Nanometer nickel cobaltite and preparation method thereof

A technology of nano-cobalt and nickel acid, which is applied in nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problems of uneven distribution of nickel cobaltate particles, cumbersome and complicated production methods, and poor dispersion. Large-scale production, simple preparation method, and the effect of increasing the reaction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A kind of preparation method step of nano-nickel cobaltate of the present invention is as follows:

[0020] (1) 11.6gNi(NO 3 ) 2 ·6H 2 O (contains nickel ion 0.04mol), 23.3gCo(NO 3 ) 2 ·6H 2 Add O (containing 0.08 mol of cobalt ions) and 24.0 g of urea into 100 ml of absolute ethanol, stir at room temperature, and mix the solution evenly to obtain solution A;

[0021] (2) Add 20ml of sorbitan fatty acid ester S-20 and 30ml of sorbitan fatty acid ester S-40 into solution A, and ultrasonically mix them uniformly to obtain solution B;

[0022] (3) Transfer the solution B to the reaction kettle, and react at a constant temperature of 110°C for 22 hours, with a stirring speed of 90r / min. The stirring process is to use non-magnetic stirring; wash 3 times with deionized water and absolute ethanol respectively, Drying at a constant temperature at 62°C to obtain a precursor;

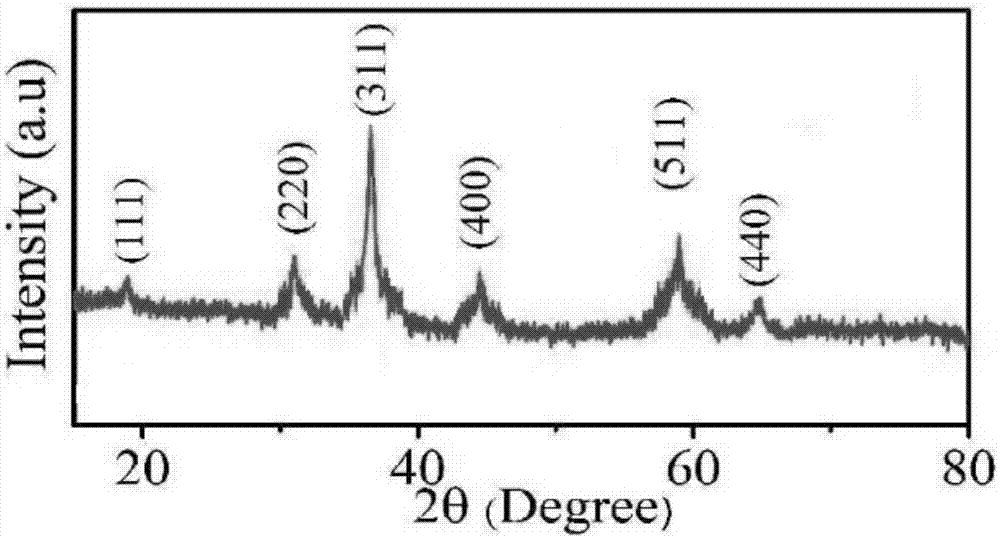

[0023] (4) After the precursor was heat-treated at a constant temperature of 370°C for 2h in air...

Embodiment 2

[0026] The preparation method step of nano nickel cobaltate of the present invention is as follows:

[0027] (1) 11.6gNi(NO 3 ) 2 ·6H 2 O (contains nickel ion 0.04mol), 23.3gCo(NO 3 ) 2 ·6H 2 O (containing 0.08 mol of cobalt ions) and 36.0 g of urea were added to 100 m of absolute ethanol, stirred at room temperature, and the solution was mixed evenly to obtain solution A;

[0028] (2) Add 20ml of sorbitan fatty acid ester S-20 and 30ml of sorbitan fatty acid ester S-40 into solution A, and ultrasonically mix them uniformly to obtain solution B;

[0029] (3) Transfer the solution B to the reaction kettle, and react at a constant temperature of 100°C for 24 hours, the stirring speed is 80r / min, and the stirring process is to use non-magnetic stirring; wash 3 times with deionized water and absolute ethanol respectively, Dry at a constant temperature of 60°C to obtain a precursor;

[0030] (4) After the precursor was subjected to constant temperature heat treatment at 360°...

Embodiment 3

[0033] The preparation method step of nano nickel cobaltate of the present invention is as follows:

[0034] (1) 11.6gNi(NO 3 ) 2 ·6H 2 O (contains nickel ion 0.04mol), 23.3gCo(NO 3 ) 2 ·6H 2 O (containing 0.08 mol of cobalt ions) and 31.0 g of urea were added to 100 ml of absolute ethanol, stirred at room temperature, and the solution was mixed evenly to obtain solution A;

[0035] (2) Add 20ml of sorbitan fatty acid ester S-20 and 30ml of sorbitan fatty acid ester S-40 into solution A, and ultrasonically mix them uniformly to obtain solution B;

[0036] (3) Transfer the solution B to the reaction kettle, and react at a constant temperature of 130°C for 25 hours, with a stirring speed of 100r / min. The stirring process is to use non-magnetic stirring; wash with deionized water and absolute ethanol three times respectively, Dry at a constant temperature of 65°C to obtain a precursor;

[0037] (4) After the precursor was heat-treated at a constant temperature of 350° C. f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com