Quantum dot light-emitting diode and preparation method of quantum dot light-emitting diode

A quantum dot light-emitting and diode technology, which is applied in semiconductor/solid-state device manufacturing, nanotechnology for materials and surface science, nanotechnology, etc., can solve problems such as poor conductivity, reduce the impact of device performance, and enhance conductivity , The effect of improving dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

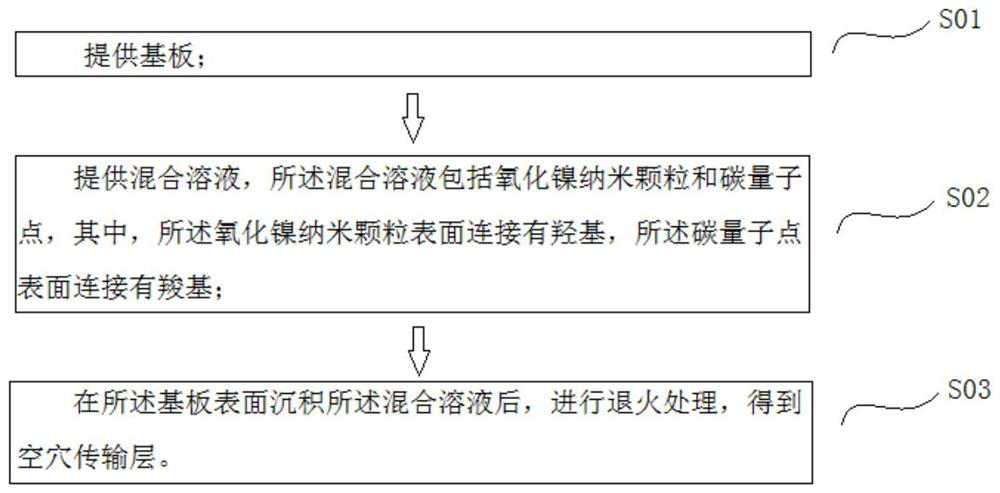

[0031] Correspondingly, such as image 3 As shown, the second aspect of the present invention provides a method for preparing a quantum dot light-emitting diode, comprising the following steps:

[0032] S01. Provide the substrate;

[0033]S02. A mixed solution is provided, the mixed solution includes nickel oxide nanoparticles and carbon quantum dots, wherein the surface of the nickel oxide nanoparticles is connected to a hydroxyl group, and the surface of the carbon quantum dots is connected to a carboxyl group;

[0034] S03. After depositing the mixed solution on the surface of the substrate, perform annealing treatment to obtain a hole transport layer.

[0035] In the method for preparing a quantum dot light-emitting diode provided in the embodiment of the present invention, a mixed solution of nickel oxide nanoparticles and carbon quantum dots is deposited on the surface of a substrate and then annealed to prepare a hole transport layer. The material of the obtained hole...

Embodiment 1

[0067] A preparation method of nickel oxide nanomaterials, comprising the following steps:

[0068] Add an appropriate amount of nickel chloride to 50ml of methanol to form a nickel chloride solution with a total concentration of 1mol / L, stir and dissolve at 60°C, add sodium hydroxide dropwise to dissolve in lye of 10ml of methanol (OH - : Ni 2+ The molar ratio is 2:1 ratio), continue stirring at 60°C for 3h to obtain a homogeneous transparent solution.

[0069] Dissolve an appropriate amount of benzoic acid in 50ml ODE to form a benzoic acid solution with a concentration of 1mol / L; transfer the benzoic acid solution to a polytetrafluoroethylene liner, and place it in a reactor. In a preheated oven, react at a reaction temperature of 250° C. for 3 hours. After the reaction, precipitate and wash with acetone, and centrifuge to prepare carbon quantum dots.

[0070] Disperse an appropriate amount of carbon quantum dots in 50ml of mixed acid (volume ratio of concentrated sulfur...

Embodiment 2

[0074] A preparation method of nickel oxide nanomaterials, comprising the following steps:

[0075] Add an appropriate amount of nickel nitrate to 50ml propanol to form a nickel nitrate solution with a total concentration of 1mol / L, stir and dissolve at 80°C, add ethanolamine dropwise to dissolve in 10ml propanol lye (OH - : Ni 2+ The molar ratio is 2:1); continue to stir at 80° C. for 3 h to obtain a homogeneous transparent solution.

[0076] Dissolve an appropriate amount of phthalic acid in 50ml 1-hexadecene to form a phthalic acid solution with a concentration of 1mol / L; transfer the phthalic acid solution to a polytetrafluoroethylene liner and place it in a reaction kettle , after tightening and sealing the reactor, put it into a preheated oven, and react for 3 hours at a reaction temperature of 250°C. After the reaction, precipitate and wash with acetone, and centrifuge to prepare carbon quantum dots.

[0077] Disperse an appropriate amount of carbon quantum dots in 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com