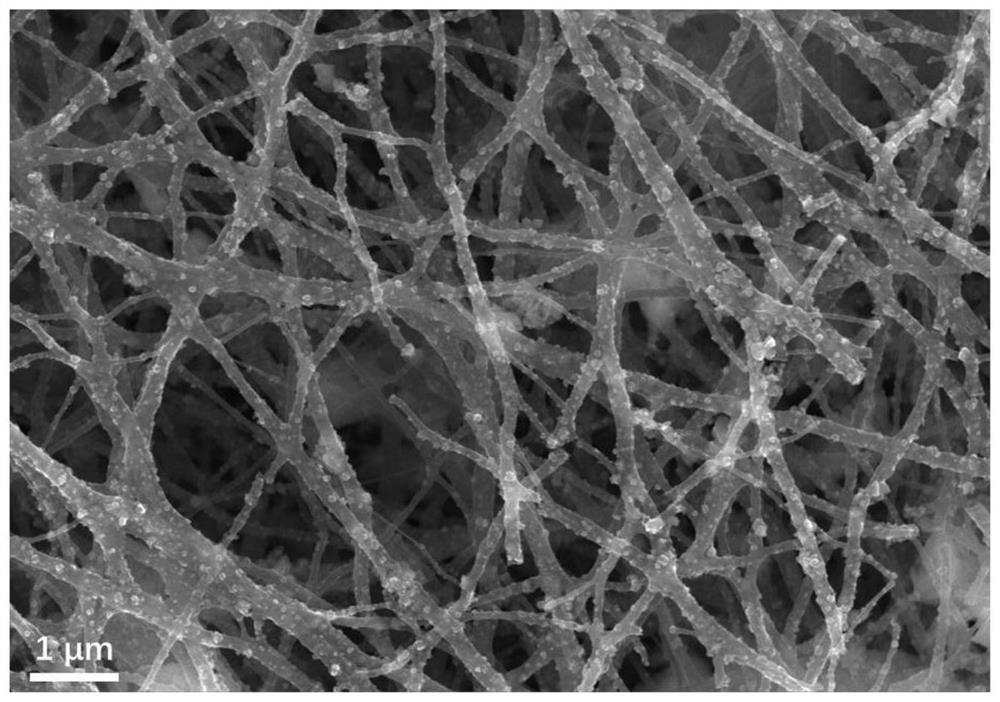

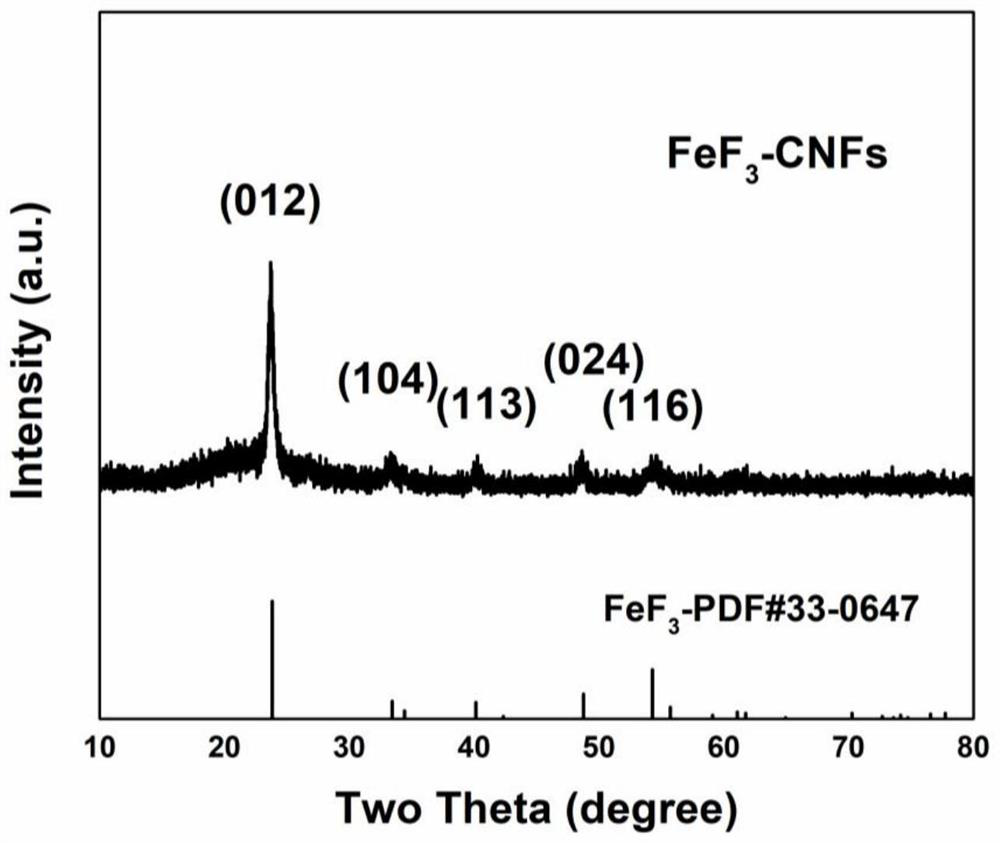

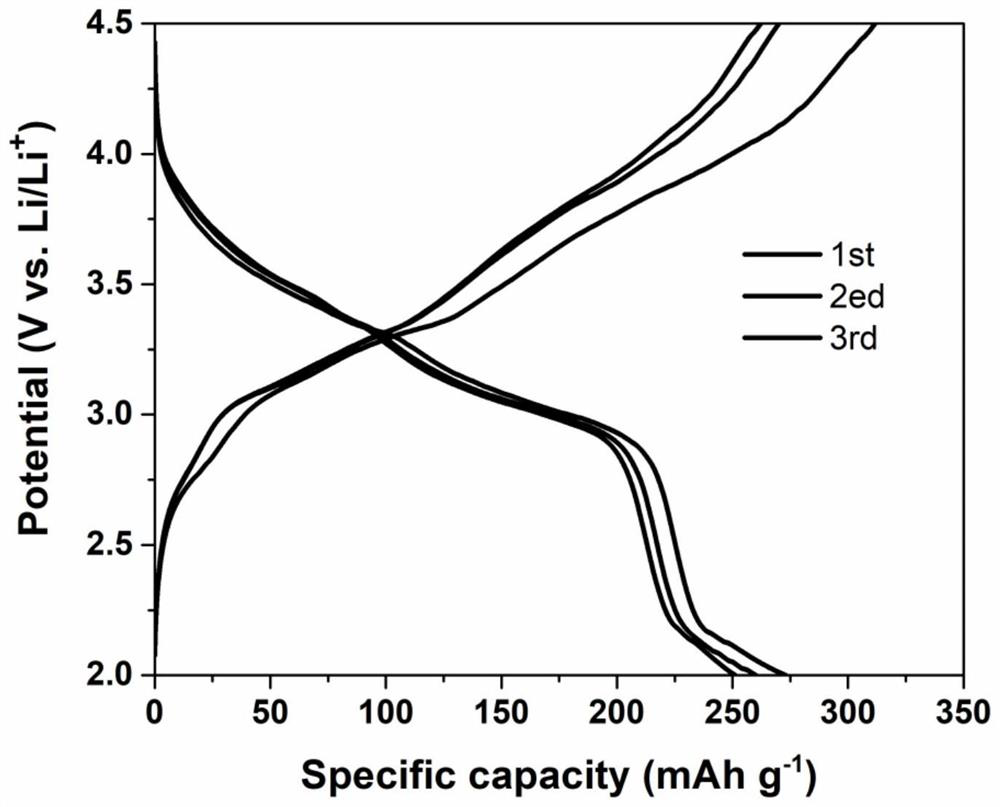

Self-supporting iron trifluoride-carbon nanofiber positive electrode material and preparation method thereof

A technology of carbon nanofibers and ferric trifluoride, applied in battery electrodes, circuits, electrical components, etc., can solve problems such as poor conductivity and volume expansion, and achieve the effects of improving poor conductivity, increasing the proportion, and alleviating volume expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Step 1: Weigh polyacrylonitrile and acetyl iron acetate according to the mass ratio of 2:1, dissolve them in 20ml of N,N-dimethylformamide; stir thoroughly for 16 hours, and then let stand for 1 hour after no obvious agglomeration and precipitation;

[0034] Step 2, put the precursor solution in step 1 into a 10ml syringe, and drain the air bubbles. The conditions of the electrospinning process are: negative pressure 3kV; positive pressure 16kV; glue pushing speed 0.6ml / h; distance between the needle and the receiver 18cm; ambient temperature controlled at about 30°C; ambient humidity controlled at about 28%;

[0035] Step 3, spread the composite fiber membrane obtained in step 2 in a blast drying oven, heat to 260°C at a heating rate of 5°C / min and keep it for 2 hours, then cool down naturally; then place the pre-oxidized membrane in a tubular In the furnace, under a nitrogen atmosphere, heat up to 800°C at a heating rate of 5°C / min and keep it for 2 hours, then cool d...

Embodiment 2

[0039] Step 1, weigh polyacrylonitrile and acetyl iron acetate according to the mass ratio of 1:2, dissolve in 20ml of N,N-dimethylformamide; stir thoroughly for 18 hours, and then let stand for 1 hour after no obvious agglomeration and precipitation;

[0040] Step 2, put the precursor solution in step 1 into a 10ml syringe, and drain the air bubbles. The conditions of the electrospinning process are: negative pressure 3kV; positive pressure 16kV; glue pushing speed 0.6ml / h; distance between the needle and the receiver 18cm; ambient temperature controlled at about 30°C; ambient humidity controlled at about 28%;

[0041] Step 3, spread the composite fiber membrane obtained in step 2 in a blast drying oven, heat to 260°C at a heating rate of 5°C / min and keep it for 2 hours, then cool down naturally; then place the pre-oxidized membrane in a tubular In the furnace, under a nitrogen atmosphere, heat up to 800°C at a heating rate of 5°C / min and keep it for 2 hours, then cool down t...

Embodiment 3

[0045] Step 1, weigh polyvinylpyrrolidone and ferric nitrate according to the mass ratio of 1:2, dissolve in 20ml of N,N-dimethylformamide; stir thoroughly for 12 hours, and then let stand for 1 hour after no obvious agglomeration and precipitation;

[0046] Step 2, put the precursor solution in step 1 into a 10ml syringe, and drain the air bubbles. The conditions of the electrospinning process are: negative pressure 3kV; positive pressure 16kV; glue pushing speed 0.6ml / h; distance between the needle and the receiver 18cm. The ambient temperature is controlled at about 30°C; the ambient humidity is controlled at about 28%;

[0047] Step 3, spread the composite fiber membrane obtained in step 2 in a blast drying oven, heat to 260°C at a heating rate of 5°C / min and keep it for 2 hours, then cool down naturally; then place the pre-oxidized membrane in a tubular In the furnace, under a nitrogen atmosphere, heat up to 800°C at a heating rate of 5°C / min and keep it for 2 hours, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com