Lithium ion battery positive current collector, preparation method and lithium ion battery

A technology of lithium ion battery and positive current collector, applied in the direction of electrode carrier/current collector, battery electrode, secondary battery, etc., can solve the problems of affecting battery service life, low peel strength, increase battery resistance, etc. Radius, improving the problem of poor electrical conductivity, and improving the effect of wetting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

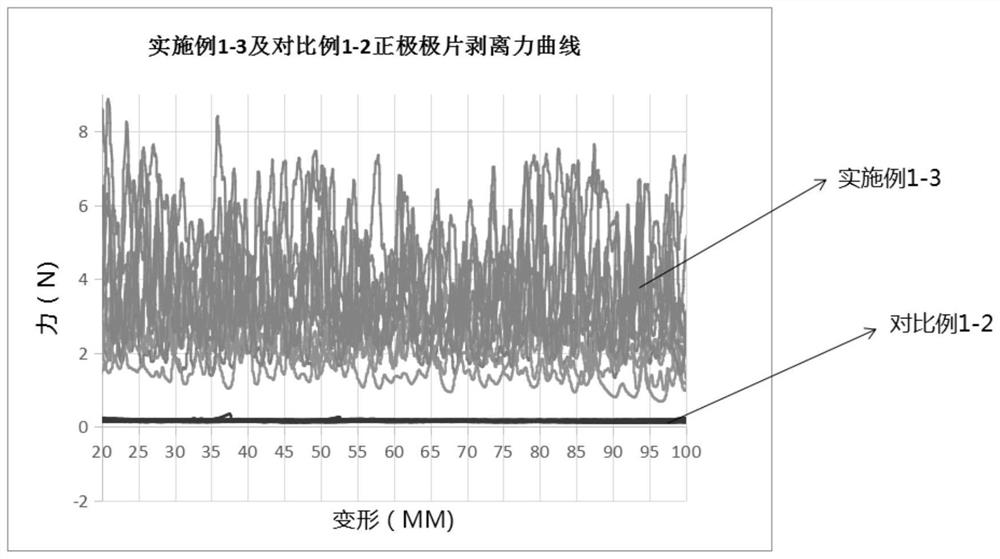

Embodiment 1

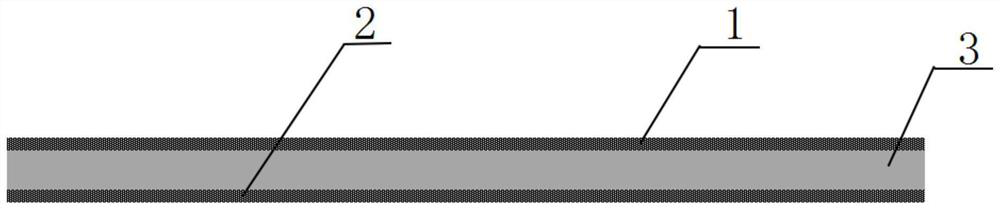

[0050] Lithium-ion battery cathode current collector:

[0051] Weigh 50g of graphene oxide powder and add it to 6L of ethylene glycol solution, and ultrasonically vibrate for 2 hours to obtain a ethylene glycol-modified graphene oxide suspension; add the prepared ethylene glycol-modified graphene oxide suspension to the reaction kettle Liquid and 5kg of terephthalic acid and esterification reaction stabilizer trimethyl phosphate 1.5g, catalyst tetrabutyl tertate 1.5g (wherein, the mol ratio of ethylene glycol and terephthalic acid is 3:1), continue Introduce N2 / Ar at a rate of 20mL / min, heat and stir, and carry out esterification reaction. The reaction temperature is 250°C, and the time is 4h to obtain the initial product; The obtained polycondensation reaction prepolymer is fed into a twin-screw extruder for extrusion and granulation to form PET-based conductive composite particles.

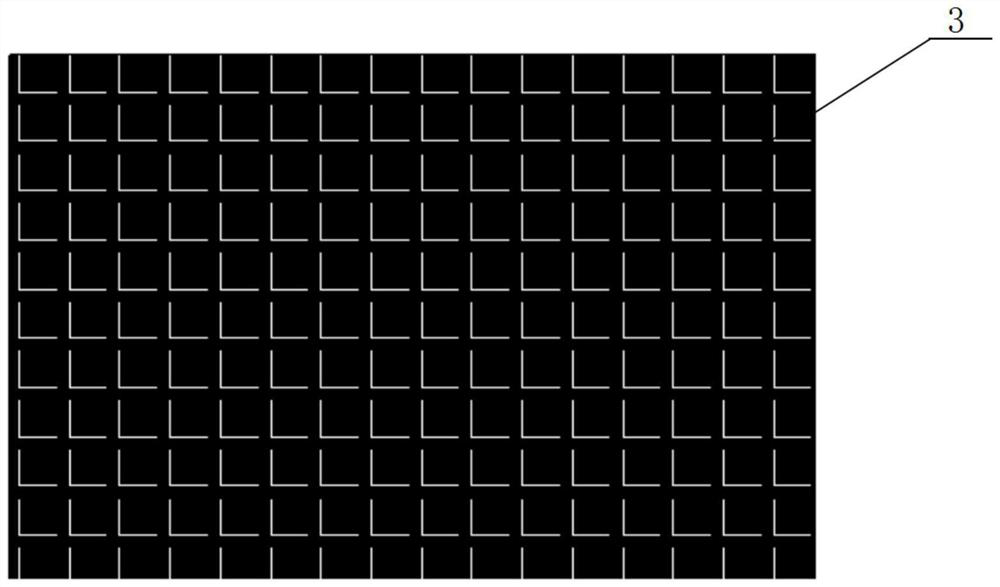

[0052] The PET-based conductive composite particles are melted on the 3D printer; and, the ...

Embodiment 2

[0054] Weigh 450g of graphene oxide powder and add it to 6L of ethylene glycol solution, and ultrasonically vibrate for 2 hours to obtain a ethylene glycol-modified graphene oxide suspension; add the prepared ethylene glycol-modified graphene oxide suspension to the reaction kettle Liquid and 10kg of terephthalic acid and esterification reaction stabilizer phosphorous acid 1.2g, catalyst antimony trioxide 1.8g (wherein, the mol ratio of ethylene glycol and terephthalic acid is 1.5:1), continue feeding N2 / Ar, rate 20mL / min, heating, stirring, carry out esterification reaction, reaction temperature 230 ℃, time 6h, get the initial product; The prepolymer is fed into a twin-screw extruder for extrusion and granulation to form PET-based conductive composite particles.

[0055] The PET-based conductive composite particles are melted on the 3D printer; and, the thickness of the required PET porous film set on the 3D printer is 8 μm and the pore diameter is 8 μm and the shape of the ...

Embodiment 3

[0057] Weigh 200g of graphene oxide powder and add it to 8L of ethylene glycol solution, and ultrasonically vibrate for 2 hours to obtain a ethylene glycol-modified graphene oxide suspension; add the prepared ethylene glycol-modified graphene oxide suspension to the reaction kettle Liquid and 10kg of terephthalic acid and esterification reaction stabilizer trimethyl phosphate 1.5g, catalyst ethylene glycol antimony 1.5g (wherein, the mol ratio of ethylene glycol and terephthalic acid is 1.5:1), continue to pass Enter N2 / Ar at a rate of 20mL / min, heat and stir, and carry out esterification reaction. The reaction temperature is 250°C, and the time is 5h to obtain the initial product; The polycondensation reaction prepolymer is fed into a twin-screw extruder for extrusion and granulation to form PET-based conductive composite particles.

[0058] The PET-based conductive composite particles are melted on the 3D printer; and, the thickness of the required PET porous film is set on ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com