Hollow negative electrode material and preparation method thereof and lithium ion battery containing hollow negative electrode material

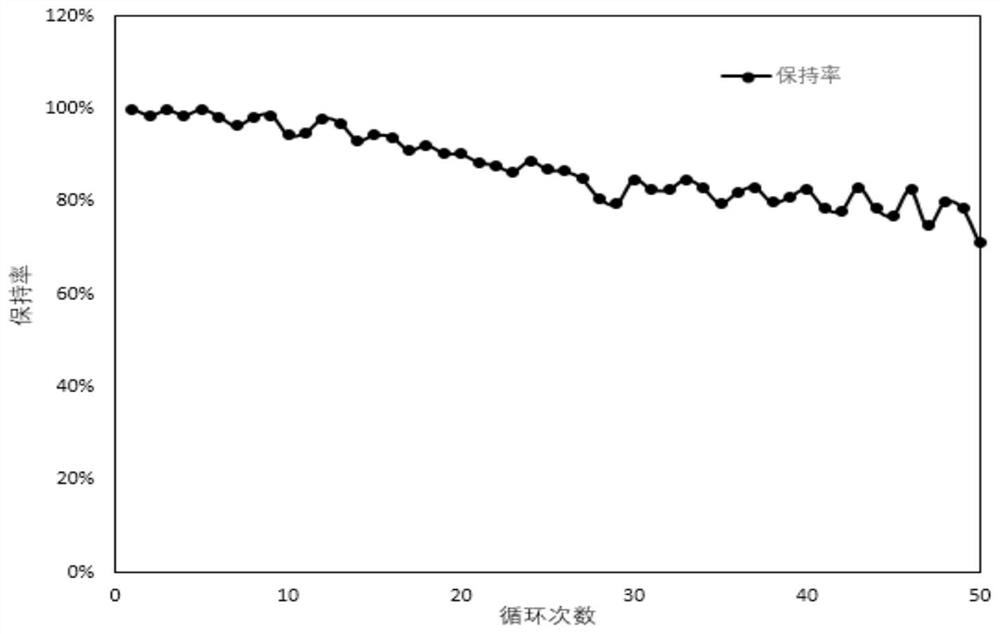

A negative electrode material, hollow technology, applied in the field of hollow negative electrode materials, its preparation method and lithium-ion batteries containing it, can solve the problems of poor coating uniformity of the silicon carbon core-shell structure, easy peeling off of the coating layer, etc., and achieve an increase in magnification and cycle performance, reducing material structure damage, and accelerating ion transport

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

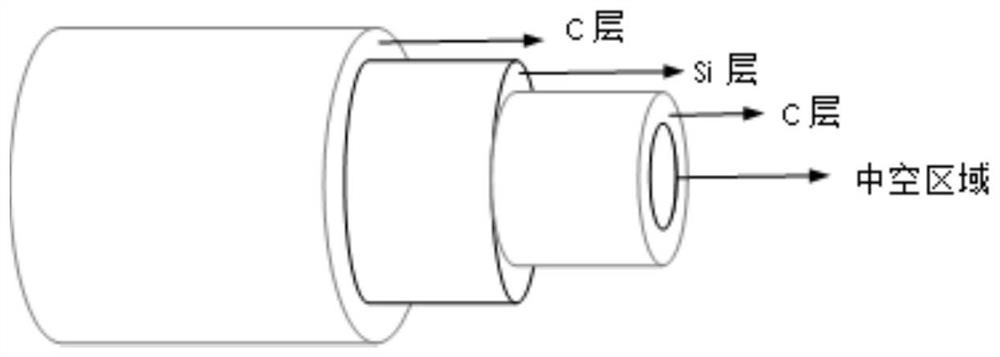

[0023] As described in the background technology, the existing negative electrode materials have the problem of poor coating uniformity of the silicon-carbon core-shell structure, and the coating layer is easy to fall off during repeated charging and discharging. In order to solve the above technical problems, the present application provides a method for preparing a hollow negative electrode material. The preparation method for the hollow negative electrode material includes: under an inert atmosphere, the template agent and the first carbon source are subjected to the first coating process to obtain carbon-coated template; make the carbon-coated template and polar solvent and tetraethyl orthosilicate carry out the second coating process to obtain a silica / carbon / template composite material; under an inert atmosphere, the Reducing the silicon dioxide / carbon / template composite material with a second carbon source to obtain a silicon / carbon / template composite material; removing ...

Embodiment 1

[0048] A carbon / silicon / carbon negative electrode material and a preparation method thereof, comprising:

[0049] Step 1: Add 50mg TiO to 45mL, 10mol / L sodium hydroxide aqueous solution 2 powder (P25 powder), stir until the P25 powder is evenly dispersed to obtain the mixed solution B;

[0050] Step 2: Transfer the mixed solution B to a polytetrafluoroethylene reactor, seal it and transfer it to an oven, and keep it warm at 180°C for 12 hours to obtain a suspension C;

[0051] Step 3: Filter the suspension C, wash it several times with deionized water, and then soak it in 0.1mol / L dilute hydrochloric acid until the supernatant becomes acidic. Filter, wash with deionized water until neutral, and dry at 70°C for 24 hours to obtain white powder D;

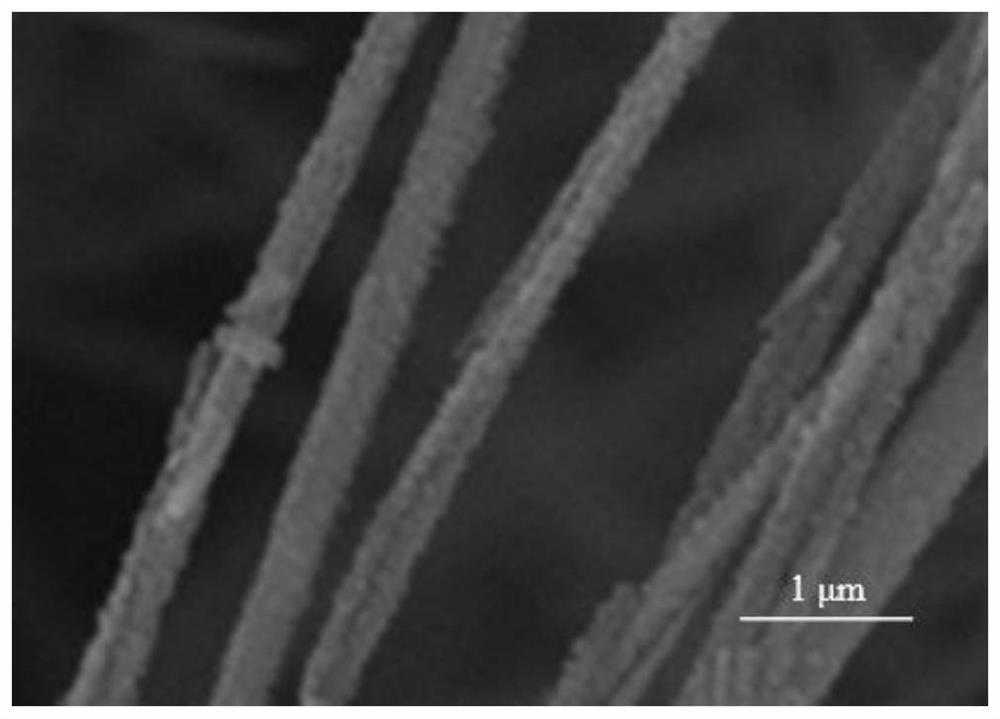

[0052] Step 4: Calcining the white powder D at 550°C for 2 hours in an air atmosphere to obtain the white powder E, which is TiO 2 Nanowire (diameter about 120nm, length about 10μm);

[0053] Step 5: Weigh 40mgTiO 2 nanowires, mi...

Embodiment 2

[0064] A carbon / silicon / carbon negative electrode material and a preparation method thereof, comprising:

[0065] Step 1: Add 50mg TiO to 45mL, 10mol / L sodium hydroxide aqueous solution 2 powder (P25 powder), stir until the P25 powder is evenly dispersed to obtain the mixed solution B;

[0066] Step 2: Transfer the mixed solution B to a polytetrafluoroethylene reactor, seal it and transfer it to an oven, and keep it warm at 200°C for 8 hours to obtain a suspension C;

[0067] Step 3: Filter the suspension C, wash it several times with deionized water, and then soak it in 0.15mol / L dilute hydrochloric acid until the supernatant becomes acidic. Filter, wash with deionized water until neutral, and dry at a certain temperature of 55°C for 22 hours to obtain white powder D;

[0068] Step 4: Calcining the white powder D at 500°C in an air atmosphere for 4 hours to obtain the white powder E, which is TiO 2 Nanowire (diameter about 150nm, length about 20μm);

[0069] Step 5: Weigh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| retention rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com