Method for preparing high-energy-density lithium ion battery negative electrode material based on silicon waste alloy method

A high-energy-density, lithium-ion battery technology with applications in nanotechnology for materials and surface science, battery electrodes, secondary batteries, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

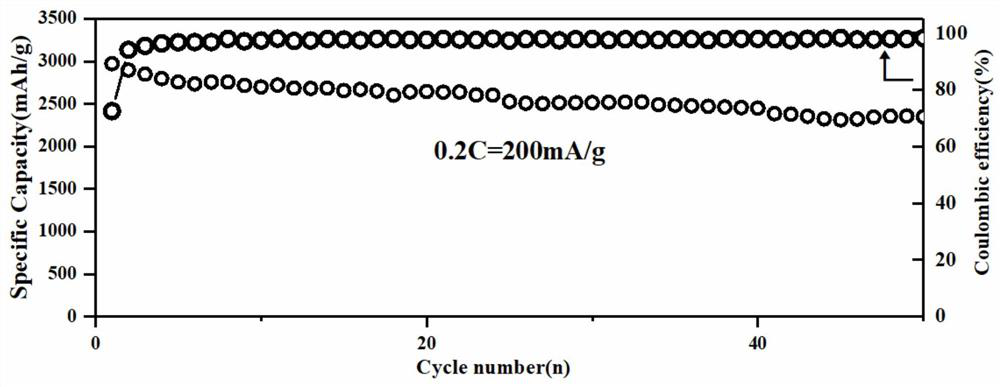

Embodiment 1

[0023] Embodiment 1: a kind of method based on silicon scrap alloy method to prepare high energy density lithium ion battery negative electrode material, concrete steps are as follows:

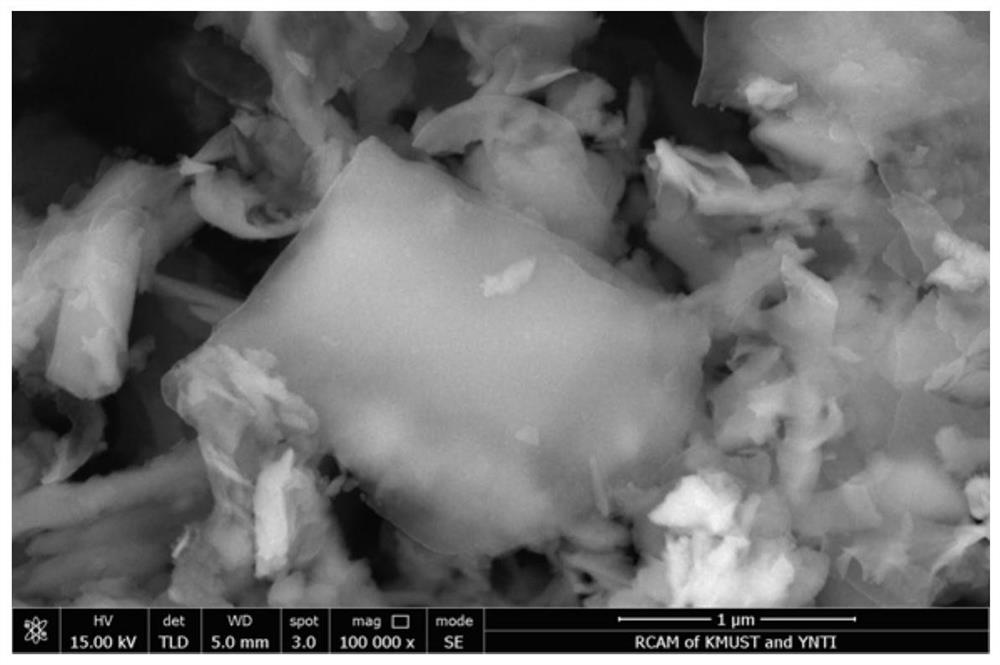

[0024] (1) Diamond wire cutting silicon waste is vacuum-dried, naturally cooled and crushed, and ground to obtain waste silicon powder (see figure 1 ), the waste silicon powder is compressed to obtain the waste silicon material;

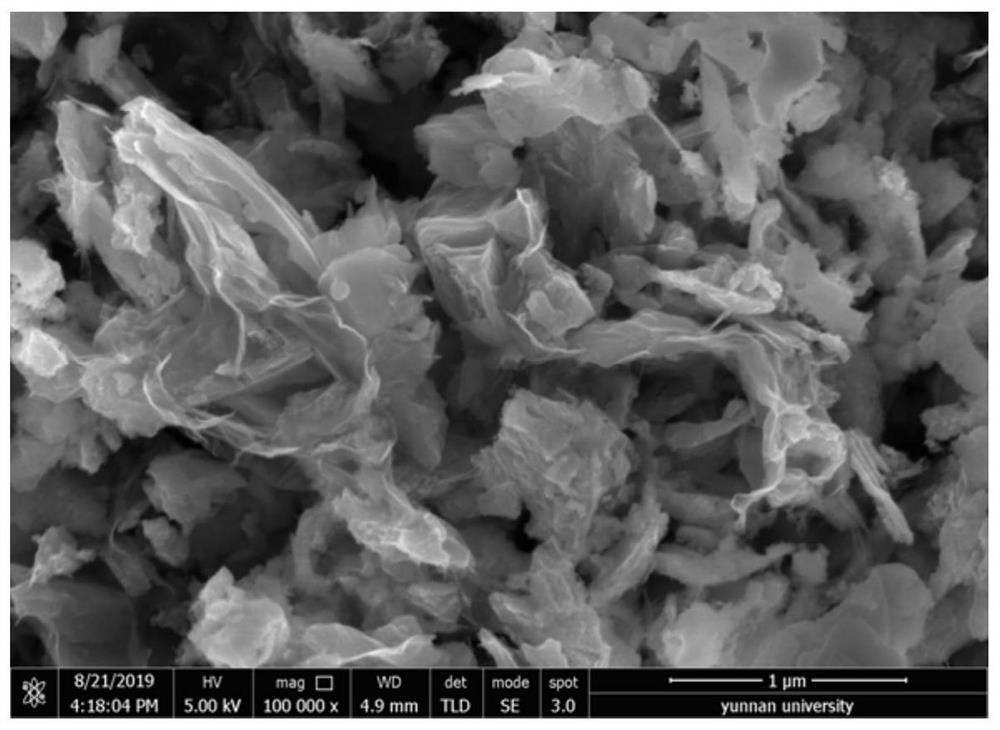

[0025] (2) Mix the waste silicon material and magnesium particles in step (1) evenly, place the temperature in an argon atmosphere at a constant rate of 5°C / min to a temperature of 1500°C and react at a constant temperature for 180min, cool to room temperature, and Ball milling in the atmosphere for 10 minutes to obtain micro-nano Si@Mg powder; the particle size of the magnesium particles is 5mm, the molar ratio of silicon and magnesium in the waste silicon material is 10:1, and the ball milling rate is 400r / min;

[0026] (3) Add the micro-nano Si@Mg powder in step ...

Embodiment 2

[0028] Embodiment 2: a kind of method based on silicon scrap alloy method to prepare high energy density lithium-ion battery anode material, concrete steps are as follows:

[0029] (1) The silicon waste material cut by diamond wire is vacuum-dried, naturally cooled, crushed, and ground to obtain waste silicon powder, and the waste silicon powder is pressed into tablets to obtain waste silicon material;

[0030] (2) Mix the waste silicon material and aluminum particles in step (1) evenly, place the temperature in an argon atmosphere at a constant rate of 10°C / min to a temperature of 1700°C and react at a constant temperature for 200 minutes, cool to room temperature, and place in an argon atmosphere. Ball milling in the atmosphere for 15 minutes to obtain micro-nano Si@Al powder; the particle size of the aluminum particles is 500 μm, the molar ratio of silicon and aluminum in the waste silicon material is 5:1, and the ball milling rate is 800r / min;

[0031] (3) Add the micro-na...

Embodiment 3

[0033] Embodiment 3: A kind of method based on silicon scrap alloy method to prepare high energy density lithium-ion battery anode material, concrete steps are as follows:

[0034] (1) The silicon waste material cut by diamond wire is vacuum-dried, naturally cooled, crushed, and ground to obtain waste silicon powder, and the waste silicon powder is pressed into tablets to obtain waste silicon material;

[0035] (2) Mix the waste silicon material and copper particles in step (1) evenly, place the temperature in an argon atmosphere at a constant rate of 5°C / min to a temperature of 1455°C and react at a constant temperature for 200min, cool to room temperature, and place in an argon atmosphere. Ball milling in the atmosphere for 30 minutes to obtain micro-nano Si@Cu powder; wherein the particle size of the copper particles is 500nm, the molar ratio of silicon and copper in the waste silicon material is 10:1, and the ball milling rate is 1000r / min;

[0036] (3) Add the micro-nano ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Reversible capacity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com