Nickel cobaltite nano material and preparation method of composite electrode material

A technology of nano-materials and composite electrodes, applied in the manufacture of hybrid capacitor electrodes, hybrid/electric double layer capacitors, etc., can solve the problems of difficult to meet large-area applications and low output, and achieve wide application, large specific surface area, and complete structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

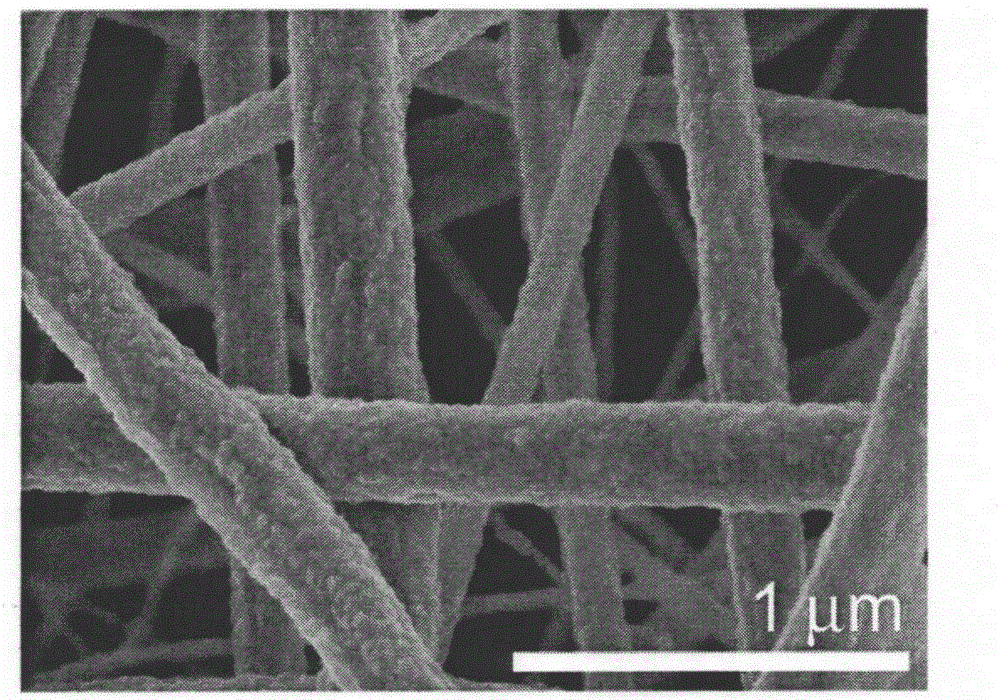

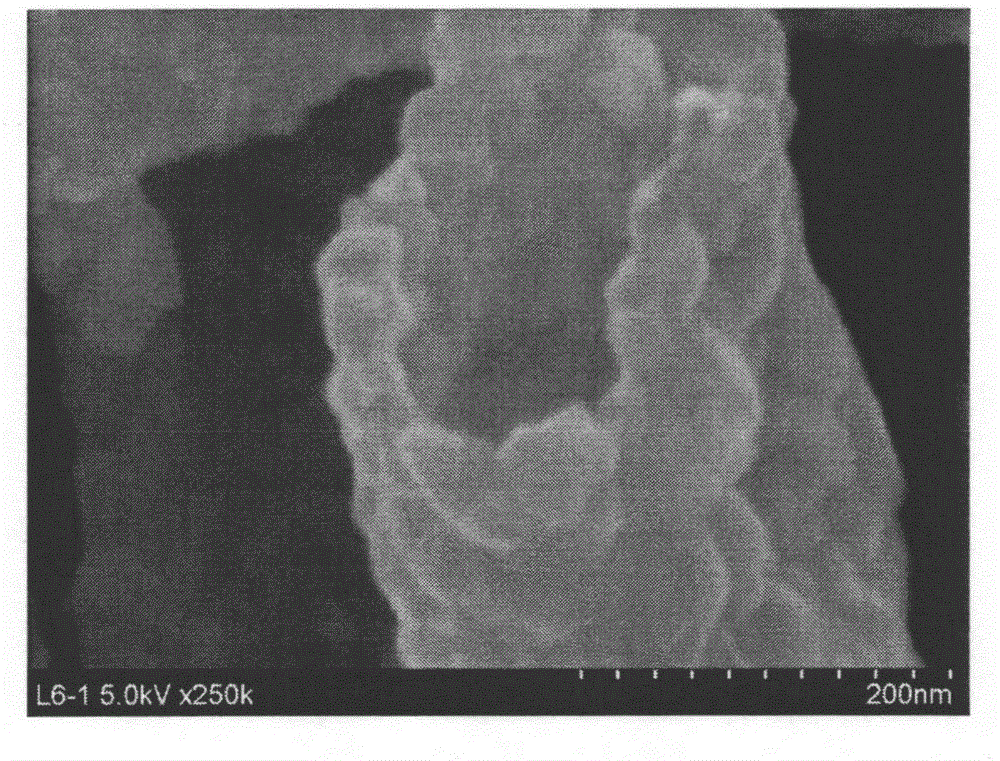

[0038] Example 1 Preparation method of nickel cobaltate nanotube X1 and manganese dioxide nanosheet-coated nickel cobaltate nanotube composite material Y1

[0039] Wherein, the preparation method of nickel cobalt oxide nanotube X1 comprises the following steps:

[0040] (1) Weigh nickel nitrate hexahydrate (Ni(NO 3 ) 2 ·6H 2 O) and cobalt nitrate hexahydrate (Co(NO 3 ) 2 ·6H 2 O) Dissolved in a mixed solution of 1.5mL acetic acid and 6mL ethanol and fully stirred to form a nickel cobaltate nanotube X1 precursor solution, wherein the molar weights of nickel nitrate hexahydrate and cobalt nitrate hexahydrate were 0.5mmol and 1mmol respectively.

[0041] (2) Adding polyvinylpyrrolidone to the nickel cobaltate nanotube X1 precursor solution to form a first mixed solution Z1.

[0042] (3) Put the first mixed solution Z1 into a disposable plastic syringe and replace it with a stainless steel needle. Put the syringe into a syringe pump, connect the needle to a high-voltage powe...

Embodiment 2

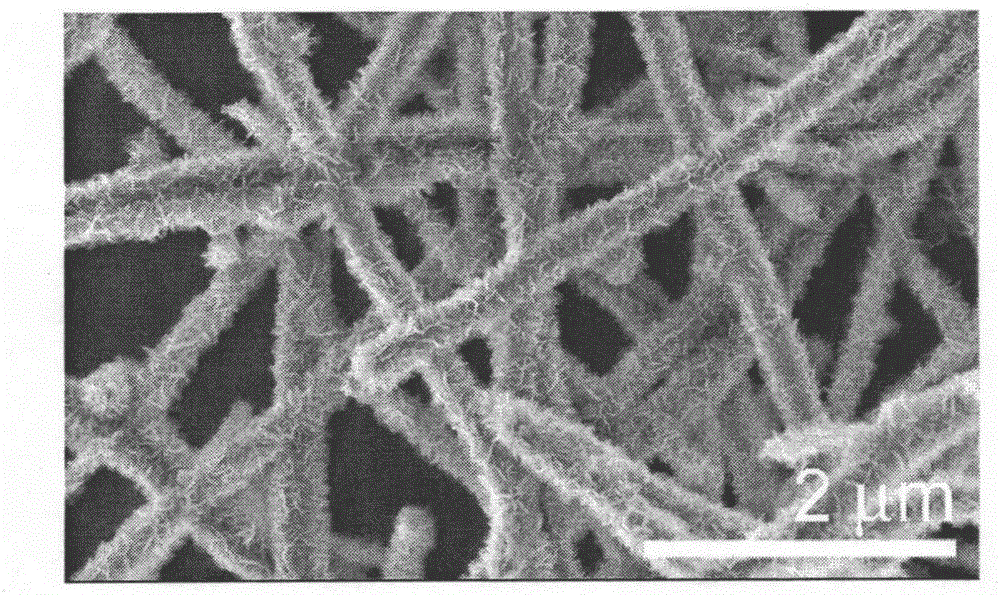

[0050] Example 2 Preparation method of nickel cobaltate nanowire X2 and manganese dioxide nanosheet-coated nickel cobaltate nanowire composite material Y2

[0051] Wherein, the preparation method of nickel cobalt oxide nanowire X2 comprises the following steps:

[0052] (1) Weigh nickel nitrate hexahydrate (Ni(NO 3 ) 2 ·6H 2 O) and cobalt nitrate hexahydrate (Co(NO 3 ) 2 ·6H 2 O) Dissolved in a mixed solution of 0.5mL acetic acid and 5mL ethanol and fully stirred to form a nickel cobaltate nanowire X2 precursor solution, wherein the molar weights of nickel nitrate hexahydrate and cobalt nitrate hexahydrate were 0.25mmol and 0.5mmol respectively.

[0053] (2) Add polyvinyl alcohol, a high molecular polymer, to the nickel cobaltate nanowire X2 precursor solution to form a first mixed solution Z2.

[0054] (3) Put the first mixed solution Z2 into a disposable plastic syringe and replace it with a stainless steel needle. Put the syringe into a syringe pump, connect the needl...

Embodiment 3

[0060] Example 3 Preparation method of nickel cobaltate nanotube X3 and manganese dioxide nanosheet-coated nickel cobaltate nanotube composite material Y3

[0061] Wherein, the preparation method of nickel cobalt oxide nanotube X3 comprises the following steps:

[0062] (1) Weigh nickel nitrate hexahydrate (Ni(NO 3 ) 2 ·6H 2 O) and cobalt nitrate hexahydrate (Co(NO 3 ) 2 ·6H 2 O) Dissolved in a mixed solution of 0.8mL acetic acid and 1.6mL ethanol and fully stirred to form a nickel cobaltate nanotube X3 precursor solution, wherein the molar weights of nickel nitrate hexahydrate and cobalt nitrate hexahydrate were 0.3mmol and 0.6mmol respectively.

[0063] (2) Adding polyvinylpyrrolidone to the nickel cobaltate nanotube X3 precursor solution to form a first mixed solution Z3.

[0064] (3) Put the first mixed solution Z3 into a disposable plastic syringe and replace it with a stainless steel needle. Put the syringe into a syringe pump, connect the needle to a high-voltage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com