Preparation method of high-specific-capacity sodium-sulfur battery positive electrode material

A sodium-sulfur battery and positive electrode material technology, which is applied in battery electrodes, positive electrodes, active material electrodes, etc., can solve the problems of battery chemical instability, large volume change, anode passivation, and low Coulombic efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The method of preparing the sodium-sulfur battery capacity than the positive electrode material, comprising the steps of:

[0027] (1) Preparation of ZIF-67: First, 1.64g dimethyl imidazole and 1.45g of cobalt nitrate hexahydrate were dissolved in 125mL methanol solution to prepare a solution of dimethyl imidazole and cobalt nitrate solution; then the solution dimethylimidazole was added to the stirred cobalt nitrate solution for 30 minutes for 24 hours, the precipitate was collected by centrifugation, and washed three times with ethanol, and dried at 70 deg.] C 24h, to give ZIF-67;

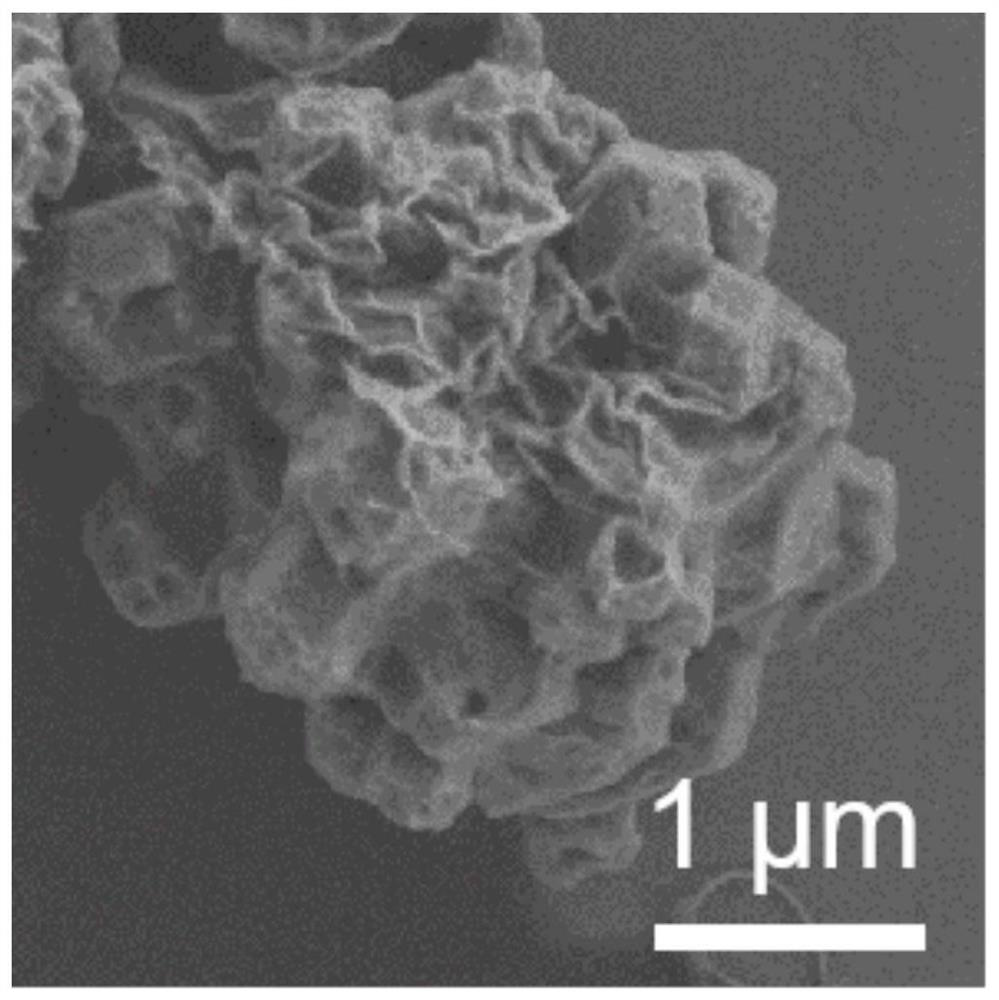

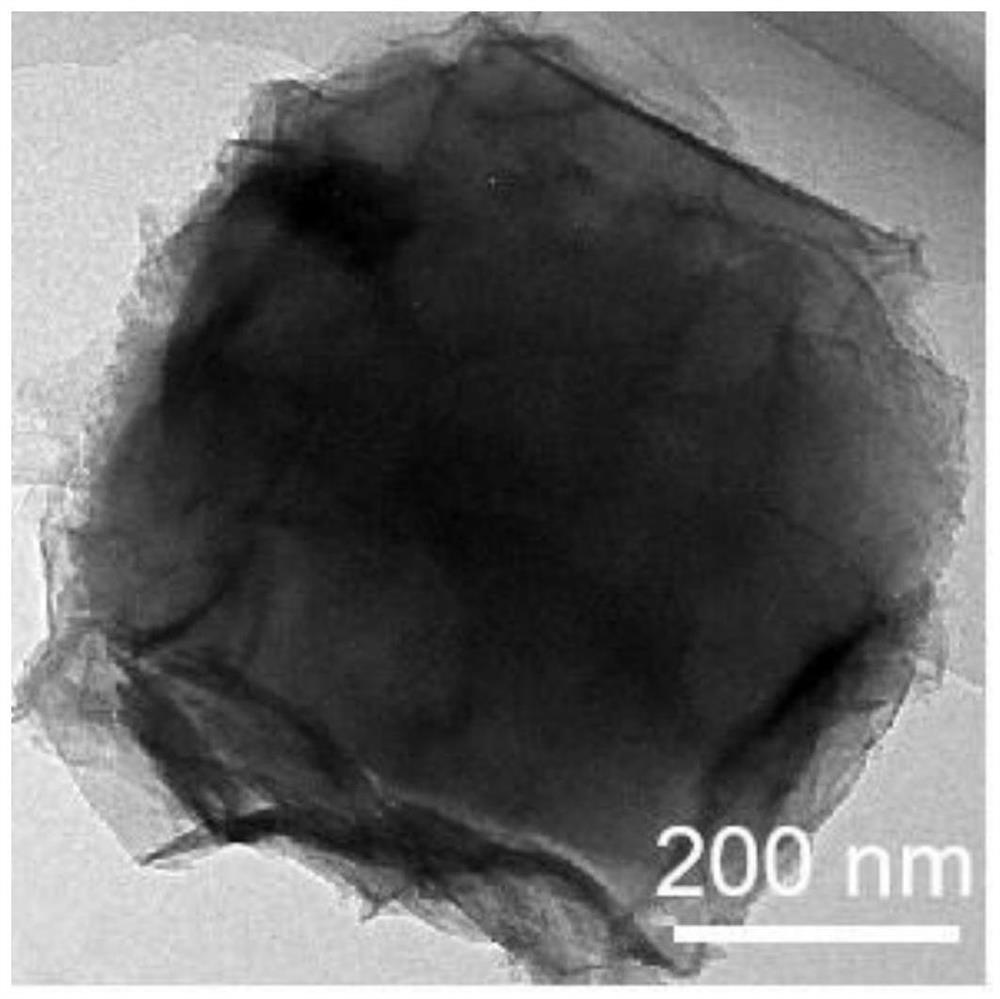

[0028] (2) Preparation of ZIF-67 @ rGO: Weigh step (1) prepared ZIF-67100mg was added to 100mL aqueous graphene oxide, the graphene oxide solution wherein the concentration of 2mg. mL -1 Ultrasonic stirring for 1 hour 24 hours to obtain a spray solution; spray solution was spray dried at 200 ℃, prepared ZIF-67 @ rGO;

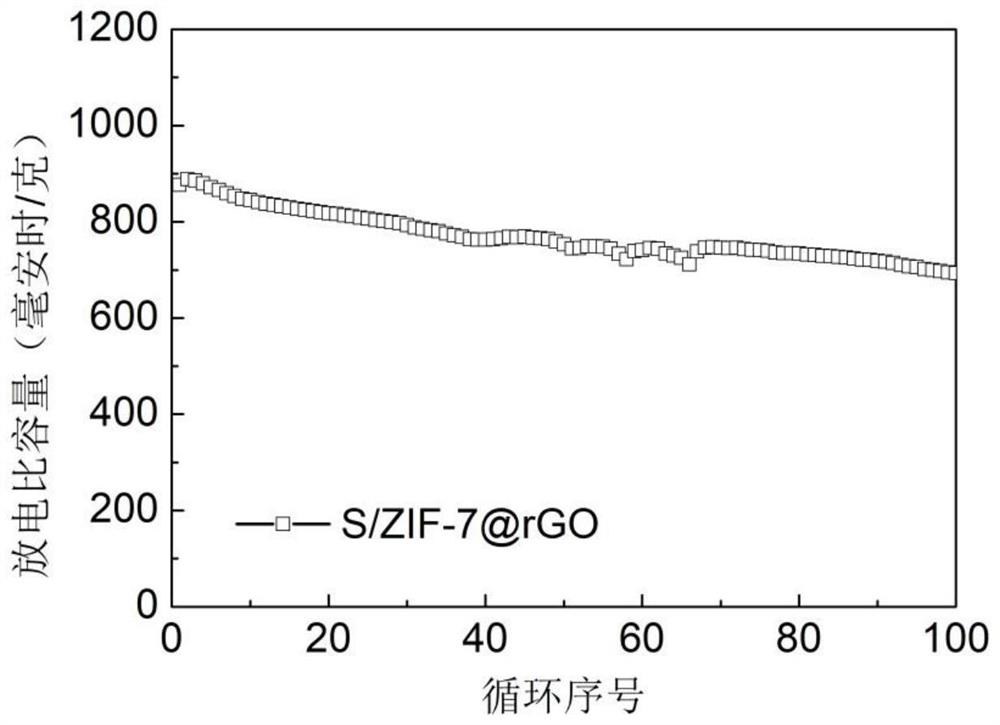

[0029] (3) Preparation of a sulfur / ZIF-67 @ rGO: pure sulfur powder in st...

Embodiment 2

[0035] The method of preparing the sodium-sulfur battery capacity than the positive electrode material, comprising the steps of:

[0036] (1) Preparation of ZIF-67: First, 2.05g dimethyl imidazole and 1.81g of cobalt nitrate hexahydrate were dissolved in 175mL methanol solution to prepare a solution of dimethyl imidazole and cobalt nitrate solution; then the solution dimethylimidazole was added to the stirred cobalt nitrate solution for 30 minutes for 24 hours, the precipitate was collected by centrifugation, and washed three times with ethanol, and dried at 70 deg.] C 24h, to give ZIF-67;

[0037] (2) Preparation ZIF-67 @ RGO: ZiF-67150 mg prepared by step (1) was added to 100 ml of the grapien oxide inkyl, wherein the concentration of the oxide in graphene has a concentration of 2 mg. ml -1 After the ultrasonic treatment was 1.5 hours, stirred for 24 hours, resulting in a spray solution; spray drying treatment at 200 ° C, producing ZIF-67 @ RGO;

[0038] (3) Preparation of sulfur ...

Embodiment 3

[0040] The preparation method of the high-specific capacity sodium battery positive material, including the following steps:

[0041] (1) Preparation ZIF-67: First, 2.46 g of dimethylimidazole and 2.18 g of hexaviric acid cobalt were dissolved in 200 mL of methanol solution, and the dimethylimidazole solution and cobalt-nitrate solution were obtained; then the dimethylimidazole solution After stirring to a cobalt nitrate solution for 30 minutes, it was allowed to stand for 24 hours, and the precipitate was collected from centrifugation, and the use of ethanol was washed three times, and 24 h was dried at 70 ° C to obtain ZIF-67;

[0042] (2) Preparation ZIF-67 @ RGO: The ZIF-67200 mg prepared by step (1) was added to 100 ml of the oxide in grapiene aqueous solution, wherein the concentration of the oxide in graphene has a concentration of 2 mg. ml -1 After 2 hours, the ultrasonic treatment was stirred for 24 hours to obtain a spray solution; the spray solution was spray drying at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com