Vanadium pentoxide/molybdenum trioxide/graphene composite electrochromic film material and preparation method thereof

A composite technology of vanadium pentoxide and graphene, applied in the direction of coating, etc., can solve problems such as poor cycle stability, narrow optical modulation range, low electronic conductivity, etc., and achieve poor conductivity, wide application prospects, preparation The effect of simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

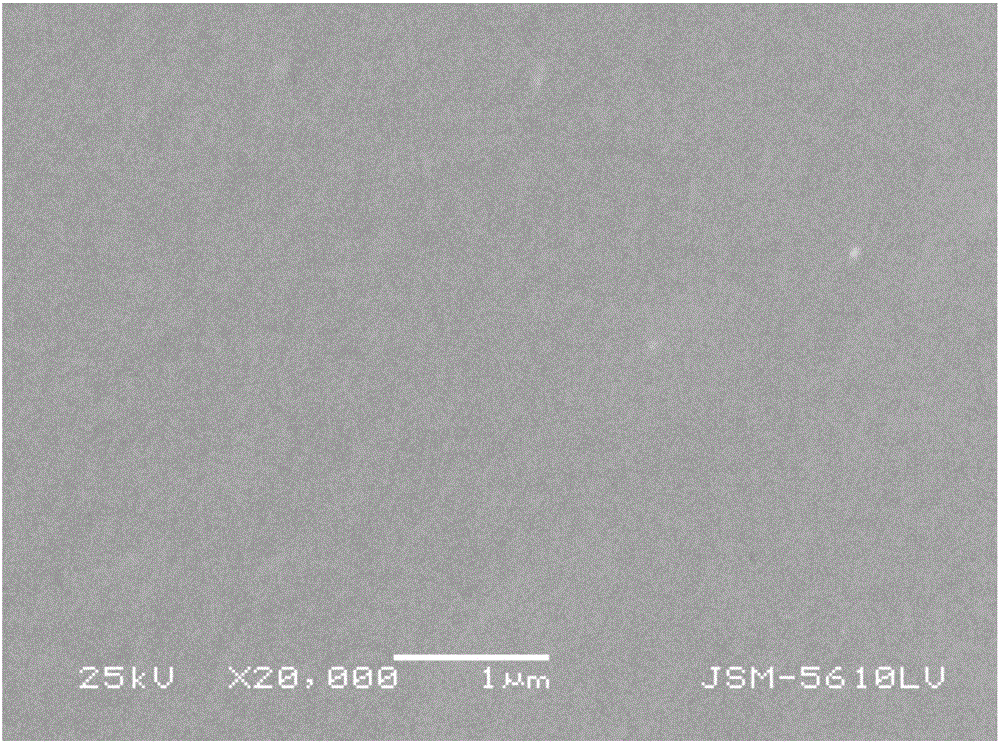

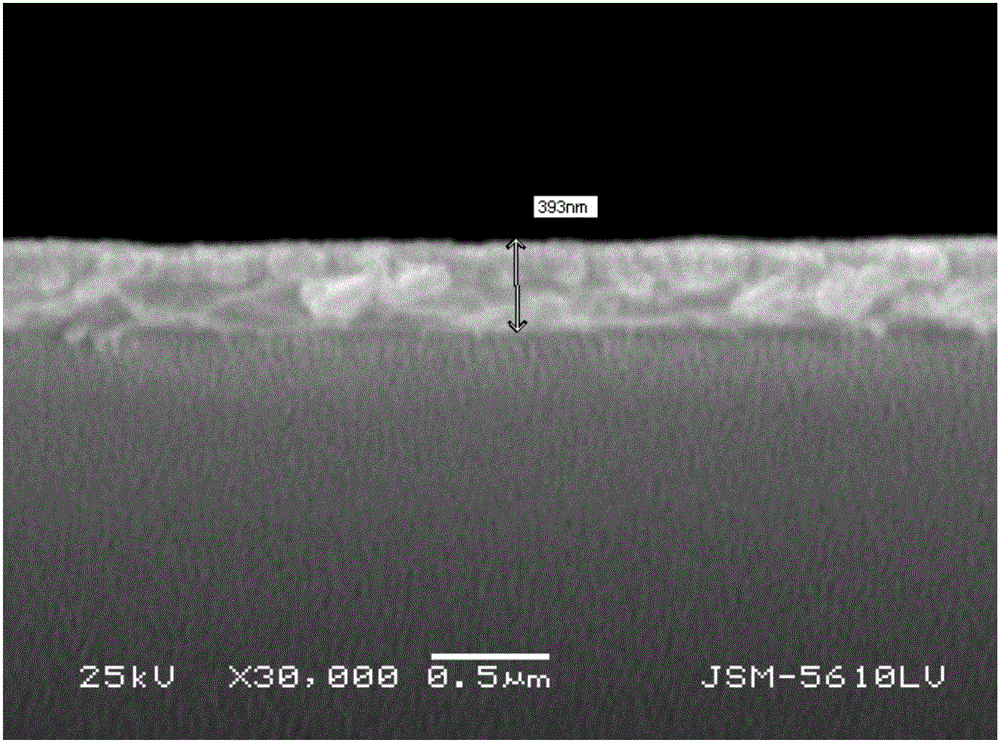

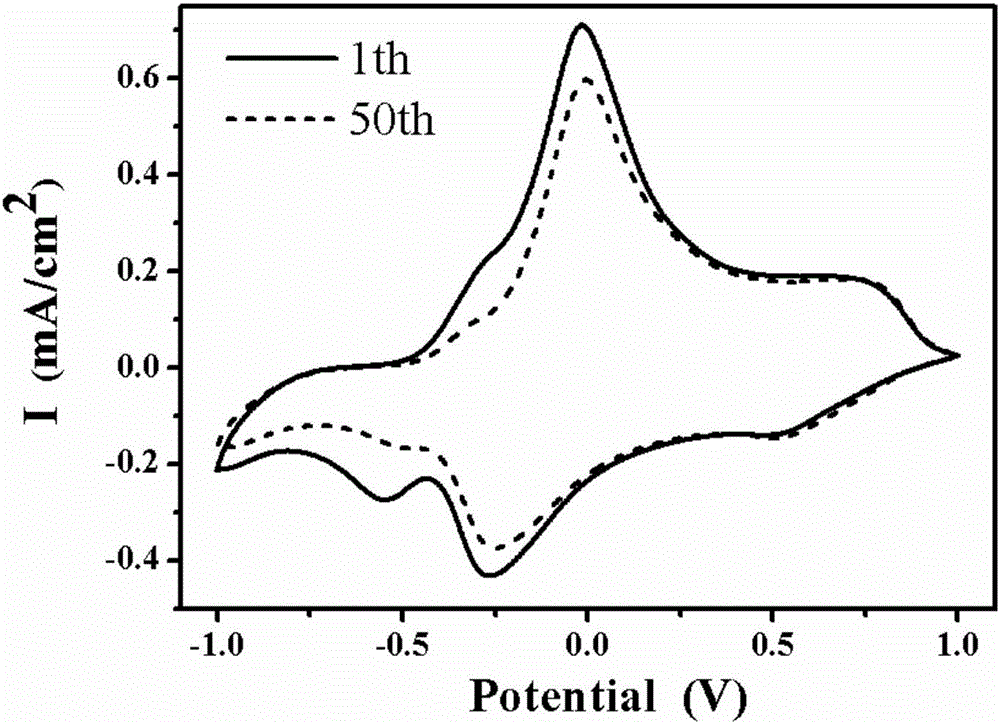

Image

Examples

Embodiment 1

[0030] 1) Immerse the ITO conductive glass in NaOH / H sequentially 2 o 2 Mixed solution (NaOH, H 2 o 2 The volume ratio is 1:1~2), acetone, absolute ethanol, and deionized water, and ultrasonically clean them in an ultrasonic cleaner for 20 minutes, and finally soak the ITO conductive glass substrate in absolute ethanol for later use. Take out and dry to obtain a cleaned and dried ITO conductive glass substrate;

[0031] 2) Press: the molar ratio of vanadium pentoxide in vanadium pentoxide sol to molybdenum trioxide in molybdenum trioxide sol is 1:0.015, the mass ratio of vanadium pentoxide and graphene in vanadium pentoxide sol For 1:0.04, select vanadium pentoxide sol, molybdenum trioxide sol and graphene raw materials;

[0032] Slowly add the molybdenum trioxide sol dropwise into the vigorously stirred vanadium pentoxide sol, continue stirring for 30 minutes at room temperature, seal and let it stand for 3 days, then add graphene to it, and ultrasonically disperse it throu...

Embodiment 2

[0040] 1) Immerse the ITO conductive glass in NaOH / H sequentially 2 o 2 Mixed solution (NaOH, H 2 o 2 The volume ratio is 1:1~2), acetone, absolute ethanol, and deionized water, and ultrasonically clean them in an ultrasonic cleaner for 30 minutes, and finally soak the ITO conductive glass substrate in absolute ethanol for later use. Take out and dry to obtain a cleaned and dried ITO conductive glass substrate;

[0041] 2) Press: the molar ratio of vanadium pentoxide in vanadium pentoxide sol to molybdenum trioxide in molybdenum trioxide sol is 1:0.015, the mass ratio of vanadium pentoxide and graphene in vanadium pentoxide sol 1:0.03, select vanadium pentoxide sol, molybdenum trioxide sol and graphene raw materials;

[0042] Slowly add the molybdenum trioxide sol dropwise into the vigorously stirred vanadium pentoxide sol, continue stirring for 30 minutes at room temperature, seal and let it stand for 3 days, then add graphene to it, and ultrasonically disperse it through...

Embodiment 3

[0046] 1) Immerse the ITO conductive glass in NaOH / H sequentially 2 o 2 Mixed solution (NaOH, H 2 o 2 The volume ratio is 1:1~2), acetone, absolute ethanol, and deionized water, and ultrasonically clean them in an ultrasonic cleaner for 30 minutes, and finally soak the ITO conductive glass substrate in absolute ethanol for later use. Take out and dry to obtain a cleaned and dried ITO conductive glass substrate;

[0047] 2) Press: the molar ratio of vanadium pentoxide in vanadium pentoxide sol to molybdenum trioxide in molybdenum trioxide sol is 1:0.015, the mass ratio of vanadium pentoxide and graphene in vanadium pentoxide sol 1:0.05, select vanadium pentoxide sol, molybdenum trioxide sol and graphene raw materials;

[0048] Slowly add the molybdenum trioxide sol dropwise into the vigorously stirred vanadium pentoxide sol, continue stirring for 30 minutes at room temperature, seal and let it stand for 3 days, then add graphene to it, and ultrasonically disperse it through...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com