A kind of preparation method of nickel cobaltate/carbon nanotube composite material

A carbon nanotube and composite material technology, applied in nanotechnology, nanotechnology, carbon compounds, etc., can solve the problems of long reaction time, increased material internal resistance, high energy consumption, and achieve good electrochemical performance stability, high ratio Capacitance value, environmentally friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

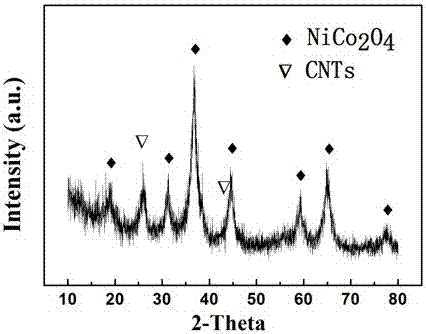

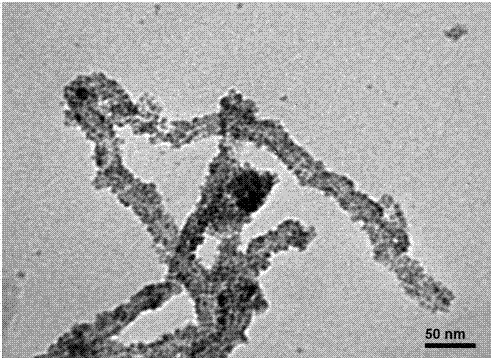

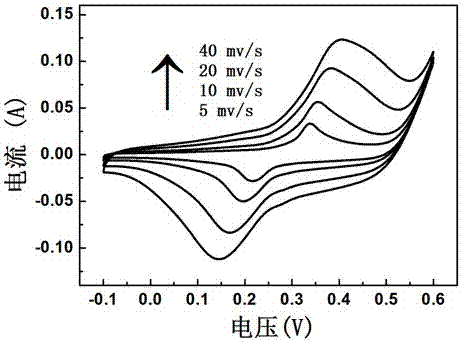

[0014] Embodiment 1: A method for preparing a nickel cobaltate / carbon nanotube composite nanomagnetic material, which is specifically completed by the following steps: 1.5 mmol Ni(NO 3 ) 2 ·6H 2 O and 3 mmol Co(NO 3 ) 2 ·6H 2 O was dissolved in 20ml of diethylene glycol, stirred at 80°C until dissolved, and prepared to contain Ni 2+ / Co 2+ Mixed metal solution A with a molar ratio of 1:2; 9mmol NaOH and 30mg carbon nanotubes were dissolved in 40ml diethylene glycol, ultrasonically dispersed at 80°C for 30min to form solution B; the solution B was added dropwise to solution A The mixed solution was obtained in the reaction vessel; the mixed solution was fully stirred at 80°C, moved into the reaction kettle, and the CO was replaced. 2 , after the replacement the CO 2 The pressure was increased to 10MPa; the reaction kettle was put into the oil bath, the stirring rate was set to 400r / min, the temperature was 200°C, and the reaction time was 8h; the obtained product was was...

specific Embodiment approach 2

[0015] Specific embodiment 2: a preparation method of nickel cobaltate / carbon nanotube composite nanomagnetic material, which is completed by the following steps: 1.5mmol Ni(NO 3 ) 2 ·6H 2 O and 3 mmol Co(NO 3 ) 2 ·6H 2 O was dissolved in 10ml of diethylene glycol, stirred at 80°C until dissolved, and prepared to contain Ni 2+ / Co 2+ Mixed metal solution A with a molar ratio of 1:2; 7mmol of NaOH and 30mg of carbon nanotubes were dissolved in 20ml of diethylene glycol, and ultrasonically dispersed at 80°C for 30min to form solution B; the solution B was added dropwise to solution A The mixed solution was obtained in the reaction vessel; the mixed solution was fully stirred at 80°C, moved into the reaction kettle, and the CO was replaced. 2 , after the replacement the CO 2The pressure was increased to 10MPa; the reaction kettle was put into the oil bath, the stirring rate was set to 400r / min, the temperature was 200°C, and the reaction time was 8h; the obtained product w...

specific Embodiment approach 3

[0016] Specific embodiment three: a preparation method of nickel cobaltate / carbon nanotube composite nano-magnetic material, which is completed by the following steps: 1.5mmol Ni(NO 3 ) 2 ·6H 2 O and 3 mmol Co(NO 3 ) 2 ·6H 2 O was dissolved in 20ml of diethylene glycol, stirred at 80°C until dissolved, and prepared to contain Ni 2+ / Co 2+ Mixed metal solution A with a molar ratio of 1:2; 9mmol NaOH and 60mg carbon nanotubes were dissolved in 40ml diethylene glycol, and ultrasonically dispersed at 80°C for 30min to form solution B; the solution B was added dropwise to solution A The mixed solution was obtained in the reaction vessel; the mixed solution was fully stirred at 80°C, moved into the reaction kettle, and the CO was replaced. 2 , after the replacement the CO 2 The pressure was increased to 10MPa; the reaction kettle was put into the oil bath, the stirring rate was set to 400r / min, the temperature was 200°C, and the reaction time was 8h; the obtained product was ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com