Niobium pentoxide three-dimensional doped graphene composite material, and preparation method and application thereof

A technology of niobium pentoxide and composite material, applied in the field of niobium pentoxide three-dimensional doped graphene composite material and its preparation, can solve the problem of lack of selectivity, lack of matching degree, insufficient active sites of pure graphene, etc. problems, to achieve the effect of favorable electrical conductivity, broad application prospects, and cheap and easy availability of experimental drugs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The first step, preparation of three-dimensional doped graphene precursor solution:

[0025] Disperse 0.1g of graphene oxide in 25ml of deionized water, ultrasonically shake for 4 hours, centrifuge to take the supernatant, so that the graphene oxide is evenly dispersed to obtain a graphene oxide dispersion, add 0.1g of melamine powder, and stir at 80°C until completely Dissolve to obtain liquid A; take another 0.15g of thiocyanuric acid and dissolve it in 25ml of ethanol to obtain liquid B; slowly add liquid B to liquid A, stir at 70°C for 10 minutes, stir well and set aside.

[0026] The second step, preparation of three-dimensional niobium pentoxide doped graphene composite material:

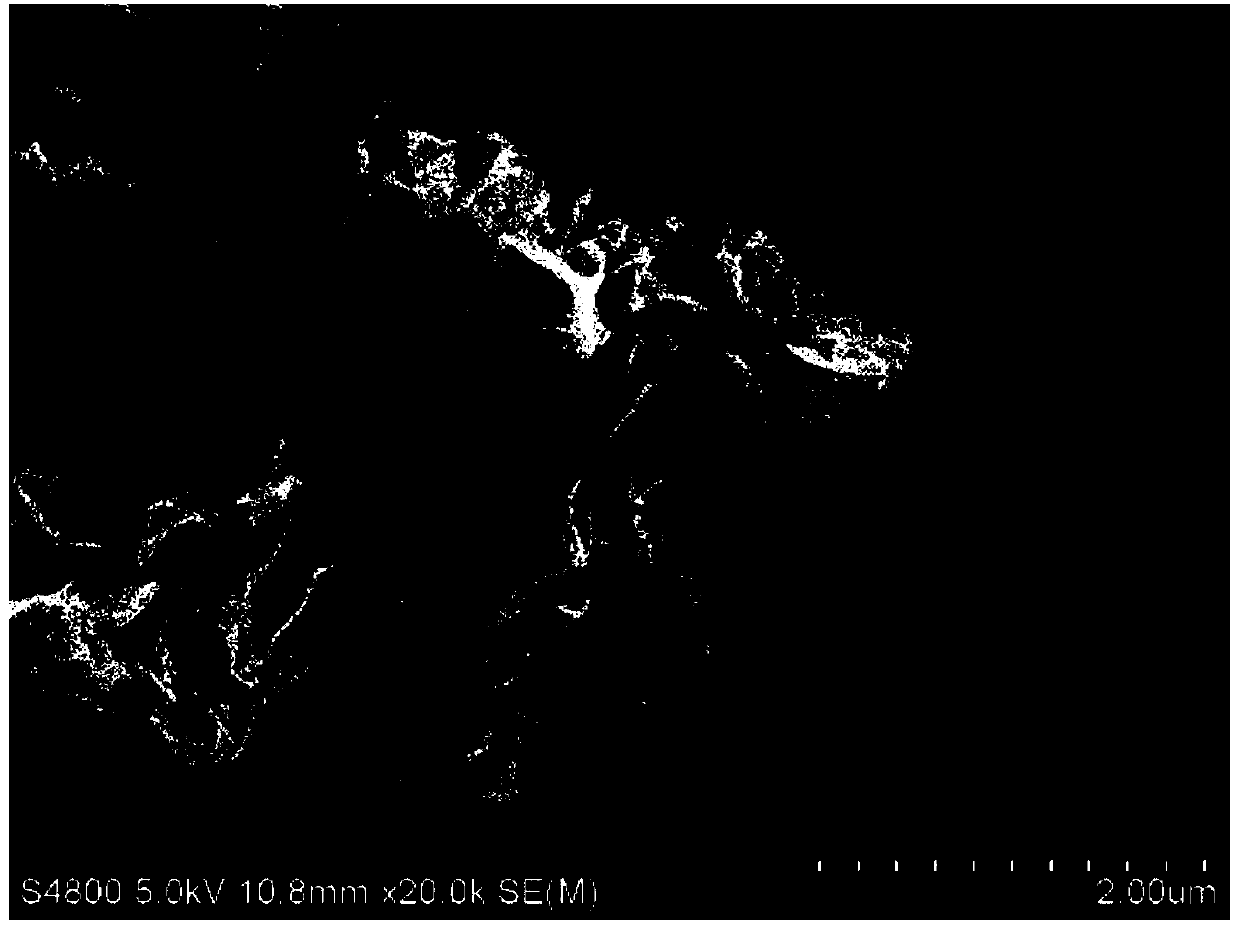

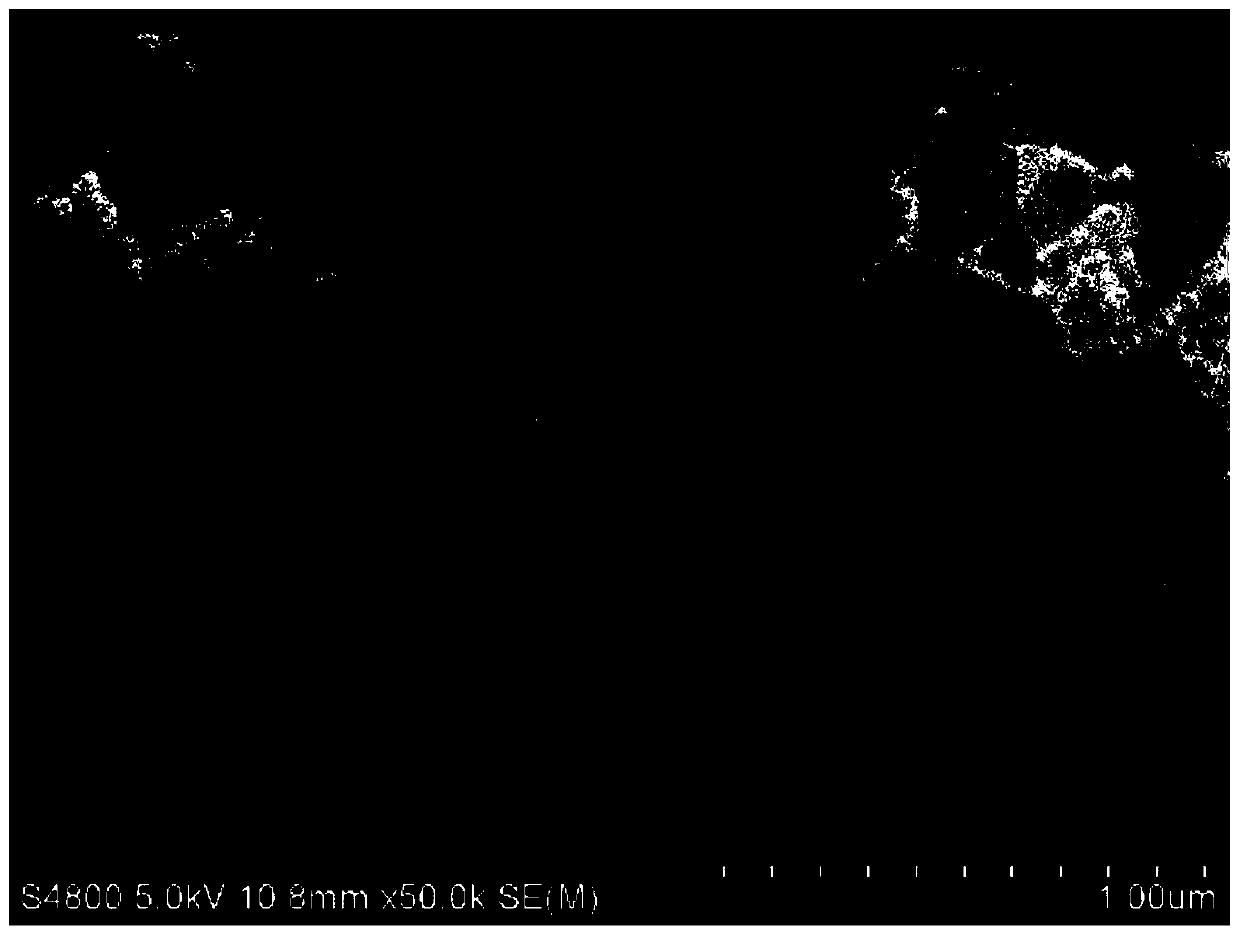

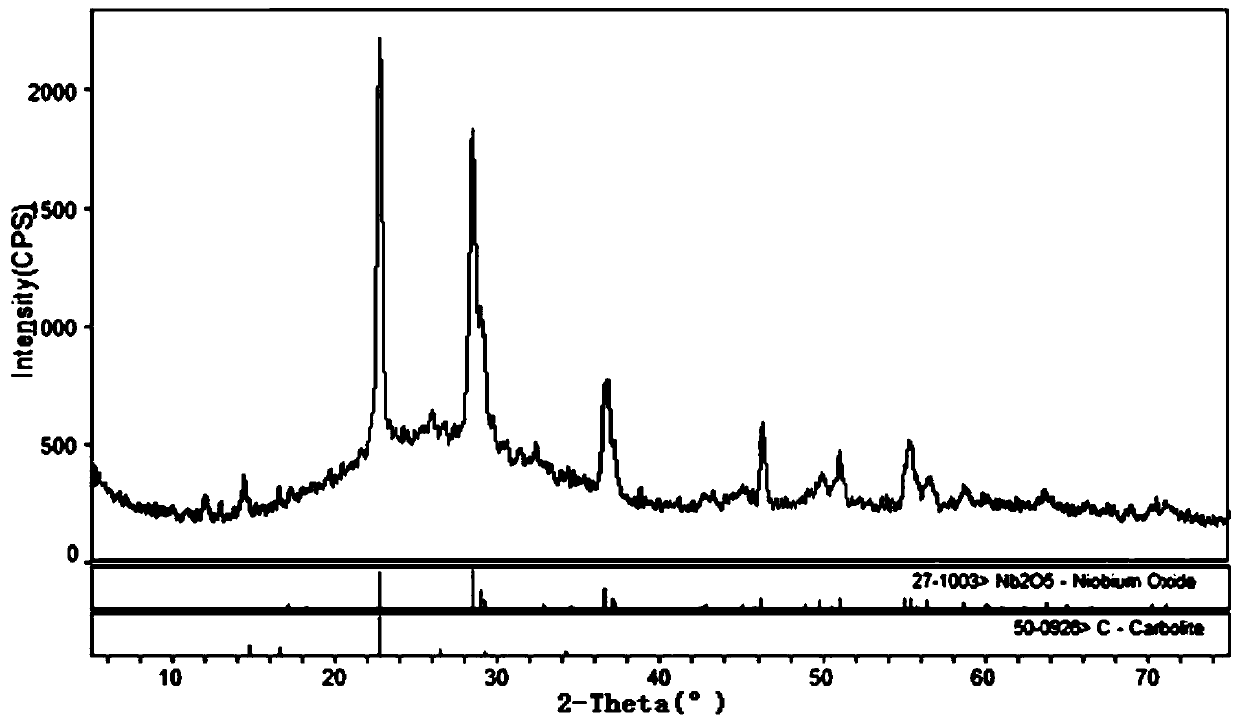

[0027] Pour the three-dimensional doped graphene precursor solution prepared in the first step into a beaker, stir evenly, add 0.1g of niobium chloride, stir evenly, and transfer it to a reaction kettle with a polytetrafluoroethylene substrate, the filling ratio is 45% , placed in a ho...

Embodiment 2

[0031] The first step, preparation of three-dimensional doped graphene precursor solution:

[0032] Disperse 0.15g of graphene oxide in 50ml of deionized water, ultrasonically oscillate for 4 hours, centrifuge to take the supernatant to disperse the graphene oxide evenly, add 0.25g of melamine powder, stir at 80°C until completely dissolved, and obtain liquid A; Dissolve 0.3g of thiocyanuric acid in 25ml of ethanol to obtain liquid B; slowly add liquid B to liquid A, stir at 80°C for 20min, stir well and set aside.

[0033] The second step, preparation of three-dimensional niobium pentoxide doped graphene composite material:

[0034] Pour the three-dimensional doped graphene precursor solution prepared in the first step into a beaker, stir evenly, add 0.2g of niobium chloride, stir evenly, and transfer it to a reaction kettle with a polytetrafluoroethylene substrate, the filling ratio is 65% , placed in a homogeneous reactor for hydrothermal reaction at 150°C / 12h; the hydroth...

Embodiment 3

[0039] The first step, preparation of three-dimensional doped graphene precursor solution:

[0040] Disperse 0.2g of graphene oxide in 50ml of deionized water, ultrasonically shake for 4 hours, centrifuge to take the supernatant to disperse the graphene oxide evenly, add 0.2g of melamine powder, stir at 80°C until completely dissolved, and obtain liquid A; Dissolve 0.35g of thiocyanuric acid in 25ml of ethanol to obtain liquid B; slowly add liquid B to liquid A, stir at 80°C for 30min, stir well and set aside.

[0041] The second step, preparation of three-dimensional niobium pentoxide doped graphene composite material:

[0042] Pour the three-dimensional doped graphene precursor solution prepared in the first step into a beaker, stir evenly, add 0.3g of niobium chloride, stir evenly, and transfer it to a reaction kettle with a polytetrafluoroethylene substrate, and the filling ratio is 75% , placed in a homogeneous reactor for hydrothermal reaction at 180°C / 12h; the hydrothe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com