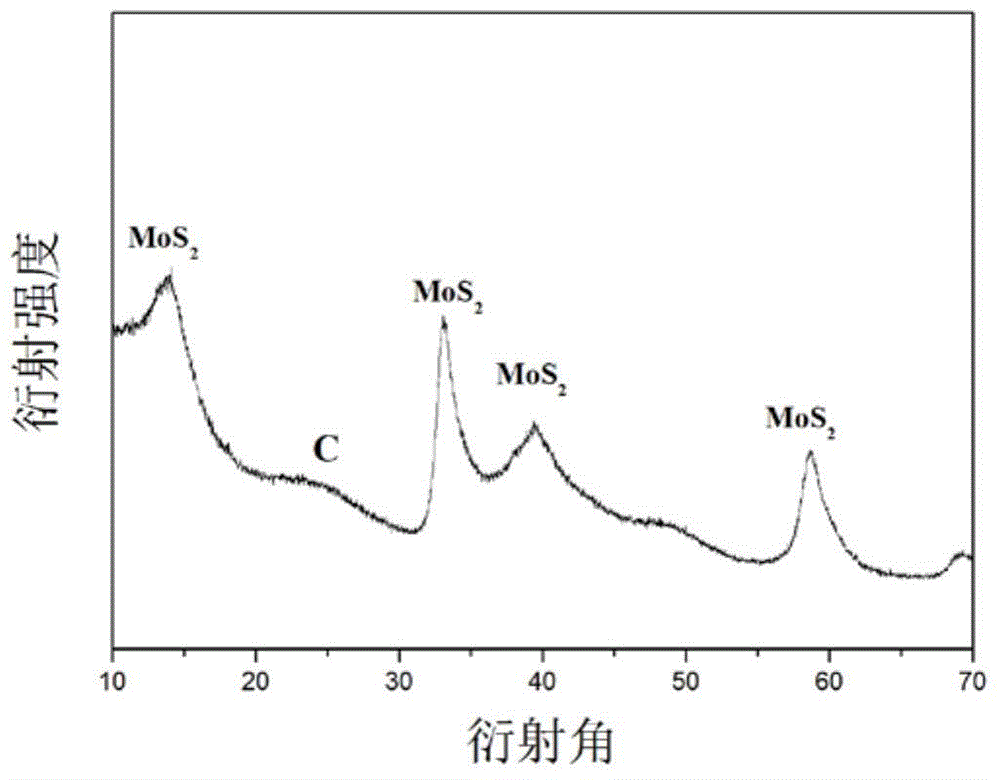

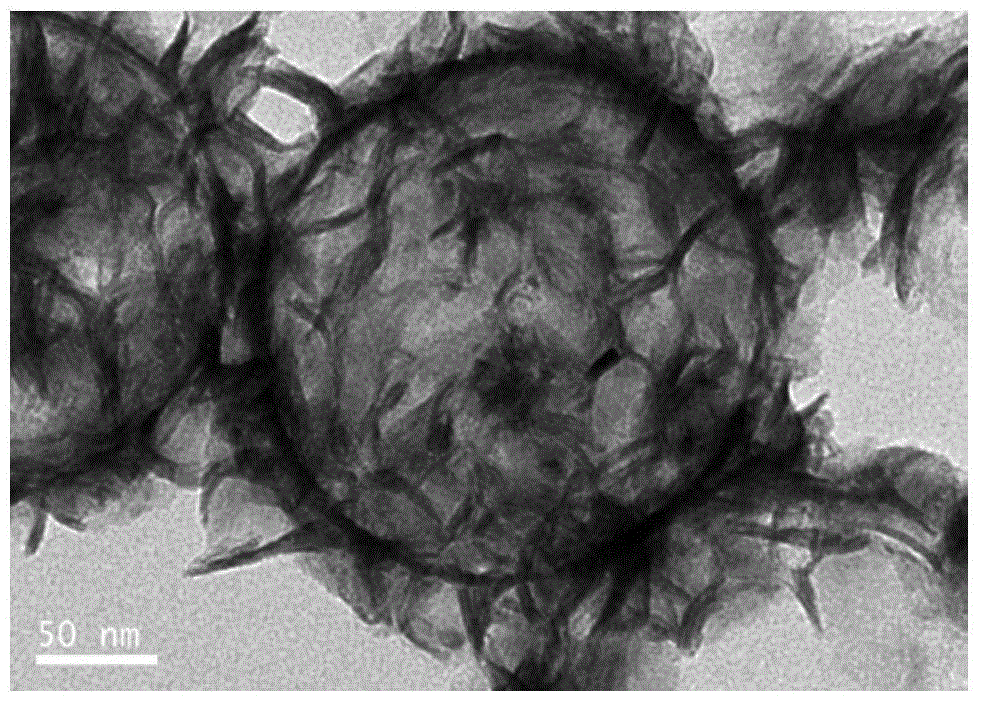

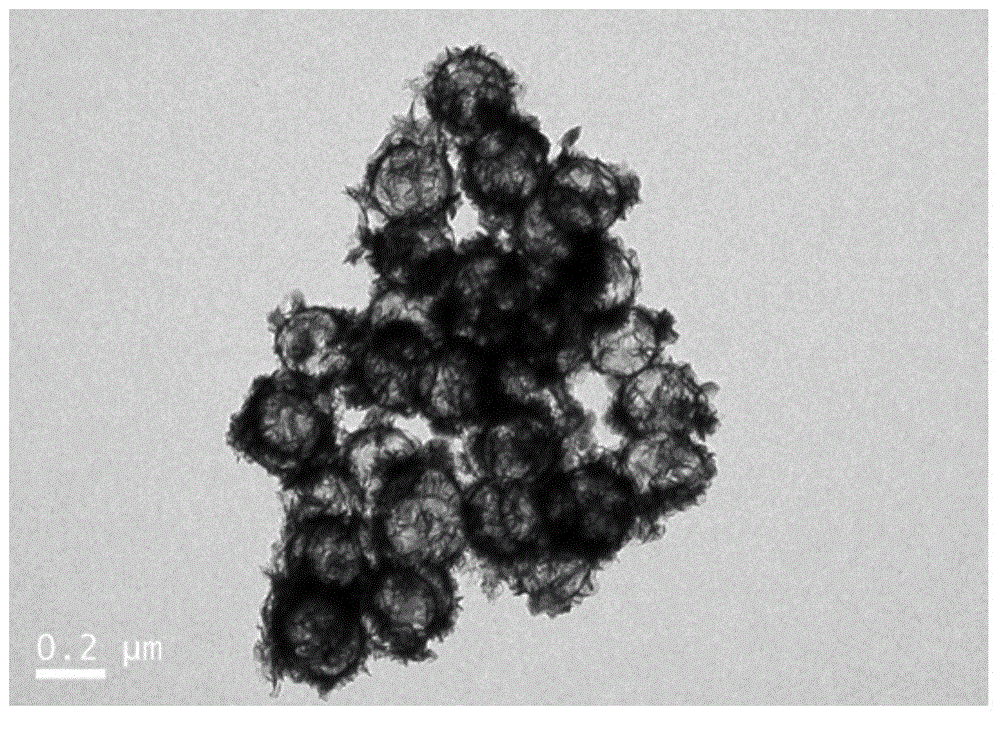

Molybdenum disulfide/carbon composite material and preparation method thereof

A carbon composite material and molybdenum disulfide technology, applied in the field of energy storage materials, can solve the problems of complex preparation process, poor electrical conductivity of molybdenum disulfide and high synthesis cost, and achieve the effect of simple process and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Preparation of negative electrode material (molybdenum disulfide / carbon composite material):

[0031] Step 1, at room temperature, add 1g of silica nanospheres (particle size about 200nm) to 50ml of anhydrous methanol, after ultrasonic treatment, then add 8ml of triaminopropyltriethoxysilane, and magnetically stir for 2 hours to form Suspension: centrifuging the suspension to obtain a first reaction product, washing the first reaction product with ethanol, and then drying the first reaction product, the dried first reaction product That is, amino-modified silica particles.

[0032]Step 2, add the amino-modified silicon dioxide particles (0.7g) and glucose (3g) obtained in the step 1 into 70ml of aqueous solution, stir vigorously for 2 hours and then pour them into a 100ml first reaction kettle, and then put the The first reaction kettle was heated from room temperature to 180°C, and kept at 180°C for 4 hours, and then the product in the first reaction kettle was ce...

Embodiment 2

[0045] Preparation of negative electrode material (molybdenum disulfide / carbon composite material):

[0046] Step 1, at room temperature, add 0.5g of silica nanospheres (particle size about 250nm) to 3ml of anhydrous methanol, after ultrasonic treatment, then add 473ul of triaminopropyltriethoxysilane, and stir magnetically for 0.5 hours forming a suspension; centrifuging the suspension to obtain a first reaction product, washing the first reaction product with ethanol, and then drying the first reaction product, and the first reaction product after drying The product is amino-modified silica particles.

[0047] Step 2, add the amino-modified silica particles (0.5g) and glucose (2g) obtained in the step 1 into 30ml of aqueous solution, stir vigorously for 0.5 hours and then pour them into a 50ml first reaction kettle, and then put the The first reaction kettle was heated from room temperature to 200°C, and kept at 200°C for 5 hours, and then the product in the first reaction ...

Embodiment 3

[0052] Preparation of negative electrode material (molybdenum disulfide / carbon composite material):

[0053] Step 1, at room temperature, add 2g of silica nanospheres (particle size about 50nm) to 70ml of anhydrous methanol, after sonication, then add 1.8ml of triaminopropyltriethoxysilane, and stir magnetically for 0.5 hours forming a suspension; centrifuging the suspension to obtain a first reaction product, washing the first reaction product with ethanol, and then drying the first reaction product, and the first reaction product after drying The product is amino-modified silica particles.

[0054] Step 2, add the amino-modified silica particles (1g) and glucose (10g) obtained in the step 1 into 80ml of aqueous solution, stir vigorously for 2 hours and pour them into a 100ml first reaction kettle, and then put the second A reaction kettle was heated from room temperature to 160°C, and kept at 160°C for 8 hours, and then the product in the first reaction kettle was centrifug...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com