Bridging structure for conductor terminals

A technology of wire terminal and bridge structure, which is applied in the field of wire terminal devices and can solve problems such as poor heat dissipation and unsatisfactory conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

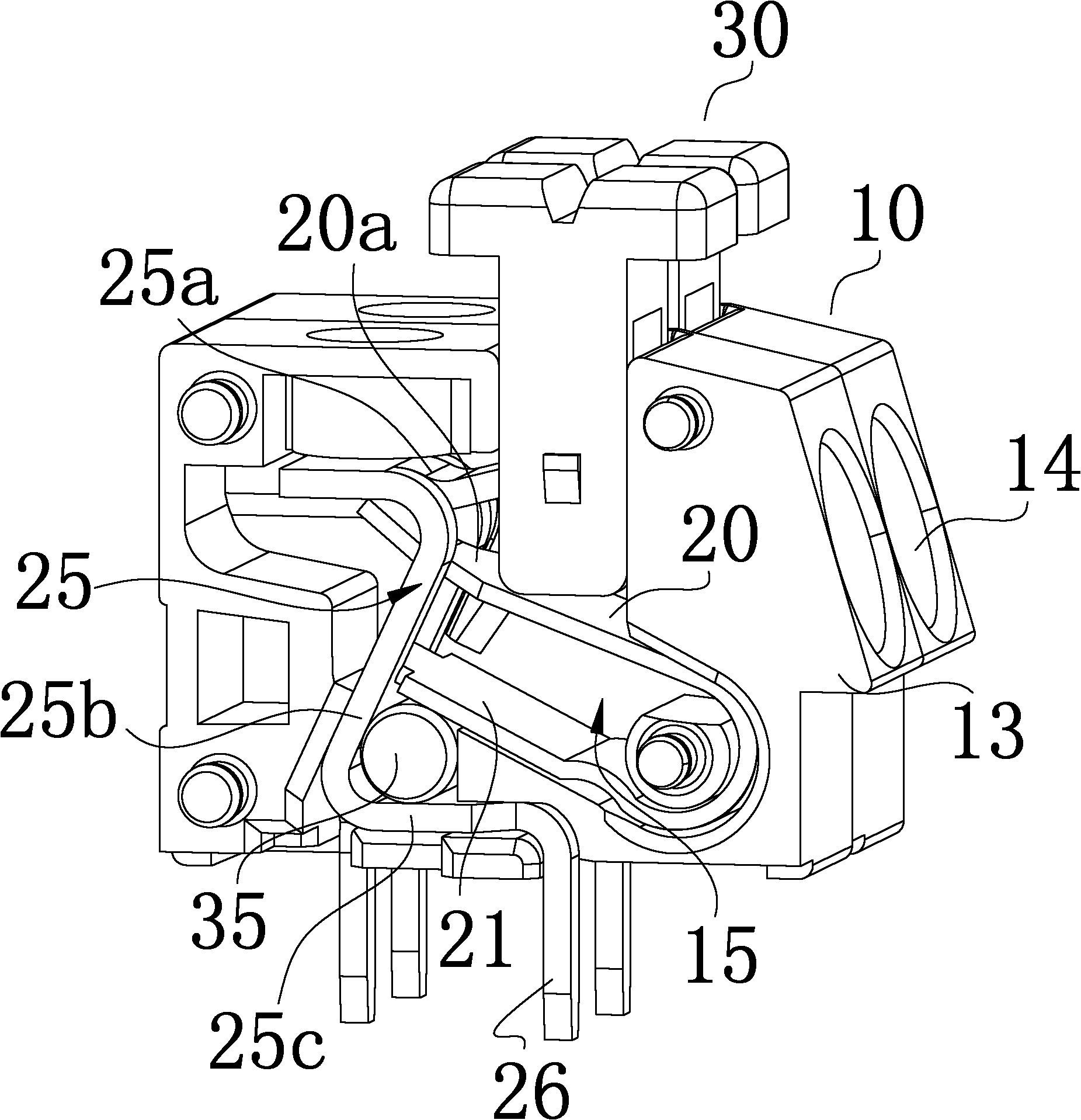

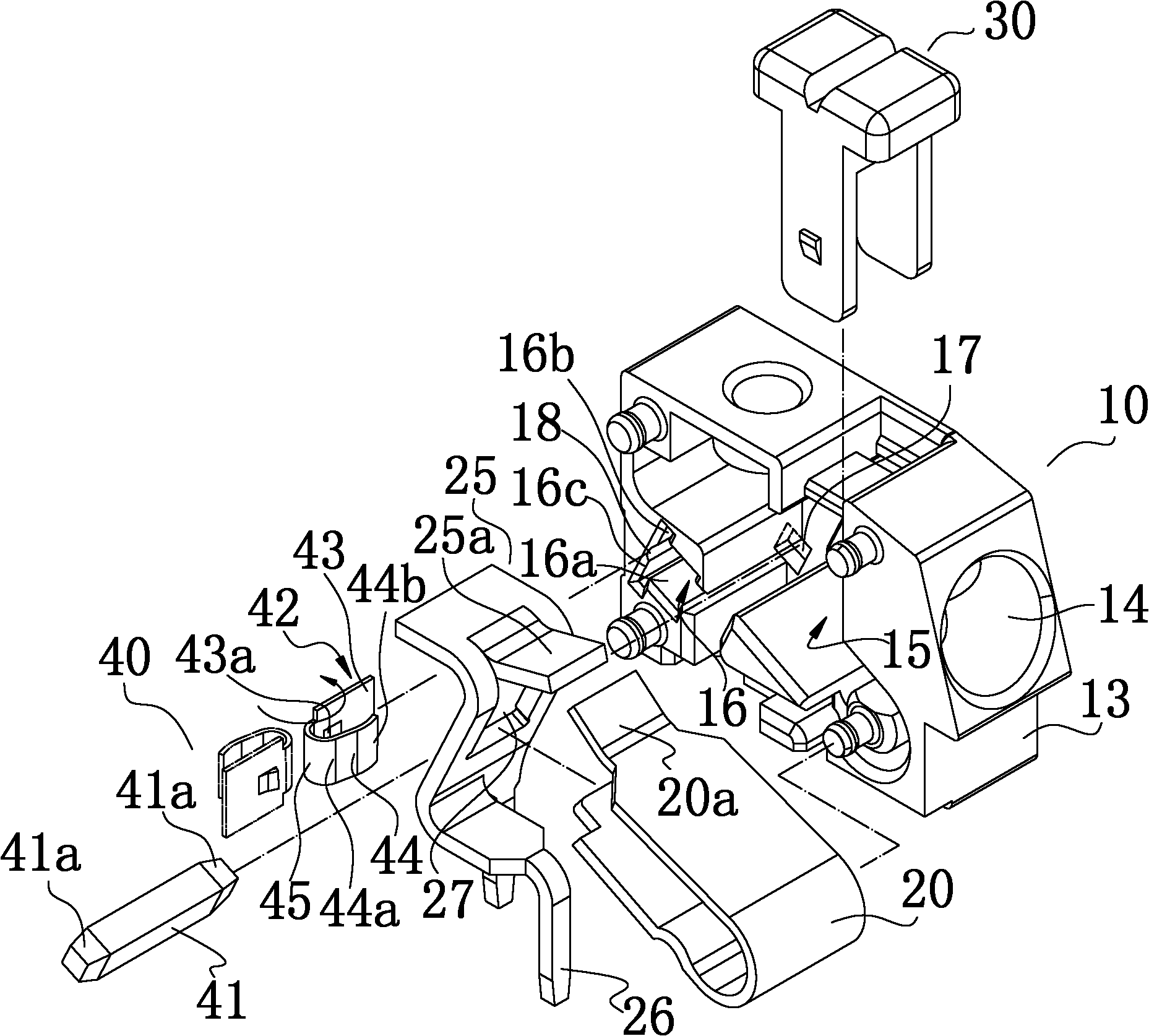

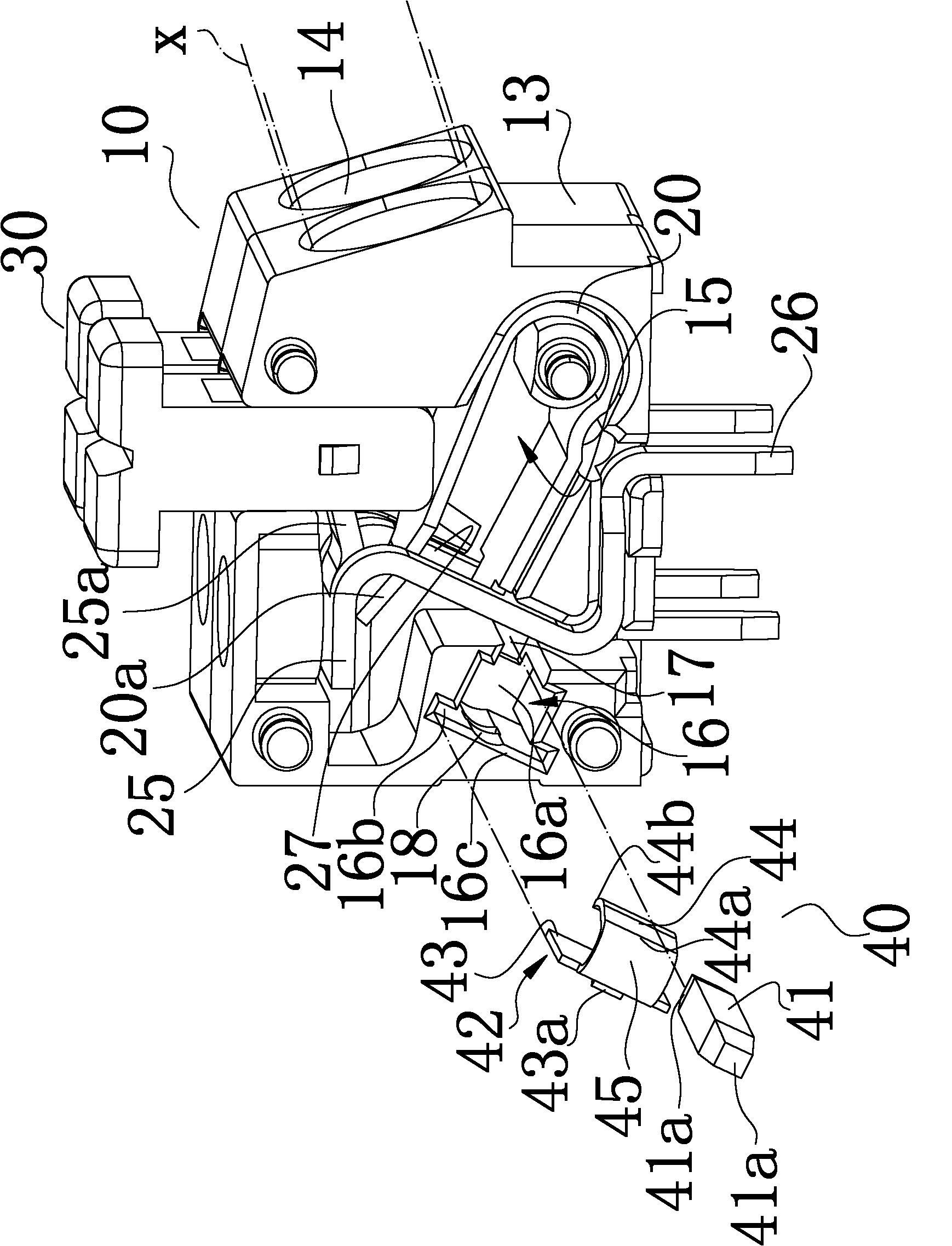

[0037] see figure 2 , image 3 and Figure 4 , the present invention is used for the bridging structure of the wire terminal, which is a combination of a wire (or connection) terminal 10 and a network bridge 40 . The network bridge 40 can be elastically inserted into the connection terminals 10 to electrically connect at least two connection terminals 10 to each other. image 3 , Figure 4 In particular, two terminals 10 arranged together are depicted, and the terminal 10 is chosen to be in the form of an insulating housing 13 made of plastic material. The housing 13 has a plurality of inlets 14 for the wires x received from the machine equipment to be inserted into the housing 13 . The terminal 10 or the housing 13 defines a cavity 15 , the spring piece 20 and the conductor (or metal piece) 25 are fitted in the cavity 15 , and form contact or electrical connection with the wire x inserted into the housing 13 .

[0038] In this embodiment, the spring sheet 20 and the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com