Lithium ion battery electrolyte suitable for silicon carbon material and application of electrolyte

A lithium-ion battery, silicon carbon material technology, applied in secondary batteries, circuits, electrical components, etc., can solve the problems of poor cycle performance, unstable electrode/electrolyte interface properties, etc. Contact, improve the effect of interface composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The preparation method of the lithium-ion battery electrolyte adapted to the silicon-carbon material comprises the following steps:

[0033] 1) mixing a cyclic carbonate solvent and a linear carbonate solvent, and purifying to obtain an organic solvent;

[0034] 2) Mix and stir the electrolyte lithium salt, functional additives, auxiliary additives, and the organic solvent obtained in step 1) at room temperature to obtain the above-mentioned lithium-ion battery electrolyte suitable for silicon-carbon materials.

[0035] Preferably, in step 1) of the electrolyte preparation method, the specific method of purification is to process the mixed solvent through molecular sieves; further preferably, the model of the molecular sieves is type, type or Type; Further preferably, the model of the molecular sieve is type or type.

[0036] Preferably, in step 2) of the electrolyte preparation method, the room temperature refers to a temperature of 25°C to 40°C.

[0037] A ...

Embodiment 1

[0051] Example 1 takes a button-type silicon carbon battery as an example, and the specific preparation method is as follows:

[0052] (1) The cyclic carbonate solvent ethylene carbonate (EC) and the linear carbonate solvent ethyl methyl carbonate (EMC) and dimethyl carbonate (DMC) are mass ratio EC:EMC:DMC=3:5:2 mix and use Type molecular sieve, calcium hydride, lithium hydride to purify and remove impurities and water to obtain non-aqueous organic solvent;

[0053] (2) At room temperature, add the electrolyte lithium salt lithium bistrifluoromethanesulfonimide (LiTFSi) to the solvent obtained in step (1), the final concentration is 1.0mol / L, stir well, and obtain a common electrolyte ;

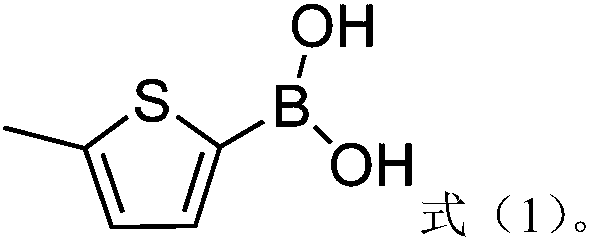

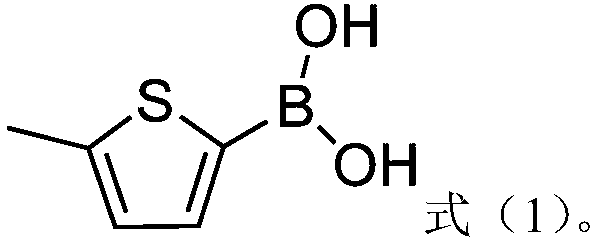

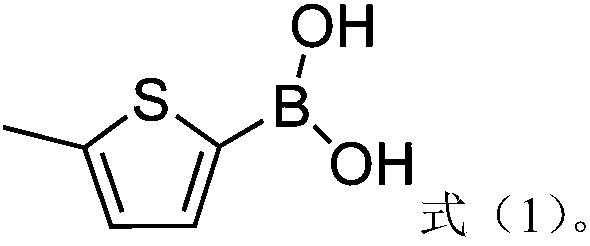

[0054] (3) Add functional additive 5-methylthiophene-2-boronic acid to the ordinary electrolyte obtained in step (2), the mass percentage of the functional additive in the electrolyte is 1%, suitable for high energy density silicon carbon Lithium-ion electrolyte for negative electrode ma...

Embodiment 2

[0060] A lithium ion battery was prepared according to the method of Example 1, except that the mass percentage of the functional additive in the electrolyte was 0.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com