Lithium cell cathode material with manganese-based laminated crystal structure and preparation method thereof

A crystal structure and positive electrode material technology, applied in battery electrodes, structural parts, circuits, etc., can solve problems such as complex preparation process, unstable batch quality, and difficult preparation process, and achieve low raw material cost, excellent battery performance, and broad The effect of applying the foreground

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

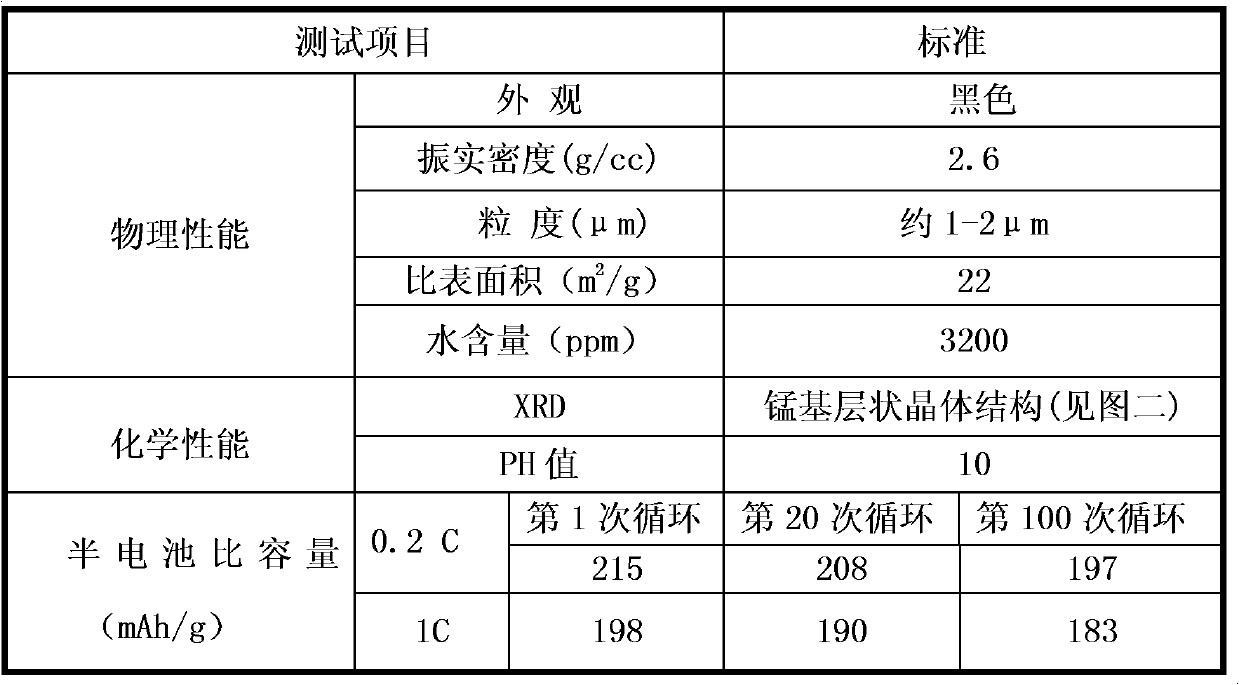

[0022] Preparation of manganese-based layered crystal structure lithium battery cathode material Li[Li] by mechanical activation combined with high-temperature solid-state method 0.20 Ni 0.133 co 0.133 mn 0.534 ]O 2 , including the following steps:

[0023] In the first step, Li[Li 0.20 Ni 0.133 co 0.133 mn 0.534 ]O 2 Prebody, the specific steps are

[0024] 1) will Li 2 CO 3 , Ni 2 o 3 , electrolytic MnO 2 ,Co 3 o 4 Take each raw material by stoichiometric ratio and mix homogeneously, make the positive ion molar ratio Li of raw material: Ni: Co: Mn=1.3: 0.133: 0.133: 0.534; Here Li + : The sum of metal ions = 1.25: 0.8, greater than Li[Li 0.20 Ni 0.133 co 0.133 mn 0.534 ]O 2 In the theoretical value (1.2:0.8), the use of excess lithium is because a small part of lithium will volatilize during the sintering process.

[0025] 2) Input isopropanol (isopropanol as a dispersant) into the agitating ball mill through a peristaltic pump, then transfer the unifor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com