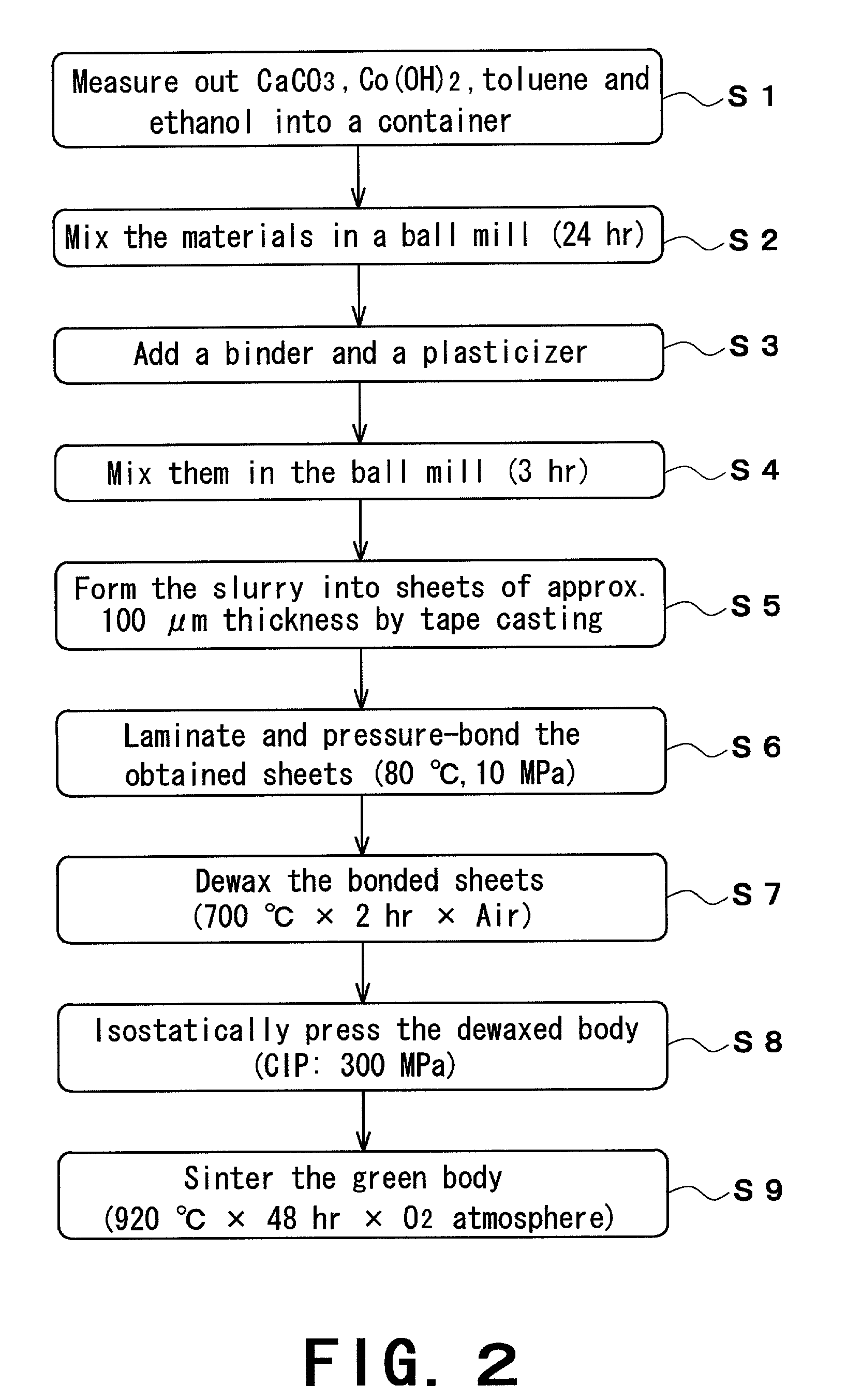

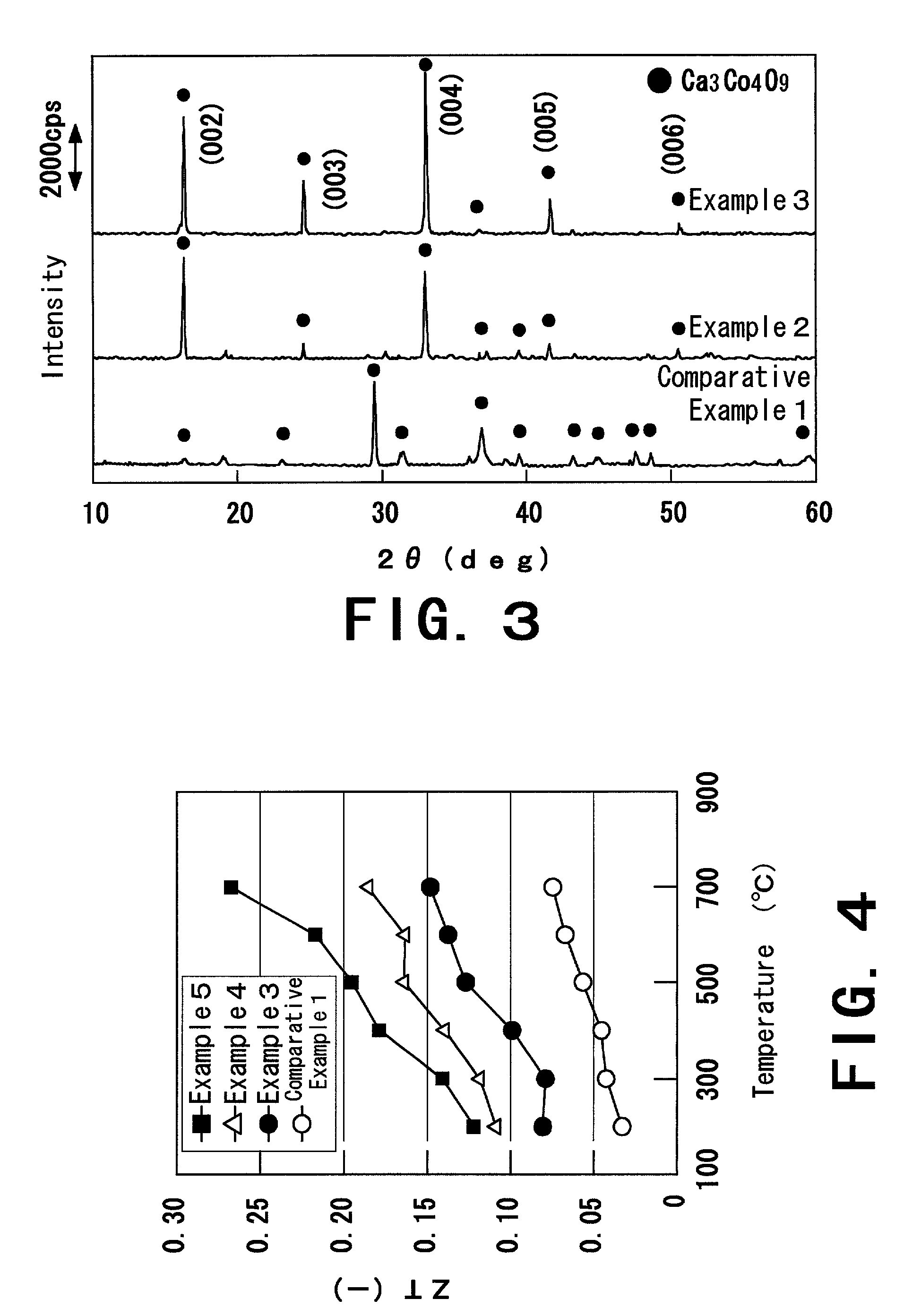

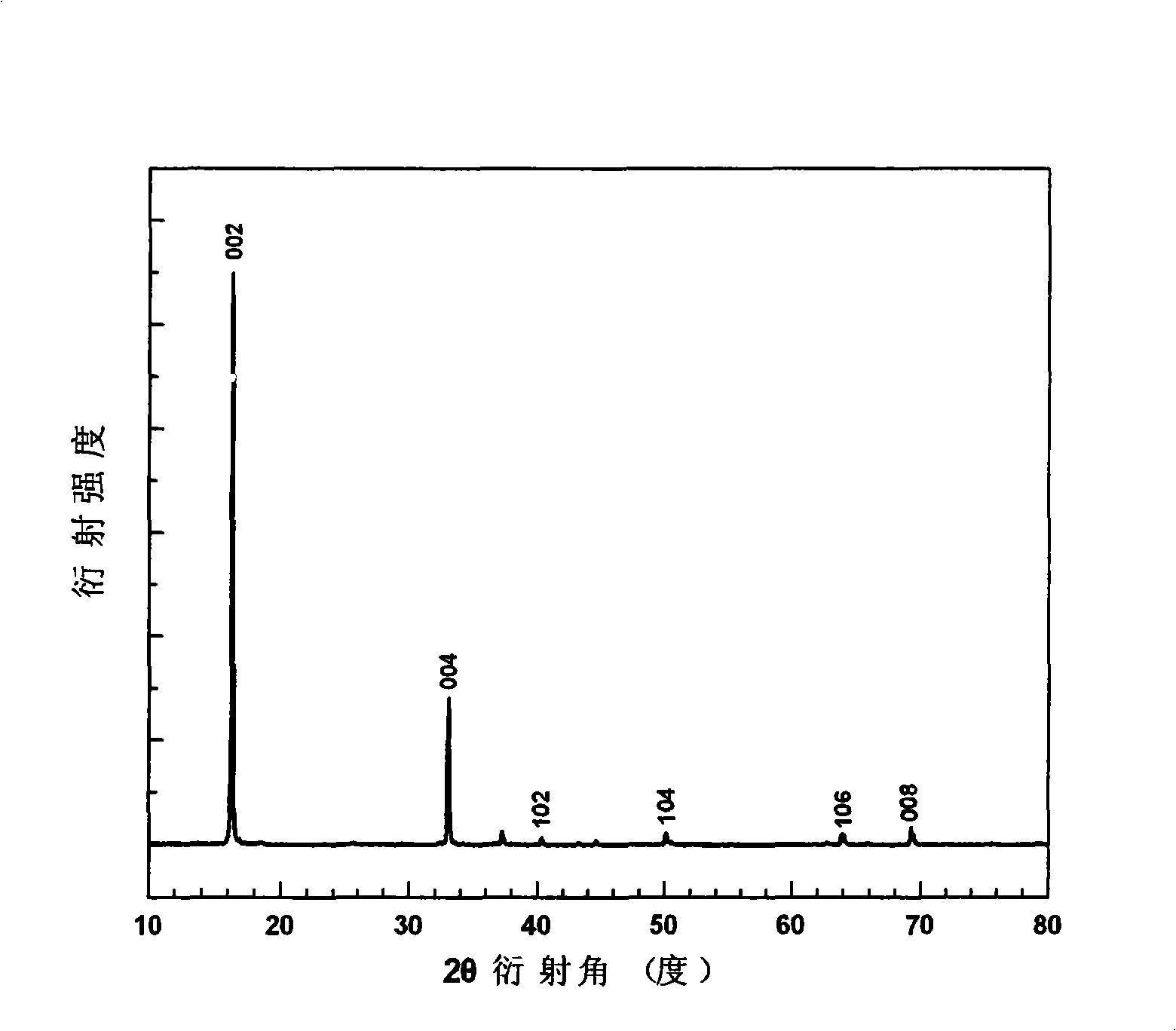

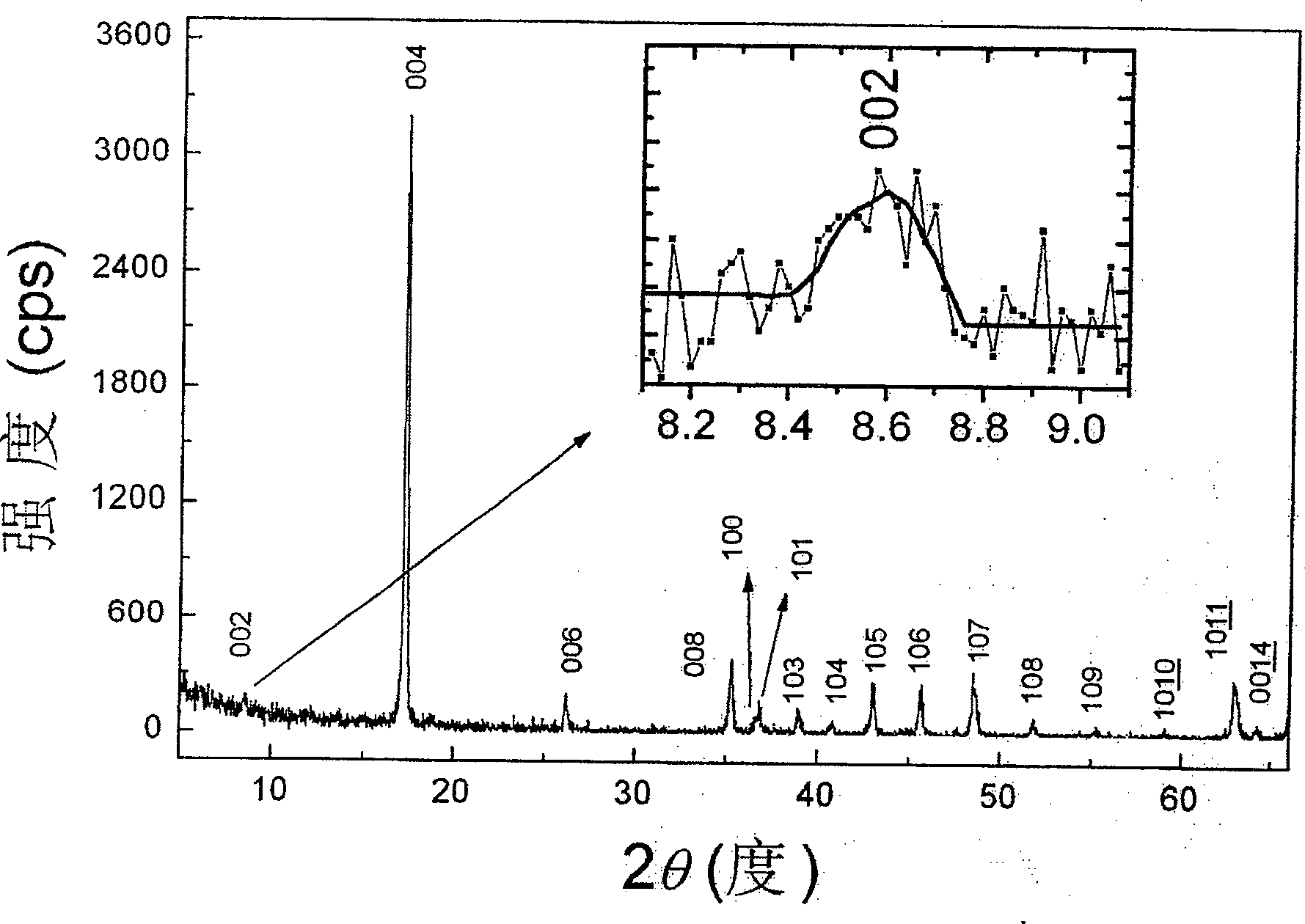

Grain oriented ceramics and a production process thereof, a platelike powder for producing the grain oriented ceramics, and a thermoelectric conversion element

InactiveUS20030013596A1Improve conductivityReasonable thicknessConductive materialRare earth metal compoundsAlkaline earth metalShell molding

Grain oriented ceramics constituted of a polycrystalline body of a layered cobaltite in which a {001}plane of each grain constituting the polycrystalline body has an average orientation degree of 50% or more by the Lotgering's method. In this case, the layered cobaltite is preferably a layered calcium cobaltite expressed by the following general formula: {(Ca1-xAx)2CoO3+alpha} (CoO2+beta)y (where A represents one or more elements selected among an alkali metal, an alkaline earth metal and Bi, 0 <=x<=0.3, 0.5 <=y <=2.0, and 0.85 <={3+alpha+(2+beta)y} / (3+2y) <=1.15). Such grain oriented ceramics are obtained by molding a mixture of the first powder constituted of a Co(OH)2 platelike powder and the second powder constituted of CaCO3 and the like such that a developed plane of the platelike powder is oriented, and by heating the green body at a predetermined temperature.

Owner:TOYOTA CENT RES & DEV LAB INC

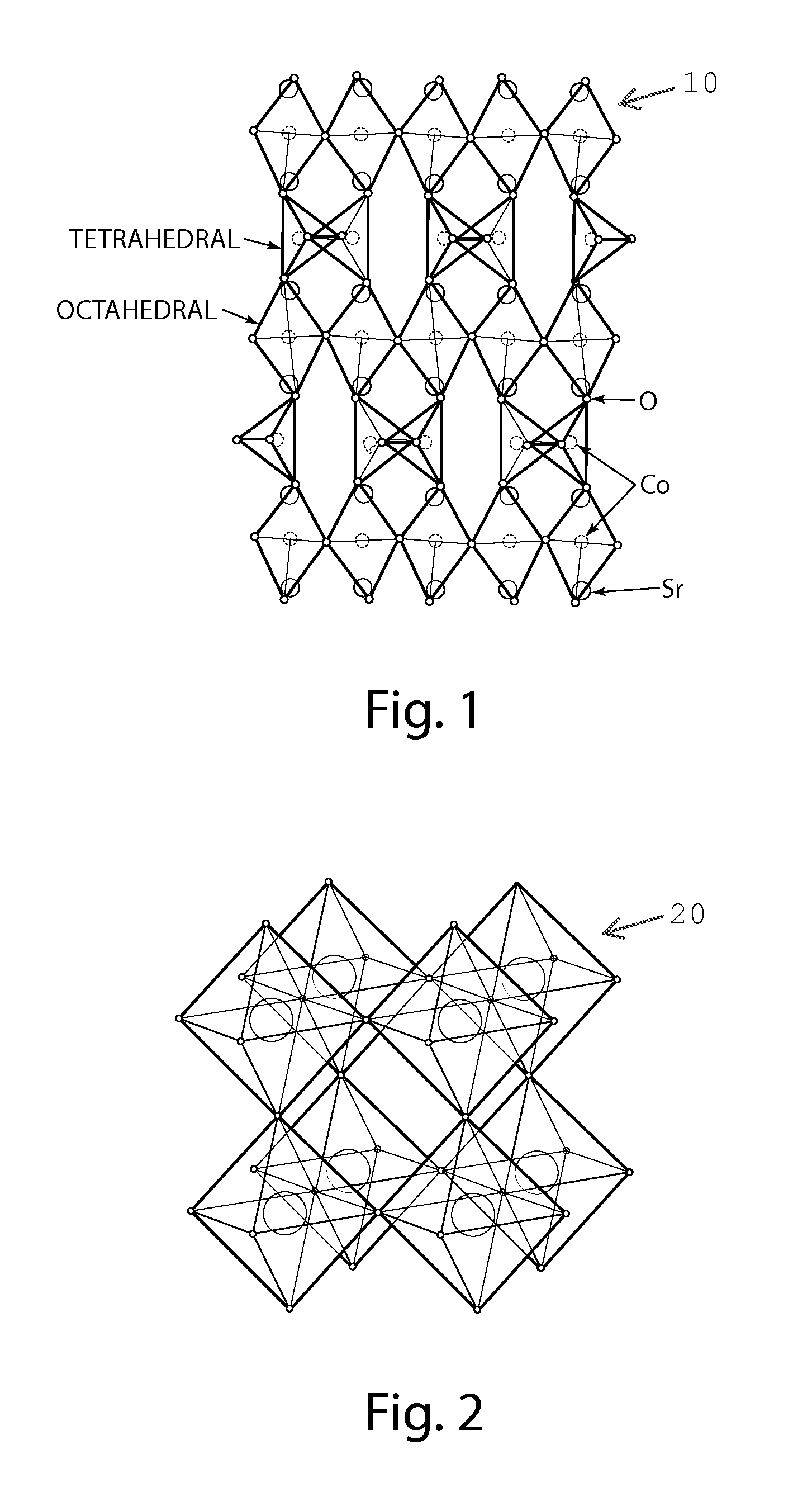

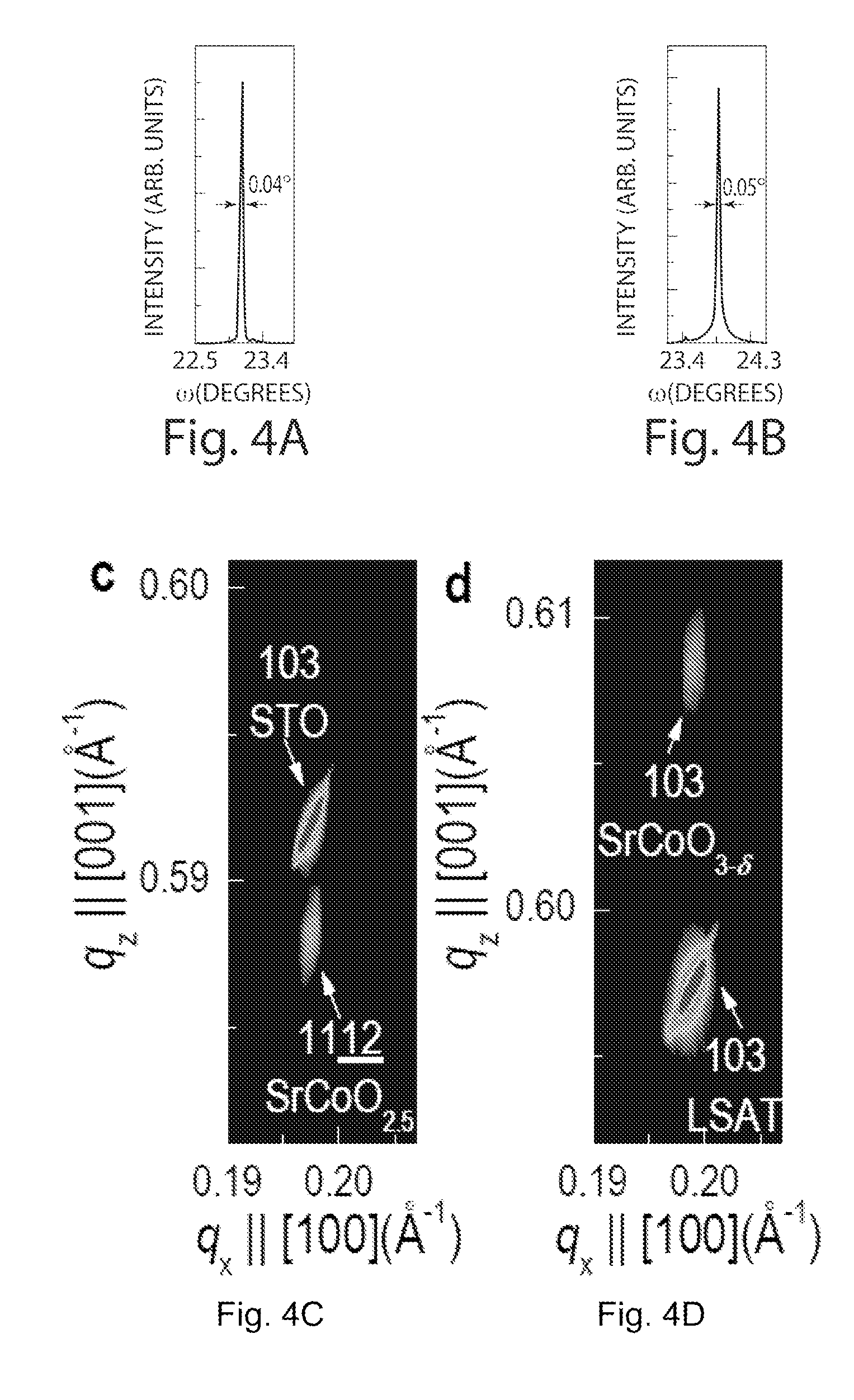

Strontium cobaltite oxygen sponge catalyst and methods of use

ActiveUS20150148218A1Other chemical processesCatalyst activation/preparationGibbs free energyPtru catalyst

Rapid, reversible redox activity may be accomplished at significantly reduced temperatures, as low as about 200° C., from epitaxially stabilized, oxygen vacancy ordered SrCoO2.5 and thermodynamically unfavorable perovskite SrCoO3-δ. The fast, low temperature redox activity in SrCoO3-δ may be attributed to a small Gibbs free energy difference between the two topotactic phases. Epitaxially stabilized thin films of strontium cobaltite provide a catalyst adapted to rapidly transition between oxidation states at substantially low temperatures. Methods of transitioning a strontium cobaltite catalyst from a first oxidation state to a second oxidation state are described.

Owner:UT BATTELLE LLC

Acetate doping natrium cobaltite thermoelectric materials and preparation method thereof

InactiveCN101254952AWon't happenGood chemical uniformityCobalt compoundsThermoelectric materialsAcetic acid

The invention belongs to the technology field of oxide thermoelectric materials of the functional materials and the preparation thereof, and relates in particular to thermoelectric materials of acetate doping with co-o-Na. The invention utilizes sol-gal method, takes the acetate as the raw material and the citric acid as the complexing agent. The sol is formed at the temperature of 353 K to 363K and the xerogel is formed at the temperature of 323 K to 393K. The precursor nano meter powder can be obtained by gel pyrolysis and roasting; and the bulk material can be got by sintering finally. The invention utilizes the common water metal acetate as the raw material and the whole preparation process does not produce poisonous and harmful gas. The synthesis technology is simple and safe; furthermore, the drying process adopts decompression drying and realizes the drying process with low temperature and short time; also, the precursor powder has good uniformity and obvious layered structure, which is helpful to producing the bulk thermoelectric materials with high crystal orientation and high performance.

Owner:CENT IRON & STEEL RES INST

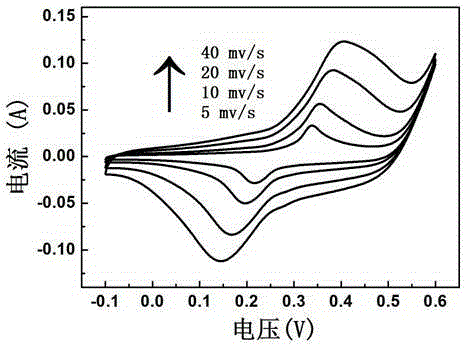

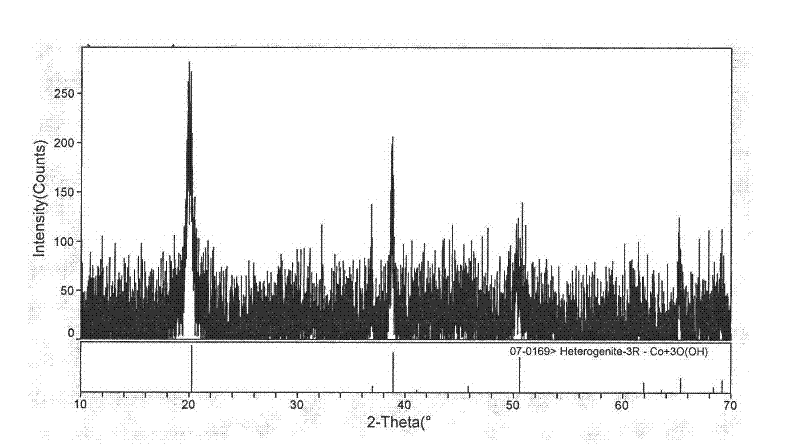

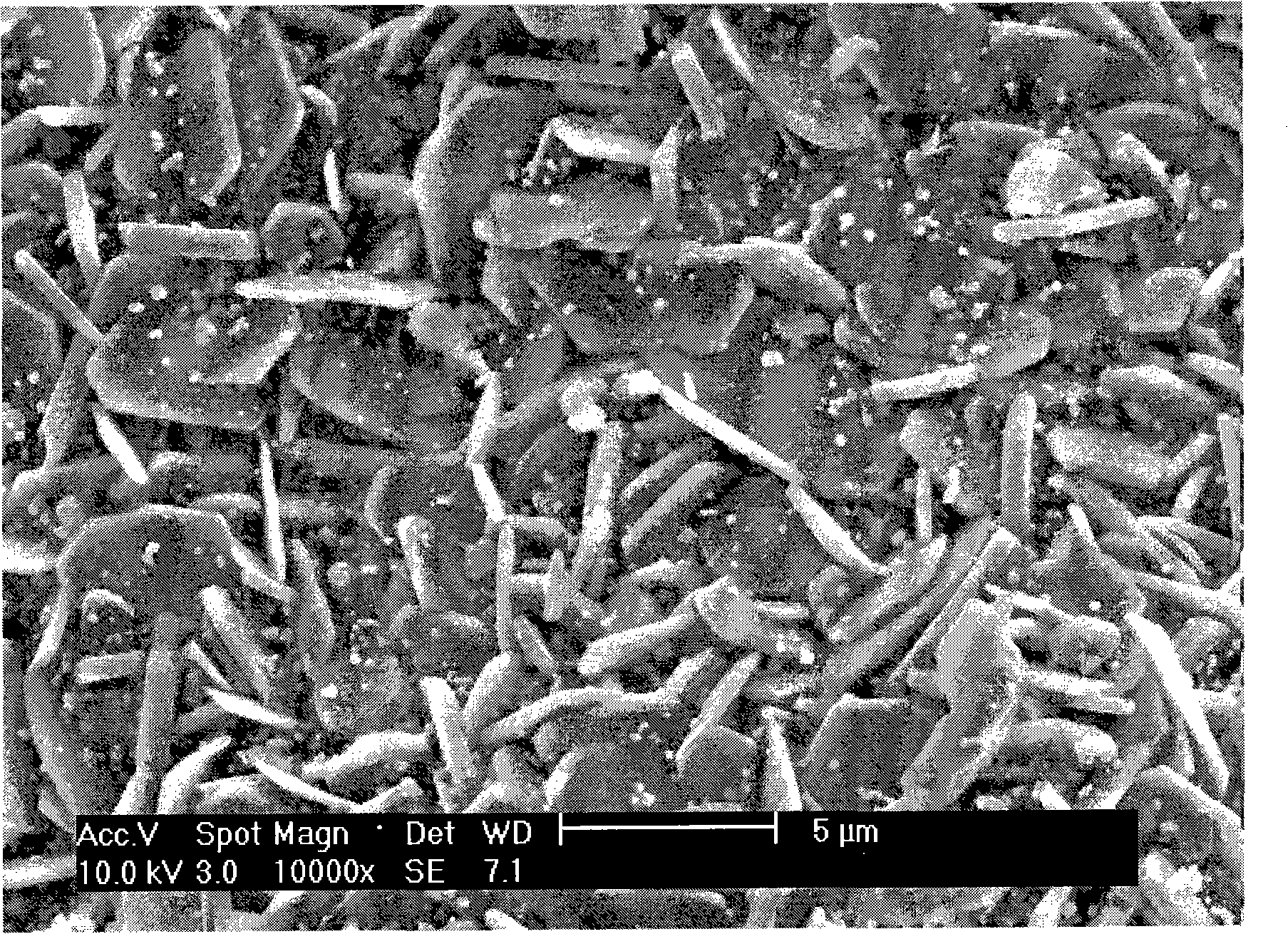

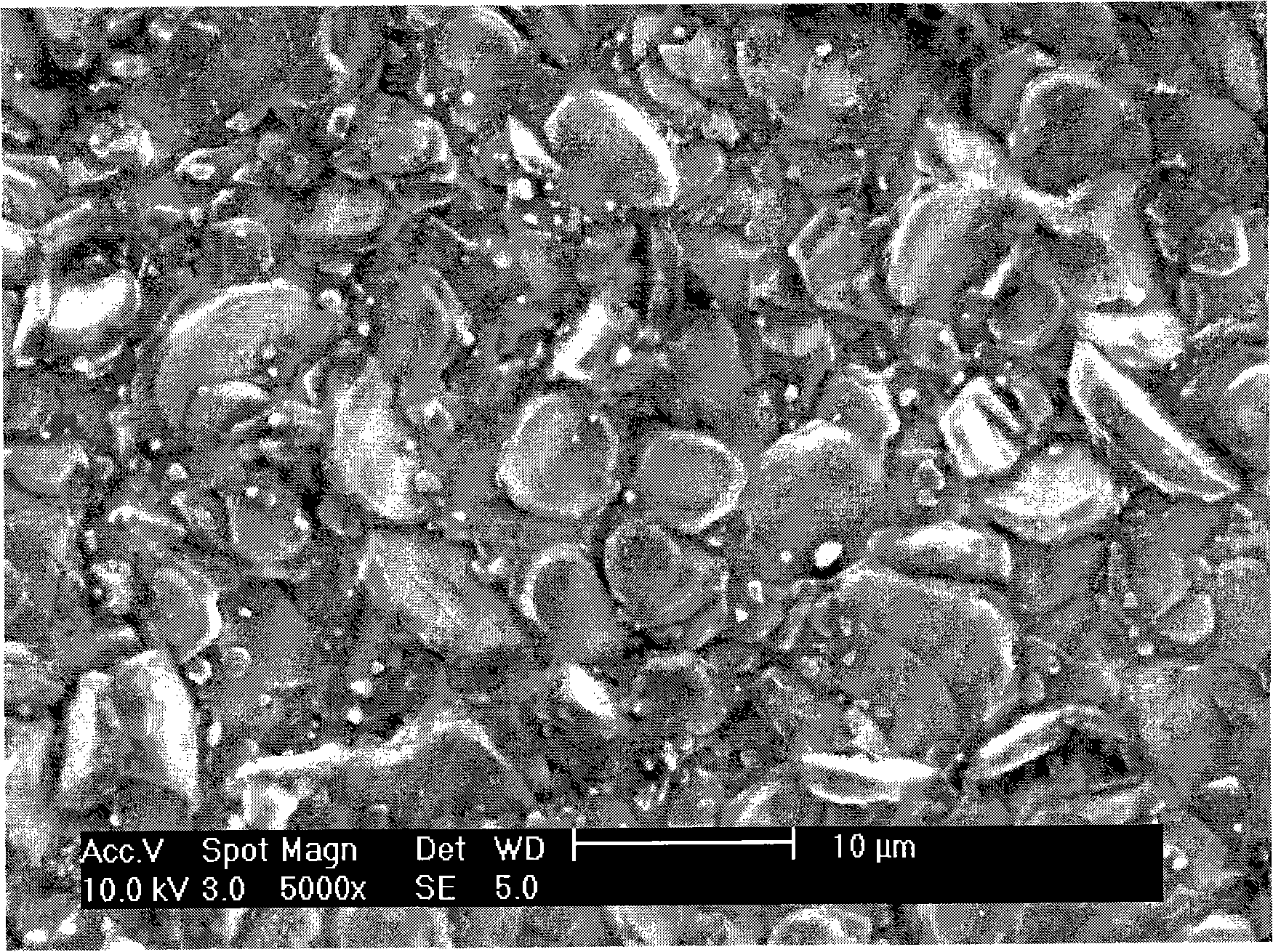

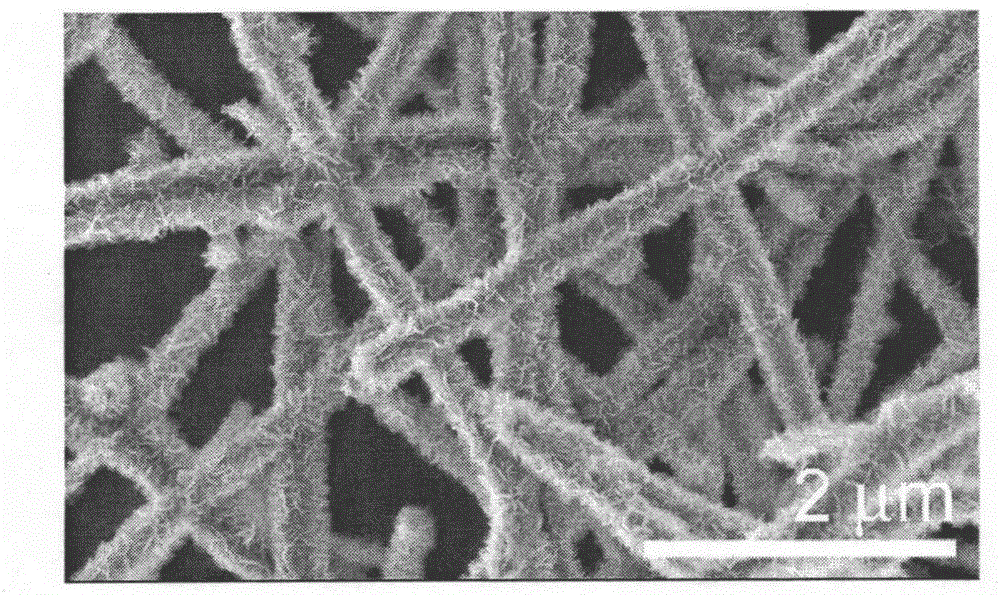

Nanometer nickel cobaltite and preparation method thereof

ActiveCN105439213AHigh purityLarge specific surface areaMaterial nanotechnologyHybrid capacitor electrodesCharge dischargeSorbitan

The invention provides a preparation method for nanometer nickel cobaltite. The preparation method comprises the following steps: (1) adding nickel nitrate, cobalt nitrate and urea into anhydrous ethanol, and stirring at ordinary temperature to enable the solution to be uniformly mixed, so as to obtain a solution A; (2) adding sorbitan fatty acid ester S-20 and sorbitan fatty acid ester S-40 into the solution A, and uniformly mixing through ultrasonography to obtain a solution B; (3) transferring the solution B into a reaction kettle, conducting solvent thermal reaction, washing, and drying to obtain a precursor; (4) conducting constant temperature heat treatment on the precursor at 350-375 DEG C in air to obtain nanometer nickel cobaltite. In the charge-discharge test, the current density of nanometer nickel cobaltite is 2A / g, the specific capacity value is 2130 F / g which is a relatively high value, and the specific capacity still keeps 92% or above after the charge-discharge test is carried out for 400 times, so that nanometer nickel cobaltite can be used as an electrode material of a supercapacitor.

Owner:安徽富锂新能源科技有限公司

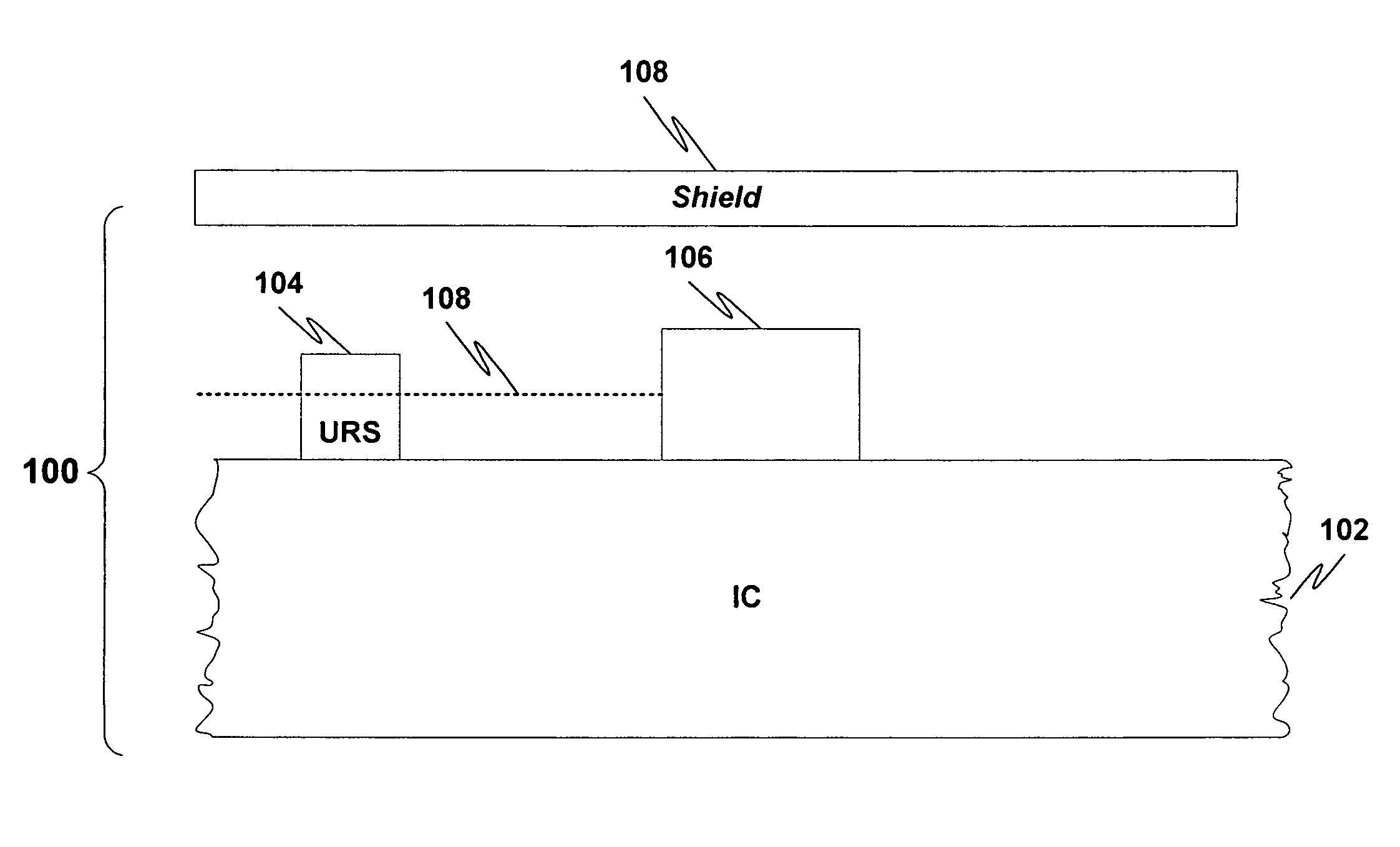

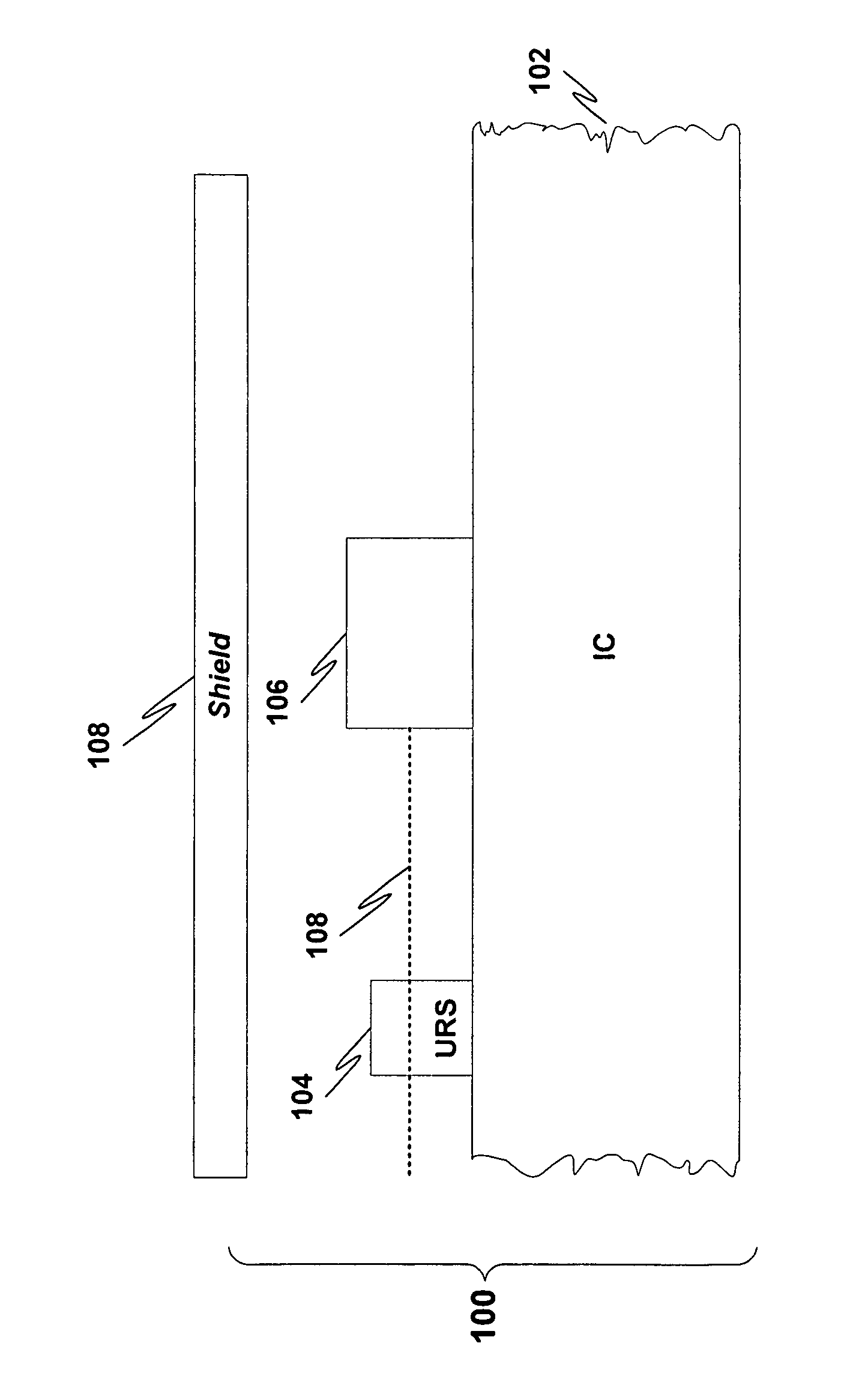

Shielding of integrated circuit package with high-permeability magnetic material

A device includes at least one ultra-small resonant structure; and shielding constructed and adapted to shield at least a portion of said ultra-small resonant structure with a high-permeability magnetic material. The magnetic material is formed from a substance selected from a non-conductive magnetic oxide such as a ferrite; a cobaltite, a chromite, and a manganite. The magnetic material may be mumetal, permalloy, Hipernom, HyMu-80, supermalloy, supermumetal, nilomag, sanbold, Mo-Permalloy, Ultraperm, or M-1040.

Owner:ADVANCED PLASMONICS

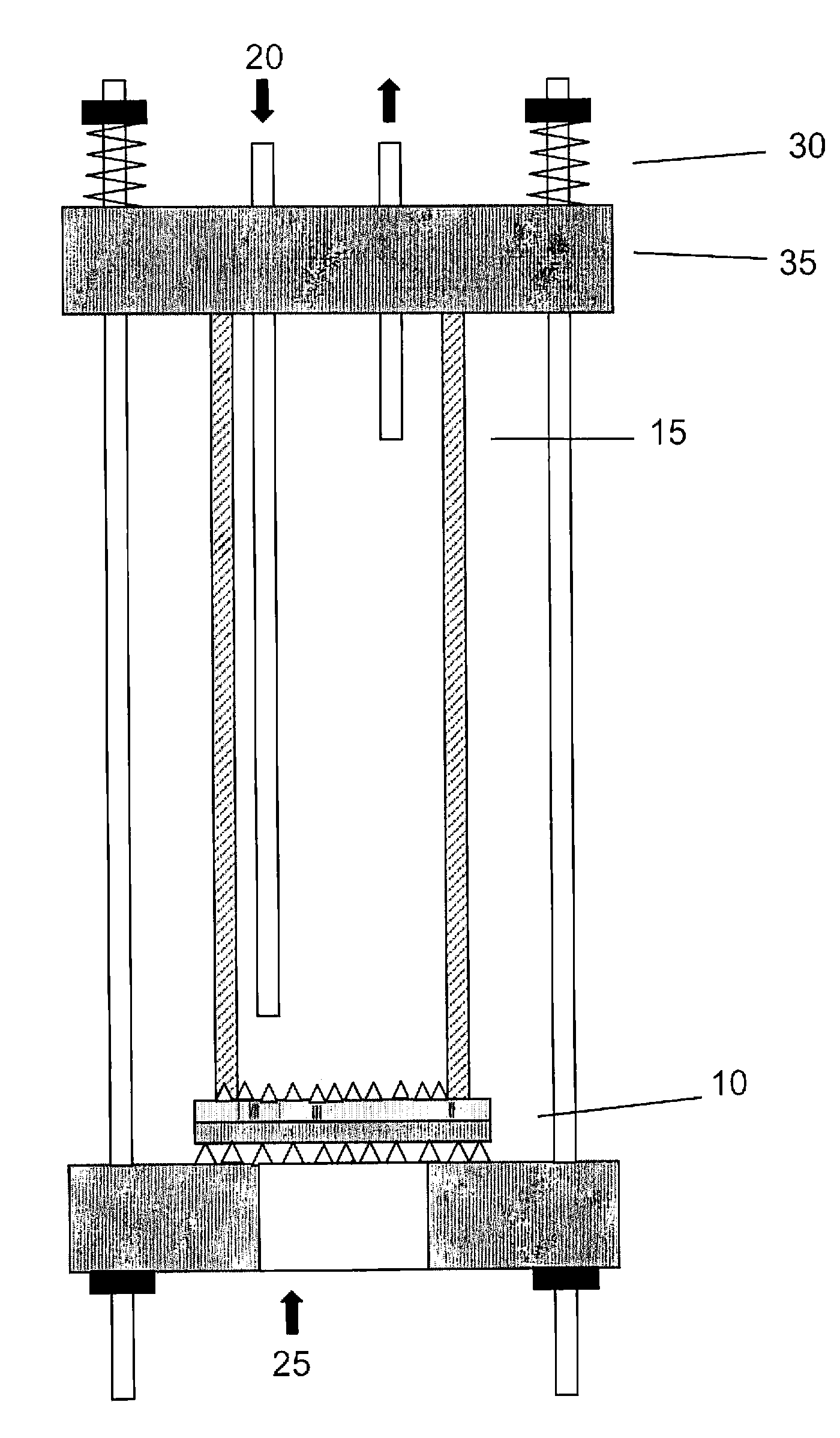

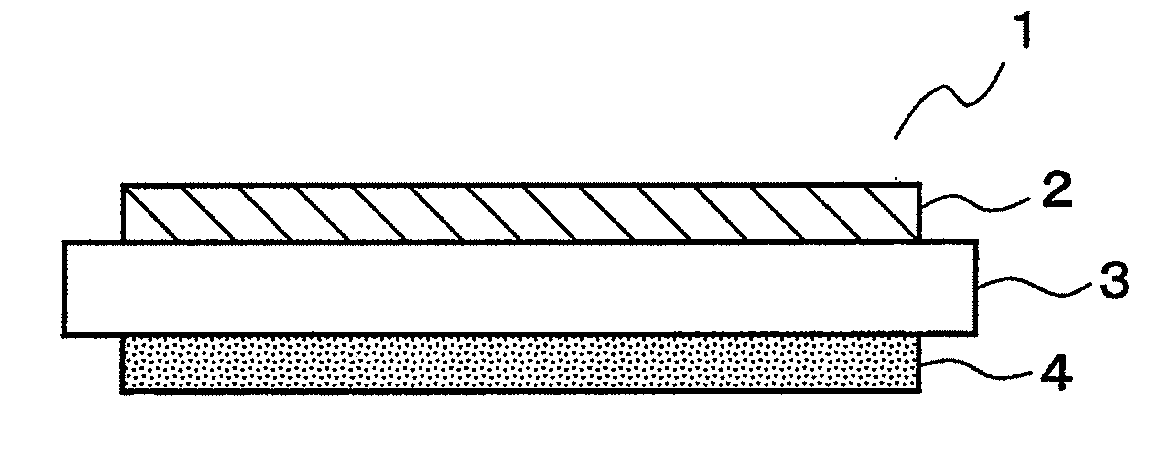

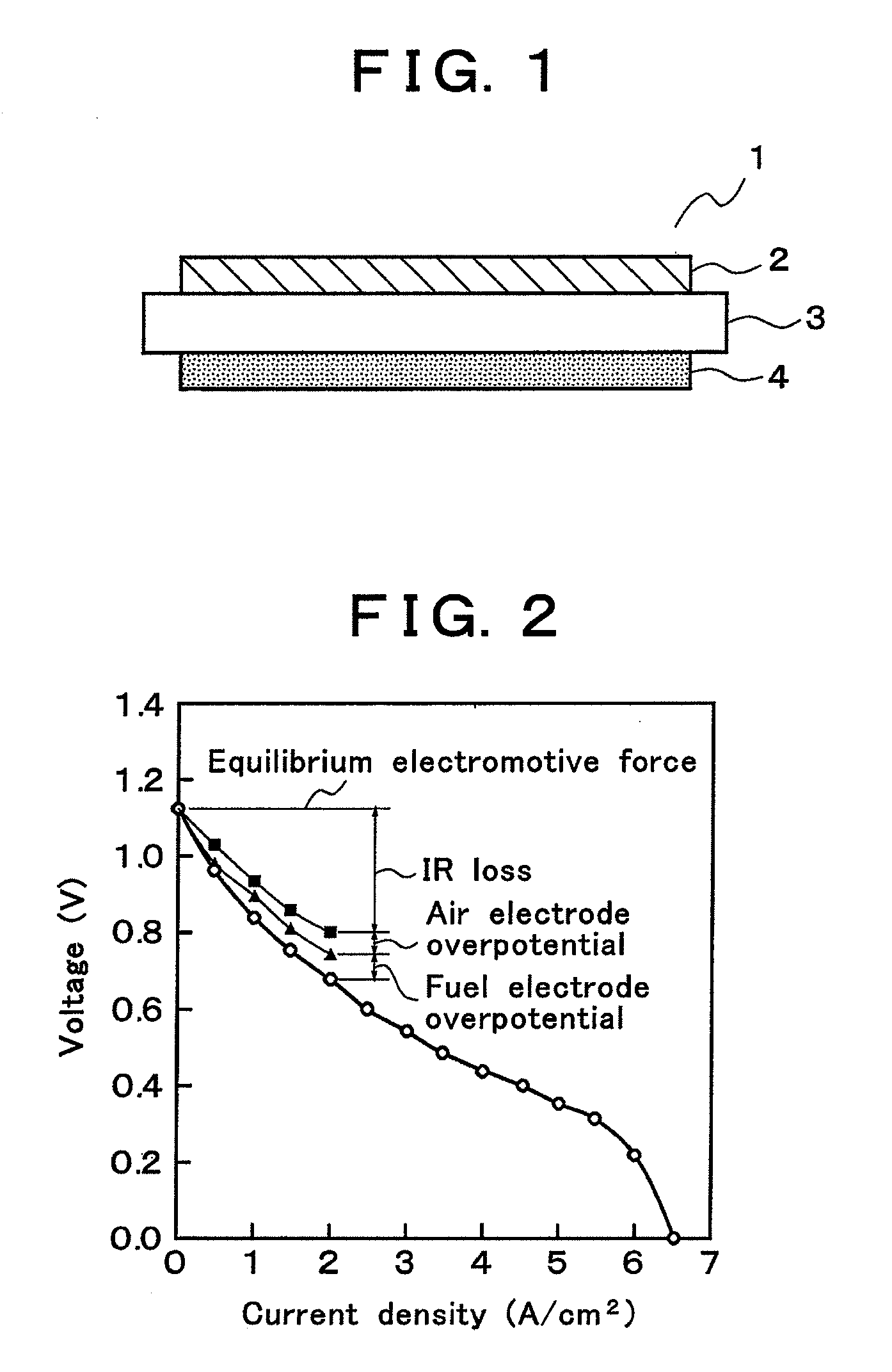

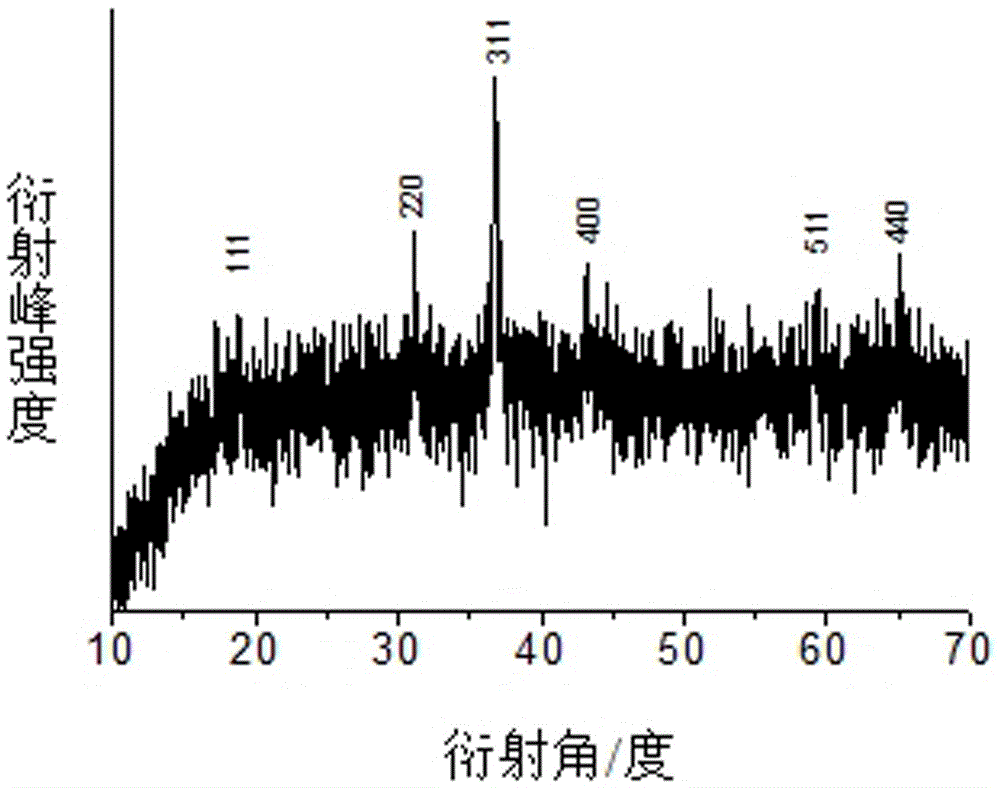

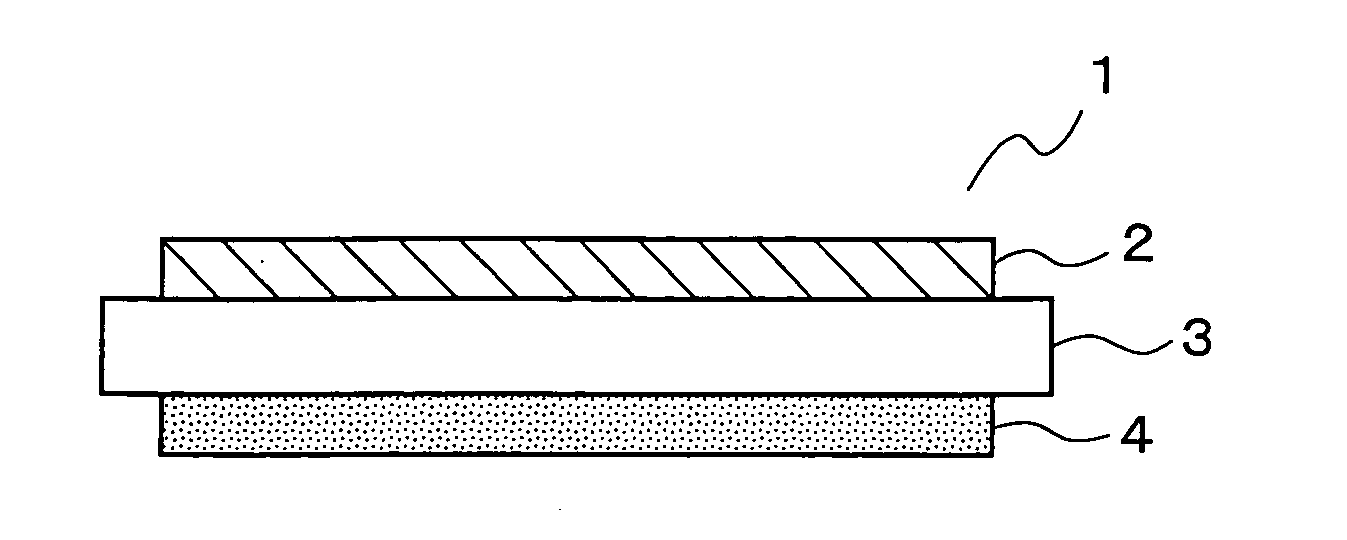

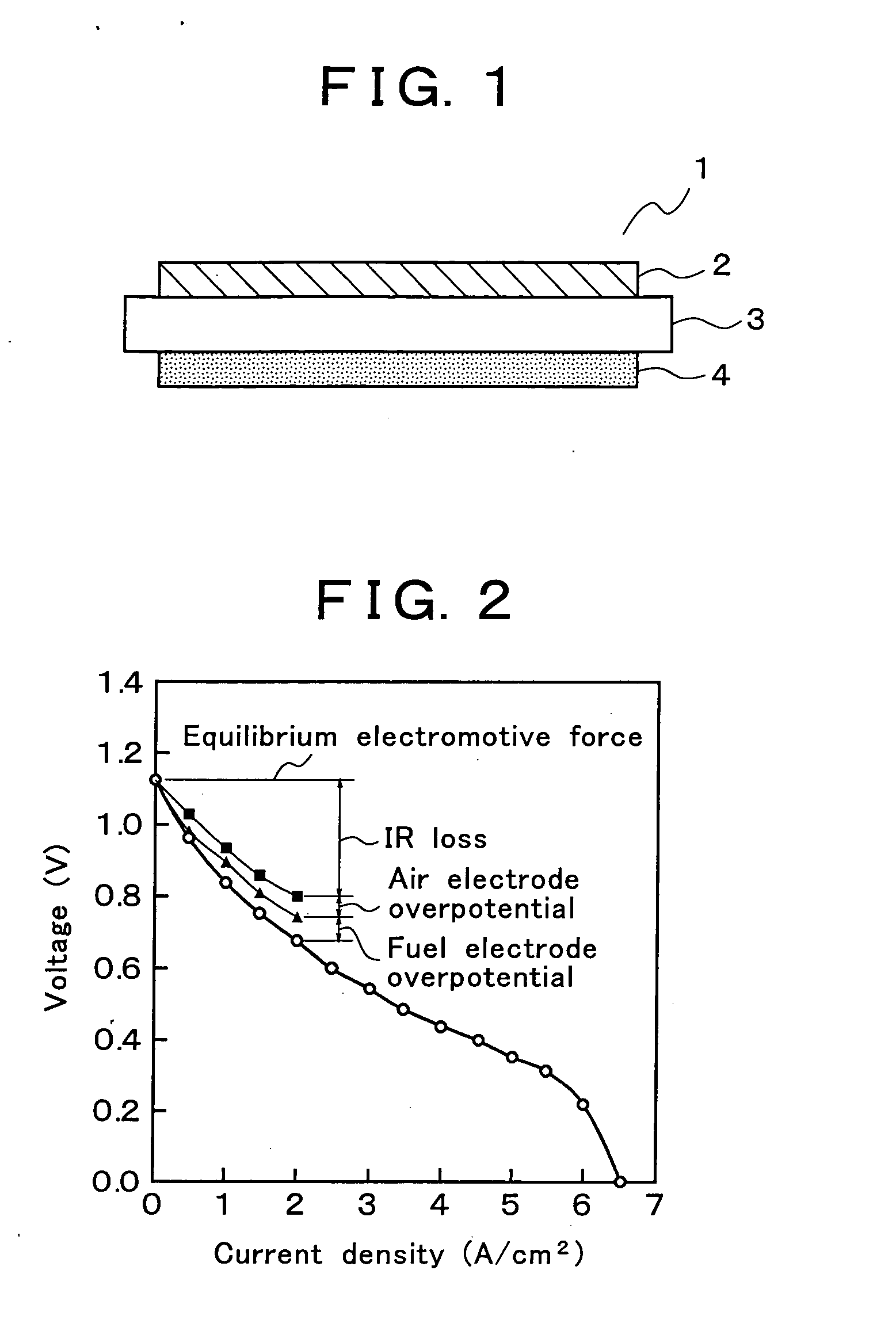

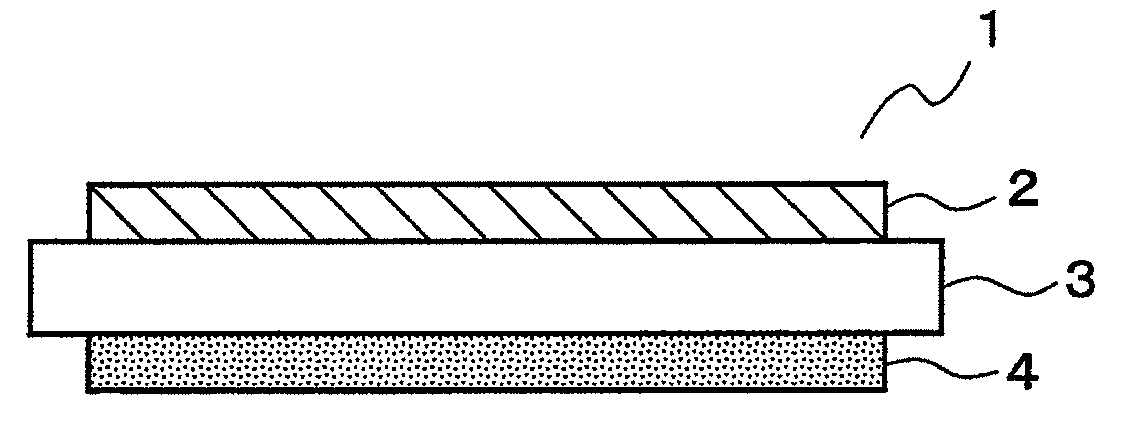

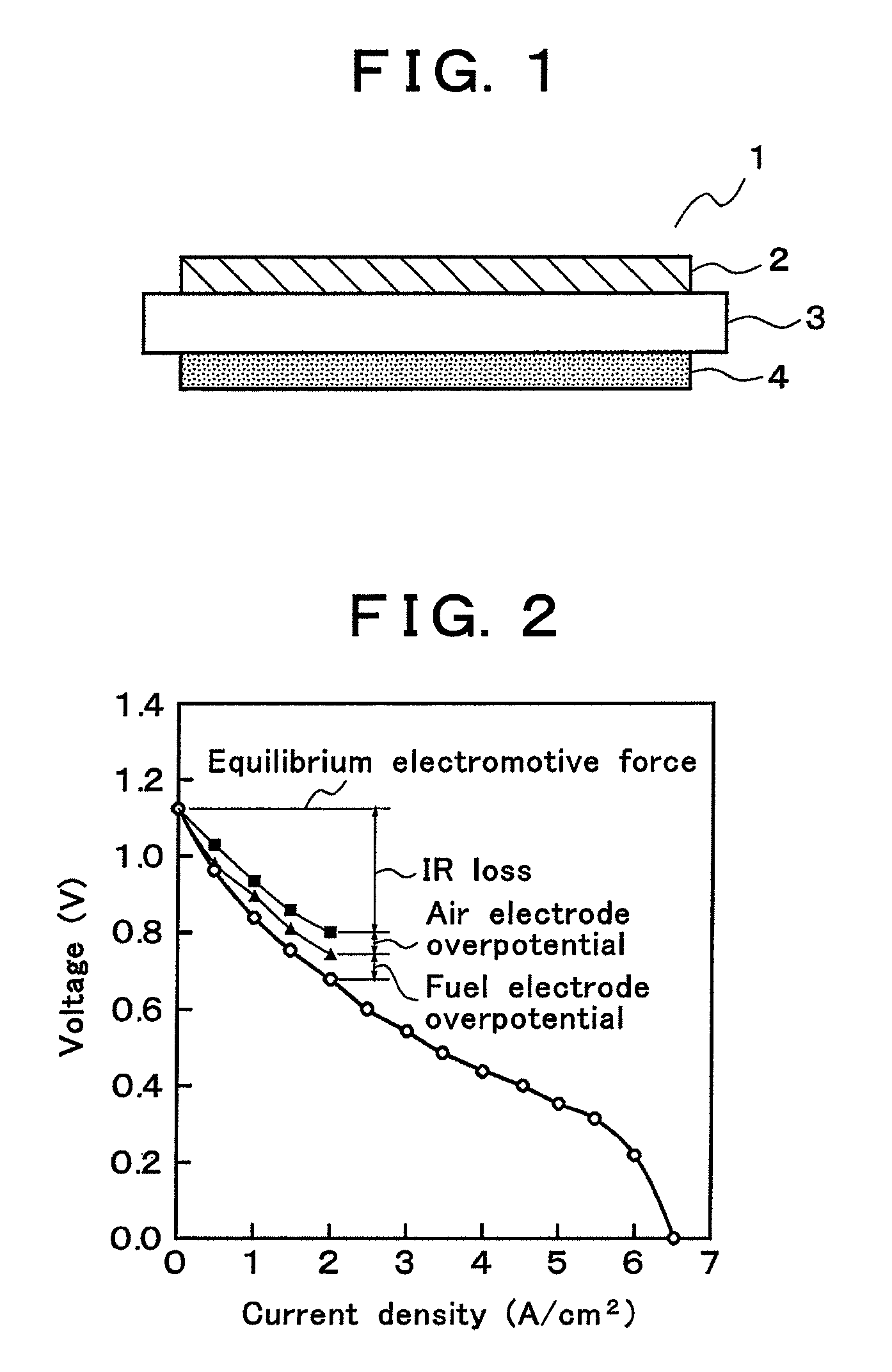

Solid oxide fuel cell and manufacturing method thereof

InactiveUS20100021792A1Improve performanceImprove powerFinal product manufactureGallium/indium/thallium compoundsFuel cellsNetwork structure

An electric power generation cell 1 is constituted by arranging a fuel electrode layer 4 on one side of a solid electrolyte layer 3 and an air electrode layer 2 on the other side of the solid electrolyte layer 3. The solid electrolyte layer 3 is constituted of an oxide ion conductor mainly composed of a lanthanum gallate based oxide. The fuel electrode layer 4 is constituted of a porous sintered compact having a highly dispersed network structure in which a skeletal structure formed of a consecutive array of metal grains is surrounded by mixed conductive oxide grains. For the air electrode layer 2, a porous sintered compact mainly composed of cobaltite is used. This configuration reduces the overpotentials of the respective electrodes and the IR loss of the solid electrolyte layer 3, and accordingly can actualize a solid oxide type fuel cell excellent in electric power generation efficiency.

Owner:THE KANSAI ELECTRIC POWER CO +2

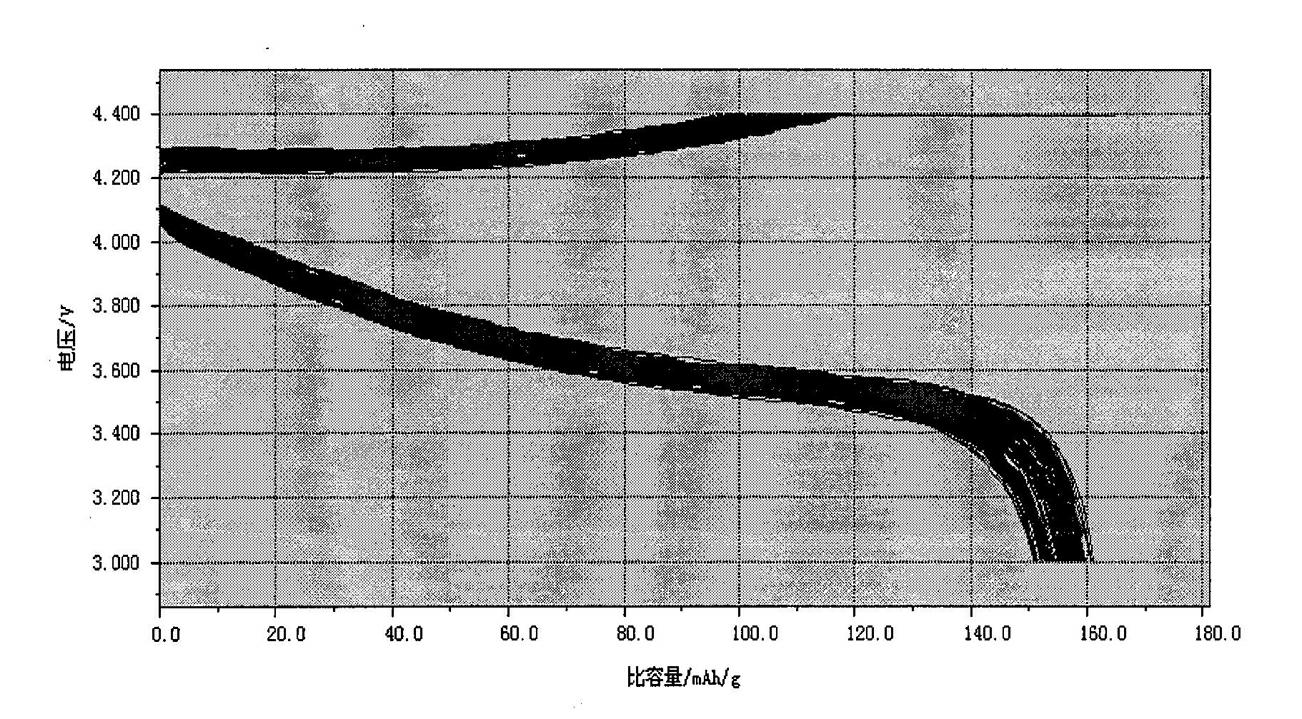

Method for ultrasonically repairing lithium cobaltite material of failed lithium ion battery

InactiveCN102344172AEasy to handleSimple processing methodWaste processingSolid waste disposalAluminium-ion batteryLithium hydroxide

The invention relates to a method for ultrasonically repairing a lithium cobaltite material in a failed lithium ion battery. The method specifically comprises the following steps of: (1) separating lithium cobaltite powder waste from a used and failed waste lithium ion battery by using a mechanical separation method; (2) filling the lithium cobaltite powder waste in 1-2mol / L lithium hydroxide solution and performing ultrasonic radiation under a room temperature condition for 6-12 hours; (3) cleaning and filtering ultrasonically treated mixed solution by using de-ionized water to obtain black lithium cobaltite paste; and (4) drying under an environment of 50-80 DEG C for 6-10 hours to obtain a repaired lithium cobaltite material. By adopting the ultrasonic radiation method, regeneration ofthe failed lithium cobaltite material is realized, and the lithium cobaltite material can be newly used as a positive material to produce a new lithium ion battery. By adopting the method, the lithium cobaltite material which is produced in the waste lithium battery after use and failure can be effectively treated; and the method has the characteristics of simple process method, strong operability, no secondary pollution and the like, and has high social benefit, economic benefit and environmental benefit.

Owner:TONGJI UNIV

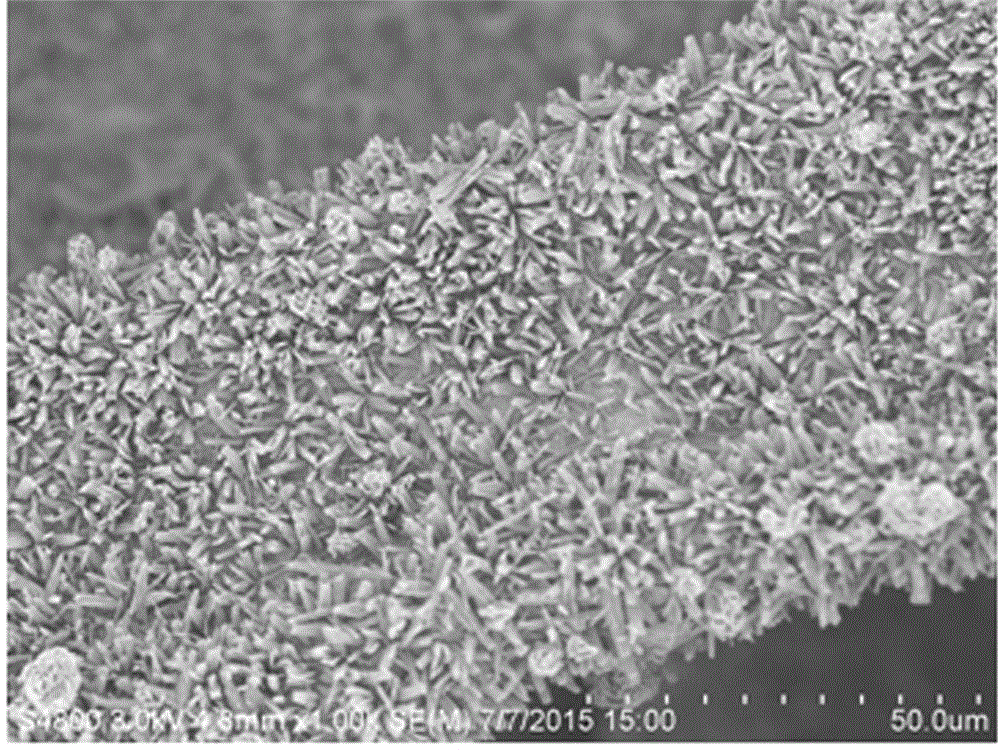

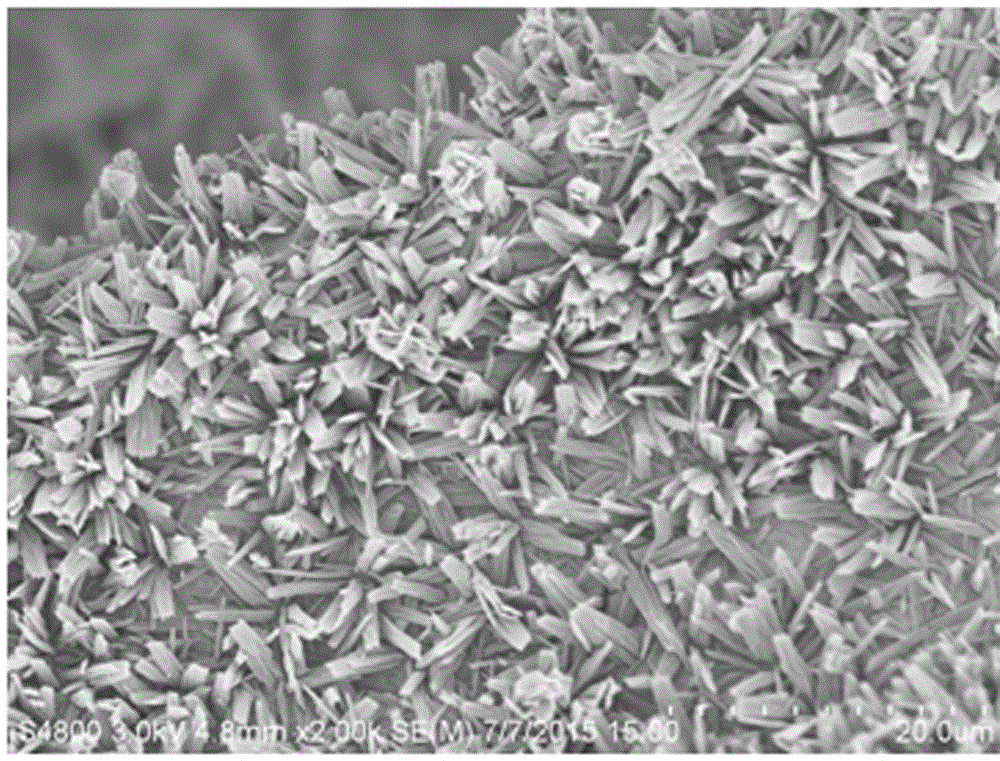

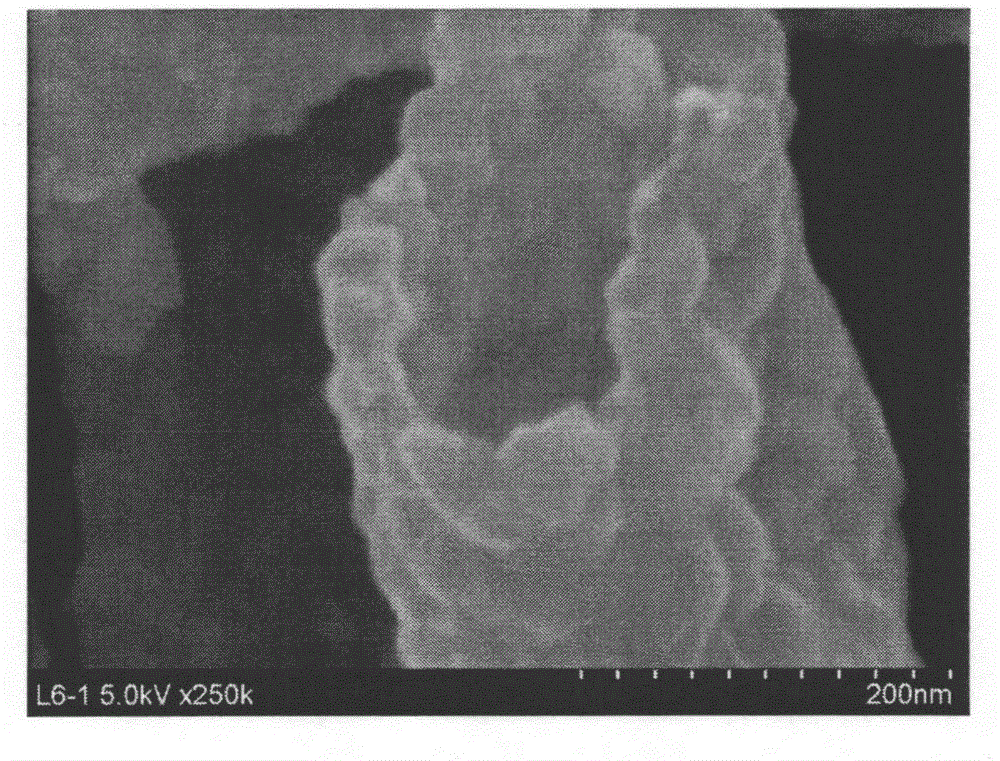

Preparation method of nickel cobaltite porous micron belt/foamed nickel composite electrode material

InactiveCN105470002AImprove diffusion and mass transfer performanceLarge specific surface areaHybrid capacitor electrodesHybrid/EDL manufactureDispersityNickel salt

The invention belongs to the inorganic non-metal material preparation field and relates to a preparation method of a nickel cobaltite porous micron belt / foamed nickel composite electrode material. The preparation method includes the following steps that: clean foamed nickel is immersed in an oxalic acid aqueous solution; a soluble nickel salt and soluble cobalt salt mixed aqueous solution is added in an obtained solution dropwise under stirring at room temperature; stirring is performed until a micron structure precursor grows from the surface of the foamed nickel through a reaction; the foamed nickel is removed out, and cleaning, drying and calcining are performed sequentially, so that the nickel cobaltite porous micron belt / foamed nickel composite electrode material can be obtained. The preparation method of the invention has the advantages of simple and feasible process, high product purity and low production cost. With the method adopted, an obtained product has a novel appearance, and is firmly grown on the surface of the high-conductivity foamed nickel; the thickness of the nickel cobaltite porous micron belt ranges from 50 to 80 nm, and the length of the nickel cobaltite porous micron belt ranges from 3 to 5 microns, and the width of the nickel cobaltite porous micron belt ranges from 300 to 500 microns, and the size of a nano pore ranges from 5 to 20nm; and the homogeneity and dispersity of the product are excellent.

Owner:BOHAI UNIV

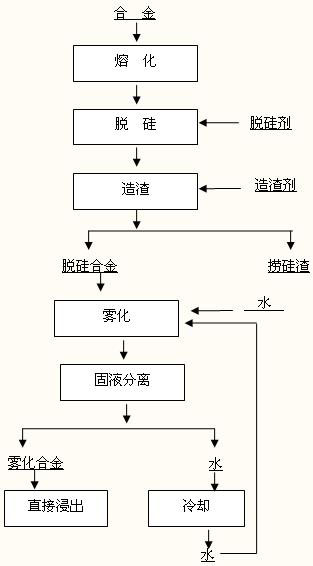

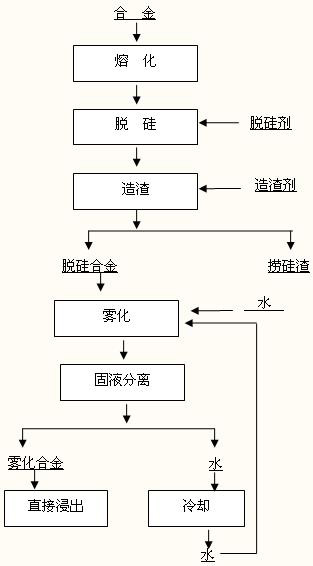

Method for desiliconizing cobalt white alloy

The invention provides a method for desiliconizing cobalt white alloy, relating to a method for preparing electrolyzed copper and high-purity cobalt salt by taking high-silicon cobalt white alloy as raw material. The method is characterized in that the desiliconizing process sequentially comprises the following steps of: (1) melting cobalt white alloy; (2) adding a desiliconization agent for reaction; (3) then adding a slag former for slagging; (4) separating slag from melt; and (5) atomizing the separated melt into alloy powder used for recovering nickel, cobalt and copper. In the method fordesiliconizing cobalt provided by the invention, the slag former is available and is low in price; the desiliconization agent can be waste cobalt oxide, waste copper oxide, waste lithium cobaltite, crude cobaltic hydroxide and the like, thus being beneficial to comprehensive recovery of raw materials; alloy after desiliconization is directly atomized into powder; the alloy after desiliconization can stably produce alloy powder with silicon content of being less than 2%. The silicon content is less than 3%, the conventional leaching method can be adopted for recovering cobalt and copper, posttreatment is easy, operation is simple and easy, metal recovery rate is high, and application prospect is good.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY +1

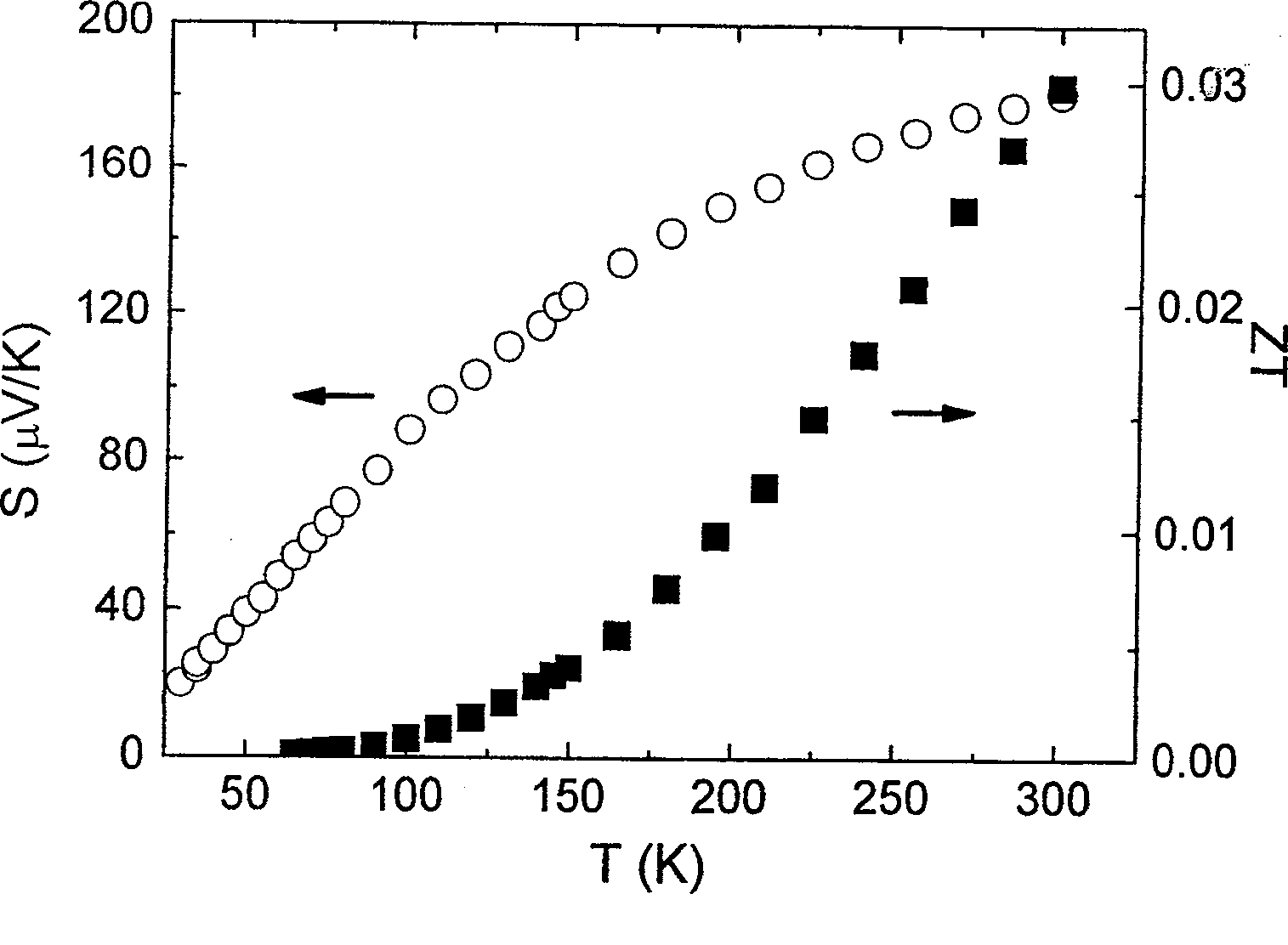

Thermoelectric transducing material, and method for producing the same

InactiveUS7067205B2Excellent thermoelectric conversion performanceQuality improvementThermoelectric device with peltier/seeback effectThermoelectric device manufacture/treatmentAlkaline earth metalGroup element

Owner:PANASONIC CORP

Solid oxide fuel cell and manufacturing method thereof

InactiveUS20050064277A1Reduce overpotentialImprove power generation efficiencyFinal product manufactureGallium/indium/thallium compoundsElectrical batteryEngineering

An electric power generation cell 1 is constituted by arranging a fuel electrode layer 4 on one side of a solid electrolyte layer 3 and an air electrode layer 2 on the other side of the solid electrolyte layer 3. The solid electrolyte layer 3 is constituted of an oxide ion conductor mainly composed of a lanthanum gallate based oxide. The fuel electrode layer 4 is constituted of a porous sintered compact having a highly dispersed network structure in which a skeletal structure formed of a consecutive array of metal grains is surrounded by mixed conductive oxide grains. For the air electrode layer 2, a porous sintered compact mainly composed of cobaltite is used. This configuration reduces the overpotentials of the respective electrodes and the IR loss of the solid electrolyte layer 3, and accordingly can actualize a solid oxide type fuel cell excellent in electric power generation efficiency.

Owner:THE KANSAI ELECTRIC POWER CO +2

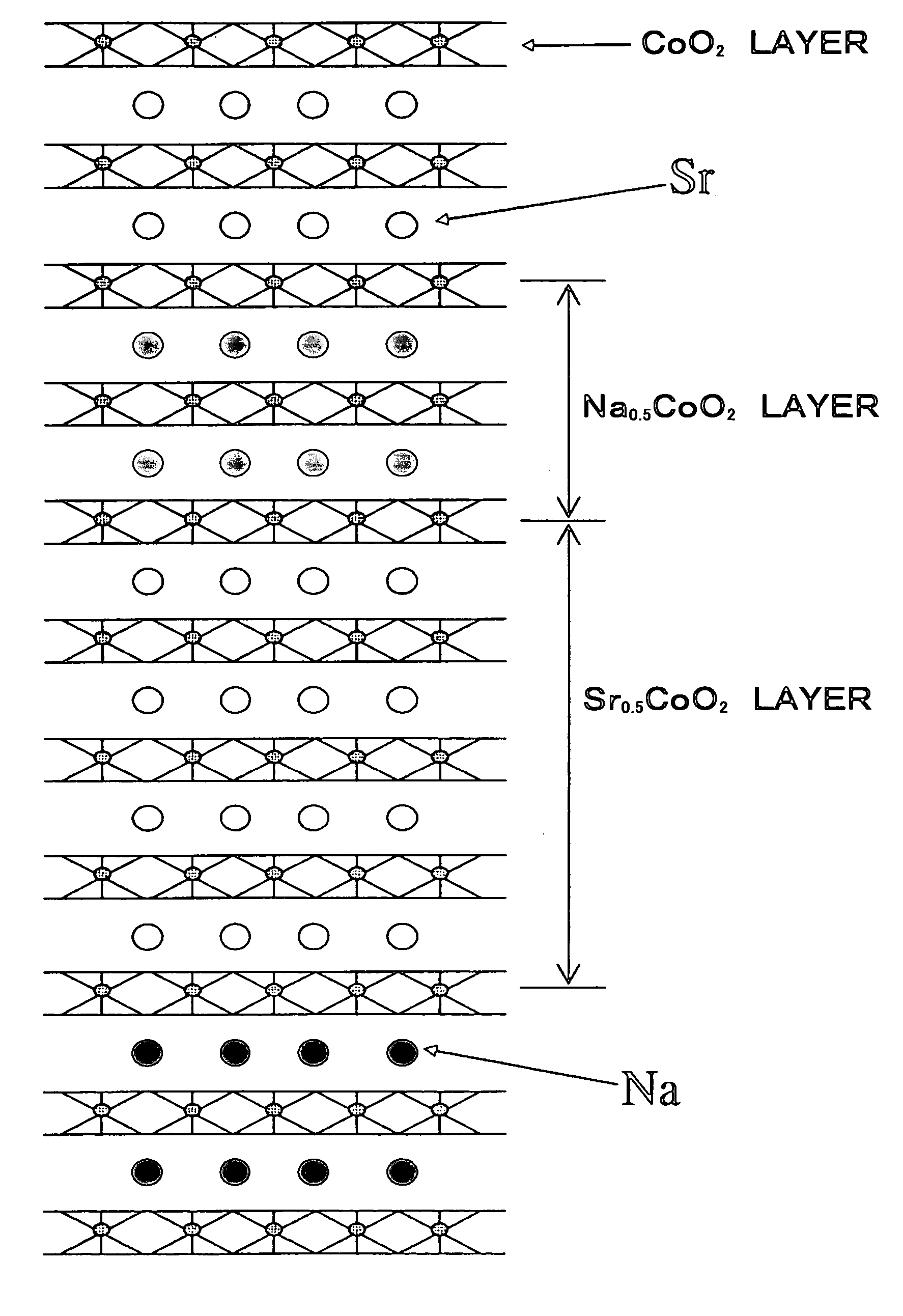

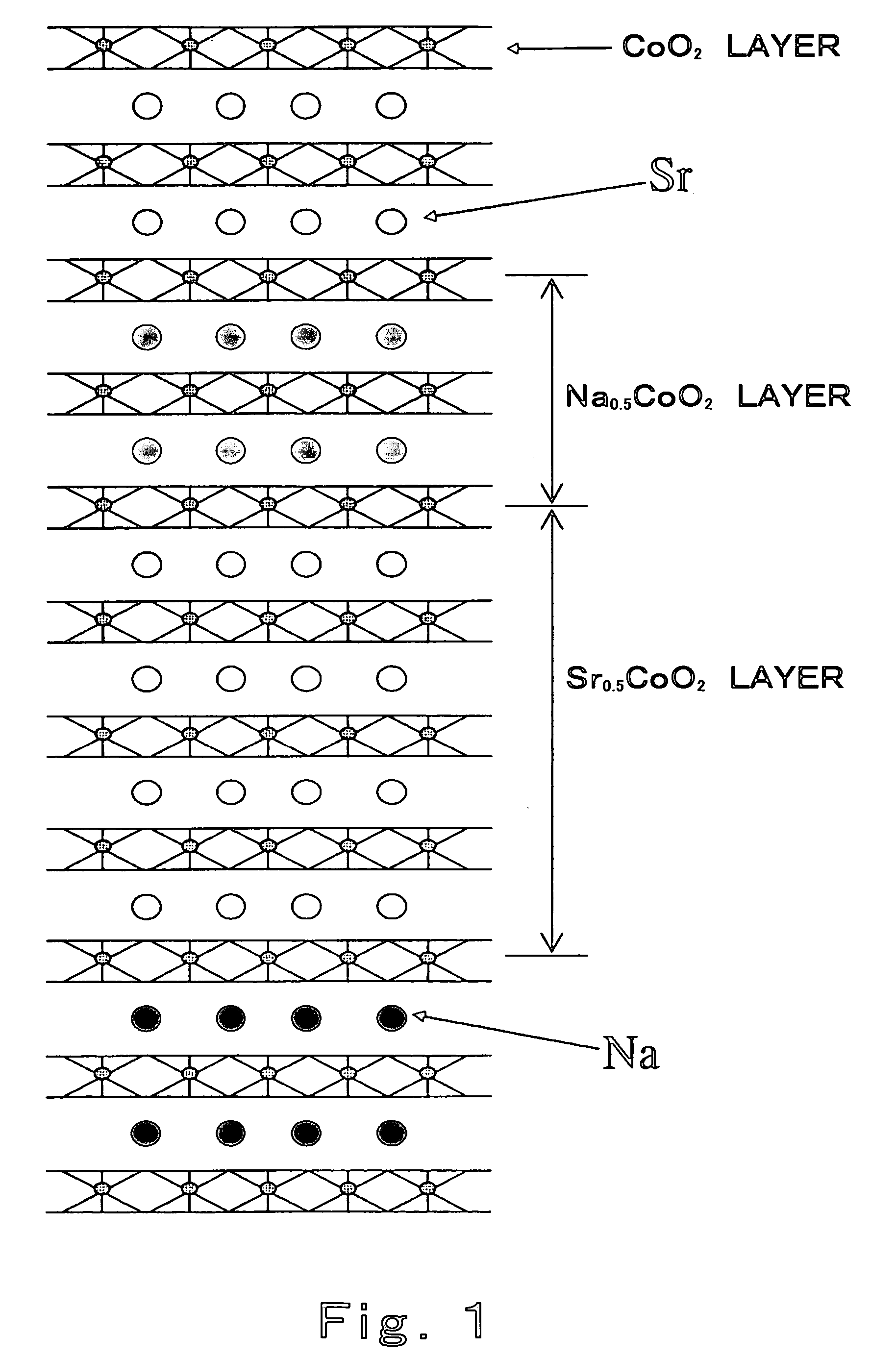

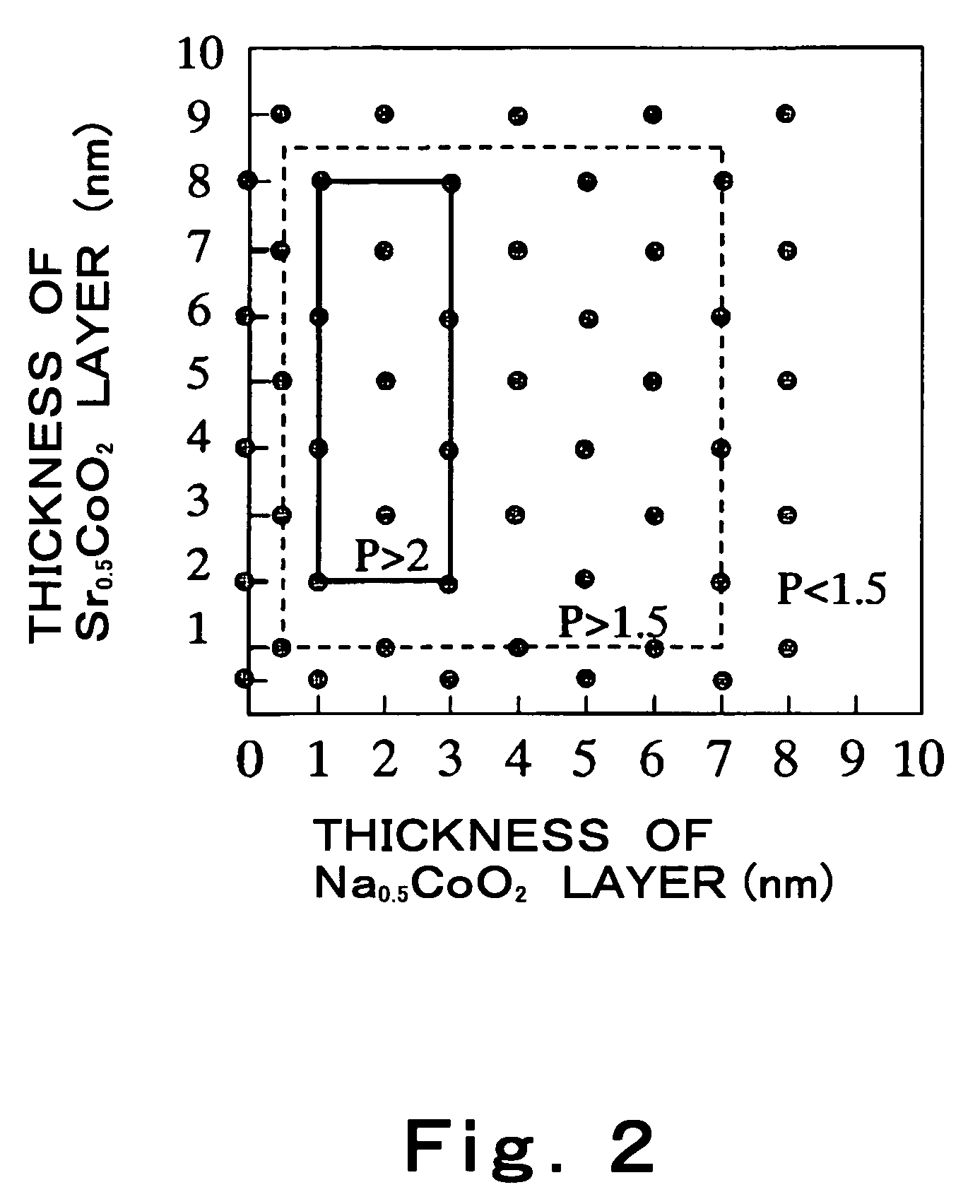

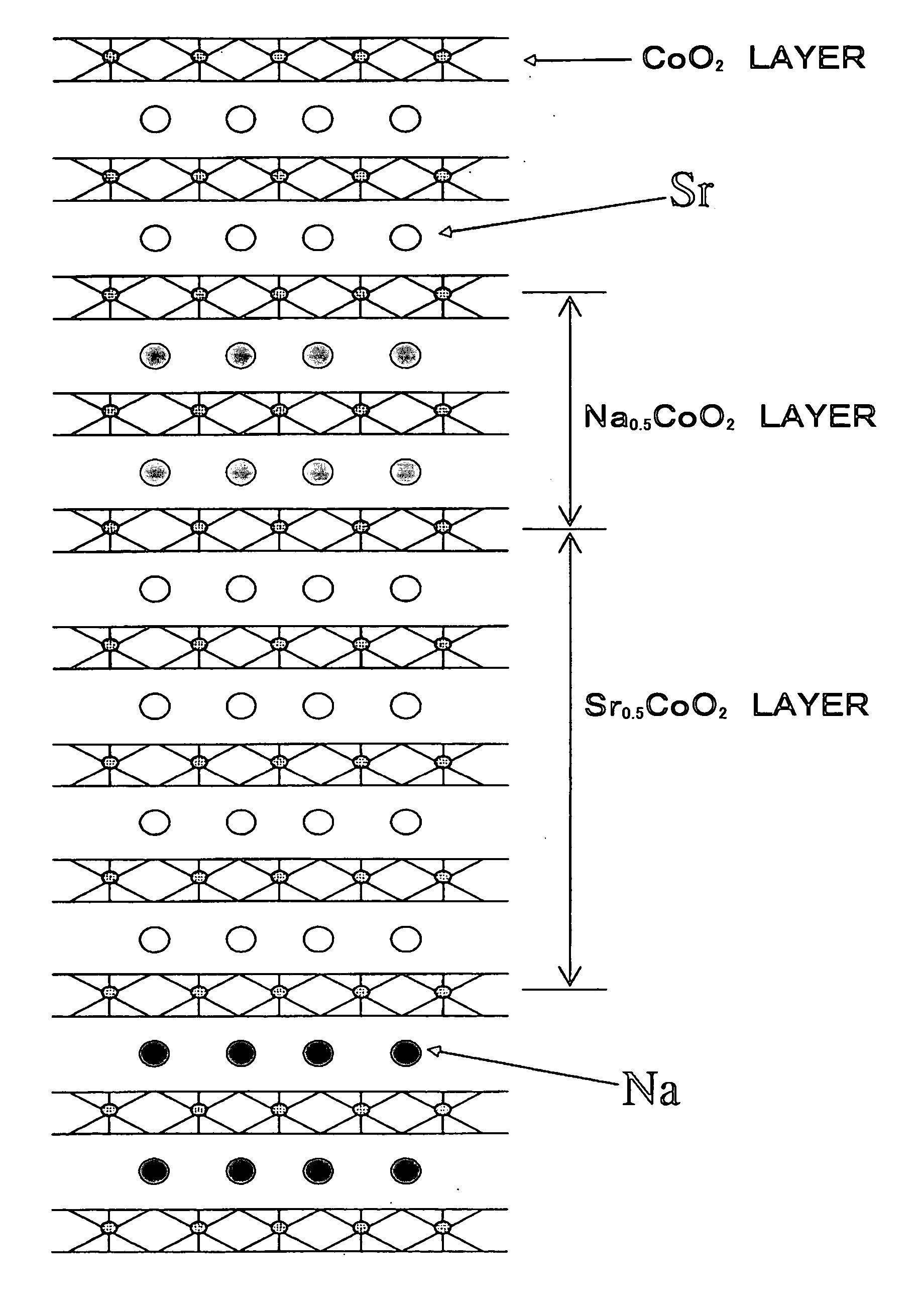

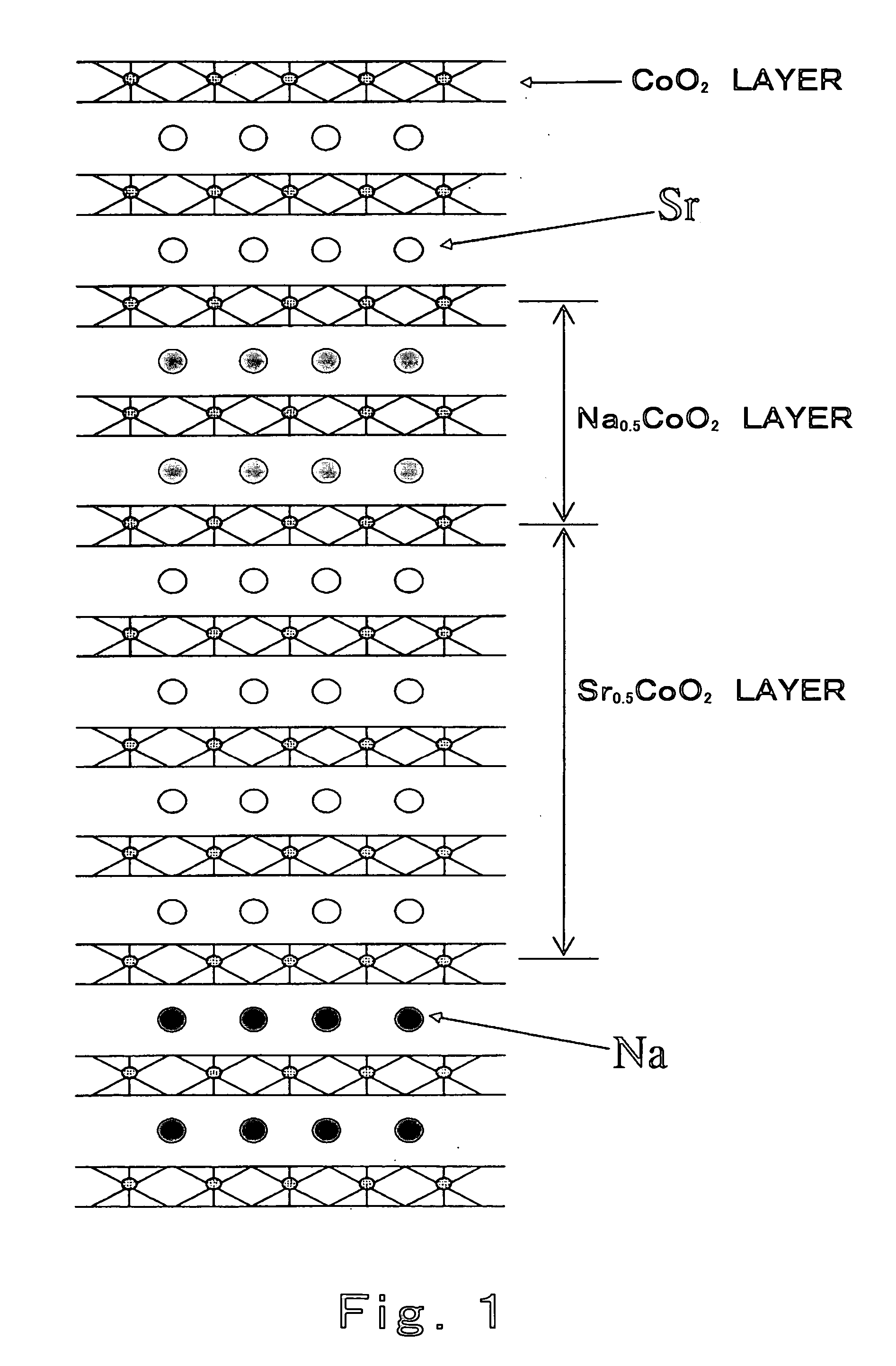

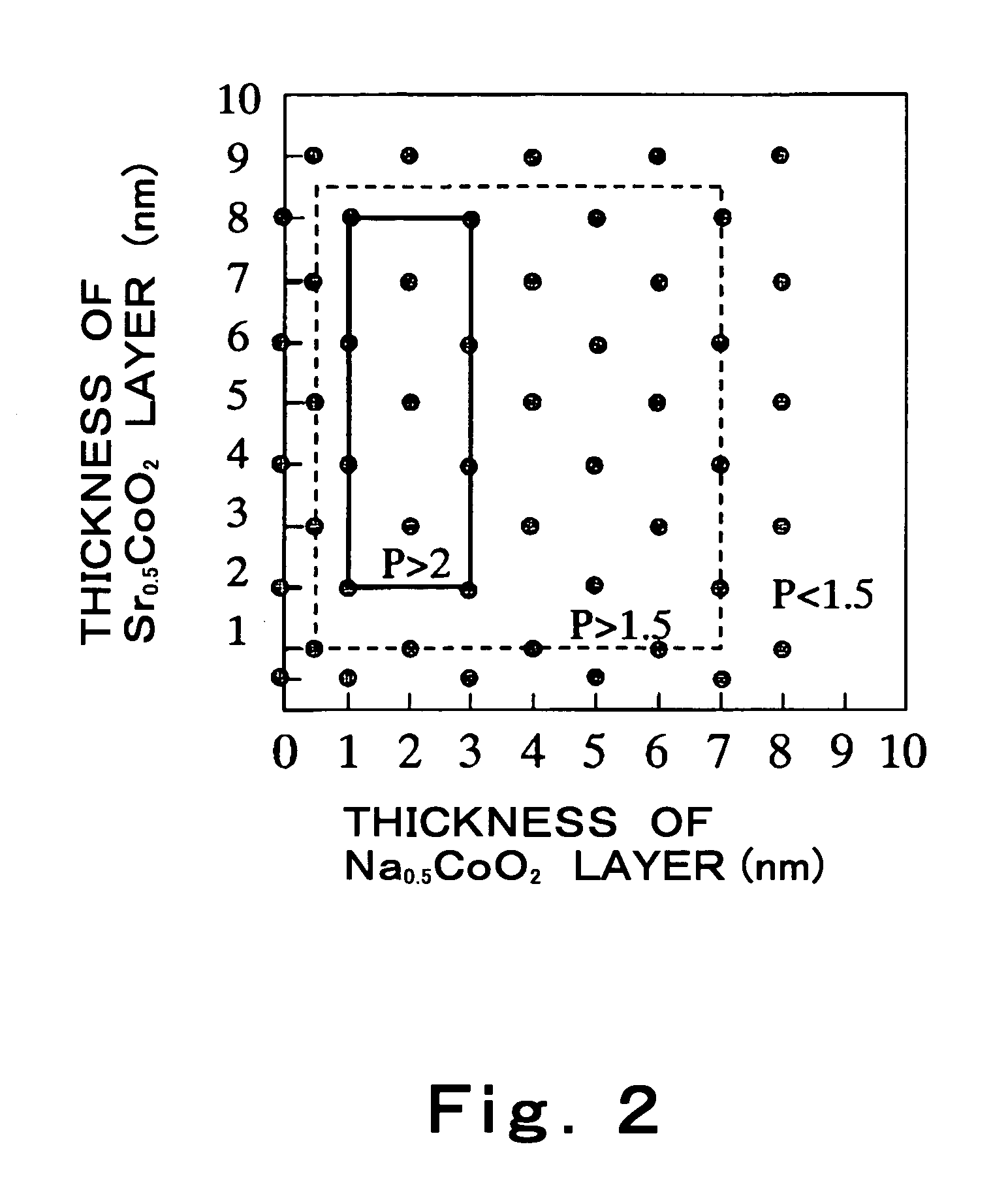

Thermoelectric transducing material, and method for producing the same

InactiveUS20040115464A1Thermoelectric device manufacture/treatmentThin material handlingAlkaline earth metalGroup element

A thermoelectric transducing material according to this invention includes a layered cobaltite based substance represented by the chemical formula AxCoO2, wherein A consists of an element or element group selected from alkali metal elements and alkali earth group elements and is compositionally modulated in a thickness-wise direction of layers in a structure of the layered cobaltite based substance.

Owner:PANASONIC CORP

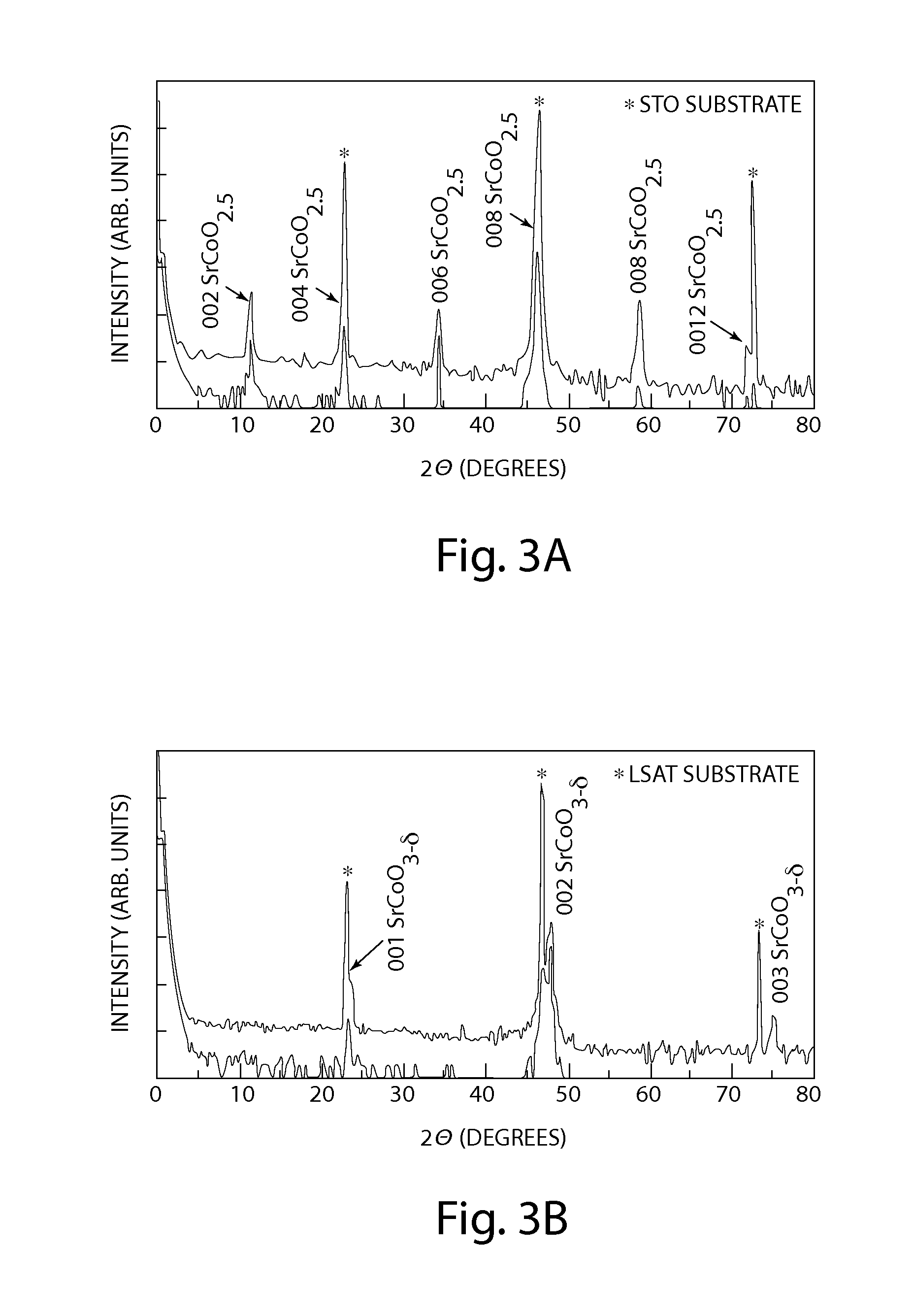

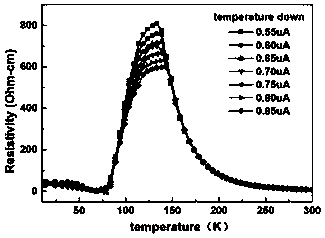

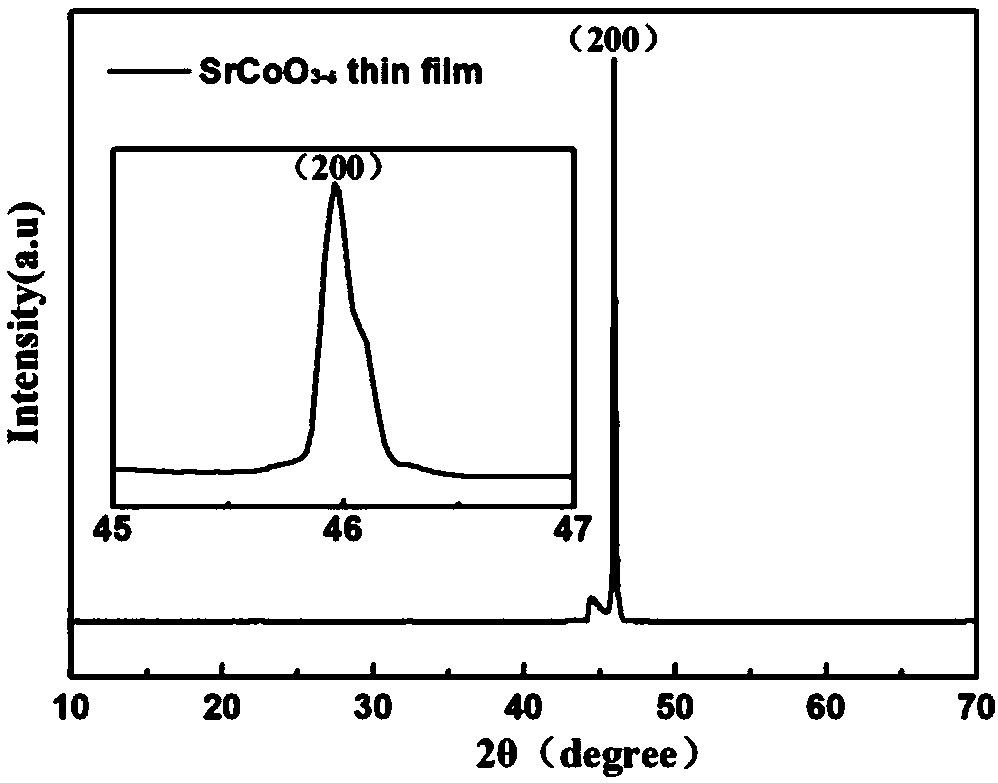

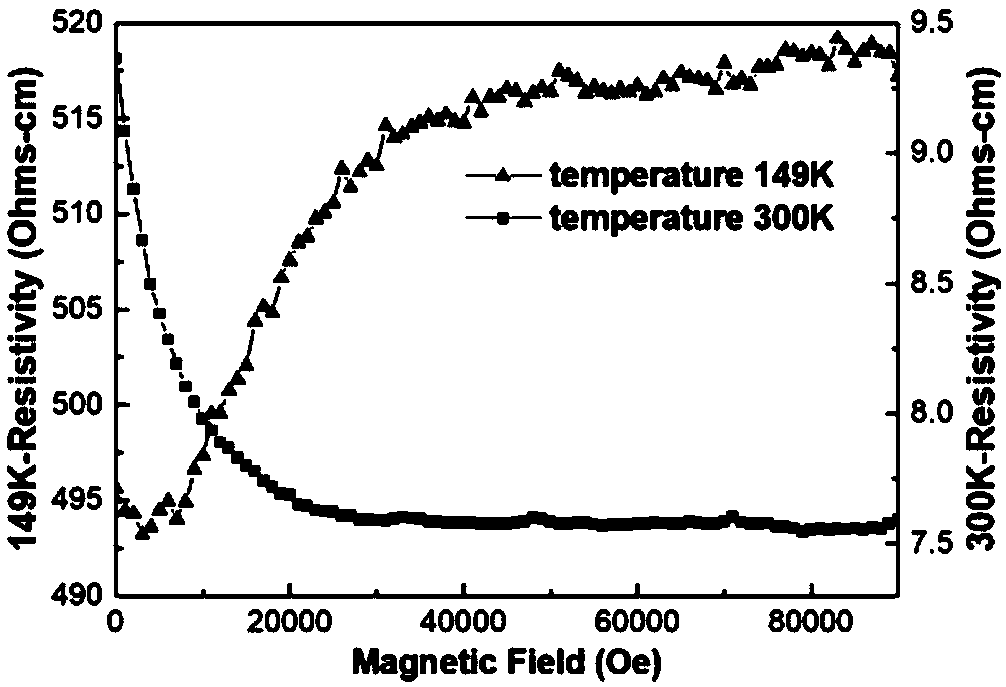

Preparation method of strontium cobaltite film material

ActiveCN109182981AQuality improvementImprove particle size uniformityVacuum evaporation coatingSputtering coatingStrontiumLattice constant

The invention discloses a preparation method of a strontium cobaltite film material; and magnetic and electric performances of the strontium cobaltite film material are researched. Firstly, a strontium cobaltite powder sample is prepared by adopting a ball milling method; then, the powder sample is dried and prepared as a massive target; and finally, the massive target is deposited on a substrateby a pulse laser deposition method, and is annealed to obtain the strontium cobaltite film material. The strontium cobaltite powder prepared by the ball milling method is more uniform in mixing and higher in particle size uniformity; the ball milling method has the characteristics of simple operation, mild conditions and easy control; a strontium cobaltite film deposited by the pulse laser deposition method has the characteristics of high quality, high uniformity and stable material components; meanwhile, the strontium cobaltite film material prepared on the substrate with similar lattice constant and the same perovskite structure is more stable in structure; and the metal-semiconductor transformation process is observed from the strontium cobaltite film sample.

Owner:FUJIAN NORMAL UNIV

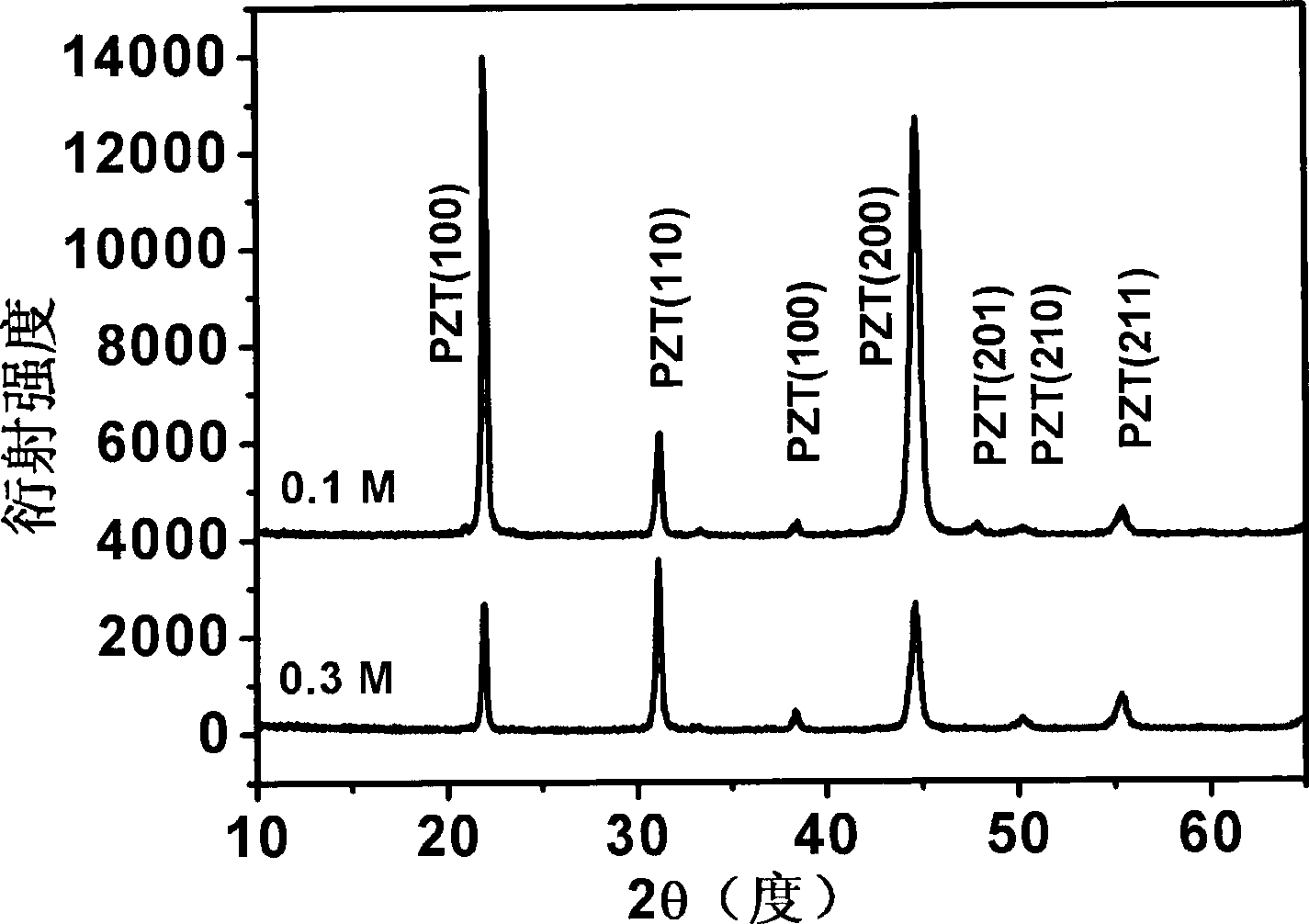

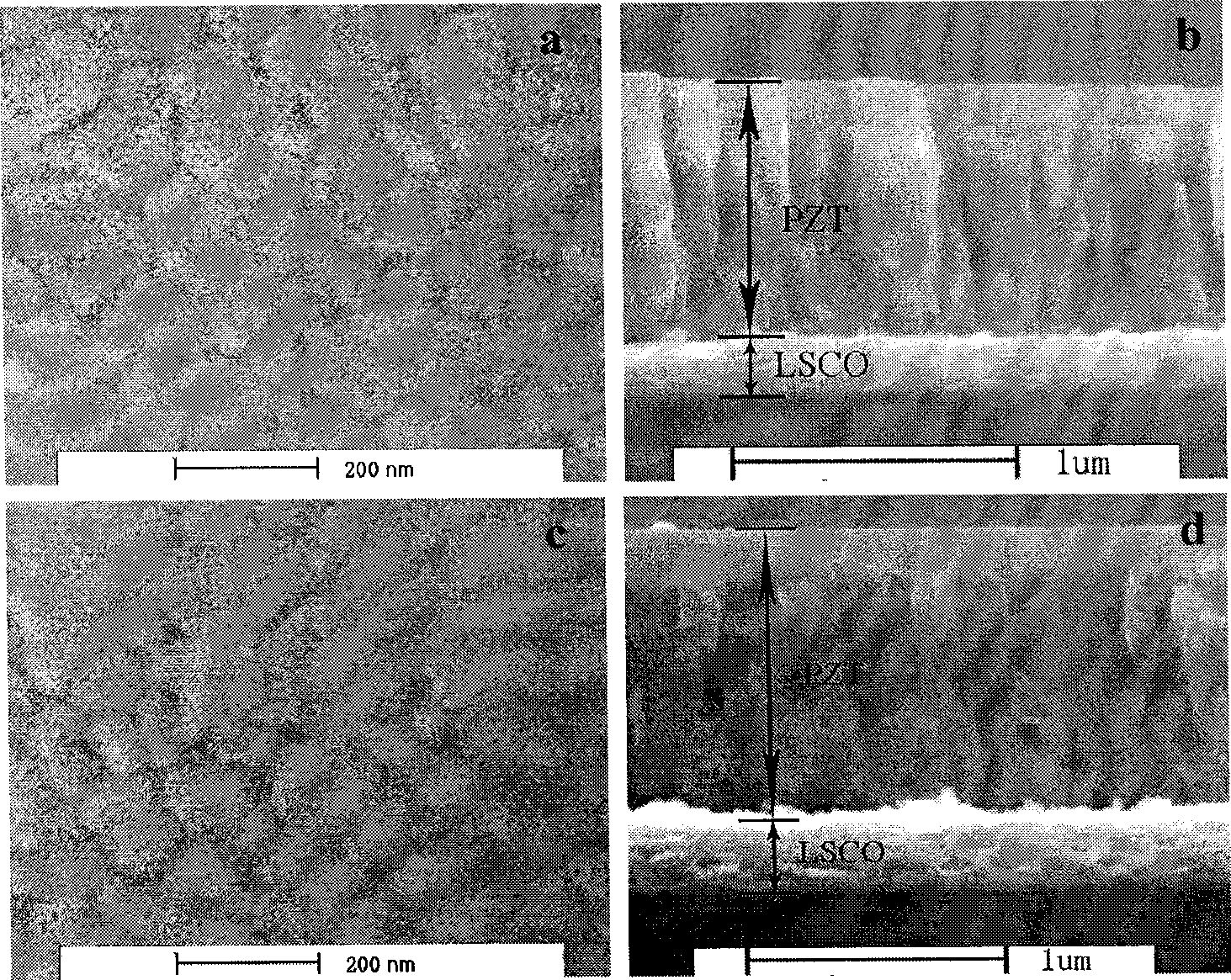

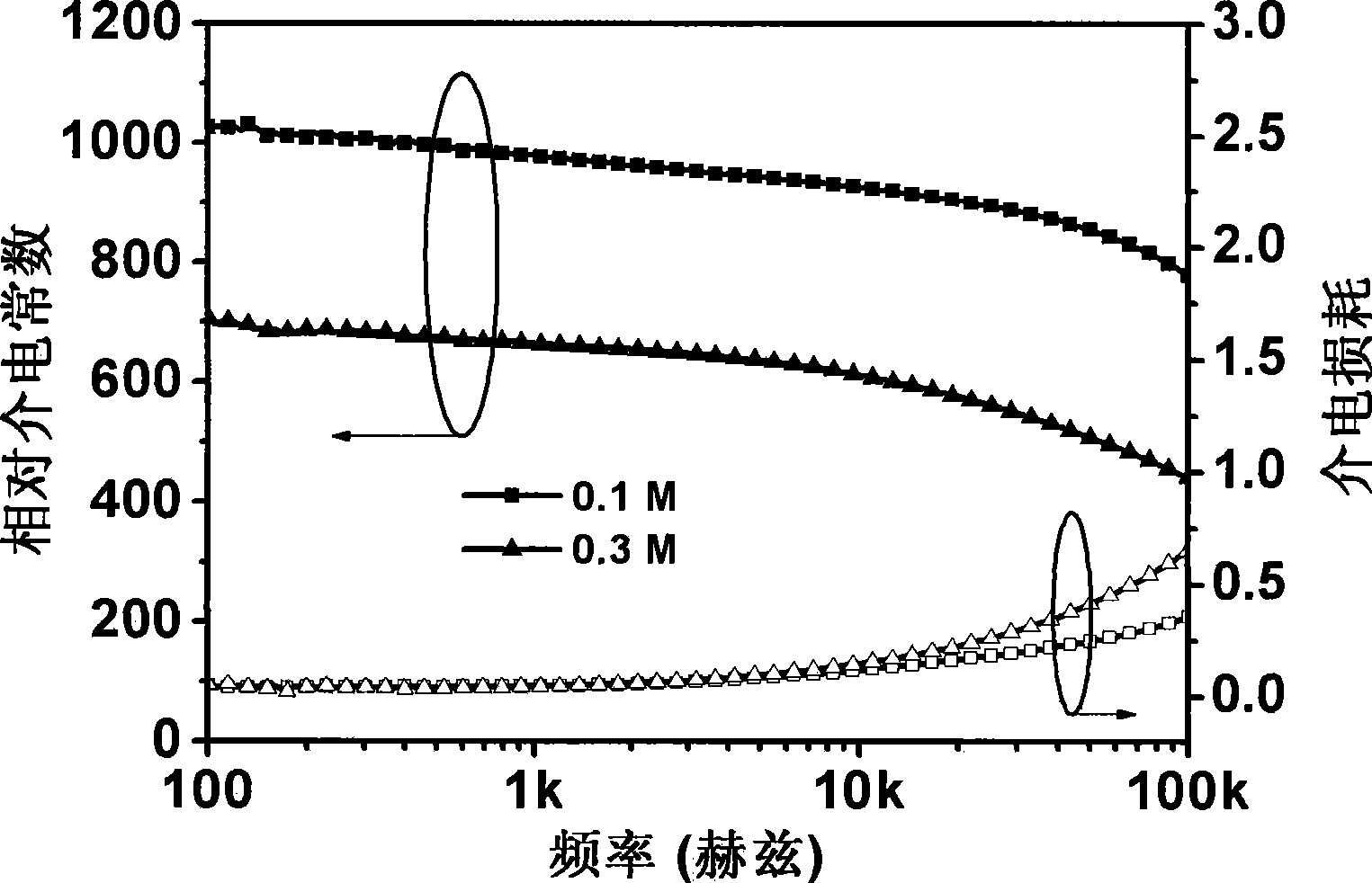

Preparation of silicium/strontium lanthanum cobaltocyanate/lead zirconate titanate three layer construction ferroelectric material

InactiveCN101388434AReduce processing costsSimple structurePiezoelectric/electrostrictive device manufacture/assemblyLead zirconate titanateLanthanum

The invention relates to a process for preparation of piezoelectric material with three-layer structure of silicon / lanthanum strontium cobaltite / lead zirconate titanate, belonging to the technical field of inorganic piezoelectric ferro-electricity material preparation processing. The invention prepares a lead zirconate titanate (PZT) film with preferred orientation of (100) crystal face and a lanthanum strontium cobaltite (LSCO) oxide electrode film on a common silicon substrate through adopting the sol-gel processing, and controls the orientation growth of the PZT film through changing the concentration of LSCO sol. The invention can reduce the processing cost of substrate and electrode, and can optimize the structure and performance of the PZT film. The products of the invention can be applied on piezoelectric ferro-electricity material which is used as micro-electronic mechanical system sensors and transducers.

Owner:SHANGHAI UNIV

Solid oxide fuel cell and manufacturing method thereof

InactiveUS7914941B2Improve performanceImprove powerFinal product manufactureGallium/indium/thallium compoundsOptoelectronicsGallate

An electric power generation cell 1 is constituted by arranging a fuel electrode layer 4 on one side of a solid electrolyte layer 3 and an air electrode layer 2 on the other side of the solid electrolyte layer 3. The solid electrolyte layer 3 is constituted of an oxide ion conductor mainly composed of a lanthanum gallate based oxide. The fuel electrode layer 4 is constituted of a porous sintered compact having a highly dispersed network structure in which a skeletal structure formed of a consecutive array of metal grains is surrounded by mixed conductive oxide grains. For the air electrode layer 2, a porous sintered compact mainly composed of cobaltite is used. This configuration reduces the overpotentials of the respective electrodes and the IR loss of the solid electrolyte layer 3, and accordingly can actualize a solid oxide type fuel cell excellent in electric power generation efficiency.

Owner:THE KANSAI ELECTRIC POWER CO +2

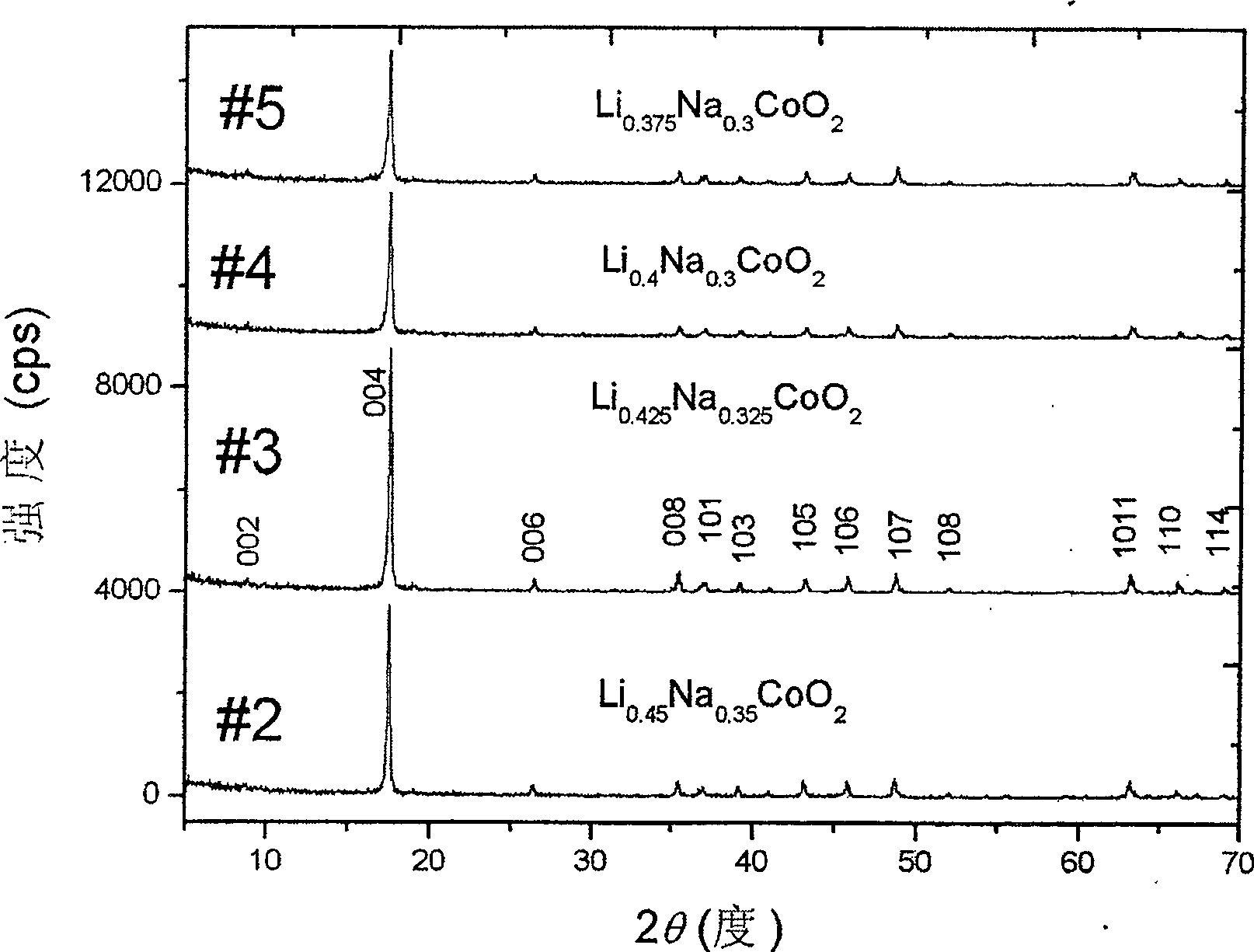

Lithium-sodium-cobalt-oxygen thermoelectric ceramic and preparation method thereof

InactiveCN100532320CSolve preparation technical problemsMake up for volatilityThermoelectric materialsOxygen

The invention relates to a lithium sodium cobalt oxygen thermoelectric ceramic and a preparation method thereof. The general formula of the cobaltate thermoelectric porcelain is LixNayCoO2, in which the contents of lithium and sodium are respectively 0.375≤x≤0.48 and 0.3≤y≤0.45; the raw materials with a molar ratio of Li2CO3:Na2CO3:Co3O4 of 3x:3y:2 are fully mixed , ground, and then punched under a pressure of 80-120 MPa to obtain compressed tablets, wherein, 0.375≤x≤0.48, 0.3≤y≤0.45; the compressed tablets were calcined in a tube furnace with flowing oxygen for 24-48 hours, calcined The temperature is 1103-1173K, and then rapidly cooled to room temperature to obtain a single-phase polycrystalline block. The invention shows that lithium sodium cobalt oxide can be used as a novel thermoelectric material. The preparation of the material is realized by changing the composition of the initial reactant, the sintering atmosphere, the sintering temperature, the sintering time and the method of rapid cooling. The material has a large thermoelectric coefficient (170-210 μV / K) near room temperature, and its quality factor is higher than that of similar cobaltate thermoelectric ceramics, so it has application prospects.

Owner:ZHEJIANG UNIV

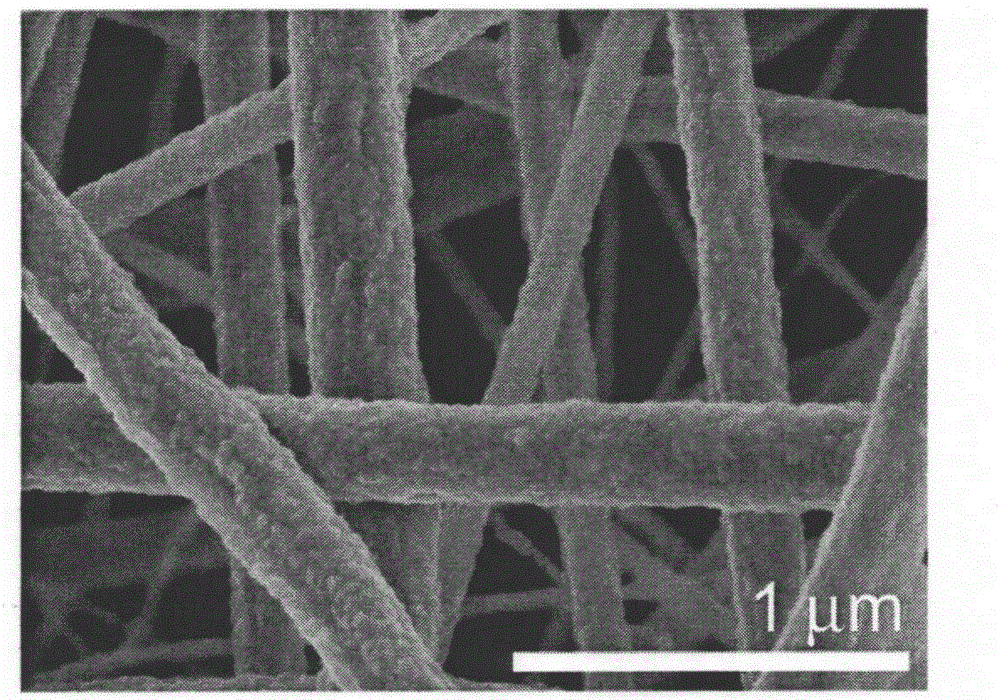

Nickel cobaltite nano material and preparation method of composite electrode material

InactiveCN106067388AIncrease productionEasy to produceHybrid capacitor electrodesHybrid/EDL manufactureCapacitanceNickel salt

The invention provides a nickel cobaltite nano material and a preparation method of a composite electrode material. The preparation method includes the following steps that: cobalt salt and nickel salt are dissolved in a mixed solution of acetic acid and ethanol, so that a nickel cobaltite precursor solution can be formed; high-molecular polymer is added into the nickel cobaltite precursor solution, so that a first mixed liquor can be formed; and the first mixed liquor is injected into a spraying device, in a high-voltage electrostatic field, based on a high-voltage electrostatic spinning technology, the first mixed liquor is sprayed to a receiving device through the spraying device, and a nickel cobaltite nano material precursor is formed on the receiving device. According to the preparation method of the composite electrode material of the invention, the nickel cobaltite nano material of a large area can be prepared through the electrostatic spinning method, and therefore, the nickel cobaltite nano material has high specific surface area; and when the nickel cobaltite nano material is composited with a traditional manganese dioxide material, so that the performance of a single material can be improved, and the problem of poor electrical conductivity of manganese dioxide can be solved. As indicated by an electrochemical test, the specific capacitance of the composite material is as high as 706.7F / g under 3A / g current density.

Owner:DONGHUA UNIV

Method for Manufacturing Composite Ceramic Material

InactiveUS20160329573A1Improve electricityChemically and mechanically stableMaterial nanotechnologyFinal product manufactureFuel cellsComposite ceramic

Provided is a method of making a composite ceramic material for a fuel cell. The composite ceramic material for the fuel cell forms a cored structure where perovskite ceramic particles having a small particle diameter surround lanthanum cobaltite particles having a large particle diameter. Lanthanum cobaltite is added as a starting material in a process of synthesizing the perovskite ceramic particles. The composite ceramic material for the fuel cell made according to this method improves an electric connection characteristic between a separation plate and a polar plate of the fuel cell, and is chemically and mechanically stable.

Owner:POHANG IRON & STEEL CO LTD

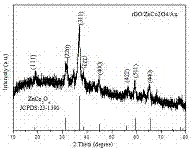

Preparation method of rGO/ZnCo2O4/Au ternary composite room temperature gas-sensitive material

InactiveCN107014952ANo pollution in the processImprove gas sensing performanceMaterial nanotechnologyAnalysing gaseous mixturesWater bathsHexamethylenetetramine

The invention provides a preparation method of a ternary composite room temperature gas-sensitive material with Au (gold) nanoparticle-loaded porous flaky ZnCo2O4 (zinc cobaltite) vertically growing on rGO (reduced graphene oxide). The preparation method specifically comprises the following steps of using GO (graphene oxide), zinc nitrate hexahydrate and cobalt nitrate hexahydrate as raw materials, using hexamethylenetetramine as an original precipitator, using trisodium citrate as a surfactant and a reducing agent, and performing water bath heating and calcining treatment, so as to obtain the porous flaky ZnCo2O4 which vertically grows on the rGO carrier; using the chloroauric acid as the raw material, loading noble metal Au nanoparticle onto the surface, and finally obtaining the ternary composite gas-sensitive material with Au nanoparticle-loaded porous flaky ZnCo2O4 vertically growing on the rGO carrier. The preparation method has the advantages that the production technology is simple; the porous flaky ZnCo2O4 which vertically grows on the rGO is prepared, and the noble metal Au nanoparticle is loaded, so as to obtain the gas-sensitive detection material with sensitive property on the NO2 (nitrogen dioxide) gas at room temperature.

Owner:UNIV OF JINAN

A kind of preparation method of nickel cobaltate/carbon nanotube composite material

InactiveCN105161313BHigh specific capacitanceImprove electrochemical stabilityMaterial nanotechnologyCarbon compoundsCapacitanceCarbon nanotube

The invention discloses a method of preparing nickel cobaltite / carbon nanotube composite materials. The invention further relates to a method of preparing a carbon nanotube loaded with nano-particles nickel cobaltite. The method comprises the following steps of dissolving Ni(NO3)2.6H2O and Co(NO3)2.6H2O in diglycol to prepare a mixed metal solution A containing Ni2+ / Co2+ with a mol ratio being 1:2; dissolving NaOH and a carbon nanotube in the diglycol and performing ultrasonic dispersion to form a solution B; making the solution B added in the solution A drop by drop to acquire a mixed solution; fully and uniformly stirring the mixed solution in a condition with a temperature of 80 DEG C, moving the solution to a reaction vessel and further replacing CO2, and after the replacement, adjusting the pressure intensity of the CO2 to be 10MPa; putting the reaction vessel in an oil bath pan, setting the stirring rate to be 400r / min, the temperature to be 140-220 DEG C, and the reaction time to be 4-10h; cleaning the acquired product by ethanol and distilled water to be neutral and further performing centrifugation and 80 DEC C drying to acquire nickel cobaltite / carbon nanotube composite materials. The method which hardly damages the structure of the carbon nanotube has the characteristics of simple operation and environment friendliness. By means of the method, products can be directly acquired in the solution without calcining. The acquired nickel cobaltite / carbon nanotube composite materials have relatively high specific capacitance and good electrochemistry performance stability when applied to super capacitor electrodes.

Owner:CHINA JILIANG UNIV

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com