Meg/si/c composite negative electrode material for lithium ion battery and preparation method thereof

A lithium-ion battery and negative electrode material technology, applied in battery electrodes, nanotechnology for materials and surface science, negative electrodes, etc., can solve the problems of poor electrode cycle stability, low lithium ion intercalation and extraction rates, and low capacity , to achieve the effects of high-current charging and discharging, increasing lithium intercalation/detachment channels, and increasing specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

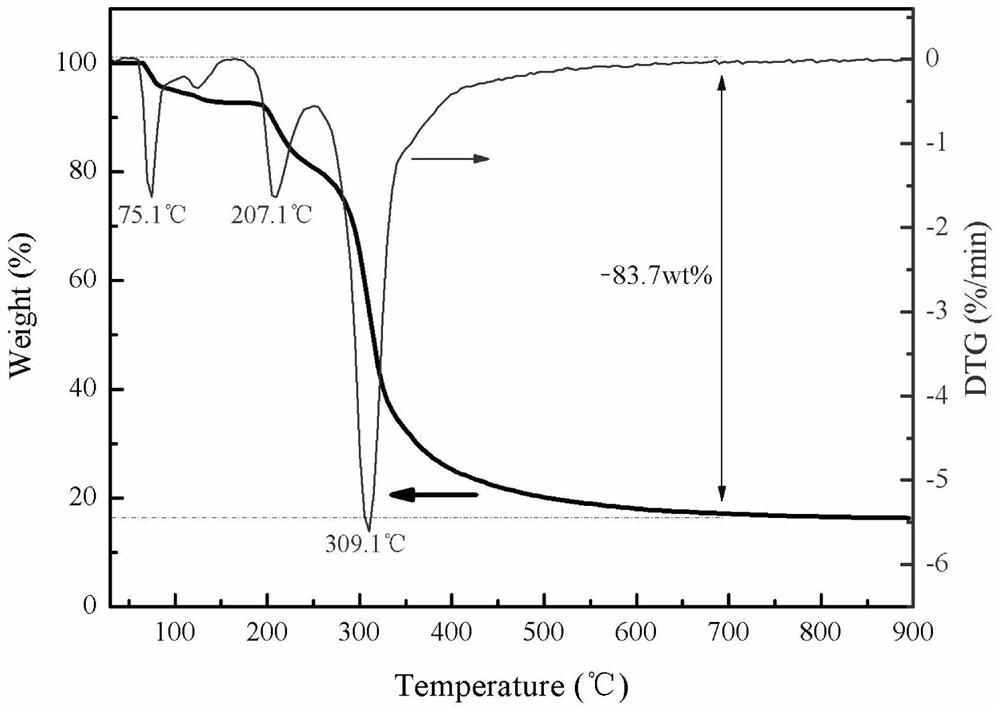

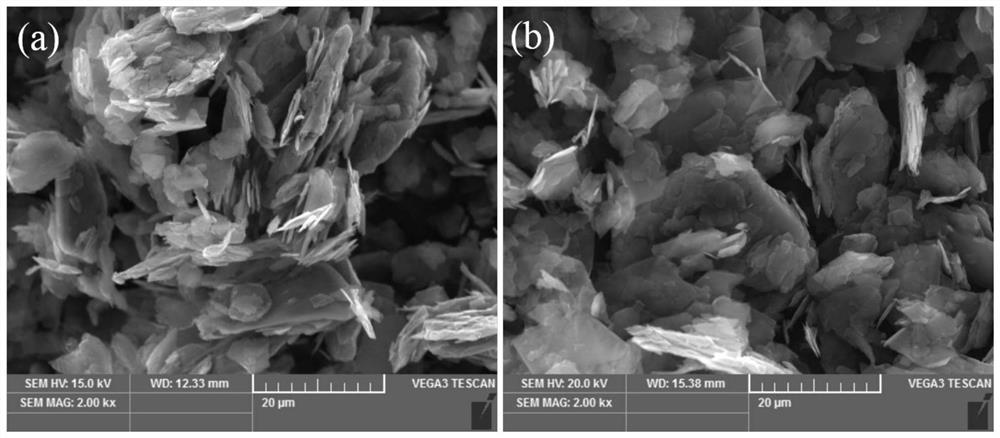

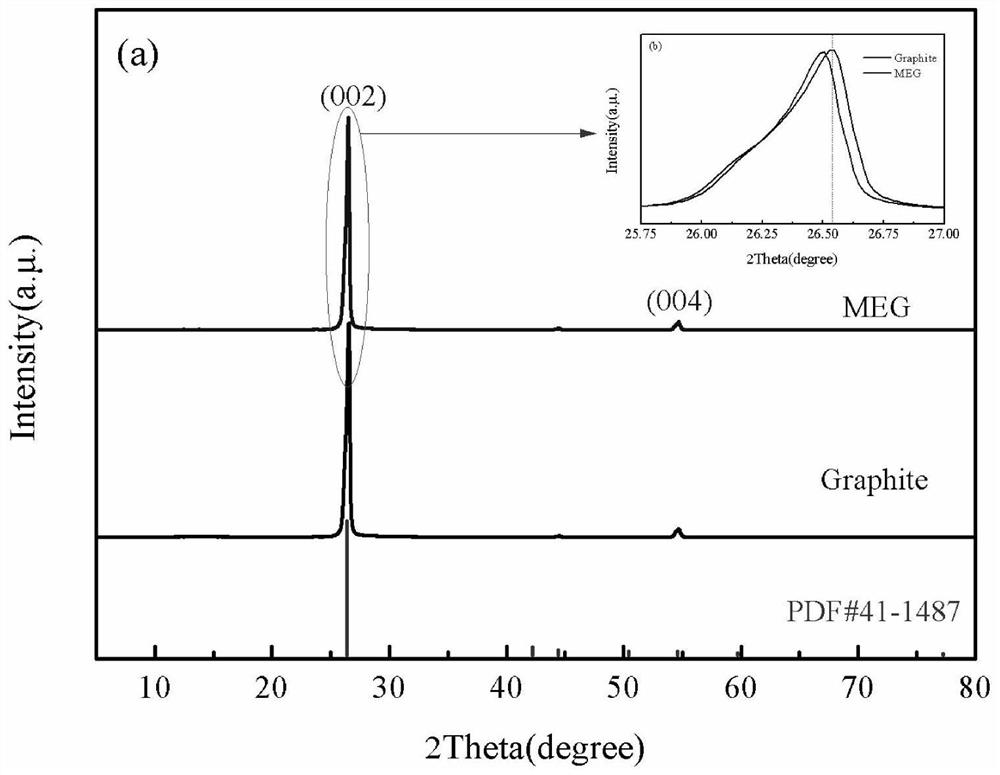

[0032]1) At room temperature, after weighing 20g of artificial flake graphite, 45mL of concentrated sulfuric acid (98%) and 35mL of hydrogen peroxide (30%) in a three-necked flask, place it in an ice-water bath for chemical oxidation intercalation reaction for 4 h , and then the solid was separated by filtration, and the solid was washed with deionized water until the supernatant was neutral (pH=7). Grind the filter cake into fine powder and set aside;

[0033] 2) Put the fine powder prepared in step 1) in a tube furnace, raise the temperature in the air to 400°C at 2K / min, keep it warm for 5 hours, and then cool it under nitrogen protection and place it at room temperature to obtain micro-expanded graphite;

[0034] 3) Accurately weigh 5g of micro-expanded graphite, 0.25g of nano silicon powder and 0.158g of PVP and place them in a ball mill at 400r / min for 4h, then add 1.99g of glucose into the ball mill tank, and mill at a speed of 400r / min for 4h. get the mixture;

[003...

Embodiment 2

[0037] 1) At room temperature, after weighing 20g of microcrystalline graphite, 45mL of concentrated nitric acid (98%) and 35mL of potassium permanganate (30%) in a three-neck flask, place it in an ice-water bath for chemical oxidation intercalation reaction for 4 h After that, the solid was separated by filtration, and the solid was washed with deionized water until the supernatant was neutral (pH=7), and then the solid was dried in a vacuum oven at 110 °C for 12 h, and the Grind the filter cake into fine powder and set aside;

[0038] 2) Put the fine powder prepared in step 1) in a tube furnace, raise the temperature in the air to 400°C at 2K / min, keep it warm for 5 hours, and then cool it under nitrogen protection and place it at room temperature to obtain micro-expanded graphite;

[0039] 3) Accurately weigh 5g of micro-expanded graphite, 0.5g of nano silicon powder and 0.165g of sodium lauryl sulfate and place them in a planetary ball mill at 500r / min for 4 hours, then ad...

Embodiment 3

[0042] 1) At room temperature, weigh 20g of secondary granulated graphite, 45mL of concentrated sulfuric acid (98%) and 35mL of hydrogen peroxide (30%) in a three-necked flask, and place it in an ice-water bath for chemical oxidation intercalation reaction4 After h, the solid was separated by filtration, washed with deionized water until the supernatant was neutral (pH=7), and then dried in a vacuum oven at 110°C for 12 h, and ground with agate Bowl to grind the filter cake into fine powder, set aside;

[0043] 2) Put the fine powder prepared in step 1) in a tube furnace, raise the temperature in the air to 400°C at 2K / min, keep it warm for 5 hours, and then cool it under nitrogen protection and place it at room temperature to obtain micro-expanded graphite;

[0044] 3) Accurately weigh 5g of micro-expanded graphite, 0.75g of nano silicon powder and 0.173g of PVP and place them in a planetary ball mill at 500r / min for 4h, then add 2.18g of glucose into the ball milling tank, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com