Preparation method for granular Cu3(PO4)2/super P positive electrode material of lithium ion battery

A lithium-ion battery and cathode material technology, applied in the field of electrochemistry, can solve problems such as poor conductivity and unsatisfactory conductivity, and achieve the effects of improving poor conductivity, rich raw materials, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

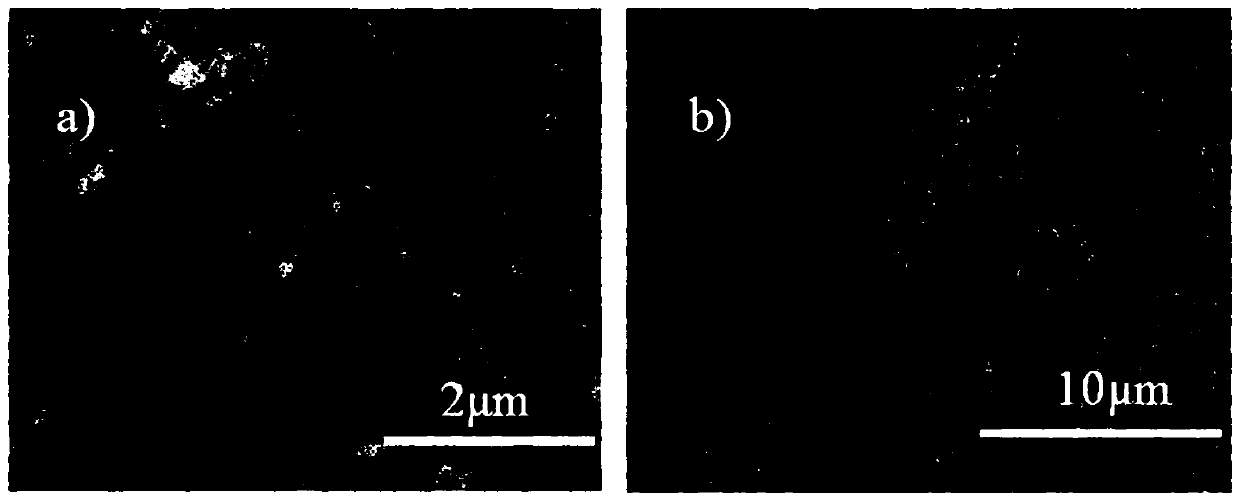

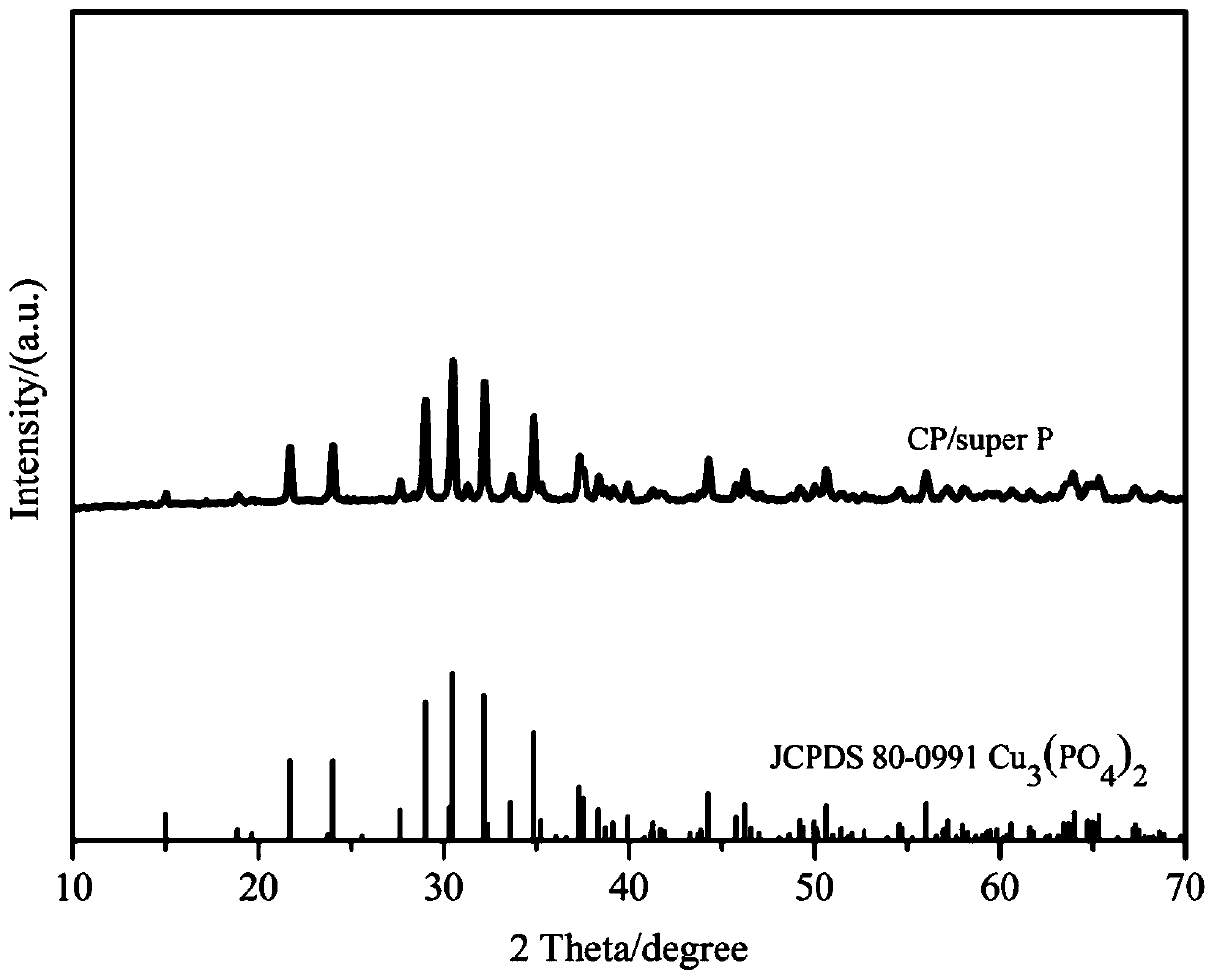

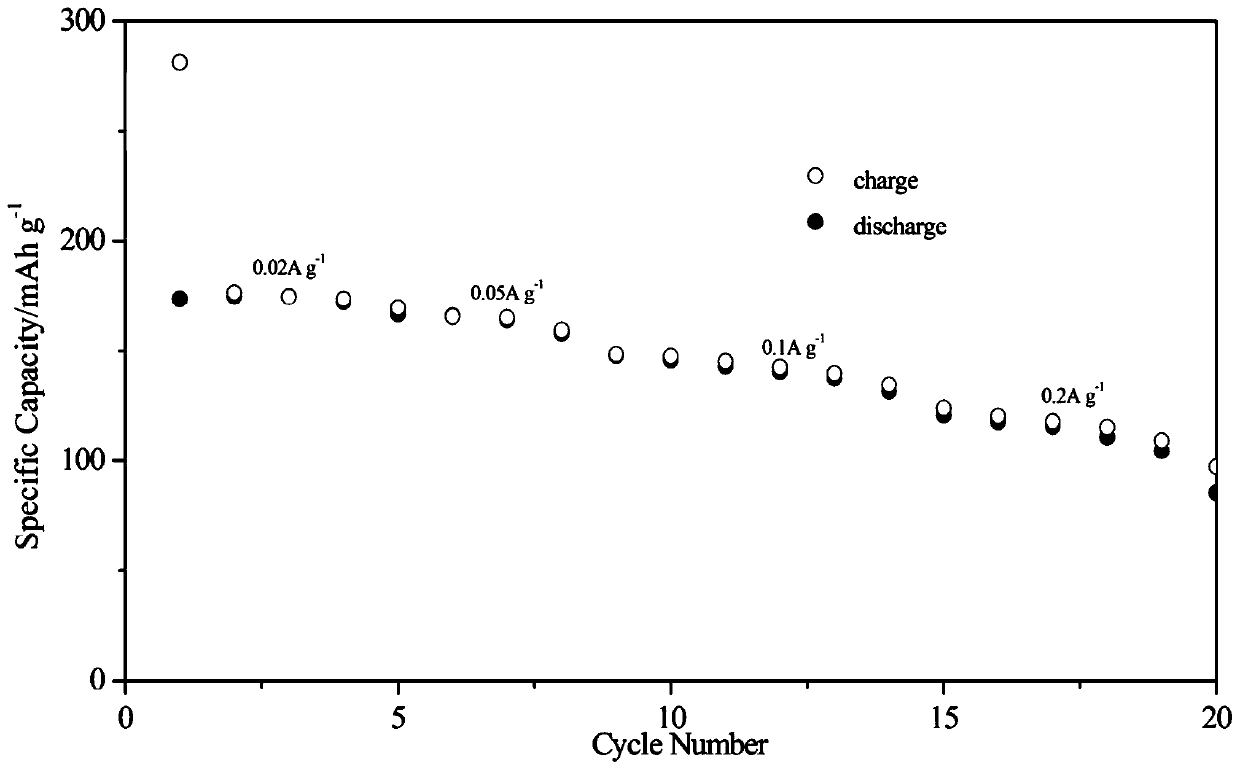

Image

Examples

Embodiment 1

[0024] 1) Dissolve ammonium phosphate in deionized water, stir and sonicate for 10 minutes to make solution A with a concentration of 0.28 mg / mL;

[0025] 2) According to the mass ratio of copper oxide and ammonium phosphate as 1:2.8, add copper oxide into solution A and magnetically stir for 1 hour, then adjust the pH value of the solution to 4, then pour the solution into a petri dish, put it in the refrigerator and freeze it for 12 hours to obtain solid B;

[0026] 3) Put the frozen solid B into a freeze dryer to dry for 12 hours, so that the phosphate is fully recrystallized on the surface of copper oxide to obtain a completely dried sample C;

[0027] 4) Spread sample C evenly in the quartz crucible, then put the crucible into the muffle furnace, -1 The heating rate was raised from room temperature to 350°C for 1h, and then at 2°C·min -1 The heating rate is increased to 650°C for 1 hour, and the heat-treated sample D is obtained;

[0028] 5) Take 1g of sample D and mix...

Embodiment 2

[0033] 1) Dissolve potassium phosphate in deionized water, stir and sonicate for 20 minutes to make solution A with a concentration of 0.3 mg / mL;

[0034] 2) According to the mass ratio of copper oxide and potassium phosphate as 1:3, add copper oxide to solution A and magnetically stir for 2 hours, adjust the pH value of the solution to 5, then pour the solution into a petri dish, put it in the refrigerator and freeze it for 18 hours to obtain solid B;

[0035] 3) Put the frozen solid B into a freeze dryer and dry it for 18 hours, so that the phosphate is fully recrystallized on the surface of copper oxide to obtain a completely dried sample C;

[0036] 4) Spread sample C evenly in the quartz crucible, then put the crucible into the muffle furnace, -1 The heating rate was raised from room temperature to 480°C for 2 hours, and then at 3°C·min -1 The heating rate is increased to 680°C for 1.5h, and the sample D after heat treatment is obtained;

[0037] 5) Mix 1g sample D wit...

Embodiment 3

[0039] 1) Dissolve ammonium phosphate in deionized water, stir and sonicate for 30 minutes to make solution A with a concentration of 0.4 mg / mL;

[0040] 2) According to the mass ratio of copper oxide and ammonium phosphate as 1:4, add copper oxide into solution A and stir magnetically for 3 hours, then adjust the pH value of the solution to 6, then pour the solution into a petri dish, put it in the refrigerator and freeze it for 24 hours to obtain solid B;

[0041] 3) Put the frozen solid B into a freeze dryer to dry for 24 hours, so that the phosphate is fully recrystallized on the surface of copper oxide to obtain a completely dried sample C;

[0042] 4) Spread sample C evenly in the quartz crucible, then put the crucible into the muffle furnace, -1 The heating rate was raised from room temperature to 500°C for 3h, and then at 4°C·min -1 The heating rate is increased to 700°C for 2 hours, and the sample D after heat treatment is obtained;

[0043] 5) Mix 1g of sample D w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com