Patents

Literature

53results about How to "Improve poor conductivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

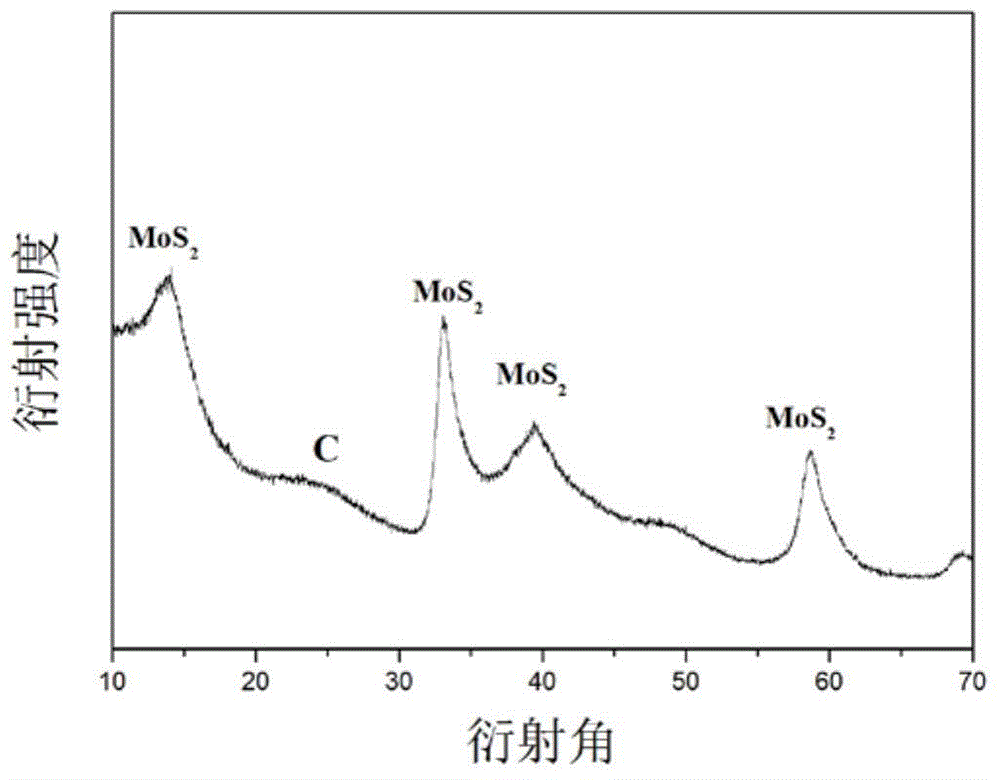

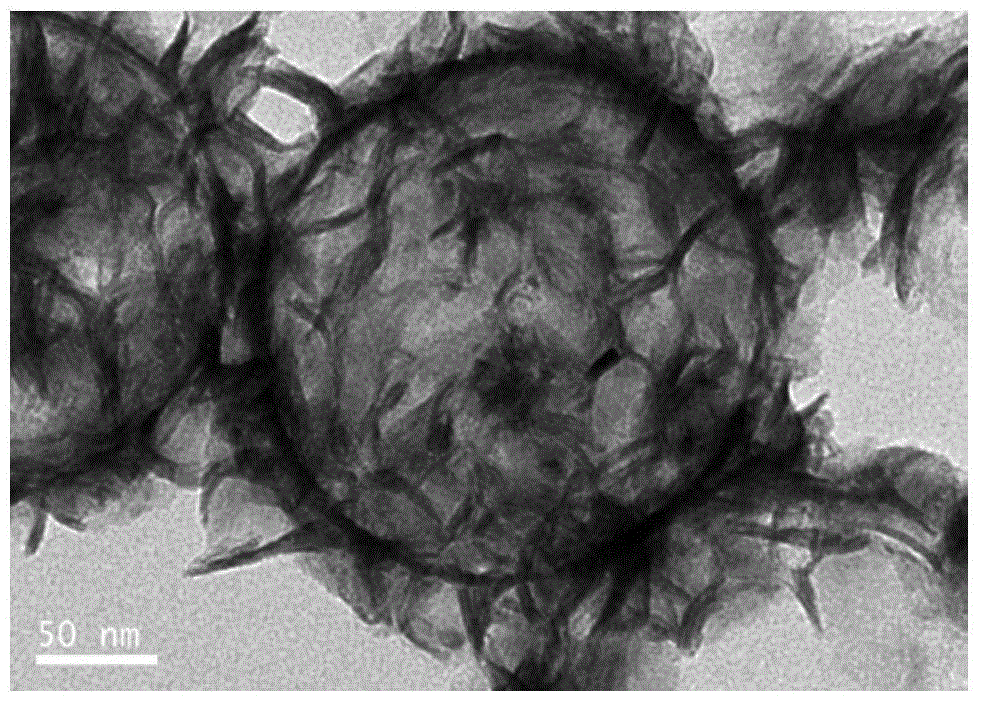

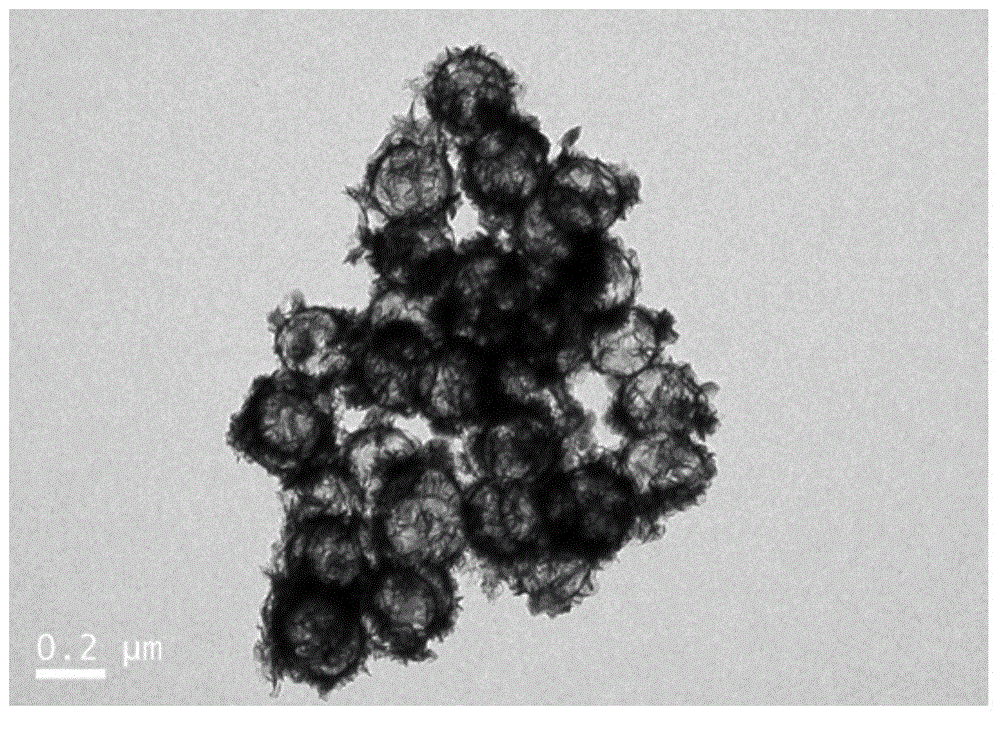

Molybdenum disulfide/carbon composite material and preparation method thereof

InactiveCN104934602AImprove poor conductivityNot easy to reuniteCell electrodesSecondary cellsCarbon compositesCarbonization

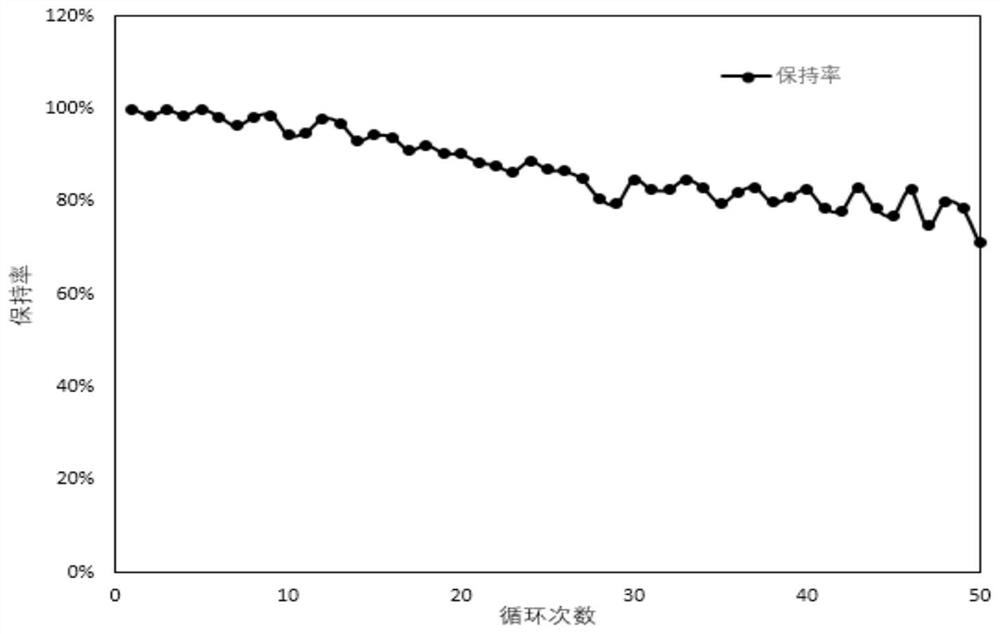

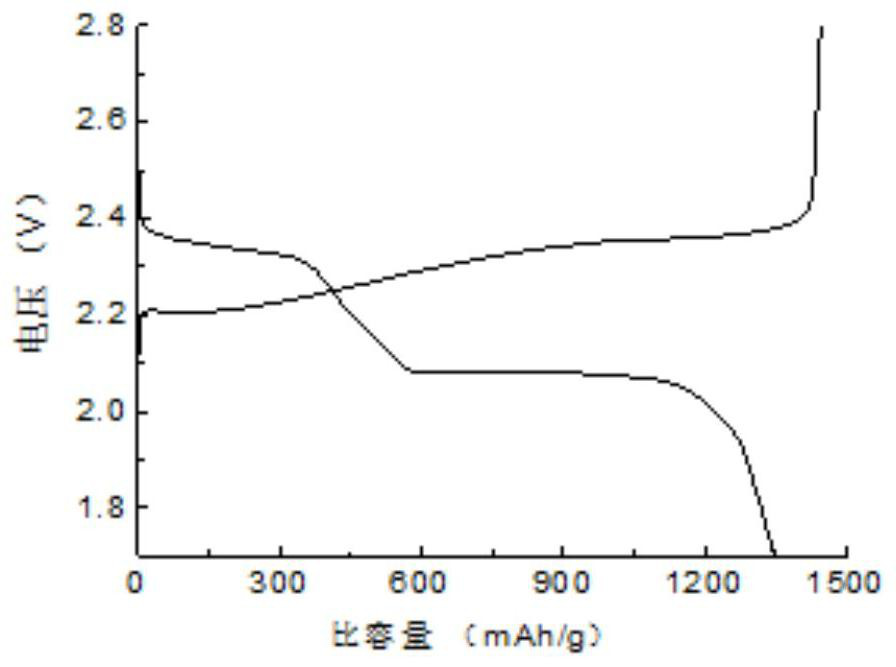

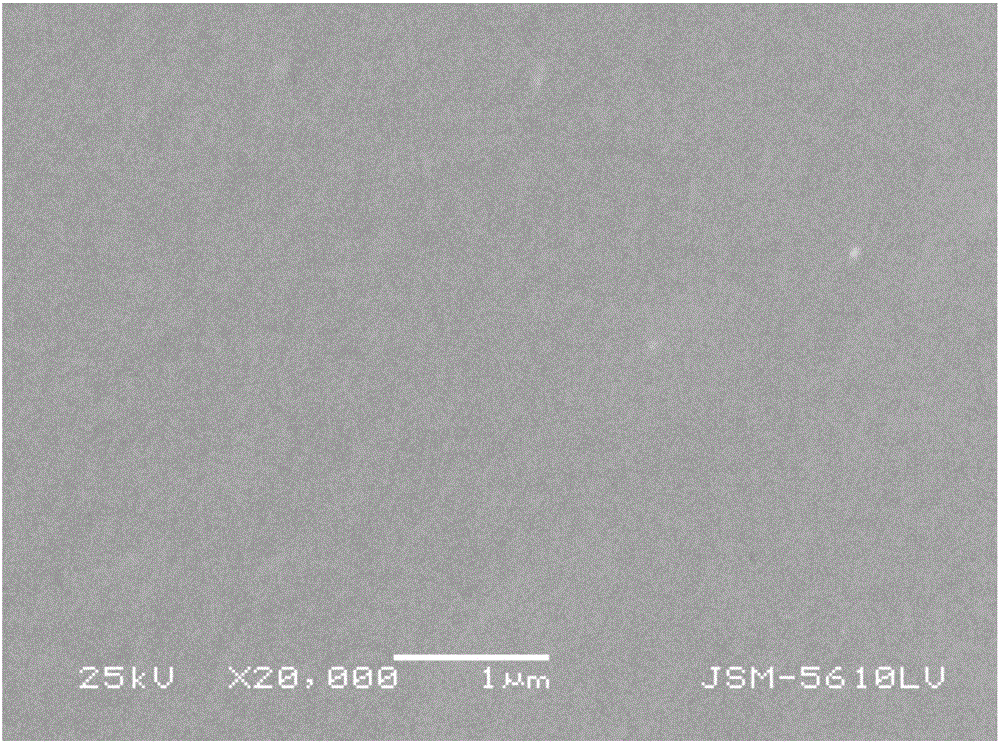

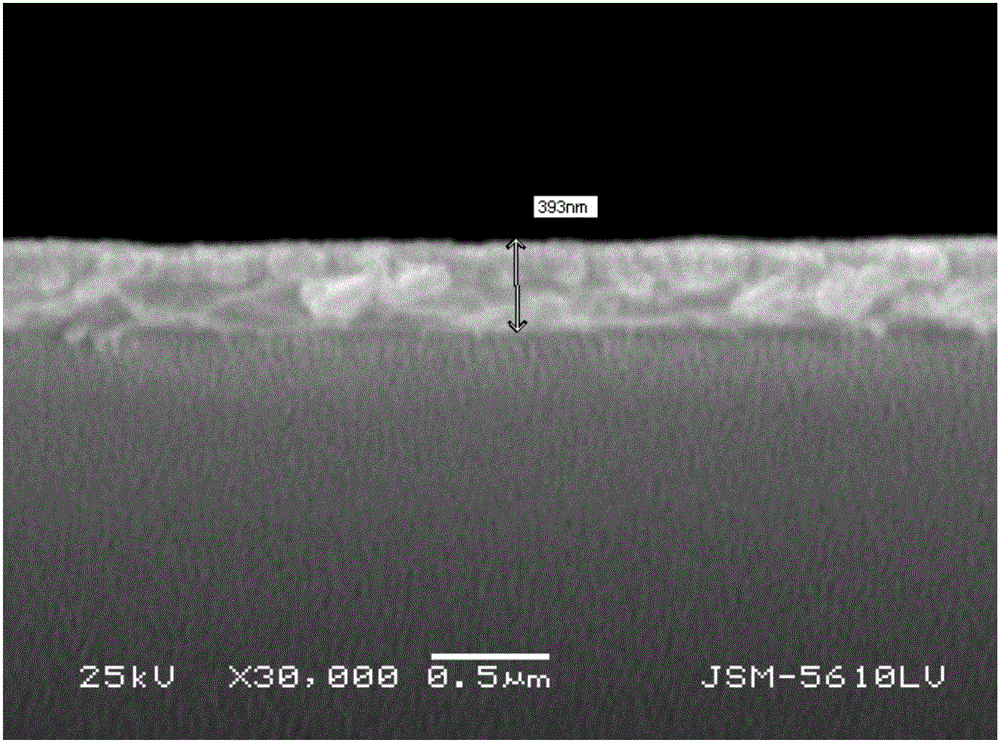

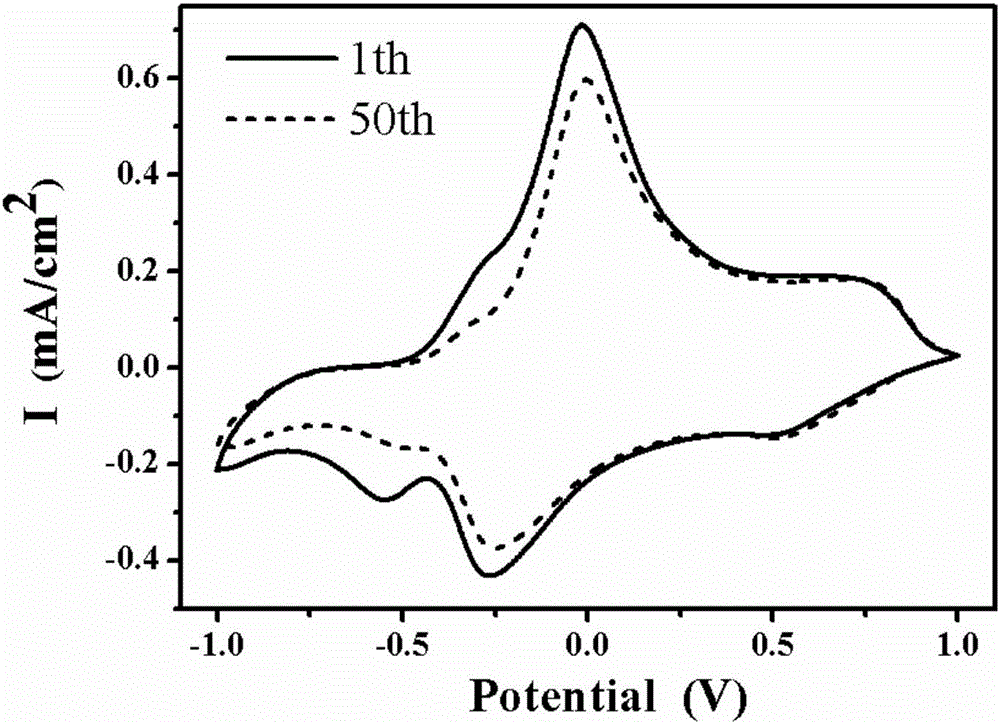

The invention discloses a molybdenum disulfide / carbon composite material. The molybdenum disulfide / carbon composite material comprises a molybdenum disulfide layer and a carbon hollow ball, wherein the molybdenum disulfide layer is positioned outside the carbon hollow ball; and the carbon hollow ball has a hollow structure. The invention also discloses a preparation method of the molybdenum disulfide / carbon composite material. The preparation method comprises the following steps of using amino modified silica spheres as a template; wrapping the template by pyrolyzation of an organic carbon source; performing thermal reaction on the template and ammonium tetrathiomolybdate through solvent; performing high-temperature carbonization in an inert atmosphere; and removing the silicon oxide template to obtain the molybdenum disulfide / carbon composite material. The lithium-intercalation capacity of the molybdenum disulfide / carbon composite material is 1467mAh / g for the first time, and the specific capacity of the molybdenum disulfide / carbon composite material can be kept at 733mAh / g after 30 times of repeated charging and discharging cycles.

Owner:SHANGHAI JIAO TONG UNIV

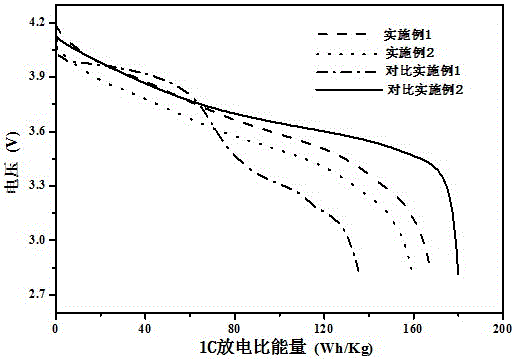

High-safety lithium manganese iron phosphate battery

ActiveCN106129365AImprove poor conductivityEasy to processCell electrodesSecondary cells servicing/maintenancePolyolefinNew energy

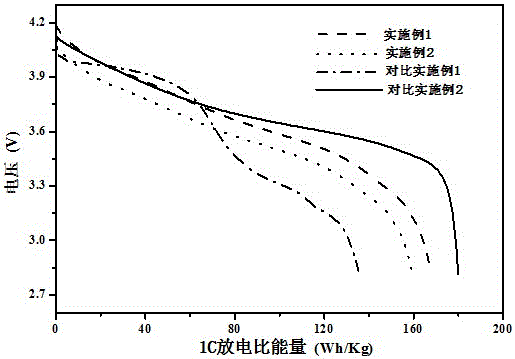

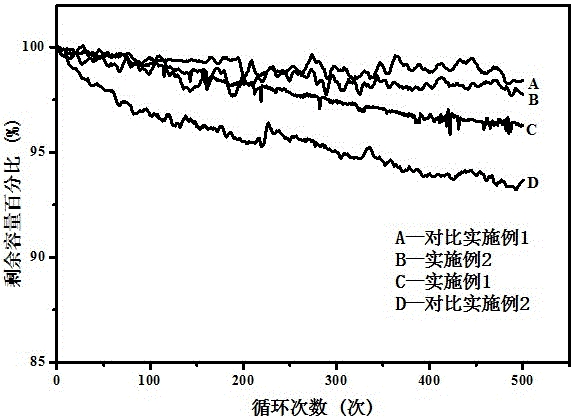

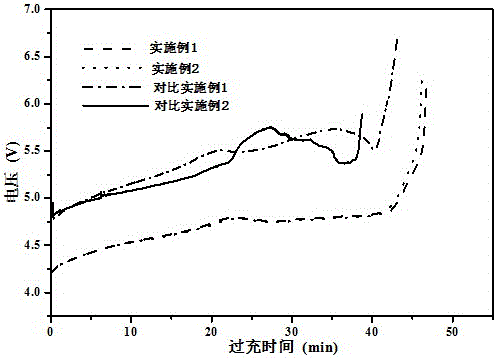

The invention belongs to the technical field of lithium ion batteries and specifically relates to a high-safety lithium manganese iron phosphate battery. The high-safety lithium manganese iron phosphate battery comprises a positive plate, a negative plate, an isolating membrane, an electrolyte and a battery shell, wherein the positive plate includes a positive pole current collector and a positive pole active material layer which is coated on a surface of the positive pole current collector; the positive pole active material layer includes the following components by weight percentage: 90wt%-96wt% of positive pole active material, 1.5wt%-5wt% of positive pole conductive agent and 2wt%-5wt% of positive pole binding agent; the positive pole conductive agent is a mixture of conductive carbon black and at least one of a carbon nano tube or graphene; and the ratio of the conductive carbon black to at least another conductive agent is 1wt%:0.5wt% to 4wt%:1wt% based on the weight percentage in the positive pole active material layer; the isolating membrane is one of a polyolefin film or a non-woven cloth film; and the electrolyte is a high-temperature-resistant electrolyte. Compared with a nickel cobalt lithium manganate ternary battery and a lithium iron phosphate battery, the high-safety lithium manganese iron phosphate battery has relatively high weight specific energy and relatively high safety performance at the same time, has a long cycle life and is suitable for popularization and application in the field of new energy vehicles.

Owner:CAMEL GRP NEW ENERGY BATTERY CO LTD

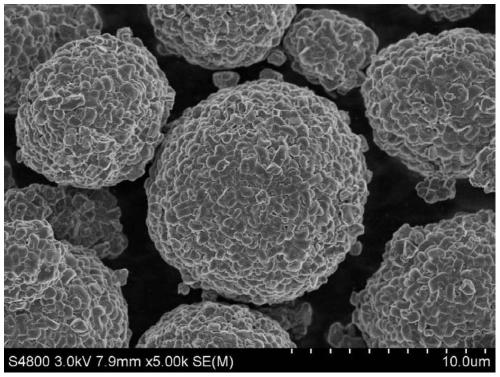

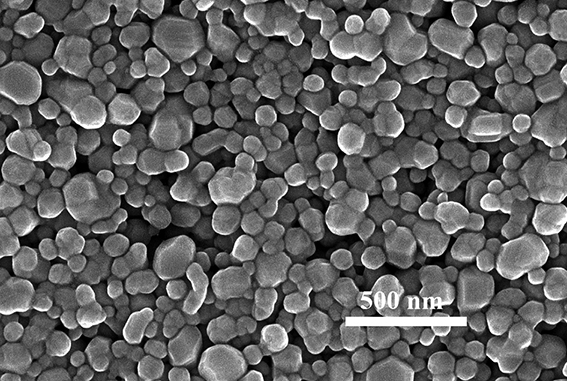

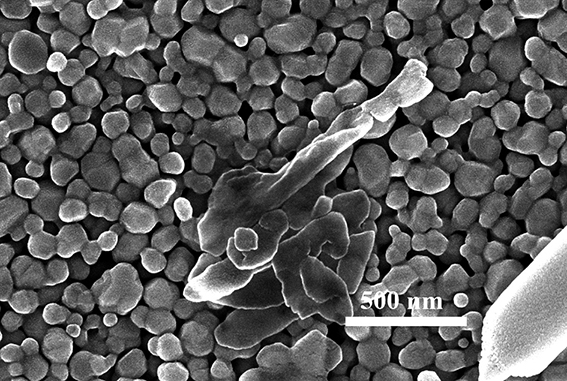

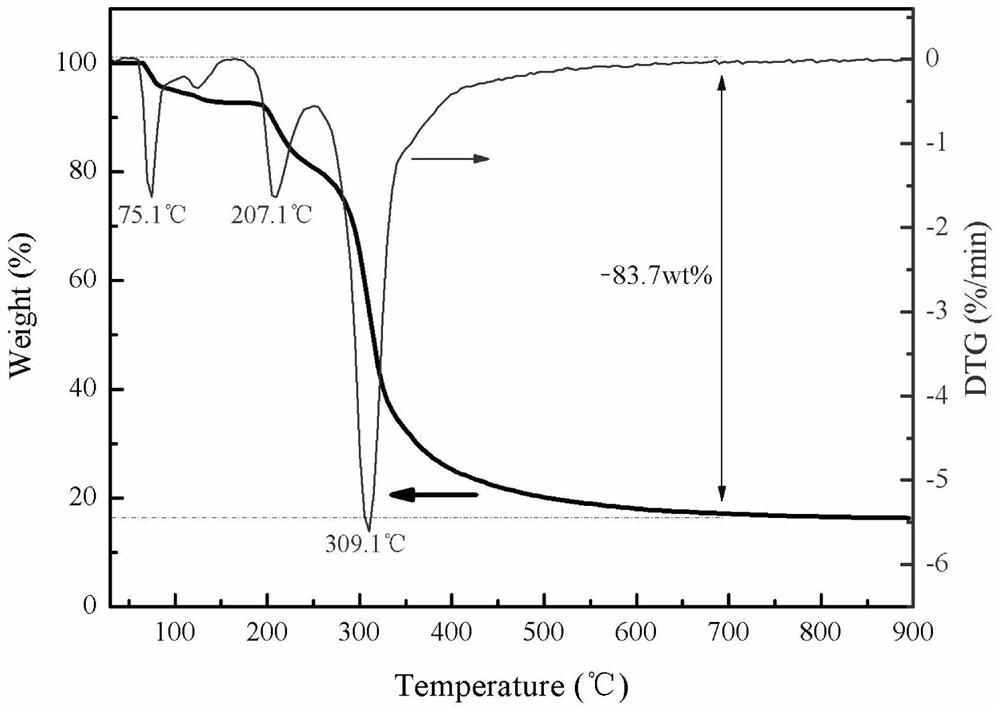

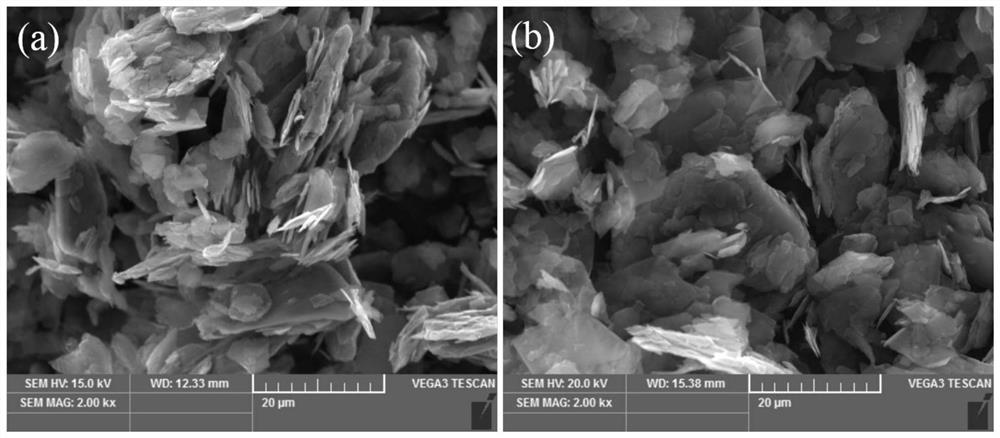

Lithium-ion battery silicon monoxide negative electrode material, preparation method and application thereof

ActiveCN110767877AShorten migration distanceImprove poor conductivitySecondary cellsNegative electrodesSilicon monoxideChemical physics

The invention relates to a lithium-ion battery silicon monoxide negative electrode material, and a preparation method and application thereof. A method for improving rate performance and cycle performance of the lithium-ion battery silicon monoxide negative electrode material includes the following steps: S1: crushing silicon monoxide to silicon monoxide particles having a particle size of 100 to800 nm; S2: after mixing the silicon monoxide particles, a conductive agent, an organic carbon source, and a solvent to obtain a slurry, performing granulation to obtain spherical silicon monoxide secondary particles having a particle size of 4 to 8 [mu]m; S3: pyrolyzing the silicon monoxide secondary particles; and S4: performing secondary coating on pyrolyzed silicon monoxide secondary particlesto obtain the silicon monoxide negative electrode material. In the invention, pulverization, secondary granulation, pyrolysis, and secondary coating processing are performed on the silicon monoxide,on the basis of retaining original first-time coulombic efficiency to a large extent, thereby shortening a lithium-ion diffusion path, improving lithium-ion conductivity, limiting lithium-ion volume expansion, and having better rate performance and cycle performance.

Owner:乳源东阳光新能源材料有限公司

Preparation and application of covalent organic skeleton/titanium carbide nano-sheet composites

ActiveCN109244388AImprove conductivityIncrease sulfur loadMaterial nanotechnologyCell electrodesNew energyButton battery

The invention relates to the preparation and application of a covalent organic skeleton / titanium carbide nano-sheet composite material, and belongs to the technical field of development and research of new energy materials. The Ti3C2 nano-sheets with single layer or few layers are mixed with organic monomer and solid catalyst and sealed in a vacuum quartz tube, and a covalent organic skeleton / Ti3C2 nano-sheet composite material is obtained by the ionothermal method. The covalent organic skeleton / Ti_3C_2 nanocomposite was coated on aluminum as working electrode after carrying sulfur, lithium metal is used as counter electrode and reference electrode, organic microporous membrane is used as separator, organic solution is used as electrolyte, and a button cell is assembled in the glove box filled with high purity argon. Compared with the prior art, the present invention can be used as a two-dimensional electrode material, is widely used in the energy field such as lithium sulfide batteryand the like, and has excellent charging / discharging performance.

Owner:TONGJI UNIV

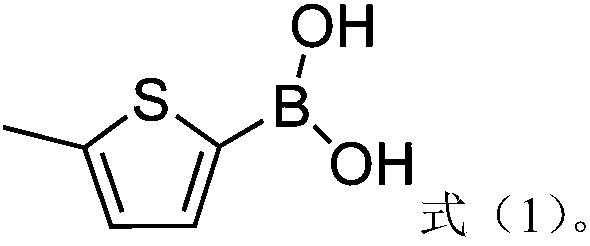

Lithium ion battery electrolyte suitable for silicon carbon material and application of electrolyte

InactiveCN108288728AImprove interface compositionInterface stabilitySecondary cellsDecompositionStructural formula

The invention discloses a lithium ion battery electrolyte suitable for a silicon carbon material and application of the electrolyte. The lithium ion battery electrolyte comprises electrolyte lithium salt, an organic solvent and a functional additive. The structural formula of the functional additive is shown in the description. Meanwhile, the invention discloses a preparing method of the electrolyte, and further discloses a silicon carbon negative electrode lithium ion battery containing the lithium ion battery electrolyte suitable for the silicon carbon material. A dual-functional group containing thiophene and boric acid forms the additive of the electrolyte suitable for the silicon carbon material; since the additive has a high reduction potential, the additive can be reduced ahead of solvent compositions in the first time of charging and discharging, the interface composition of the silicon carbon material and the electrolyte is improved, and therefore an electrode / electrolyte interface is stabilized, the electrode surface reaction activity is restrained, an electrode is prevented from making contact with the electrolyte in the charging and discharging process, and the electrolyte composition decomposition is restrained. The silicon carbon negative electrode lithium iron battery containing the additive has better circulating performance.

Owner:广东卡达克汽车科技有限公司

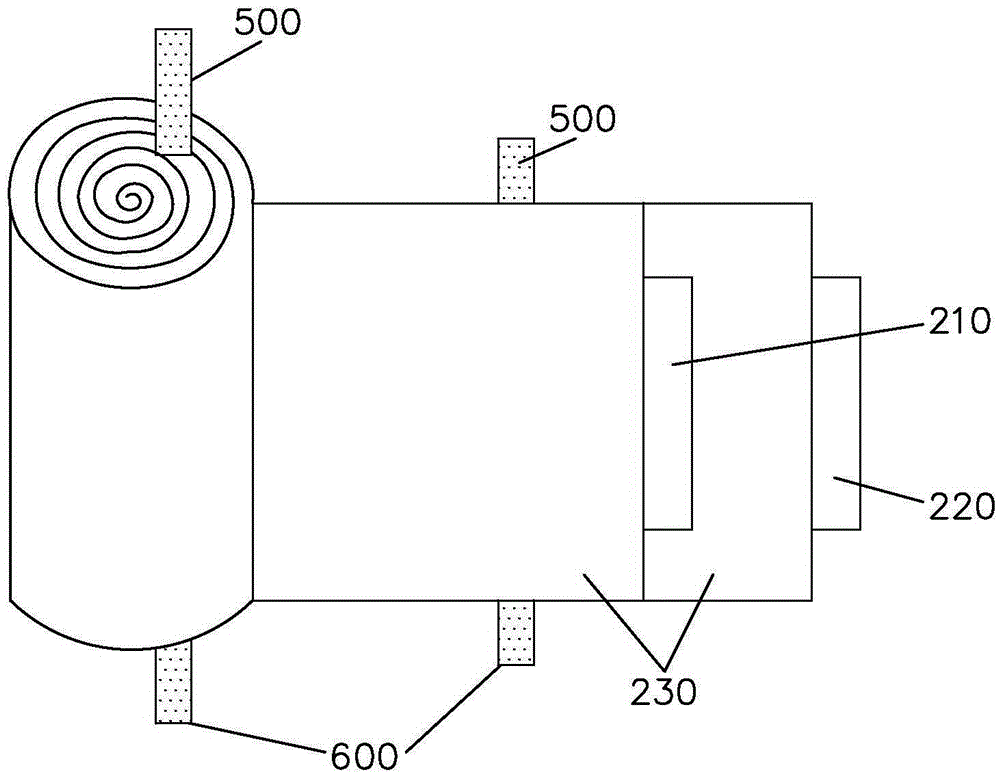

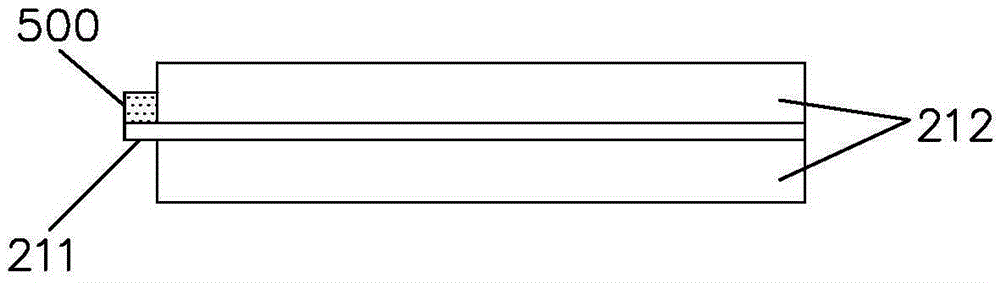

Graphene ultralow-temperature power lithium battery

ActiveCN105390695AImprove conductivityChange smoothing structureMaterial nanotechnologyCell electrodesLithium iron phosphateNanoparticle

The invention discloses a graphene ultralow-temperature power lithium battery. The power lithium battery comprises a battery case, a negative electrode insulation sheet, a battery cell, a positive electrode insulation sheet and a cap. The battery cell comprises a positive electrode plate, a negative electrode plate and a diaphragm. The positive electrode plate comprises a positive electrode current collector, and positive electrode material coatings arranged on two side surfaces of the positive electrode current collector respectively; each positive electrode material coating is prepared by coating the surface of the positive electrode current collector with a positive electrode material mixture; and the positive electrode material mixture contains a nanoparticle positive electrode material, a positive electrode binder, a positive electrode mixed conductive agent and a positive electrode solvent, wherein the nanoparticle positive electrode material is a lithium iron phosphate nanoparticle, and the positive electrode mixed conductive agent contains, by weight, 97-99 parts of a positive electrode conductive agent base material, 0.2-0.4 parts of graphene, 0.2-0.4 parts of SP and 0.2-0.4 parts of KS-6.

Owner:王立军

Coated multi-element positive electrode material for lithium ion battery, preparation method and application thereof

ActiveCN111564606AImprove poor conductivityImprove cycle performanceCell electrodesSecondary cellsDischarge efficiencyChemical composition

The invention discloses a coated multi-element positive electrode material for a lithium ion battery, a preparation method and application thereof. The coated multi-element positive electrode materialcomprises a multi-element positive electrode material and a coating layer coating the surface of the multi-element positive electrode material, wherein the chemical composition of the coating layer is element-doped In2O3 and / or element-doped CeO2, the element-doped In2O3 is Sr and / or Te element-doped In2O3, and the element-doped CeO2 is Te and / or Ge element-doped CeO2. The method comprises the step of coating a multi-element positive electrode material with a coating material, or introducing the coating material into preparation raw material components for synthesizing the multi-element positive electrode material to prepare the coated multi-element positive electrode material. The method provided by the invention can improve the first charge-discharge efficiency and cycle performance ofthe material, especially the high-temperature cycle performance.

Owner:SHENZHEN CITY BATTERY NANOMETER TECH

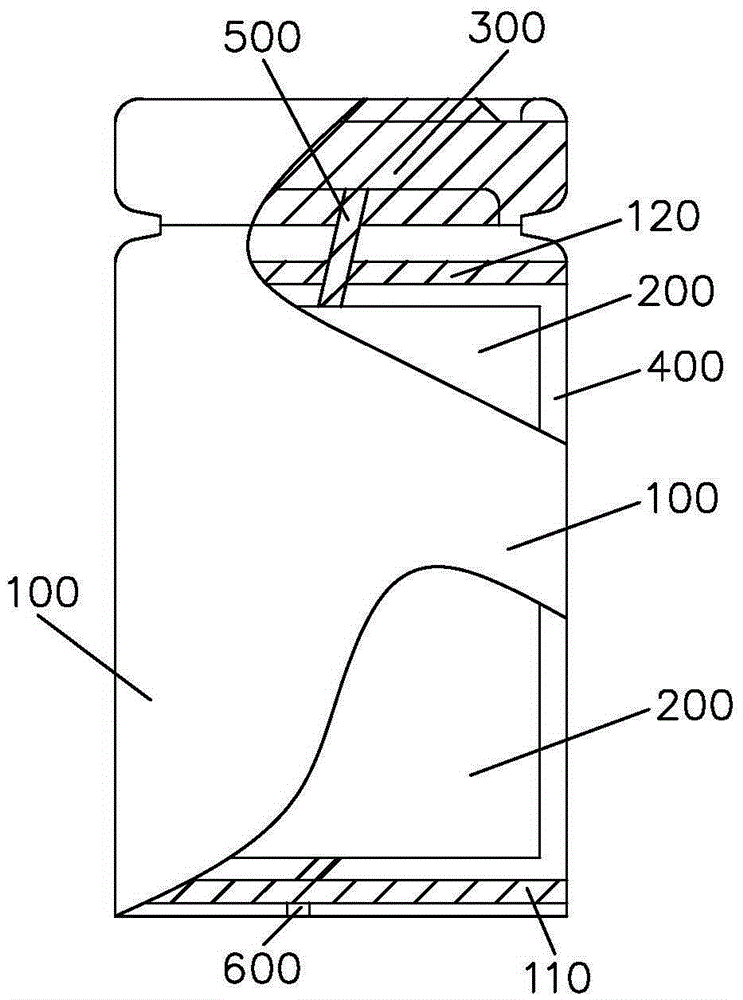

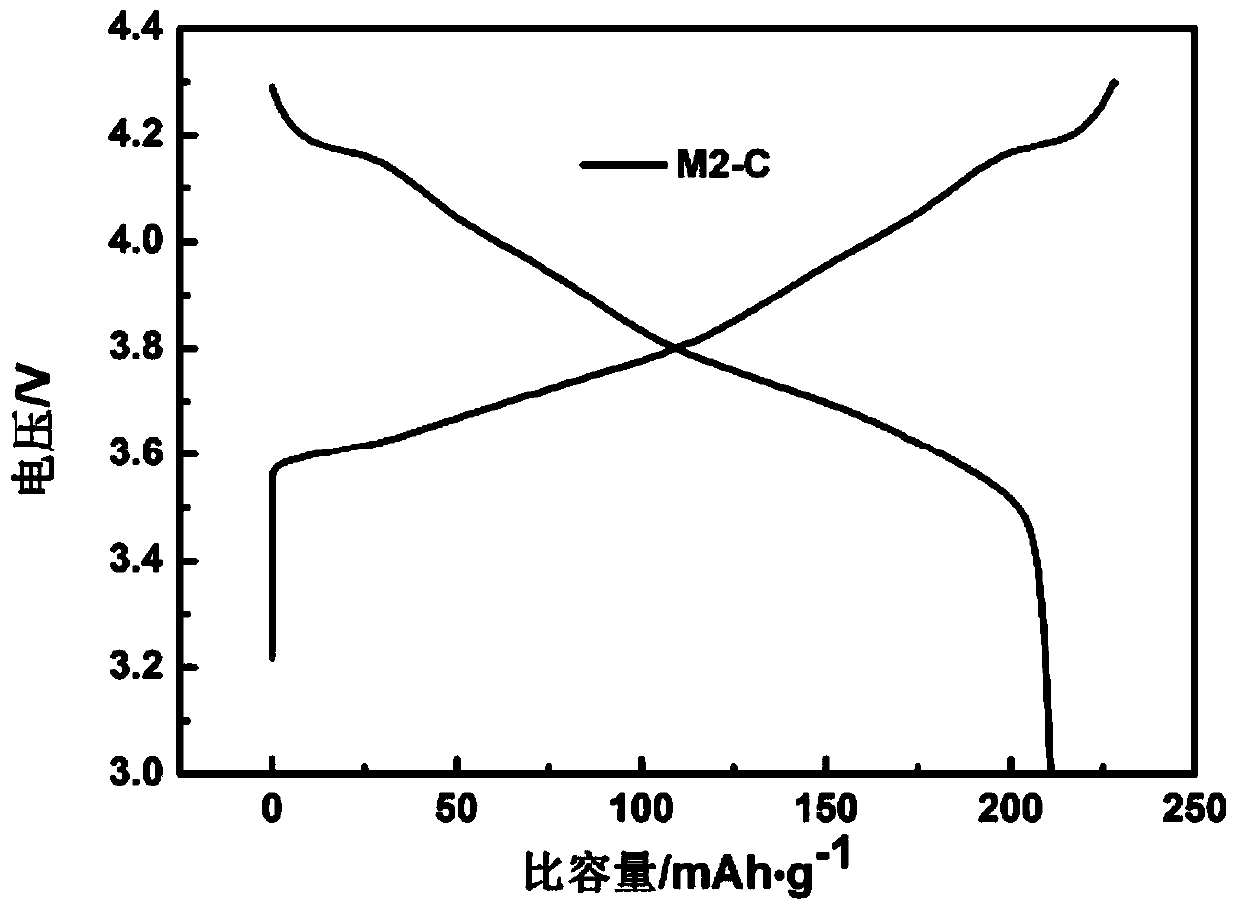

Power lithium ion battery

InactiveCN101527370AFacilitated DiffusionShorten Diffusion TimeCell electrodesSecondary cellsLithium–air batterySolvent

The invention relates to a lithium ion battery, more particularly to a power lithium ion battery. The inventive power lithium ion battery comprises an anode, a cathode, and a membrane between the anode and the cathode and organic electrolyte, wherein, the active material of the anode is nanometer LiFePO4 / C which accounts for 85-95% (by mass) of the mixed powders of the anode; the active material of the cathode is nanometer Li4Ti5O12 / C which accounts for 85-95% (by mass) of the mixed powders of the cathode; the organic electrolyte takes LiPF6 as an electrolyte and takes EC and DEC as solvents. Compared with the existing lithium ion battery which serves as the power source of electric vehicle, the inventive power lithium ion battery is good in conductivity, high in safety, stable in discharging, long in cycle life and excellent in high-current charging and discharging; the invention is extremely suitable for the power source of the electric vehicle.

Owner:GUILIN JIUYI NEW ENERGY SCI & TECH CORP

Additive for zinc-based battery

InactiveCN109962242AWide variety of sourcesEasy to getAlkaline accumulatorsCell seperators/membranes/diaphragms/spacersIndiumElectrochemistry

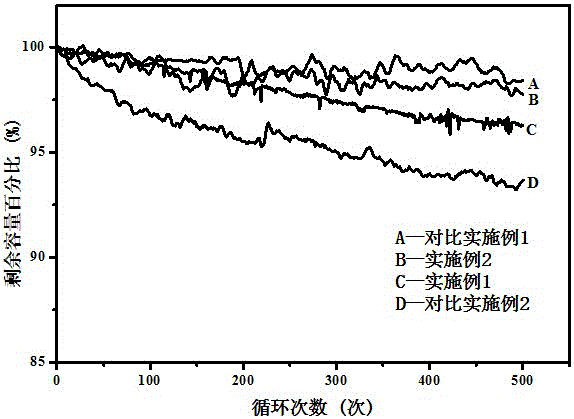

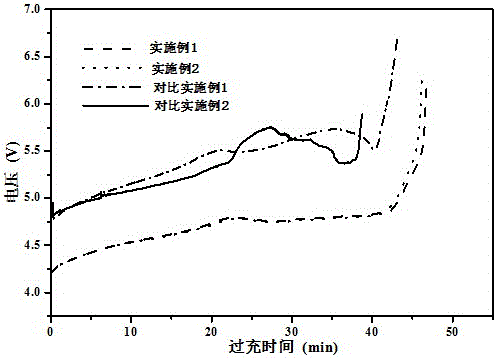

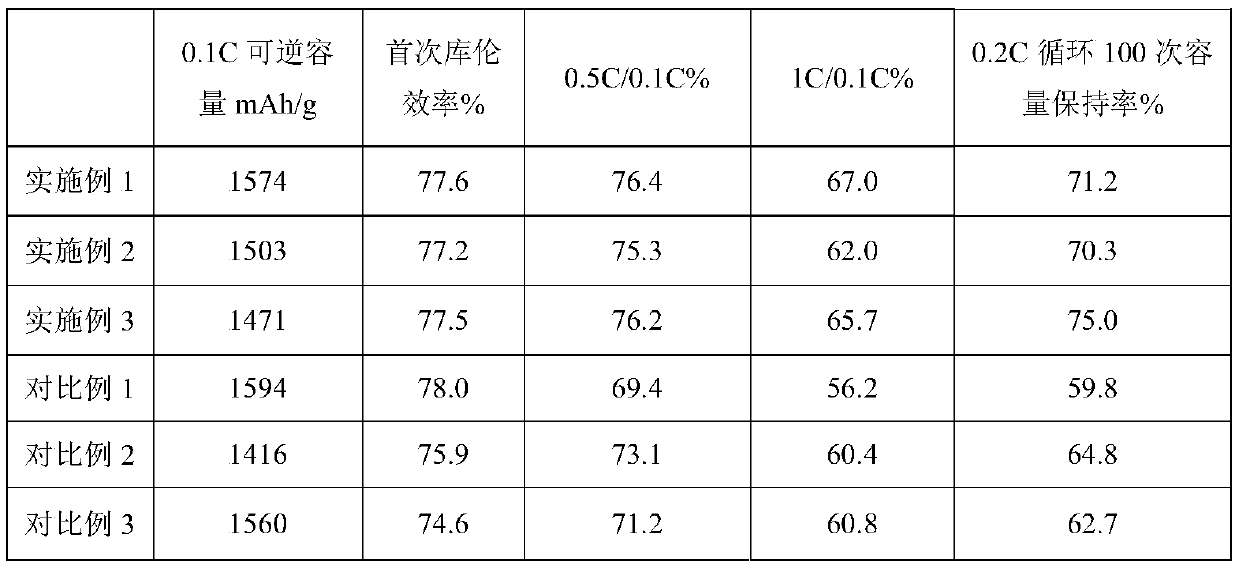

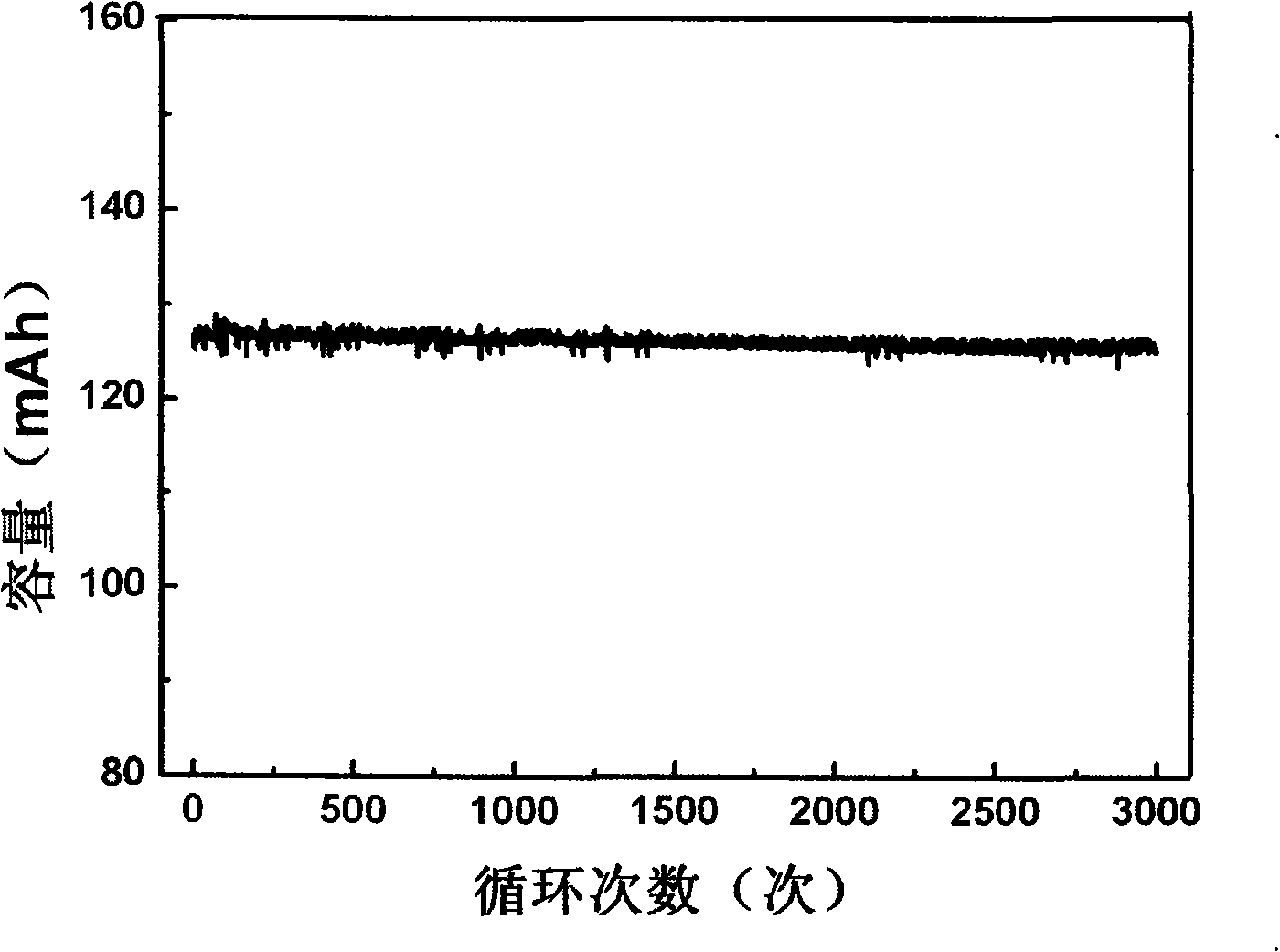

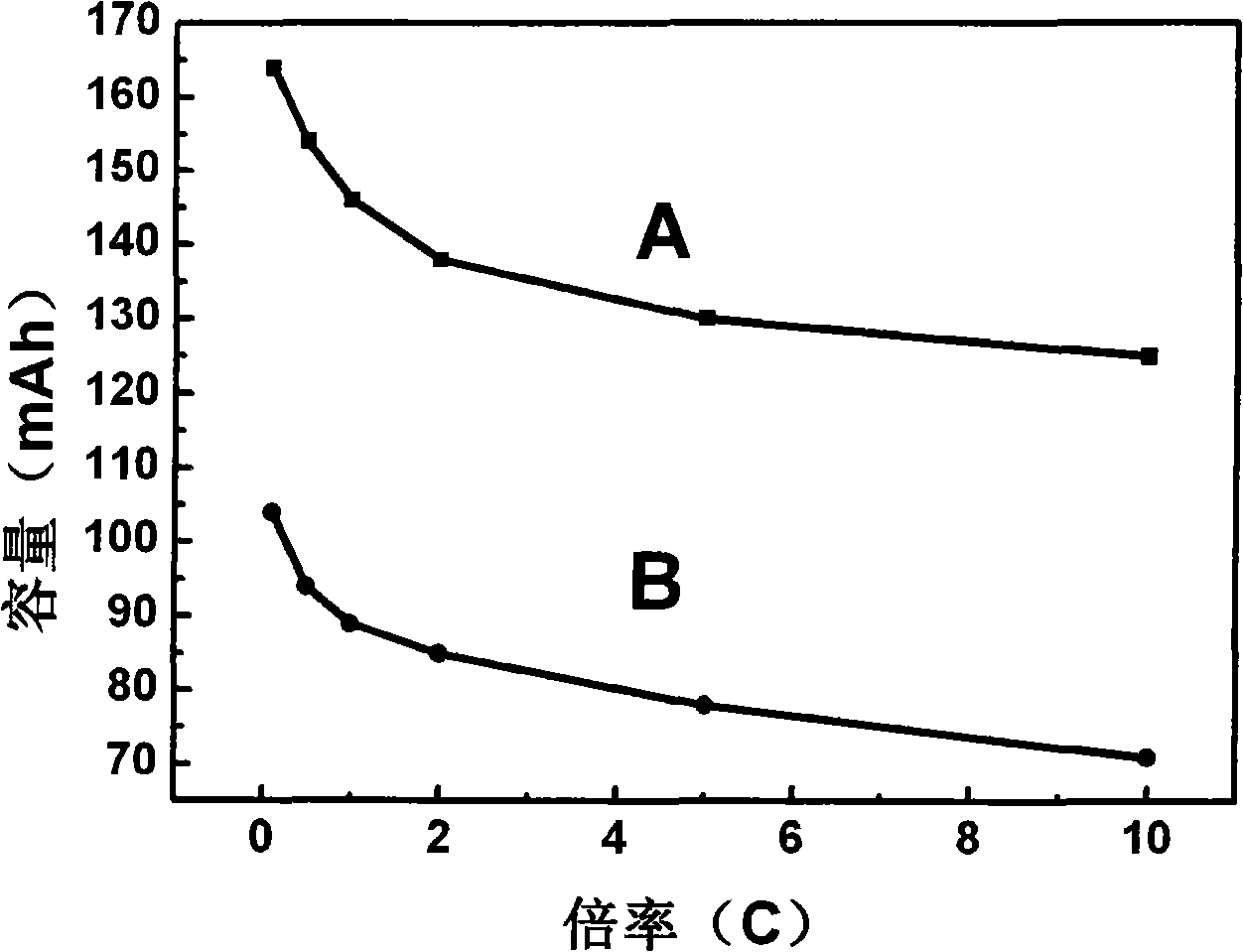

The invention relates to an additive for a zinc-based battery. The additive for the zinc-based battery is characterized in that the additive is one of metal, alloy and oxides or hydroxides of the metals and the alloy or more; the metal is one of gallium, indium, tin, lead and bismuth or more; the alloy is one of binary or multielement alloys of gallium, indium, tin, lead and bismuth or more; the metal oxide is one of oxides of gallium, indium, tin, lead and bismuth or more; the hydroxide is one of hydroxide of gallium, indium, tin, lead and bismuth or more. After the additive is used, the cycle life of the zinc-based battery is more than 500 times, and the zinc-based battery can be stably charged and discharged at the rate of 0.1-50C. The additive has the advantages that the raw materialsare easy to prepare, and the zinc dendritic crystal inhibition capability is high; and the battery shows excellent electrochemical performance and cycling stability, and can be widely applied to various portable electronic equipment, electric vehicles, aerospace and other fields.

Owner:BEIHANG UNIV

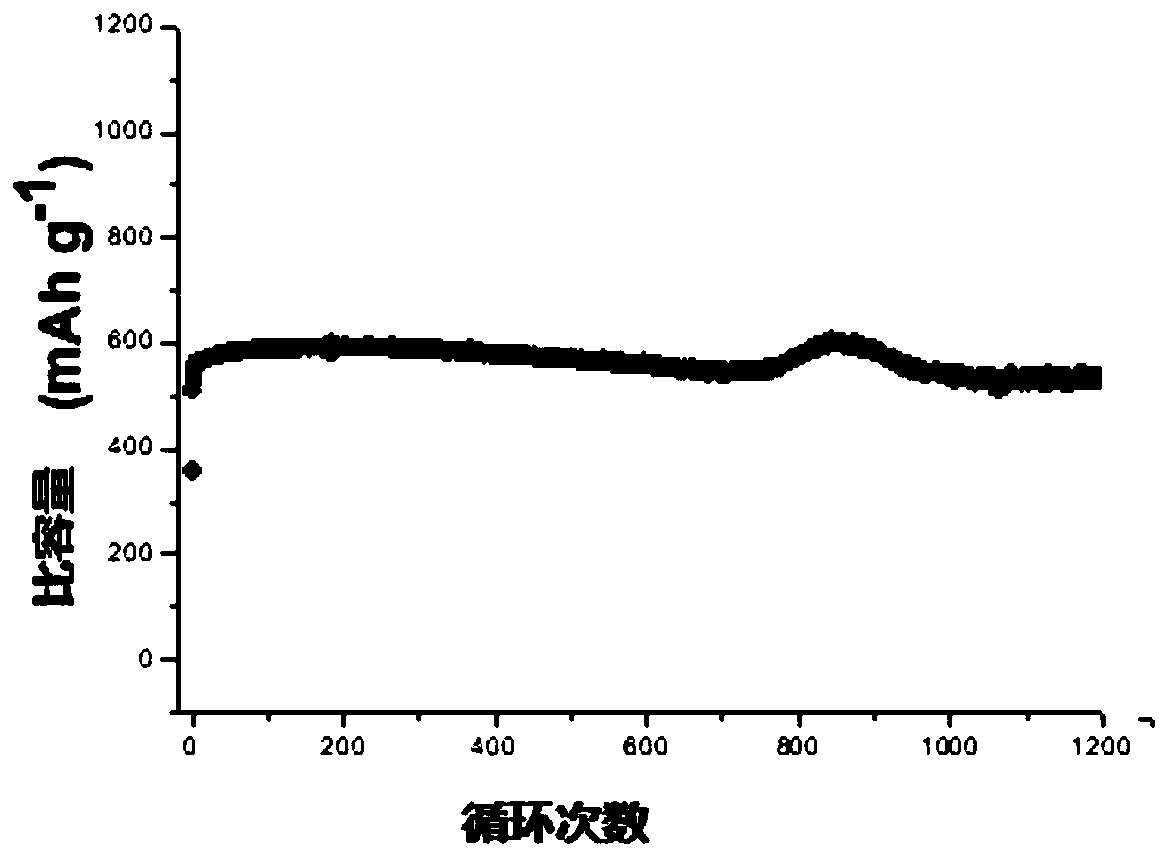

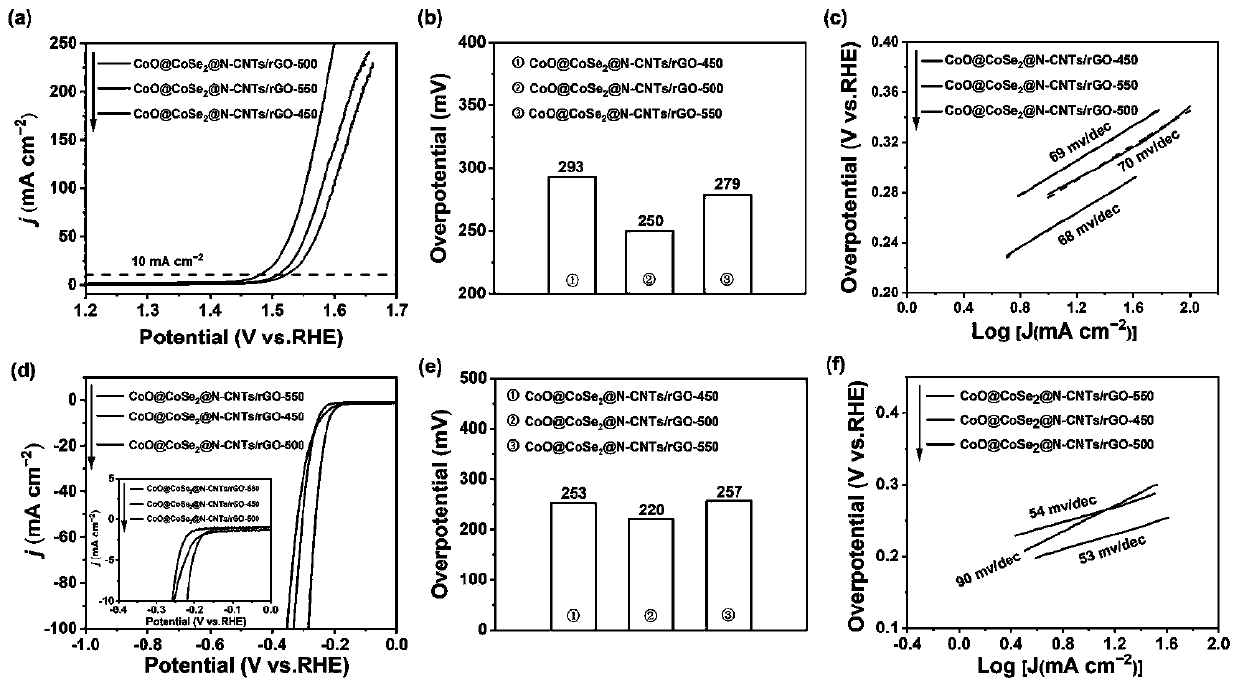

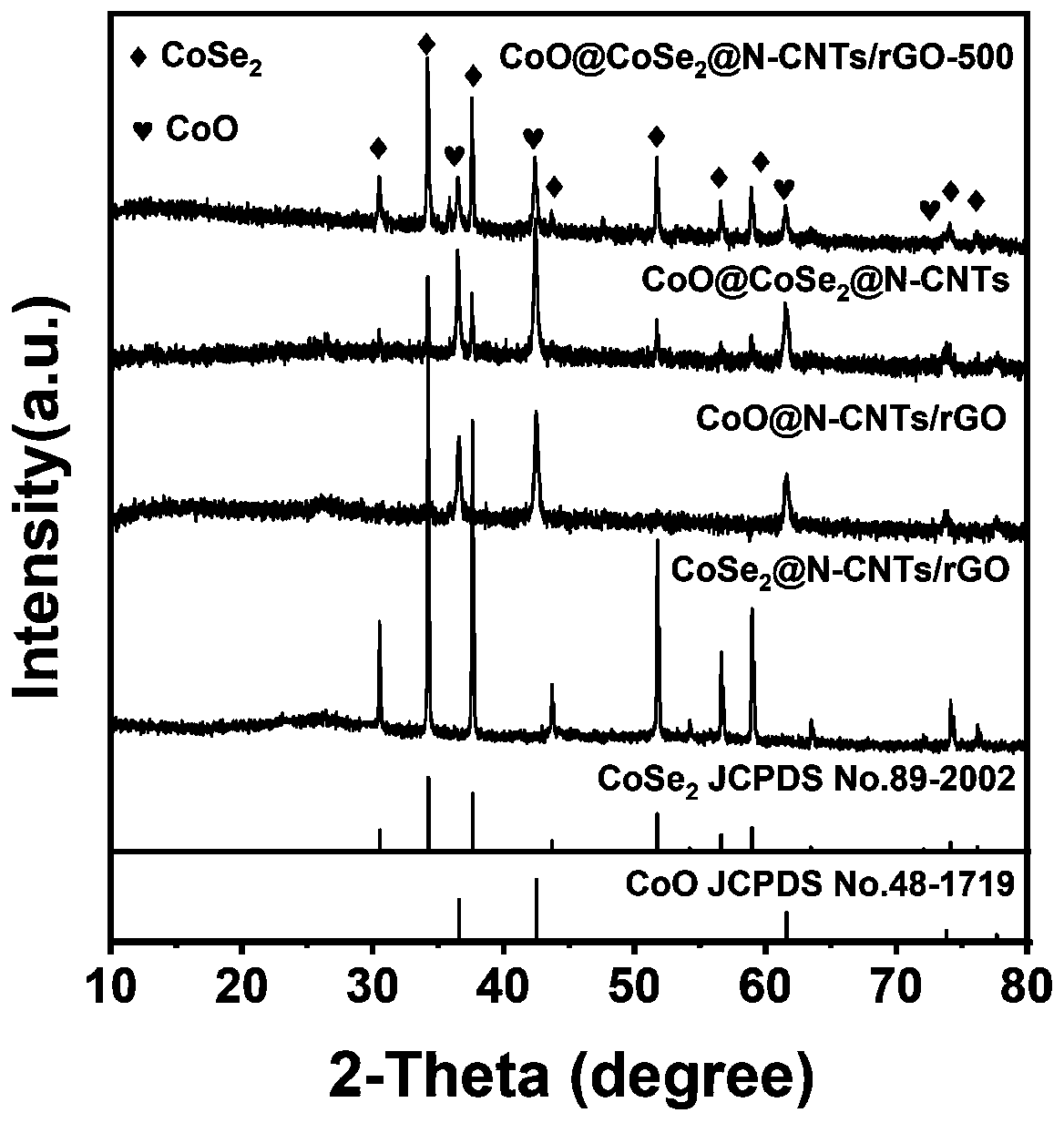

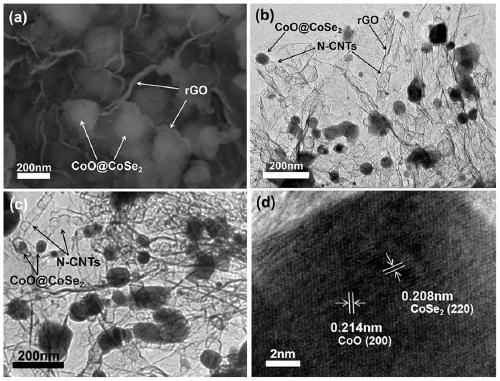

Oxygen evolution/hydrogen evolution two-dimensional cobalt monoxide-coated cobalt diselenide-coated nitrogen-doped carbon nanotube/graphene bifunctional composite catalyst

ActiveCN111054418AImprove performanceReduce reunionElectrolysis componentsCatalyst activation/preparationPtru catalystBifunctional

The invention discloses an oxygen evolution / hydrogen evolution two-dimensional cobalt monoxide-coated cobalt diselenide-coated nitrogen doped carbon nanotube / graphene bifunctional composite catalyst.The catalyst is formed by loading cobalt monoxide nanoparticles, cobalt diselenide nanoparticles and nitrogen-doped carbon nanotubes on a two-dimensional graphene sheet together, the preparation method comprises the following steps: mixing cobalt salt, a nitrogen-containing organic small molecular compound and graphene oxide through a liquid phase, drying, placing in a protective atmosphere, carrying out two-stage roasting treatment, and carrying out partial selenylation treatment on the roasted product and selenium powder in the protective atmosphere at a high temperature, thereby obtaining the product. The preparation process is simple, low in cost and beneficial to industrial production; the obtained composite catalyst is applied to an electrolytic decomposition process of water, has the characteristics of high activity and good stability, and shows a good application prospect.

Owner:CENT SOUTH UNIV

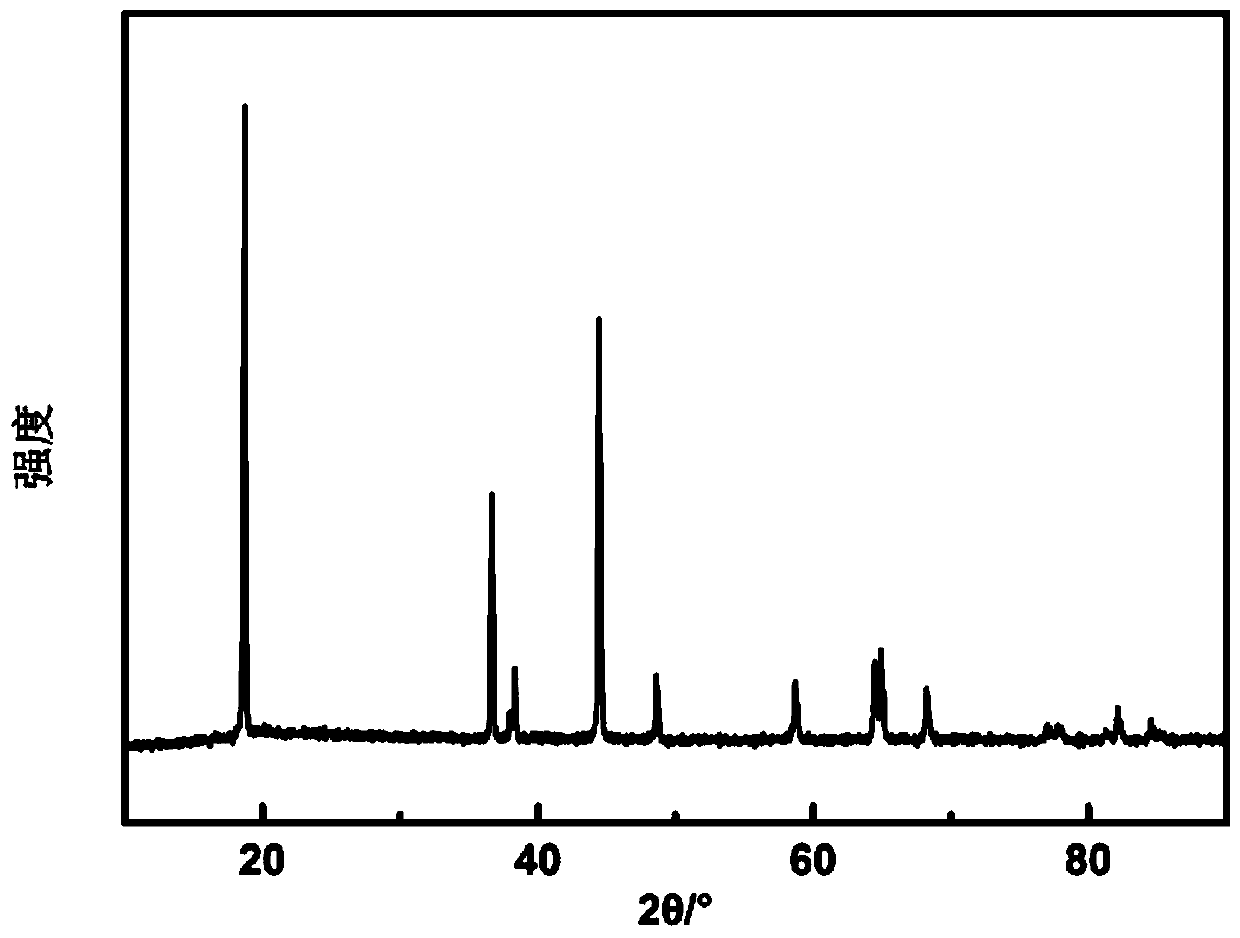

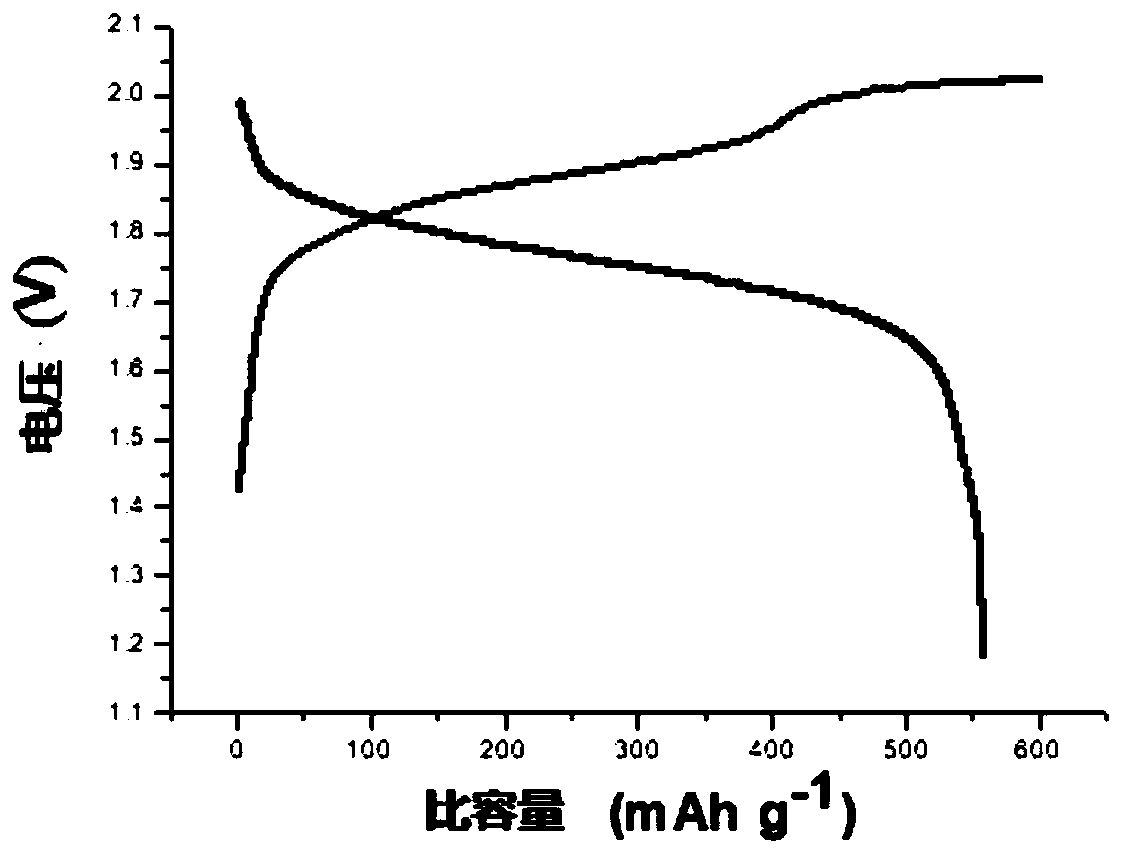

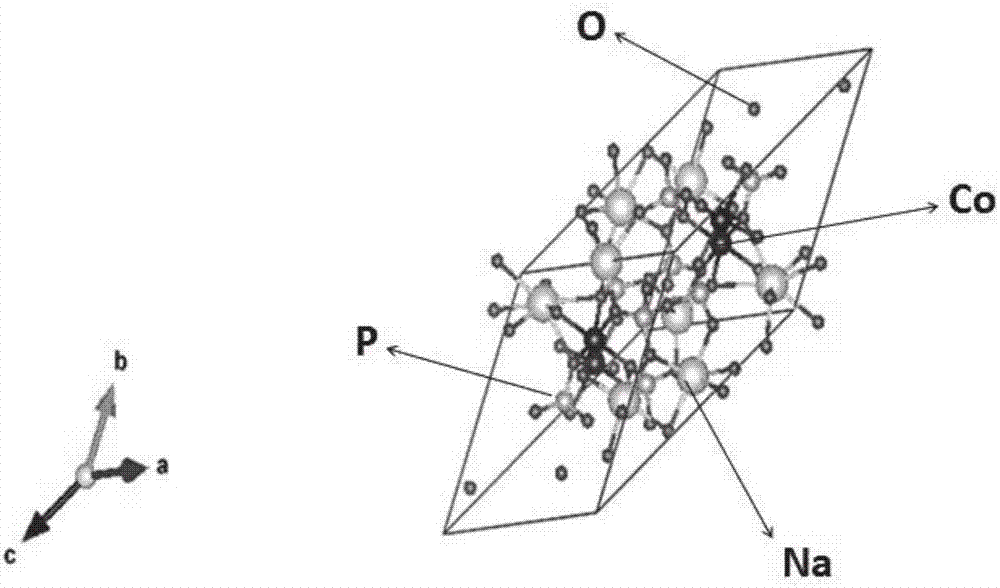

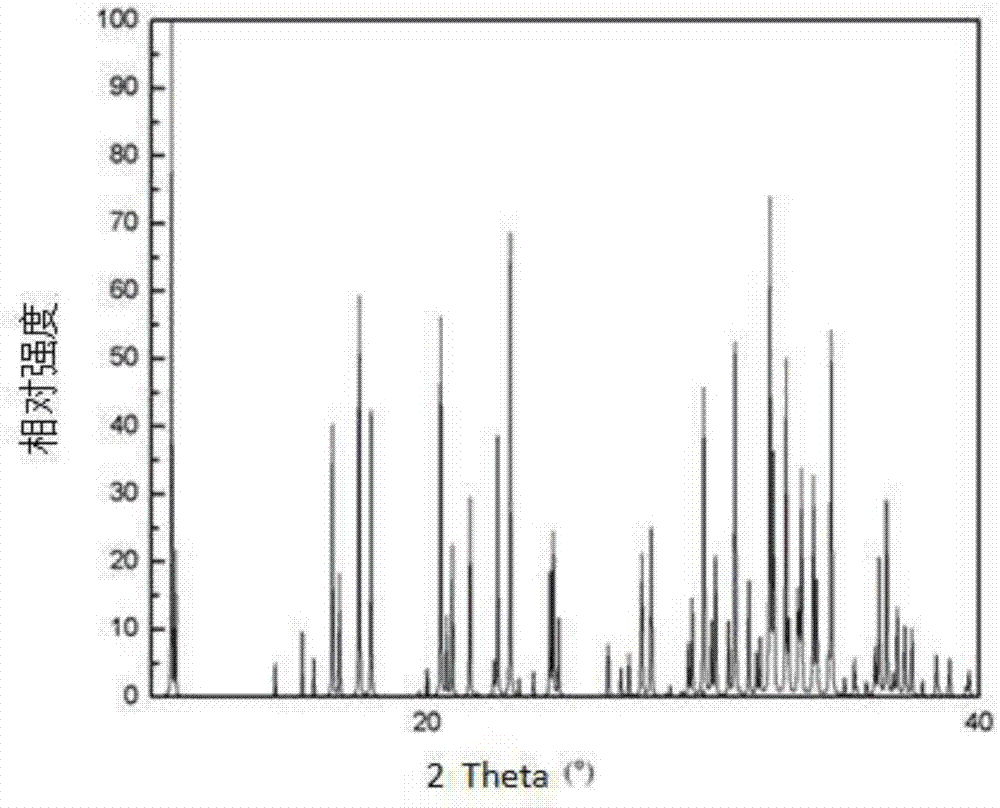

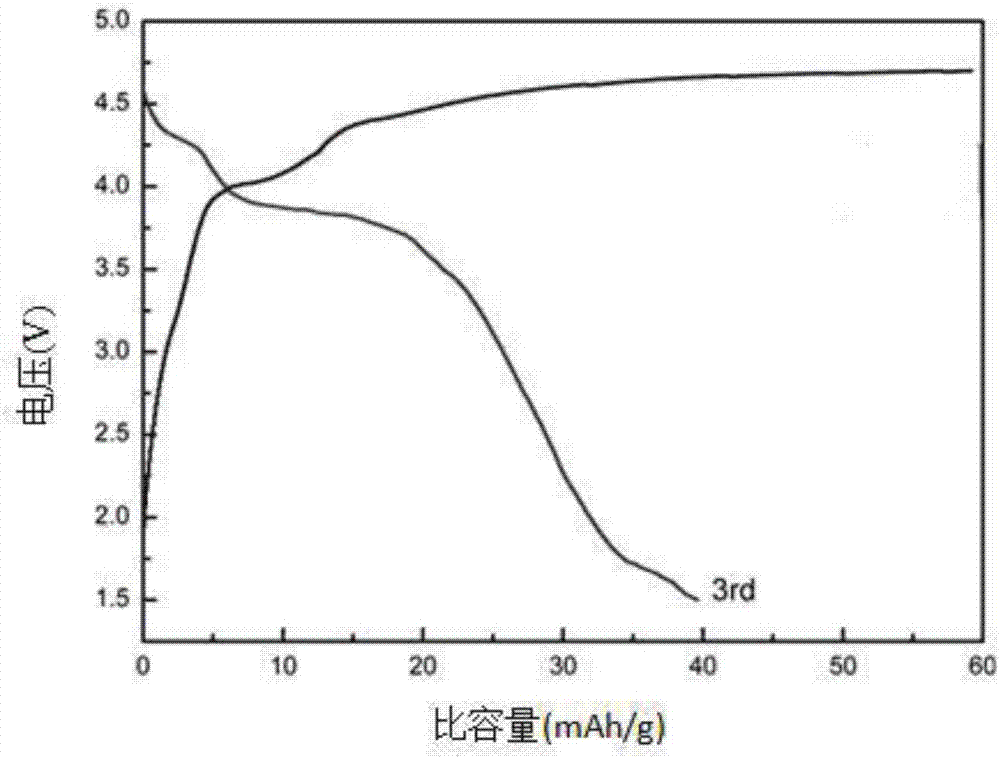

Composite electrode material of sodium cobalt pyrophosphate/carbon, preparation and application of composite electrode material

InactiveCN107017393APromote circulationImprove electrochemical performanceCell electrodesSecondary cellsComposite electrodeGranularity

The invention discloses a composite electrode material of sodium cobalt pyrophosphate / carbon. The chemical general formula of the sodium cobalt pyrophosphate / carbon is Na2-2xCo1+xP2O7, wherein x is greater than 0 and less than or equal to 0.25. The invention further discloses a preparation method of the composite electrode material. The preparation method comprises the following steps: dissolving a cobalt source, a sodium source and a phosphorus source into water according to the ratio of the elements in the chemical general formula to obtain mixed liquid, adding a complexing agent into the mixed liquid, stirring and heating to obtain gel, and drying the gel to obtain a precursor; calcining the precursor to obtain the composite positive electrode material. In addition, the invention further provides application of the composite positive electrode material serving as a sodium ion battery positive electrode material. The preparation method provided by the invention is simple and mild in condition. The prepared sodium ion battery positive electrode material has uniform granularity and good appearance, and has high specific capacity and high voltage and shows excellent circulating stability when being applied to a sodium ion battery.

Owner:CENT SOUTH UNIV

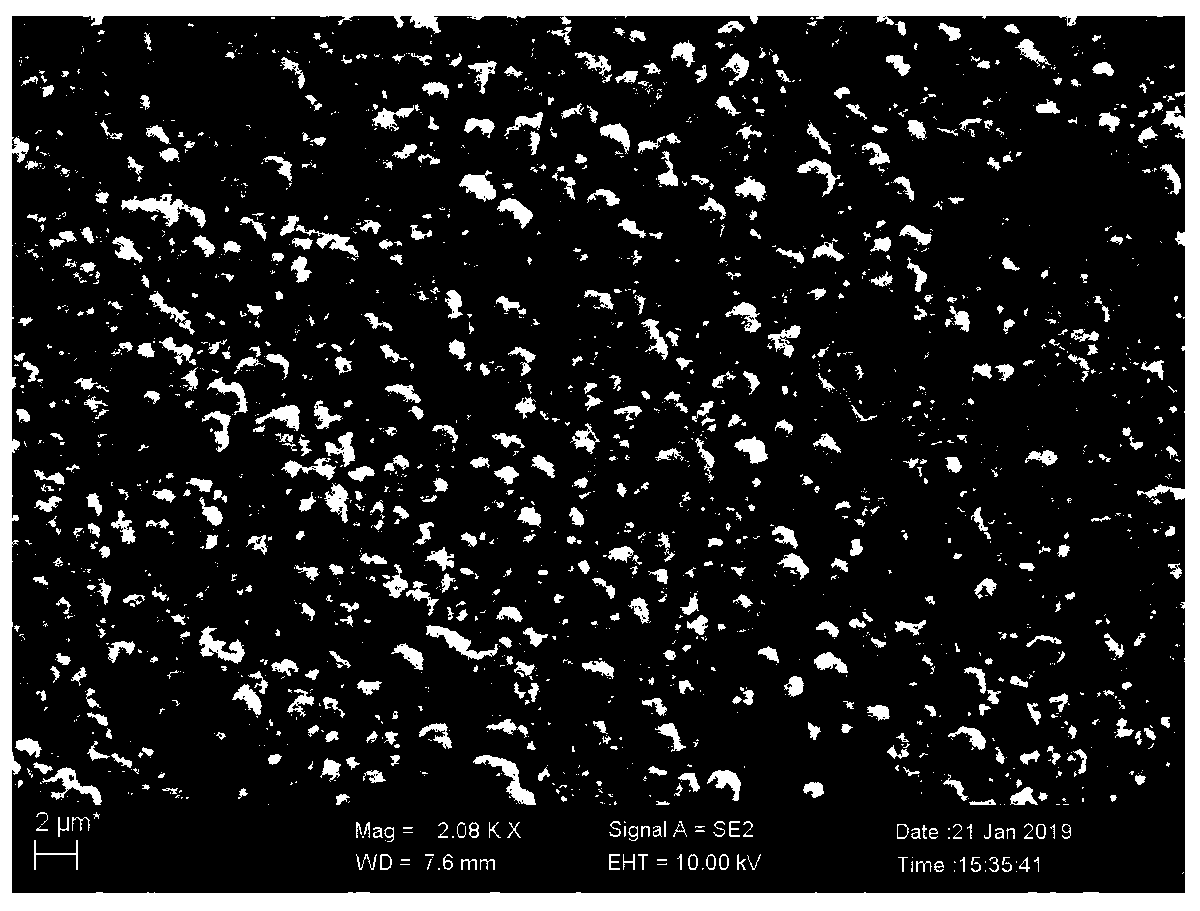

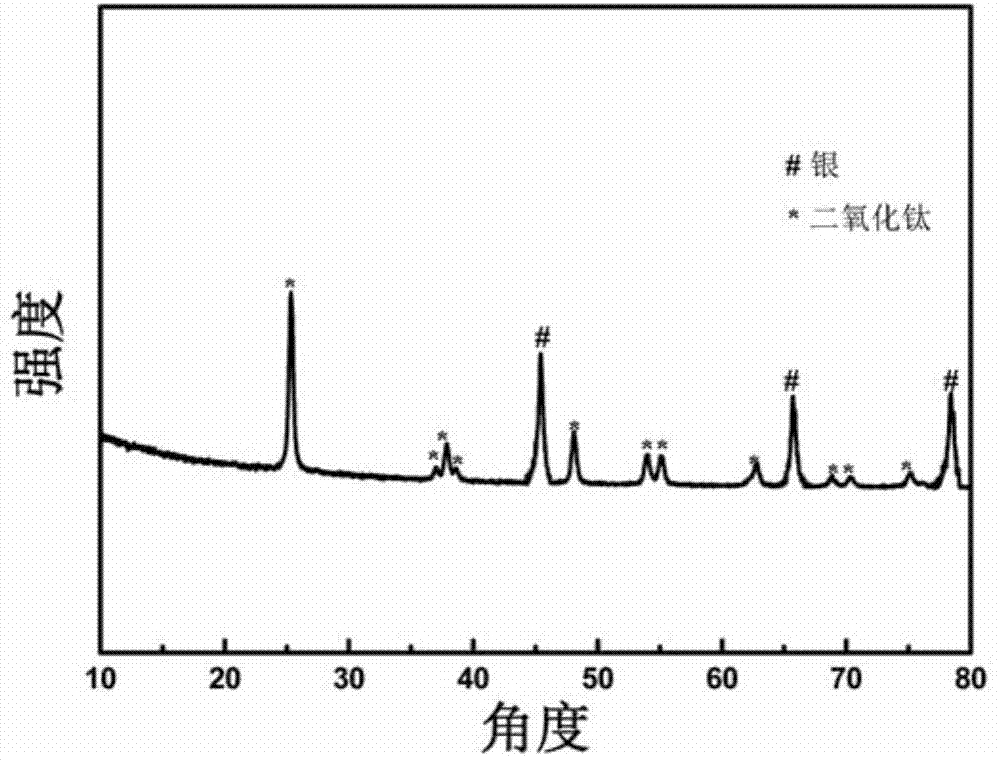

Preparation method of silver-loaded titanium dioxide anode material

ActiveCN104852032AAvoid uneven loadImprove conductivityCell electrodesSecondary cellsWater bathsElectrochemistry

The invention discloses a preparation method of a silver-loaded titanium dioxide anode material. The preparation method comprises the following steps of 1) stirring deionized water and ethylene glycol, and then adding titanyl sulfate to stir in order to obtain solution I; 2) adding polyvinylpyrrolidone into the solution I; 3) dropping methanamide into the solution II obtained in the step 2) under vigorous stirring, and drying after gel ageing in order to obtain aluminum hydroxide gel; 4) dissolving silver nitrate into alcohol to obtain mixed solution, adding the aluminum hydroxide gel, allowing the mixture to stand for 11-13 hours under the water bath condition of 50-70 DEG C, cleaning by utilizing deionized water, and drying at 50-70 DEG C for 11-13 hours to obtain a black gray block material; and 5) carrying out heat treatment on the black gray block material at 500 DEG C for 3-5 hours and cooling the material to the room temperature in order to obtain the silver-loaded titanium dioxide composite. The composite has the advantage of excellent electrochemical performance.

Owner:ZHEJIANG UNIV

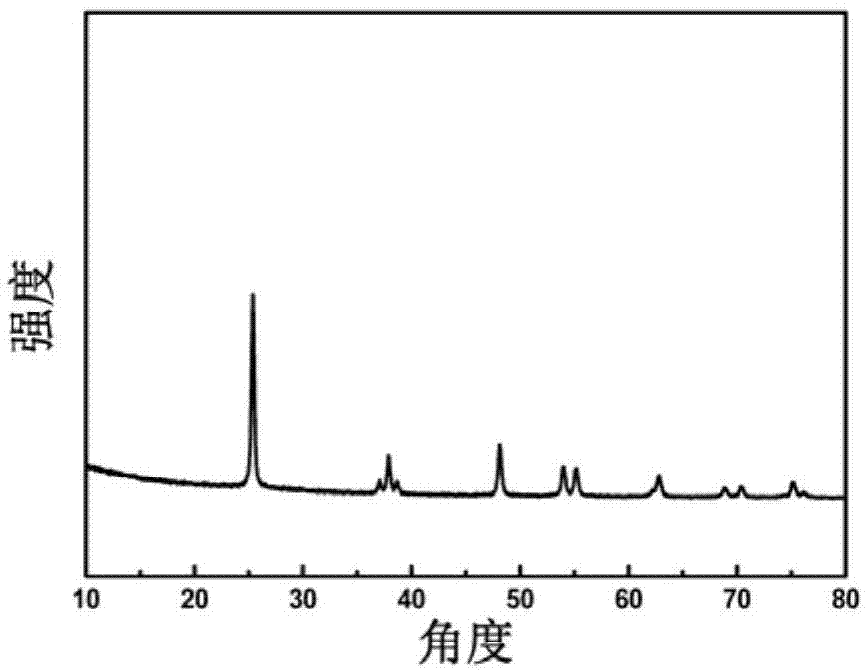

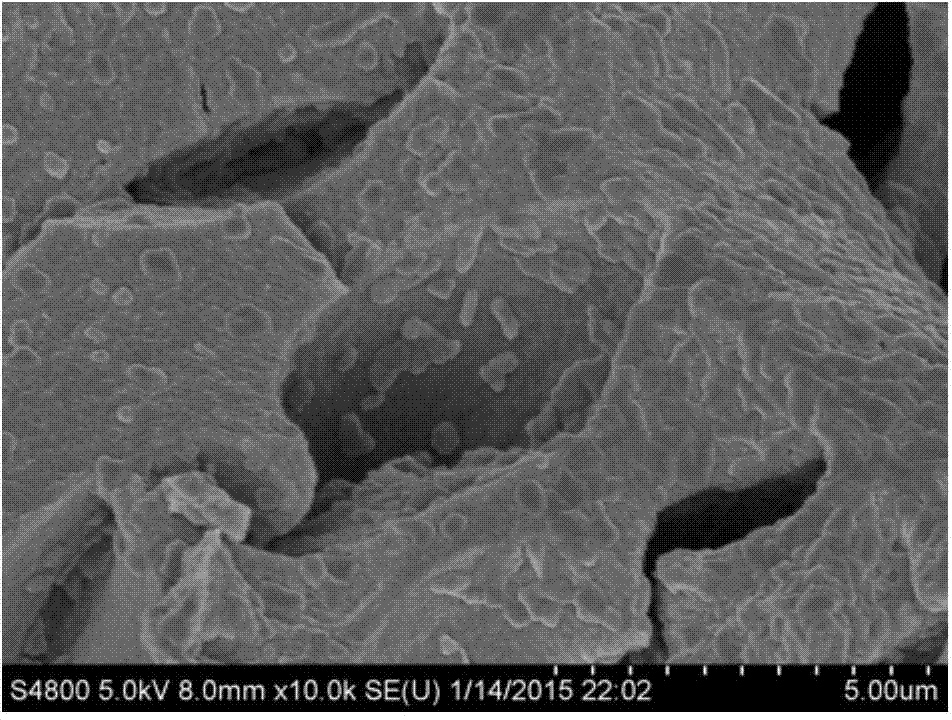

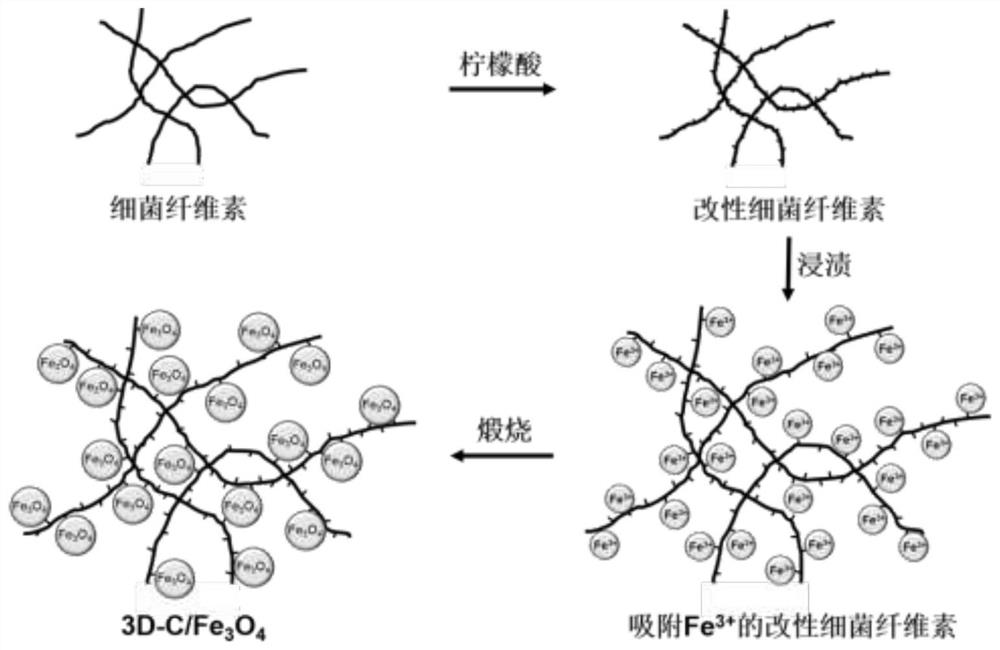

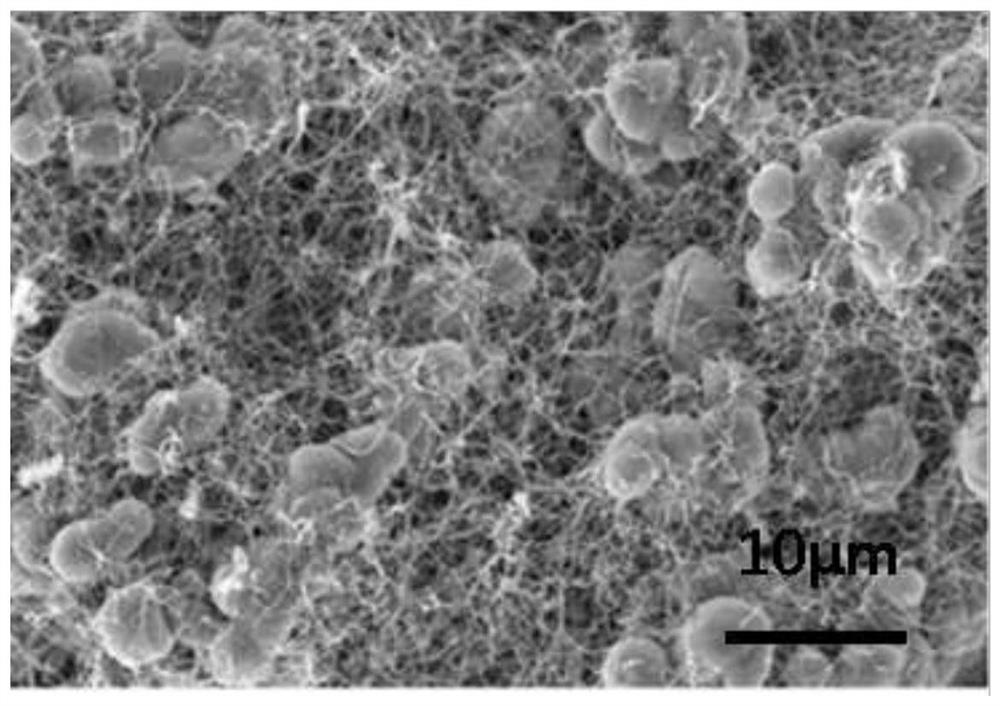

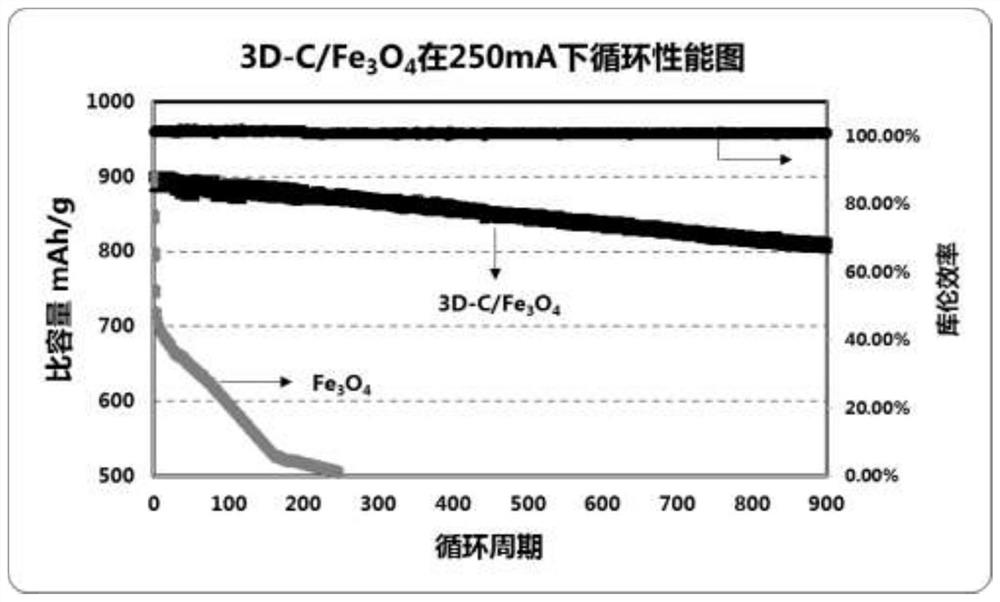

Three-dimensional C/Fe3O4 lithium ion battery negative electrode material and preparation method thereof

ActiveCN111769263AImprove adsorption capacityImprove bindingMaterial nanotechnologyCell electrodesElectrical batteryMaterials science

The invention discloses a three-dimensional C / Fe3O4 lithium ion battery negative electrode material and a preparation method thereof, and the three-dimensional C / Fe3O4 lithium ion battery negative electrode material is prepared by taking cellulose as a template and ferric salt as a precursor, firstly loading iron ions on the template through dipping treatment, and then carrying out calcining treatment in an inert atmosphere. The three-dimensional C / Fe3O4 lithium ion battery negative electrode material prepared by the invention can overcome the defects of poor conductivity and large volume change in circulation of the Fe3O4 negative electrode material, and can greatly improve the electrochemical performance of the Fe3O4 negative electrode.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

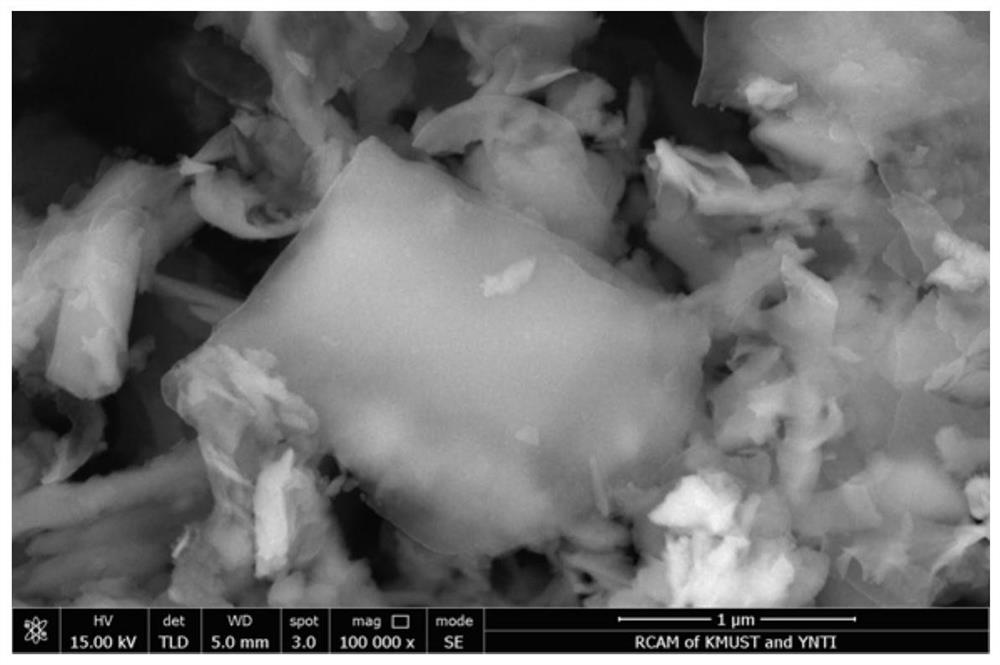

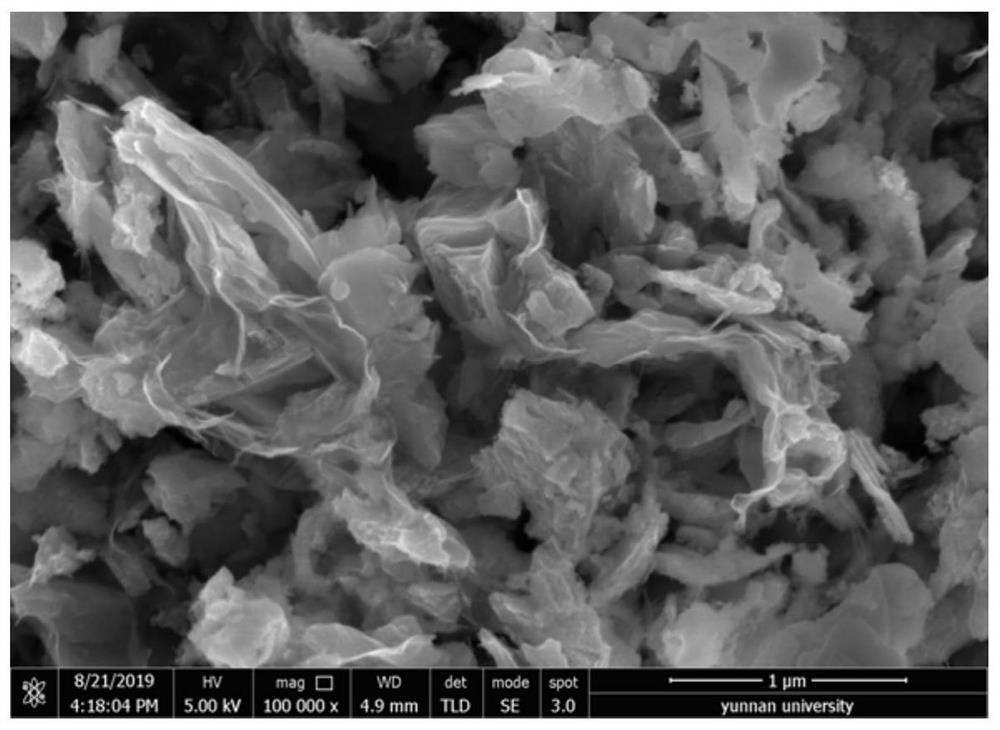

Method for preparing high-energy-density lithium ion battery negative electrode material based on silicon waste alloy method

InactiveCN111799461AImprove poor conductivityBuffer volume expansionMaterial nanotechnologyCell electrodesMicro nanoNew energy

The invention relates to a method for preparing a high-energy-density lithium ion battery negative electrode material based on a silicon waste alloy method, and belongs to the technical field of new energy materials and electrochemistry. On the basis of an alloy method, diamond wire cutting silicon waste and metal particles are mixed and heated to be in a molten state in a protective atmosphere; the heat is preserved to realize a full alloy state; ball milling is carried out in a protective atmosphere to obtain micro-nano Si@M powder; the micro-nano Si @ M powder is mixed with a graphene oxidesolution, graphene oxide is directly reduced by adopting reducing gas, oxygen-containing functional groups among carbon atom layers are removed effectively, and graphene oxide is reduced into graphene to obtain the graphene-coated Si@M high-performance lithium ion battery negative electrode material Si@M@C. Silicon waste and metal are effectively combined through an alloy method, and the conductivity difference of a silicon material is improved; meanwhile, a compact graphene coating layer is introduced to the Si@M surface of the material, the problem of volume expansion of silicon in the charging and discharging process can be effectively solved, and the material has the beneficial effects of being high in energy density, specific capacity and stability.

Owner:KUNMING UNIV OF SCI & TECH

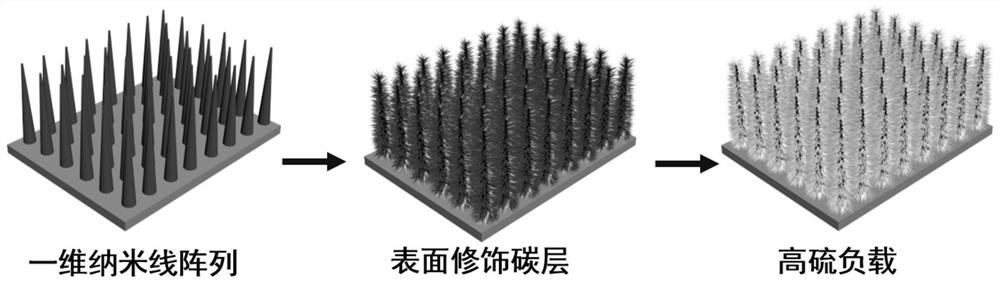

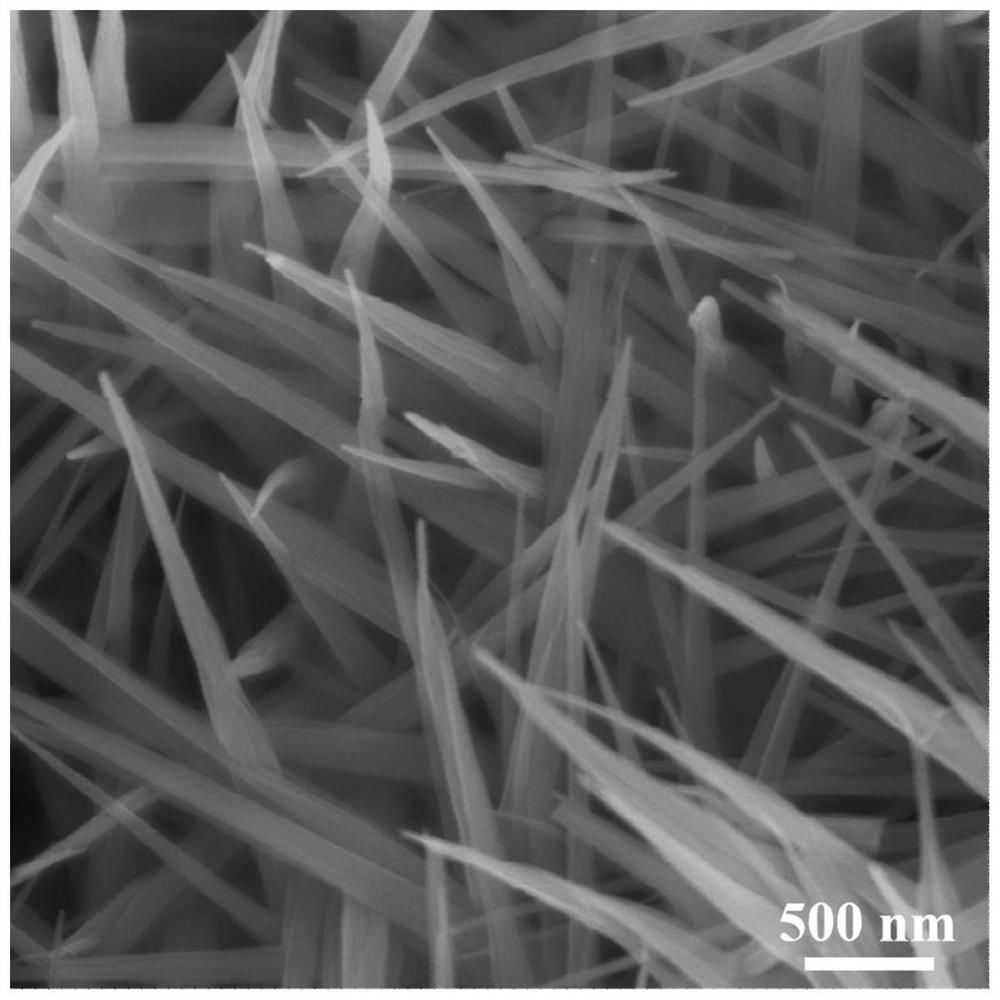

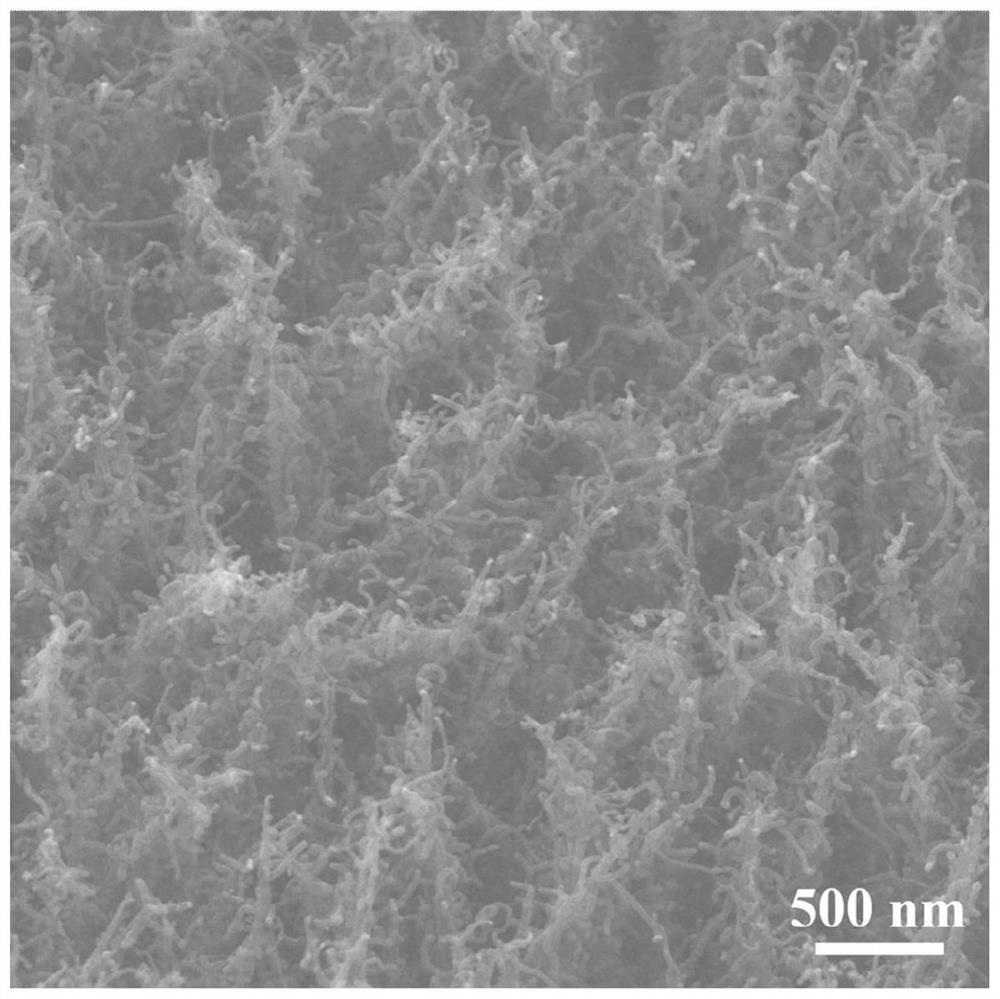

Flexible integrated lithium-sulfur battery positive electrode material and preparation method thereof

InactiveCN113346040AImprove poor conductivityReduce contact resistanceElectrode collector coatingLi-accumulatorsInternal resistanceLithium sulfur

The invention discloses a flexible integrated lithium-sulfur battery positive electrode material and a preparation method thereof. According to the method, on a flexible substrate, an ordered oxide hydroxide one-dimensional nanowire array is constructed in situ through hydro-thermal synthesis, then organic matter is subjected to high-temperature pyrolysis in an oxygen-free atmosphere, gas-phase chemical deposition of heteroatom-doped carbon nanotubes on the surfaces of nanowires is achieved, and meanwhile, corresponding oxides and hydroxides are converted into corresponding metal or derivatives thereof, so that a metal or derivative thereof / heteroatom doped carbon nanotube three-dimensional sulfur fixation carrier is obtained. The integrated electrode disclosed by the invention has relatively high interface stability, the contact internal resistance of a battery is remarkably reduced, the sulfur loading capacity of the sulfur positive electrode is 3-20mg cm<-2>, the cycling stability of the lithium-sulfur battery is effectively improved, and the overall energy density of the battery is improved. The integrated electrode can also effectively improve the insulativity of sulfur in the lithium-sulfur battery and the shuttle effect of an intermediate product, and can be widely applied to wearable lithium-sulfur batteries.

Owner:BEIJING UNIV OF CHEM TECH

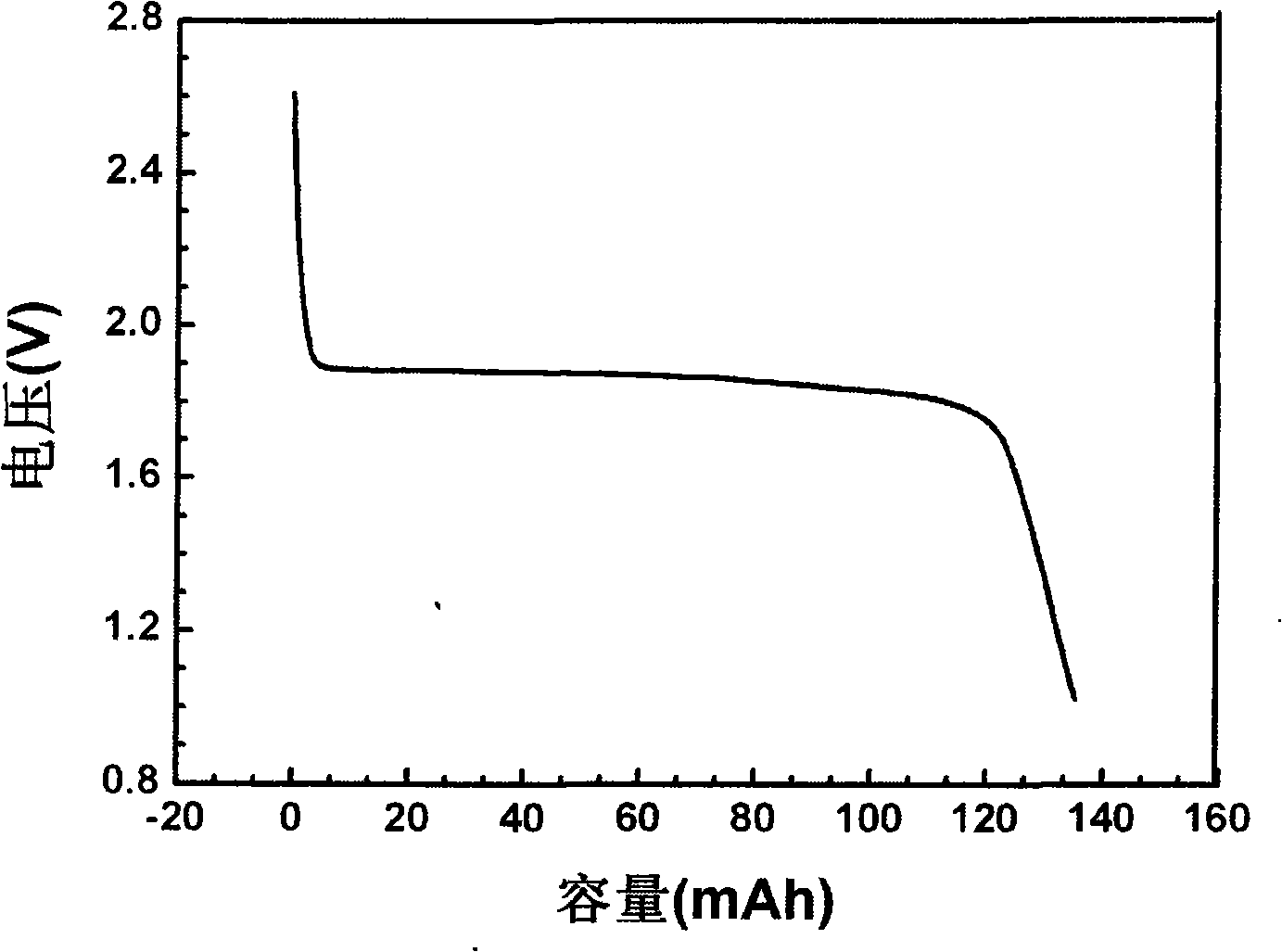

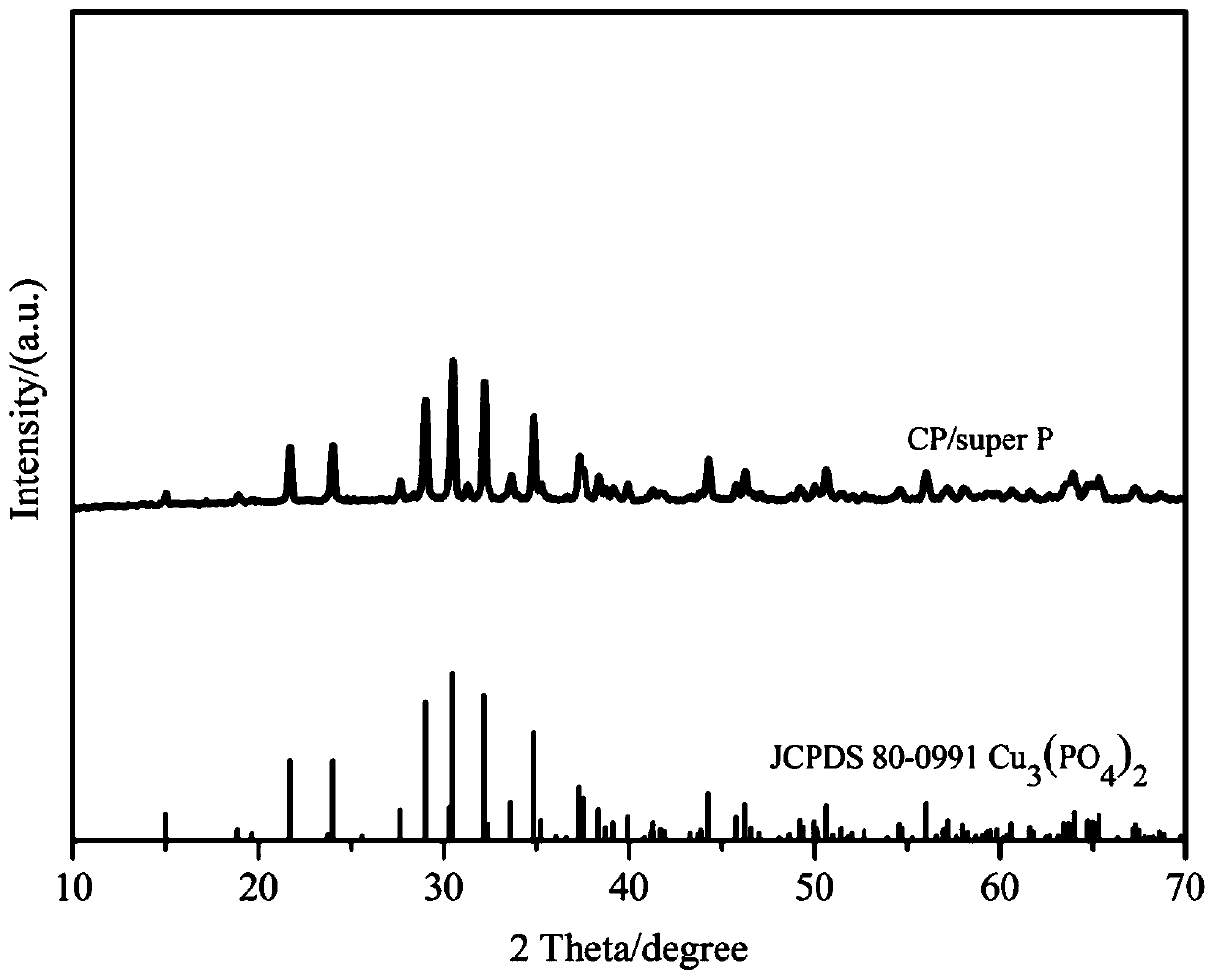

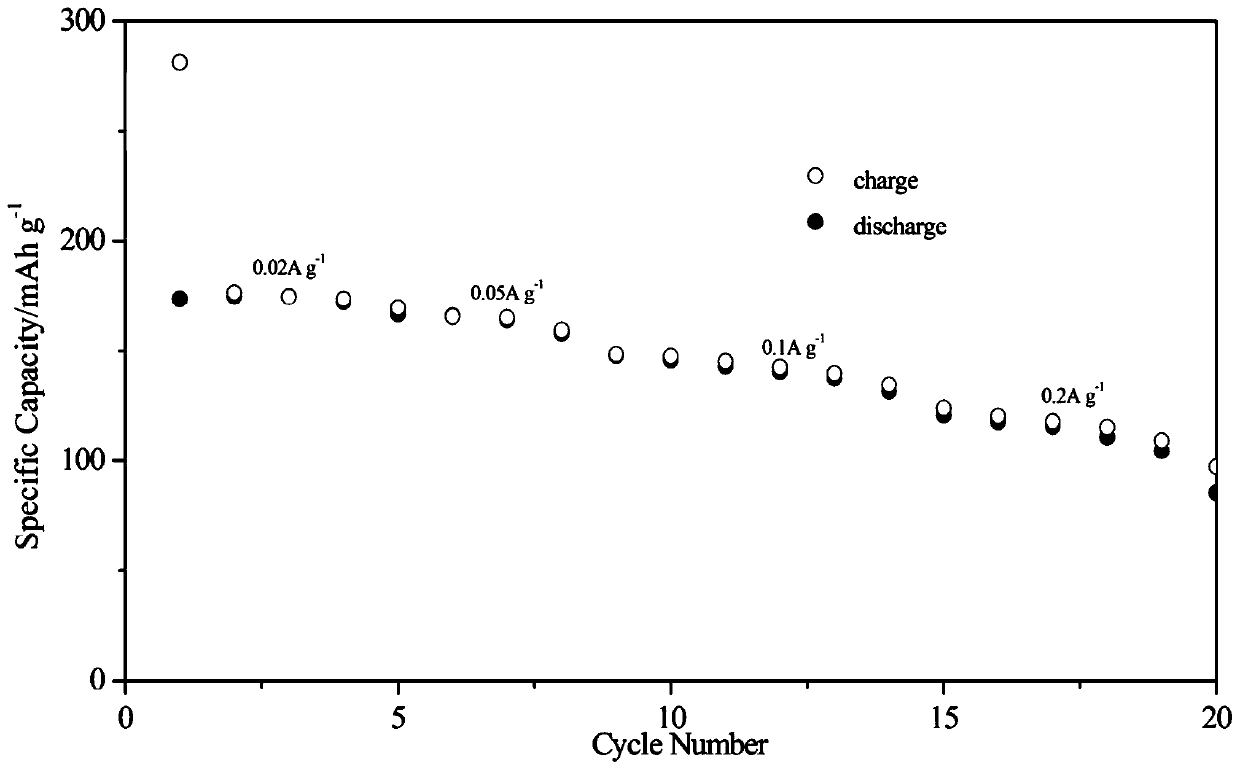

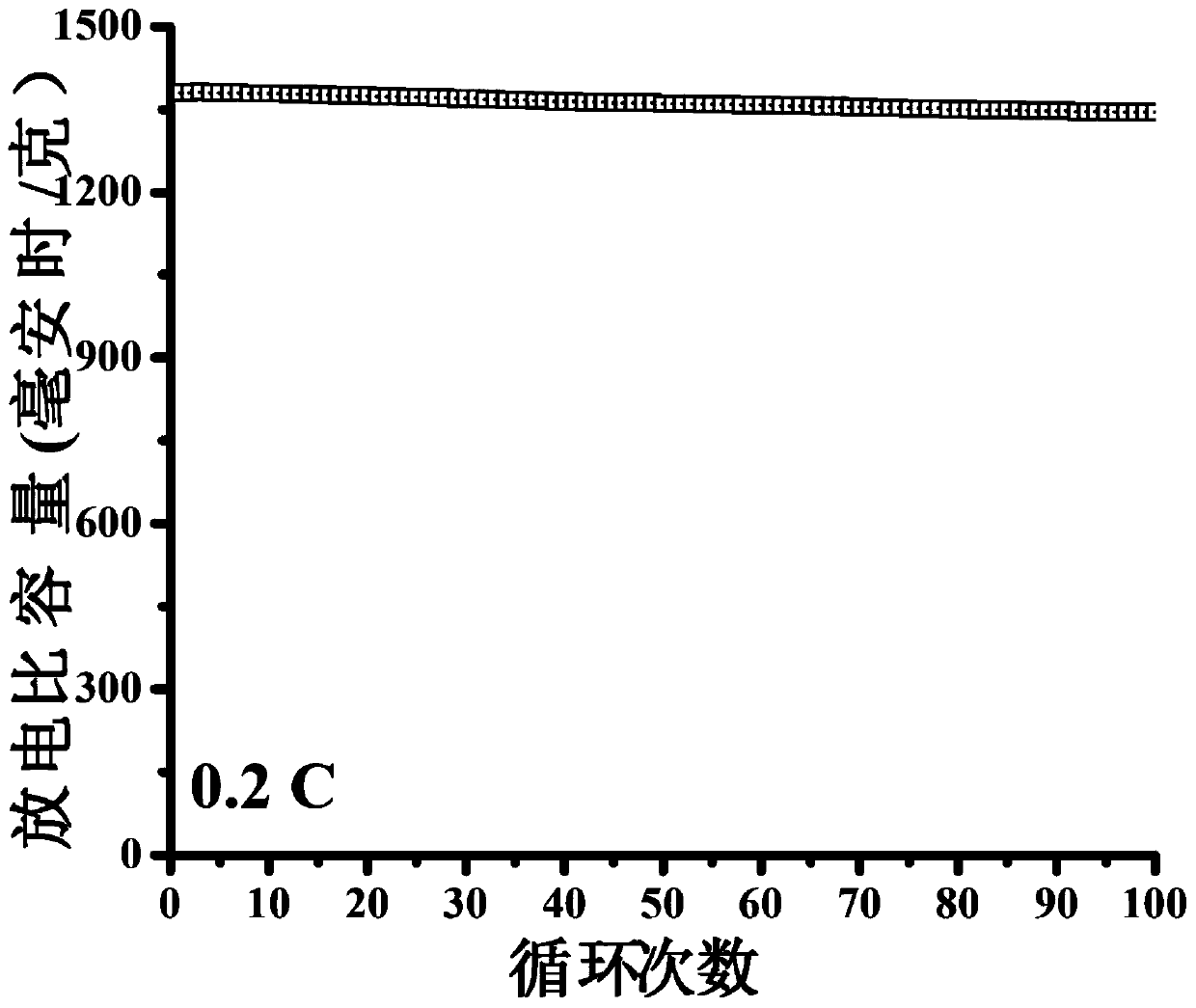

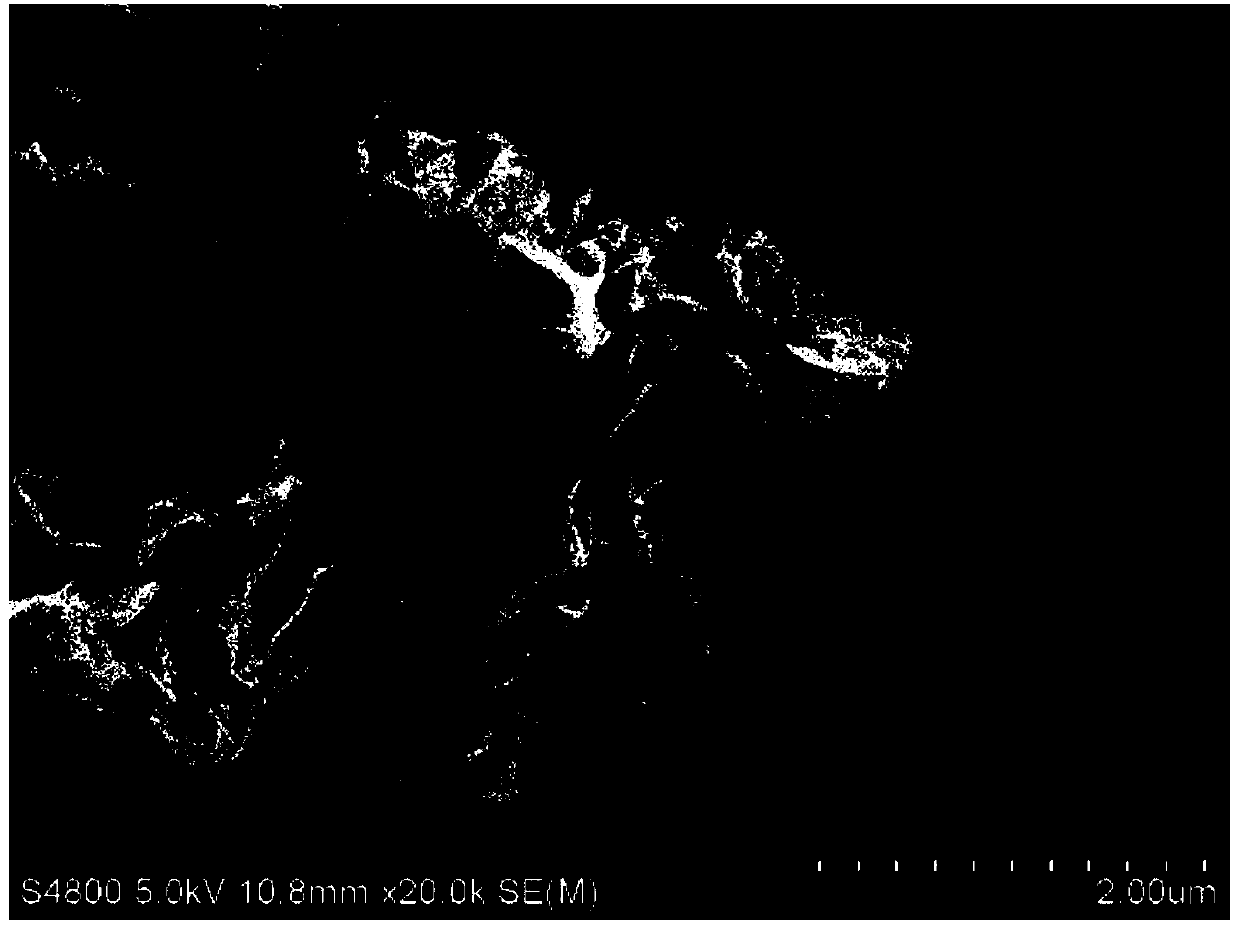

Preparation method for granular Cu3(PO4)2/super P positive electrode material of lithium ion battery

ActiveCN110120511AImprove poor conductivityGuaranteed electrical conductivitySecondary cellsPositive electrodesPhosphateSodium-ion battery

The invention relates to a preparation method for a granular Cu3(PO4)2 / super P positive electrode material of a lithium ion battery. The preparation method comprises the following steps: obtaining a copper phosphate precursor through a solid-phase method, carrying out stage heating in a muffle furnace, and carrying out full ball milling on Cu3(PO4)2 subjected to heat treatment and super P to obtain the Cu3(PO4) 2 / super P composite electrode material. According to the invention, the super P with 'three high performances and one excellent performance' is compounded, namely high specific surfacearea, high structure, high purity and excellent electrical conductivity, so that the problem of poor electrical conductivity of the copper phosphate is improved. The Super P has the good thermal conductivity to ensure the safety and service life of a battery, and the electrical conductivity of the material can be improved. Compared with the prior art, the raw materials are rich, cheap, easily available and safe, high-temperature sintering is not needed in the compounding process, the energy consumption is low, the preparation process is simple, and the application of the composite material isexpected to improve the performance of the lithium ion battery.

Owner:SHAANXI UNIV OF SCI & TECH

Preparation method of functional interlayer of lithium-sulfur battery

ActiveCN111341973ALarge specific surface areaEffective chemisorptionLi-accumulatorsCell component detailsZinc nitrideLithium–sulfur battery

The invention relates to a preparation method of a functional interlayer of a lithium-sulfur battery. The method comprises the following steps: firstly, preparing MXene, growing a layer of zinc oxidefilm on the surface of the MXene, and then coating the surface of the zinc oxide film with a layer of zinc nitride as a functional interlayer coating material of the lithium-sulfur battery. Accordingto the method, the shuttle effect of polysulfide in the lithium-sulfur battery prepared in the prior art is effectively relieved, the utilization rate of active substances in the positive electrode material is increased, and the problem that the cycle performance of the lithium-sulfur battery is unstable is solved.

Owner:INT ACAD OF OPTOELECTRONICS AT ZHAOQING SOUTH CHINA NORMAL UNIV

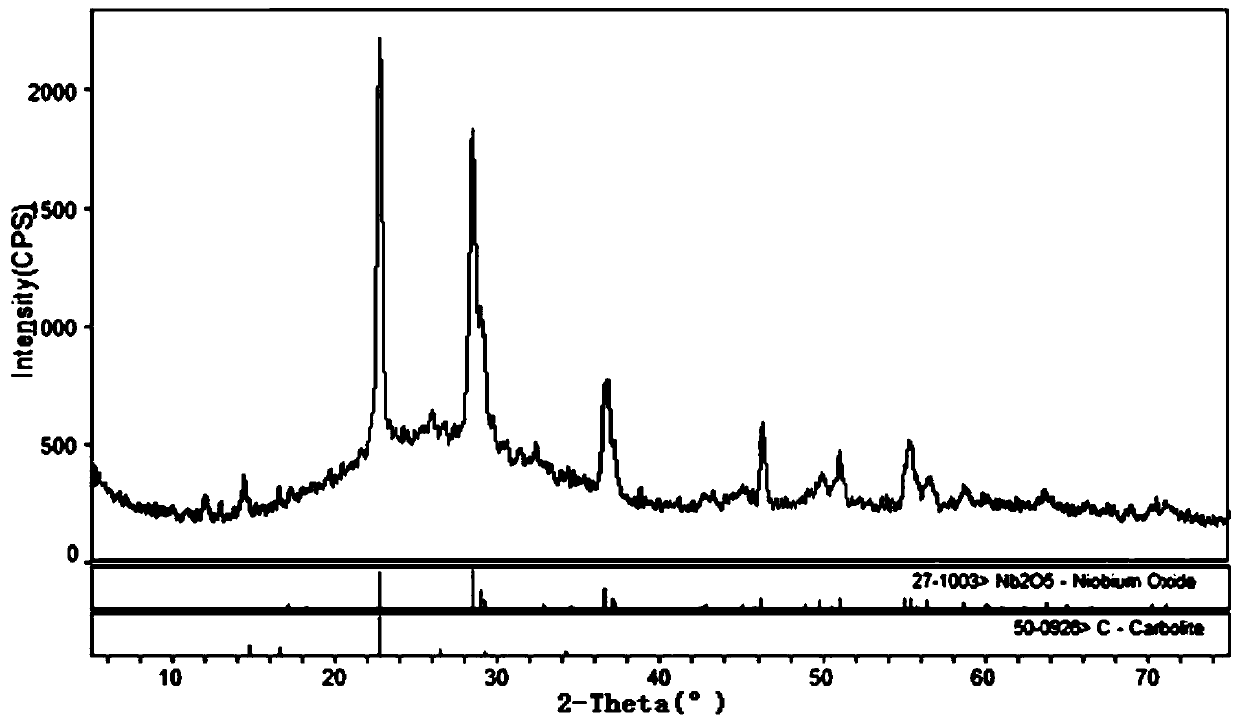

Niobium pentoxide three-dimensional doped graphene composite material, and preparation method and application thereof

ActiveCN109980210AImprove poor conductivityLarge particle sizeHybrid capacitor electrodesCell electrodesExperimental drugDoped graphene

The invention discloses a niobium pentoxide three-dimensional doped graphene composite material, and a preparation method and application thereof. The uniform niobium pentoxide three-dimensional dopedgraphene composite material is prepared by adoption of a hydrothermal method and subsequent high-temperature calcination; graphene can be self-assembled into three-dimensional graphene in situ in hydrothermal reaction; the possibility for large specific surface area is provided; niobium pentoxide and the three-dimensional graphene are composite, so that the poor conductivity problem of niobium pentoxide is greatly improved; simultaneously, N and S are doped on the surface of the graphene, so that more active sites are provided; the particle diameter of niobium pentoxide is refined; the conductivity is easily improved; a synthetic method is simple; experimental drugs are cheap and easy to obtain; the cost is low; the prepared niobium pentoxide three-dimensional doped graphene composite material can be used in the fields of lithium ion batteries, lithium-sulphur batteries, super-capacitors, electro-catalysis and the like; and thus, the application prospect is wide.

Owner:SHAANXI UNIV OF SCI & TECH

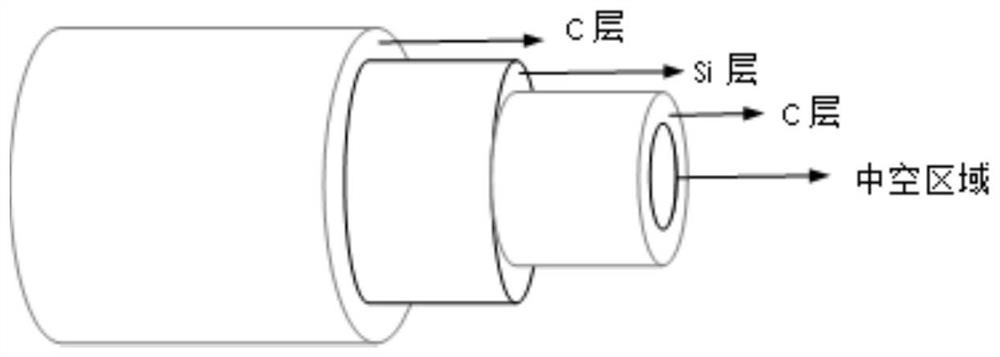

Hollow negative electrode material and preparation method thereof and lithium ion battery containing hollow negative electrode material

PendingCN112510173AWide variety of sourcesAlleviate volume changesMaterial nanotechnologyCell electrodesCarbon nanotubeElectrical polarity

The invention provides a hollow negative electrode material and a preparation method thereof and a lithium ion battery containing the hollow negative electrode material. The preparation method of thehollow negative electrode material comprises the following steps: in an inert atmosphere, carrying out a first coating process on a template agent and a first carbon source to obtain a carbon-coated template agent; carrying out a second coating process on the carbon-coated template agent, a polar solvent and tetraethyl orthosilicate to obtain a silicon dioxide / carbon / template agent composite material; in an inert atmosphere, carrying out reduction reaction on the silicon dioxide / carbon / template agent composite material and a second carbon source to obtain a silicon / carbon / template agent composite material; removing the template agent in the silicon / carbon / template agent composite material to obtain a silicon / carbon nanotube; and coating the silicon / carbon nanotube and a third carbon sourcefor the third time in an inert atmosphere to obtain the carbon / silicon / carbon nanotube, namely the hollow negative electrode material. The hollow negative electrode material prepared by the preparation method is beneficial to greatly improving the cycle performance of the lithium ion battery.

Owner:YINLONG ENERGY CO LTD

Lithium ion battery positive current collector, preparation method and lithium ion battery

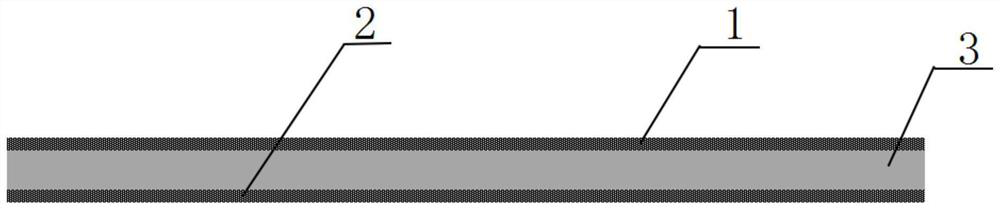

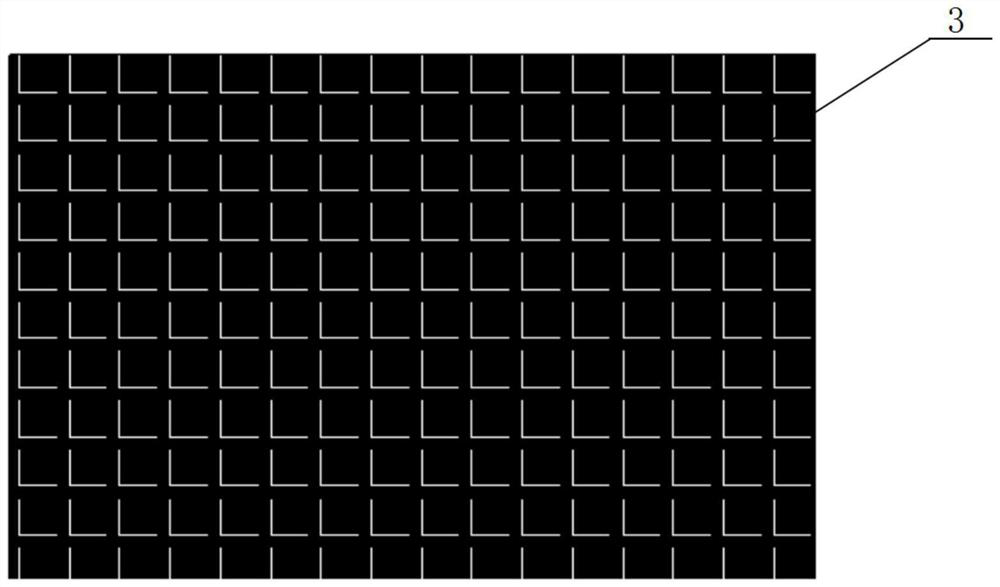

PendingCN114464813AImprove compactionReduce weightElectrode carriers/collectorsSecondary cellsInternal resistancePhysical chemistry

The invention discloses a lithium ion battery positive electrode current collector, a preparation method and a lithium ion battery, the lithium ion battery positive electrode current collector comprises a first aluminum layer, a second aluminum layer and a PET layer located between the first aluminum layer and the second aluminum layer, and the PET layer is of a latticed structure and is composed of a PET substrate and a conductive agent. The positive current collector of the lithium ion battery has relatively high binding power and electronic conductivity, and ensures that a secondary battery has relatively low internal resistance, long-term cycle stability of the battery and relatively high safety performance.

Owner:CHONGQING ZIJIAN NEW ENERGY CO LTD

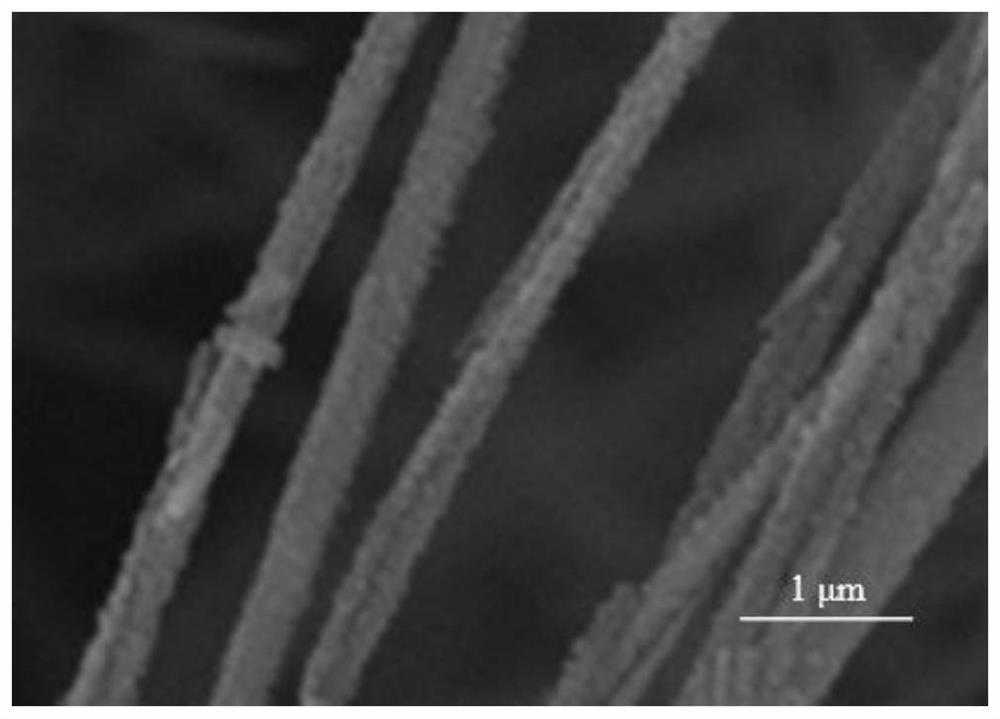

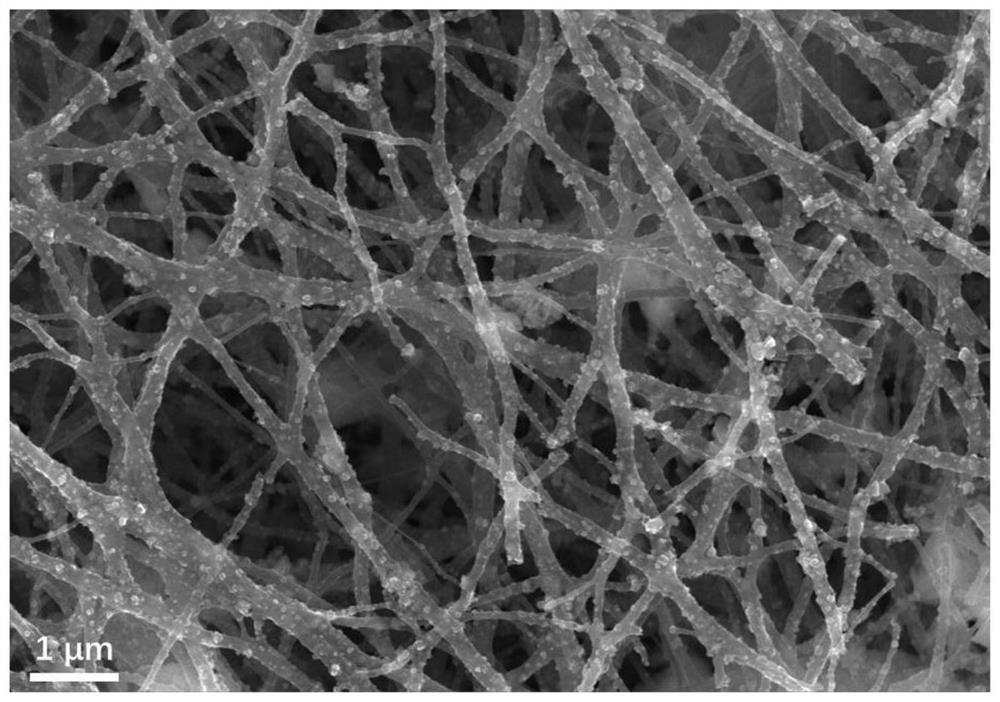

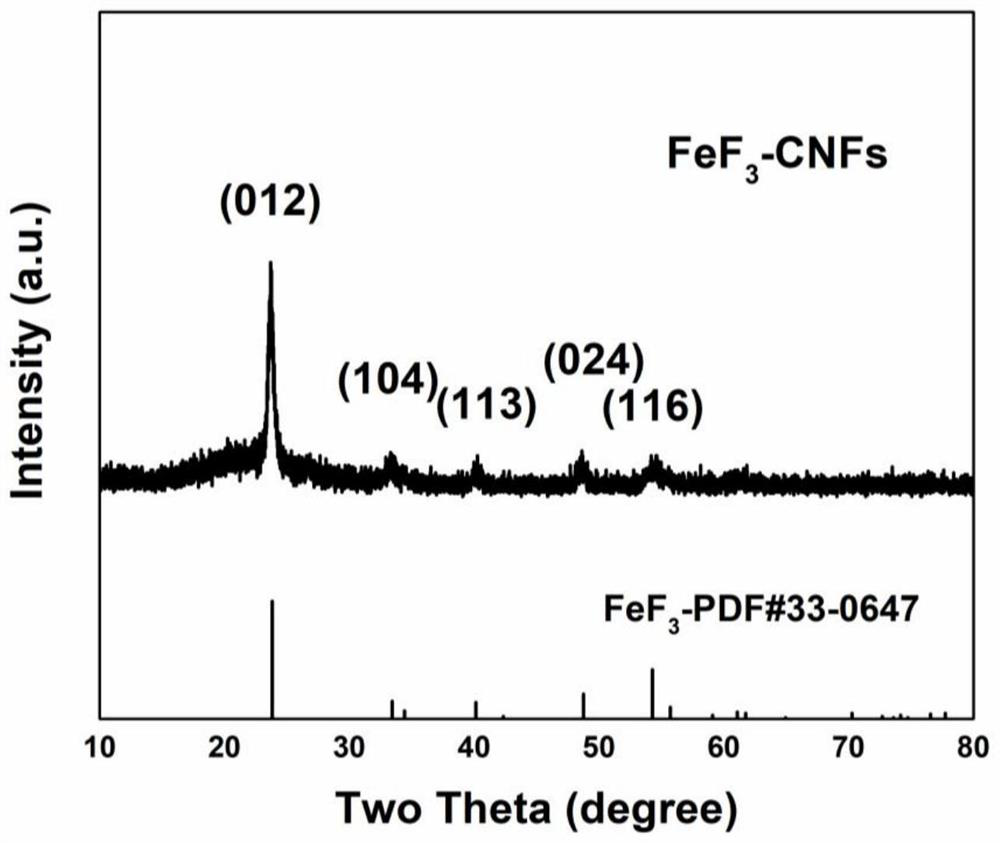

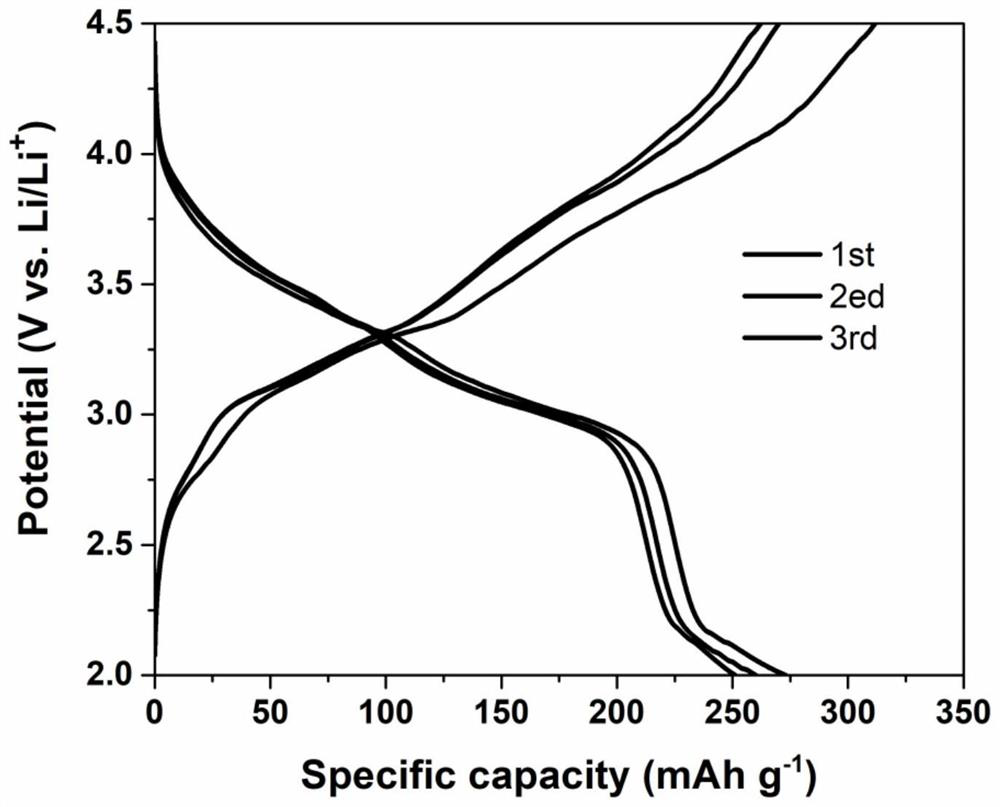

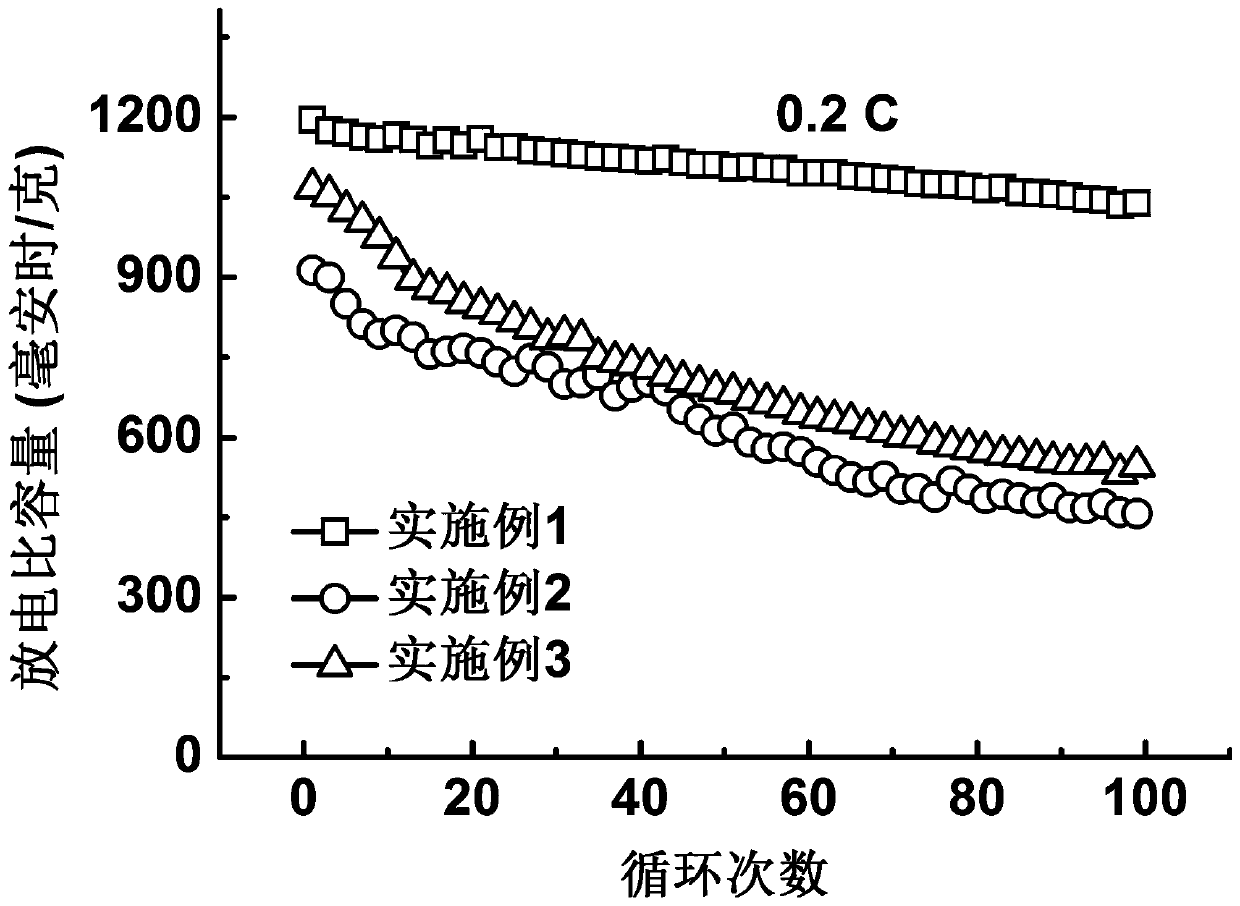

Self-supporting iron trifluoride-carbon nanofiber positive electrode material and preparation method thereof

ActiveCN114447291AImprove poor conductivityIncrease the proportionCell electrodesCarbon nanofiberNanofiber

The invention discloses a self-supporting iron trifluoride-carbon nanofiber positive electrode material, which comprises iron trifluoride nanoparticles and carbon nanofibers, the carbon nanofibers are a skeleton, and the iron trifluoride nanoparticles are uniformly distributed on the surface and inside of the carbon nanofibers; the invention also discloses a preparation method of the self-supporting iron trifluoride-carbon nanofiber positive electrode material, and the preparation method comprises the following steps: obtaining an iron-containing composite nanofiber membrane through an electrostatic spinning technology, and then carrying out pre-oxidation, high-temperature carbonization and fluorination treatment to obtain the self-supporting iron trifluoride-carbon nanofiber; the construction of the composite material structure effectively improves the problems of poor conductivity, volume expansion and the like of iron trifluoride, and the thought is expected to be applied to other electrode materials with poor conductivity.

Owner:XIAN UNIV OF TECH +1

Lithium-sulfur battery positive electrode material and preparation method thereof

ActiveCN111370658AImprove structural stabilityPrevent collapseMaterial nanotechnologyCarbon compoundsLithium–sulfur batteryLithium sulfur

The invention belongs to the technical field of lithium-sulfur batteries, and particularly relates to a lithium-sulfur battery positive electrode material and a preparation method thereof. The positive electrode material is a tricobalt tetraoxide double-layer hollow sphere-carbon nanotube-sulfur composite material, achieves high specific capacity under high current density and has good cycle life.According to the preparation method, tricobalt tetraoxide double-layer hollow spheres are coated with carbon nanotubes in a spray drying mode, so that the optimal coating effect can be achieved whilethe conductivity of the material is improved, the structural stability of the tricobalt tetraoxide spheres is enhanced through the coating support of the carbon nanotubes, and the material has the optimal adsorption effect.

Owner:INT ACAD OF OPTOELECTRONICS AT ZHAOQING SOUTH CHINA NORMAL UNIV

Lithium-sulfur battery positive electrode material and preparation method thereof

ActiveCN112002889AImprove poor conductivityImprove conductivityNitrogen compoundsPositive electrodesLithium–sulfur batteryLithium sulfur

The invention belongs to the technical field of lithium-sulfur batteries, and particularly relates to a lithium-sulfur battery positive electrode material and a preparation method thereof. The positive electrode material is a metallized boron nitride nanotube / sulfur composite material. The positive electrode material has relatively high mechanical strength and good conductivity and thermal stability; the problem of poor sulfur conductivity is solved; the shuttle effect is relieved; meanwhile, conversion of polysulfide can be promoted, and the utilization rate of active substances is increased.

Owner:INT ACAD OF OPTOELECTRONICS AT ZHAOQING SOUTH CHINA NORMAL UNIV

Vanadium pentoxide/molybdenum trioxide/graphene composite electrochromic film material and preparation method thereof

InactiveCN106316150AImprove cycle stabilityIncreased Optical Modulation RangeCoatingsGrapheneFilm material

The invention belongs to the field of electrochromic films and particularly relates to a vanadium pentoxide / molybdenum trioxide / graphene composite electrochromic film material and a preparation method thereof. The vanadium pentoxide / molybdenum trioxide / graphene composite electrochromic film material is characterized by being prepared by raw materials comprising vanadium pentoxide sol, molybdenum trioxide sol and graphene. The mole ratio of the vanadium pentoxide in the vanadium pentoxide sol to the molybdenum trioxide in the molybdenum trioxide sol is 1:(0.01-0.02). The mass ratio of the vanadium pentoxide in the vanadium pentoxide sol to the graphene is 1:0.03-0.05. The film material is good in electrochemical performance and electrochromic performance.

Owner:WUHAN UNIV OF TECH

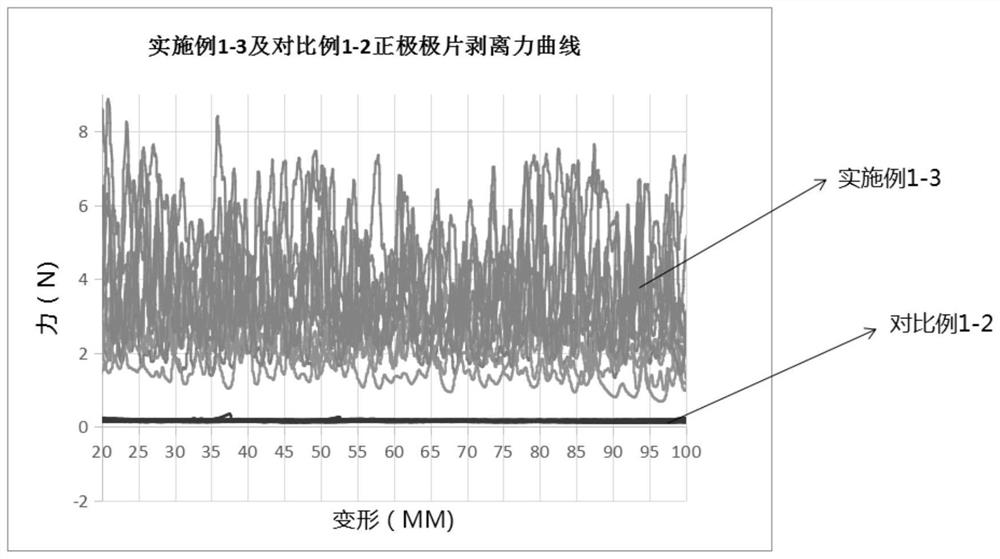

A high-safety lithium manganese iron phosphate battery

ActiveCN106129365BImprove poor conductivityEasy to processCell electrodesSecondary cells servicing/maintenancePolyolefinNew energy

The invention belongs to the technical field of lithium ion batteries and specifically relates to a high-safety lithium manganese iron phosphate battery. The high-safety lithium manganese iron phosphate battery comprises a positive plate, a negative plate, an isolating membrane, an electrolyte and a battery shell, wherein the positive plate includes a positive pole current collector and a positive pole active material layer which is coated on a surface of the positive pole current collector; the positive pole active material layer includes the following components by weight percentage: 90wt%-96wt% of positive pole active material, 1.5wt%-5wt% of positive pole conductive agent and 2wt%-5wt% of positive pole binding agent; the positive pole conductive agent is a mixture of conductive carbon black and at least one of a carbon nano tube or graphene; and the ratio of the conductive carbon black to at least another conductive agent is 1wt%:0.5wt% to 4wt%:1wt% based on the weight percentage in the positive pole active material layer; the isolating membrane is one of a polyolefin film or a non-woven cloth film; and the electrolyte is a high-temperature-resistant electrolyte. Compared with a nickel cobalt lithium manganate ternary battery and a lithium iron phosphate battery, the high-safety lithium manganese iron phosphate battery has relatively high weight specific energy and relatively high safety performance at the same time, has a long cycle life and is suitable for popularization and application in the field of new energy vehicles.

Owner:CAMEL GRP NEW ENERGY BATTERY CO LTD

Cathode film of lithium iron phosphate polymer lithium ion battery

InactiveCN102903888AImprove poor conductivityImprove processing difficultiesCell electrodesPolyvinylidene fluoridePlasticizer

The invention relates to a cathode film of a lithium iron phosphate polymer lithium ion battery. Acetone serves as a solvent; a lithium iron phosphate cathode material, a conductive agent, high-branch structure high-porosity carbon black aggregate conductive graphite, low-branch structure low-porosity carbon black aggregate conductive graphite, a plasticizer and polyvinylidene fluoride (PVDF) / hexafluoropropylene (HFP) are uniformly mixed into slurry; the slurry is uniformly coated on a base material of a polyester thin film; and the cathode film of the lithium iron phosphate polymer lithium ion battery is obtained by drying. Compared with the prior art, the cathode film of the lithium iron phosphate polymer lithium ion battery has the advantages that the problem of difficulty in coating of a lithium iron phosphate cathode film to a rolling process section can be thoroughly solved, the conductivity of the cathode film of the lithium iron phosphate polymer lithium ion battery is not influenced, the solid content of cathode slurry can be improved, the using amount of the acetone solvent is decreased, the solvent is easy to remove, the energy consumption of equipment is low, and the process is environment-friendly.

Owner:HUBEI WEWIN BATTERY TECH

High-conductivity electronic circuit capable of being rapidly printed at low temperature and preparation method and application thereof

PendingCN113709996AImprove conductivityFirmly connectedInksConductive pattern formationEngineeringConductive ink

The invention provides a method for rapidly preparing a high-conductivity electronic circuit at a low temperature, which comprises the following steps of: printing an electronic circuit by using nano-metal conductive ink in an ink-jet printing manner, performing low-temperature thermocuring or infrared sintering surface drying, performing ink-jet printing on the surface of the nano-metal electronic circuit by using a micro-sintering solution, and performing surface drying; and finally, coating the surface of the micro-sintered nano-metal electronic circuit with liquid metal to obtain the high-conductivity electronic circuit. According to the method, a high-conductivity electronic circuit can be printed at low temperature, the application range of printing can be widened, and the application requirements of the civil fields such as wearable electronics, electronic skin and intelligent sensing can be met.

Owner:山西聚微天成科技有限公司

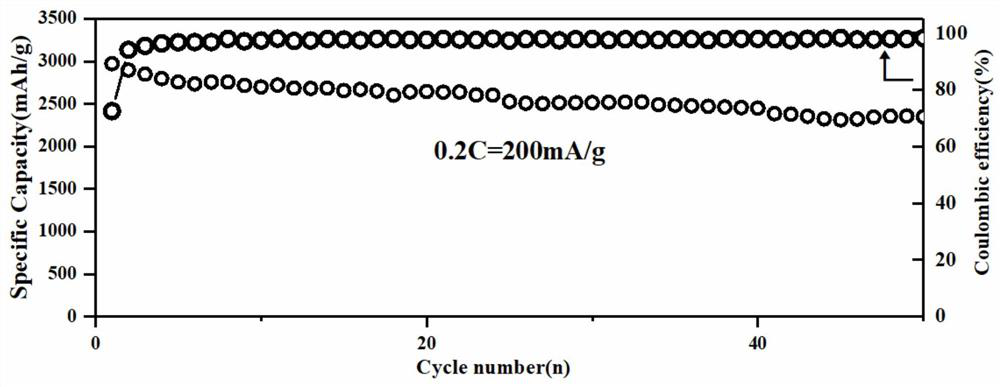

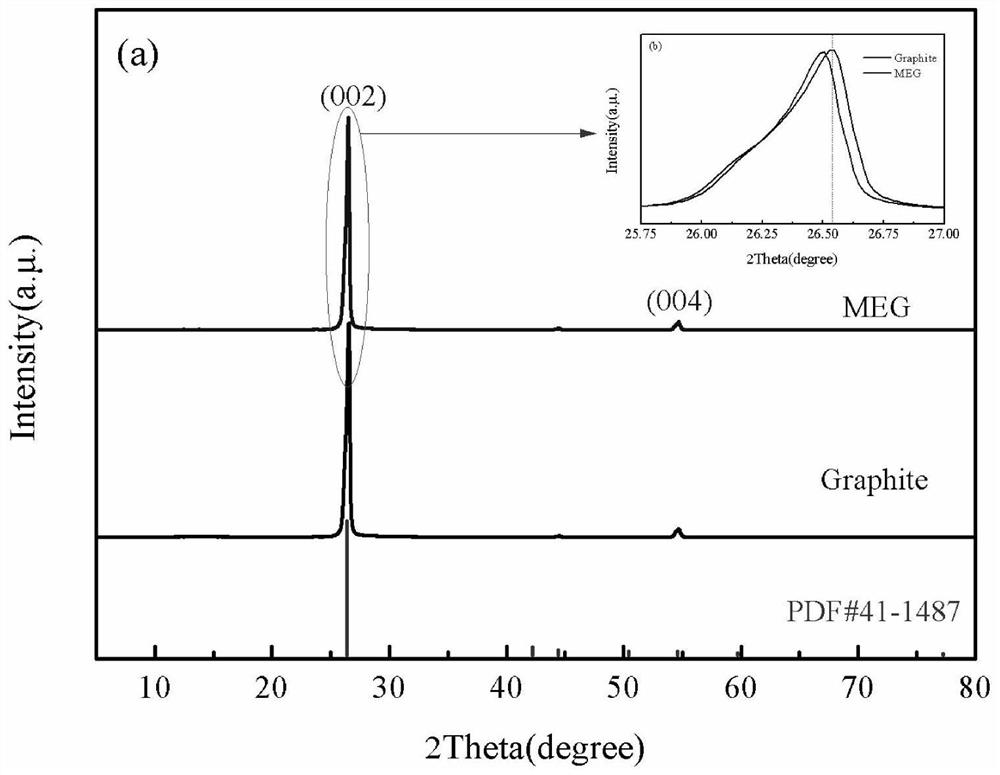

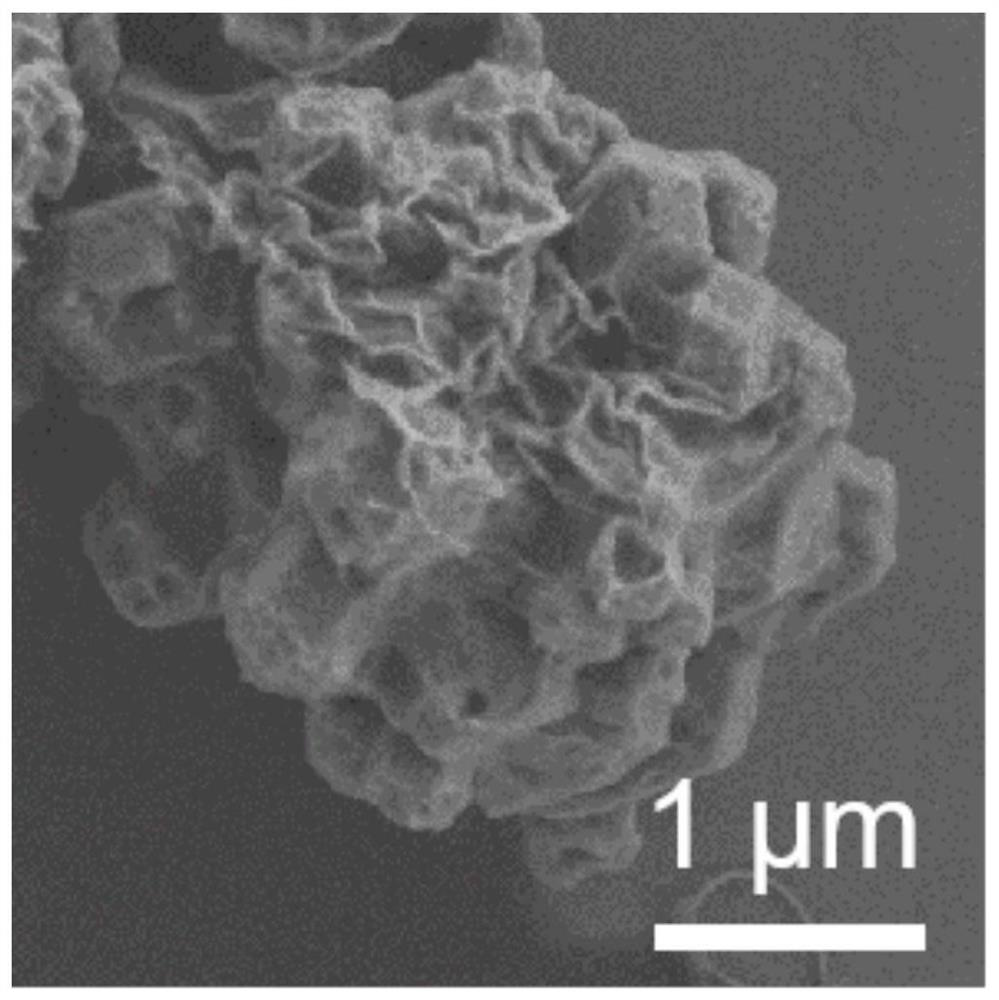

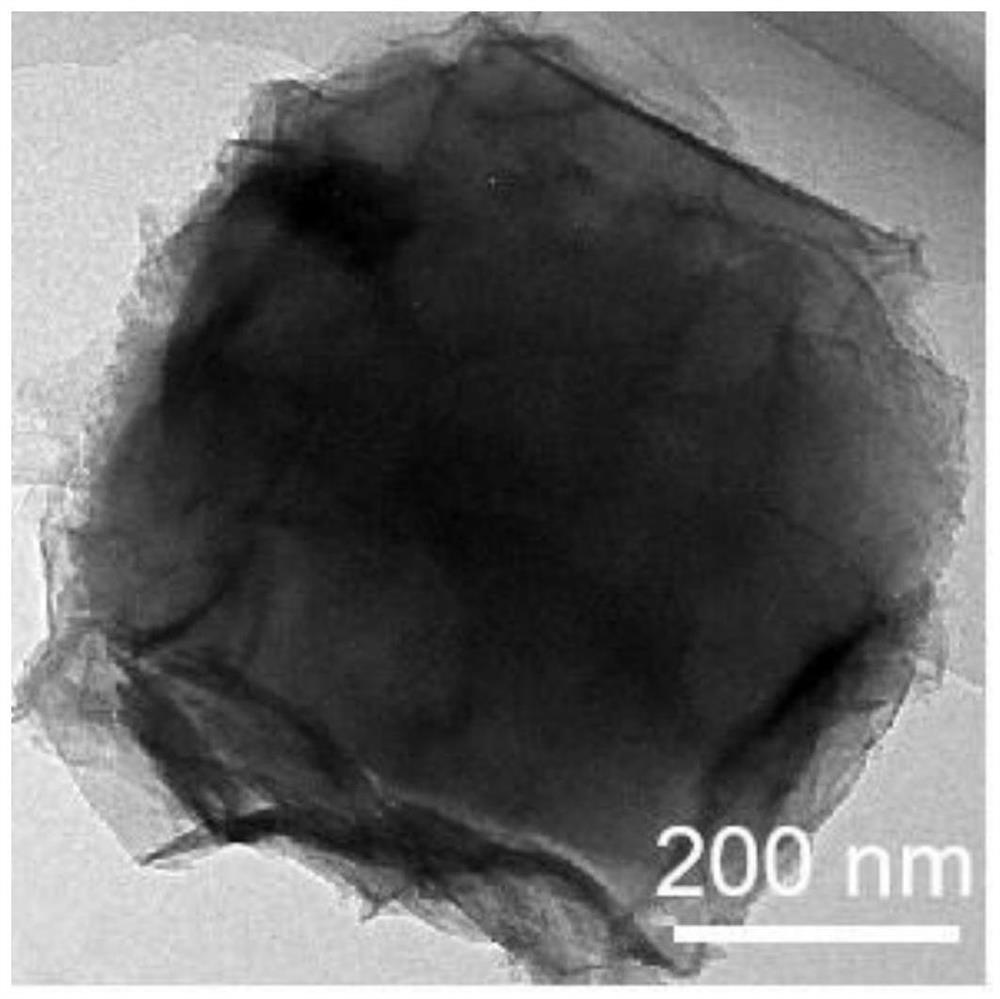

Meg/si/c composite negative electrode material for lithium ion battery and preparation method thereof

ActiveCN110429265BAppropriate volumetric energy densityGood coating effectMaterial nanotechnologySecondary cellsLithium-ion batteryLithium intercalation

The invention discloses a MEG / Si / C composite negative electrode material for lithium ion batteries and a preparation method thereof. The composite negative electrode material comprises the following components in mass fractions: 2-20% of nano silicon powder, 1%-3% of surfactant % and carbon source 10~30%, and the balance is micro-expanded graphite. Micro-expanded graphite was prepared by chemical oxidation intercalation method and low-temperature thermal expansion technology, and then micro-expanded graphite / silicon / carbon (MEG / Si / C) composite negative electrode materials for lithium-ion batteries were prepared by mechanical ball milling and high-temperature carbonization. The invention not only effectively relieves the volume expansion and contraction effect of graphite intercalation / delithiation, but also increases lithium intercalation / delithiation channels, which is beneficial to high-current charging and discharging, and ensures proper volume energy density and coulombic efficiency of the negative electrode material. The specific capacity of the first discharge can reach 857.9 mAh / g, which has large specific capacity, good rate performance and stable electrode cycle. The preparation method of the invention has simple process flow, simple and easy-to-obtain raw materials, low cost, and is easy for large-scale production.

Owner:ZIGONG DONGXIN CARBON CO LTD

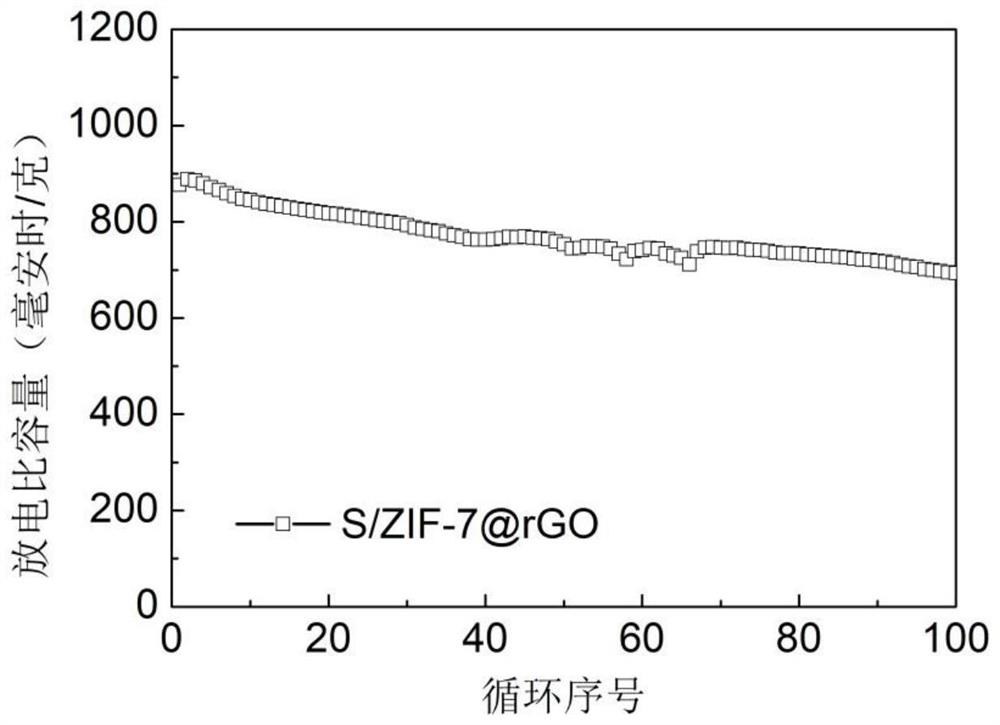

Preparation method of high-specific-capacity sodium-sulfur battery positive electrode material

PendingCN113394388AImprove the situation of poor conductivityImprove structural stabilityNon-aqueous electrolyte accumulatorsPositive electrodesPhysical chemistrySodium–sulfur battery

The invention belongs to the technical field of sodium-sulfur batteries, and particularly relates to a preparation method of a high-specific-capacity sodium-sulfur battery positive electrode material. The preparation method of the high-specific-capacity sodium-sulfur battery positive electrode material comprises the following steps: (1) preparing ZIF-67; (2) preparing ZIF-67@rGO; and (3) preparing sulfur / ZIF-67@rGO. The method is simple in process, the prepared ZIF-67@rGO can load more active substances, conversion of sodium polysulfide is accelerated, and therefore the electrochemical performance of the sodium-sulfur battery is improved.

Owner:INT ACAD OF OPTOELECTRONICS AT ZHAOQING SOUTH CHINA NORMAL UNIV

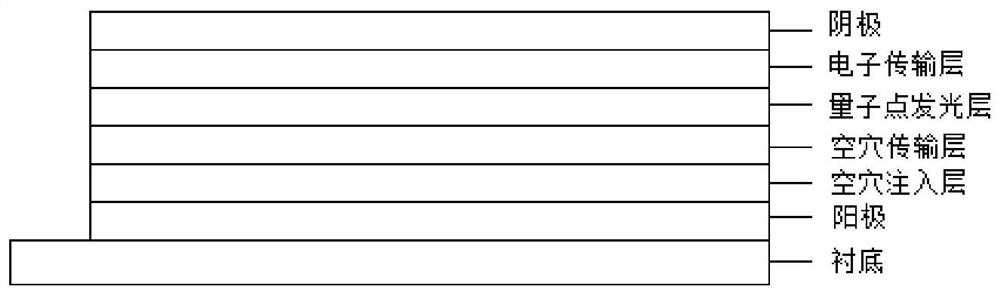

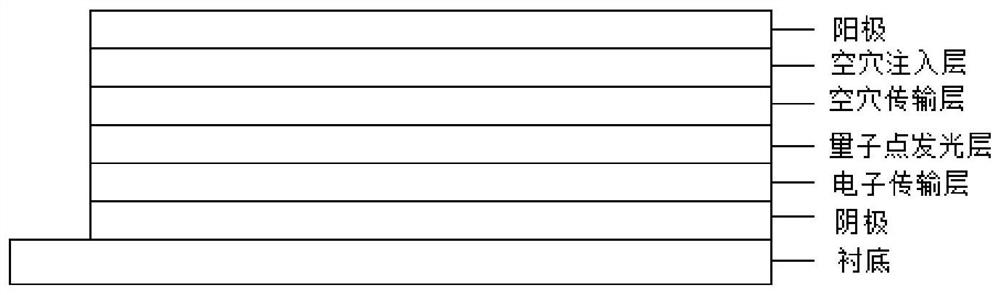

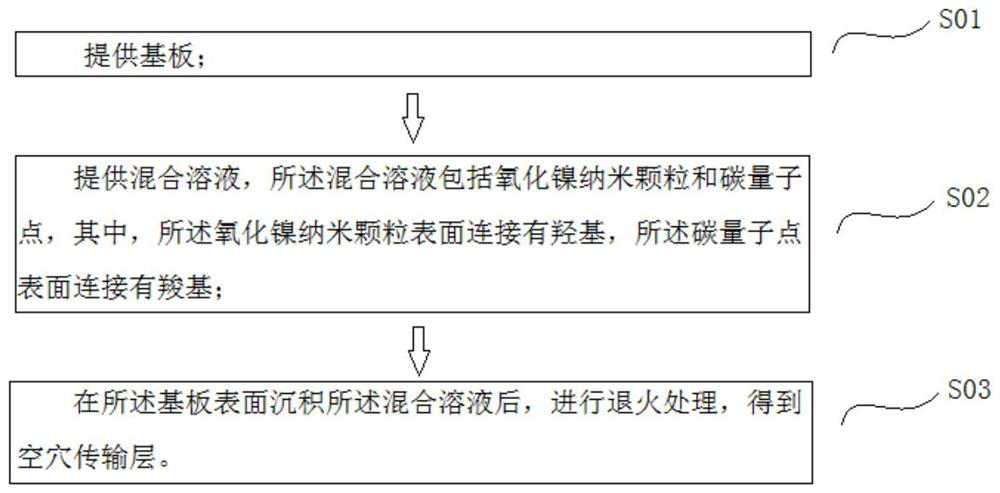

Quantum dot light-emitting diode and preparation method of quantum dot light-emitting diode

ActiveCN111725433ALittle impact on performanceAvoid reunionMaterial nanotechnologySolid-state devicesNanoparticleHole transport layer

The invention provides a quantum dot light-emitting diode, which comprises an anode and a cathode which are oppositely arranged, a quantum dot luminescent layer arranged between the anode and the cathode, and a hole transport layer arranged between the anode and the quantum dot luminescent layer, wherein the hole transport layer is made of nickel oxide nanoparticles and carbon quantum dots, and the nickel oxide nanoparticles and the carbon quantum dots are connected through ester groups.

Owner:TCL CORPORATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com