Preparation method of one-pot method double-coated lithium ion battery NCM ternary positive electrode material

A technology of lithium-ion batteries and positive electrode materials, applied in battery electrodes, electrical components, secondary batteries, etc., can solve problems such as safety and capacity attenuation, and achieve the effects of improving economic benefits, low prices, and improving electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

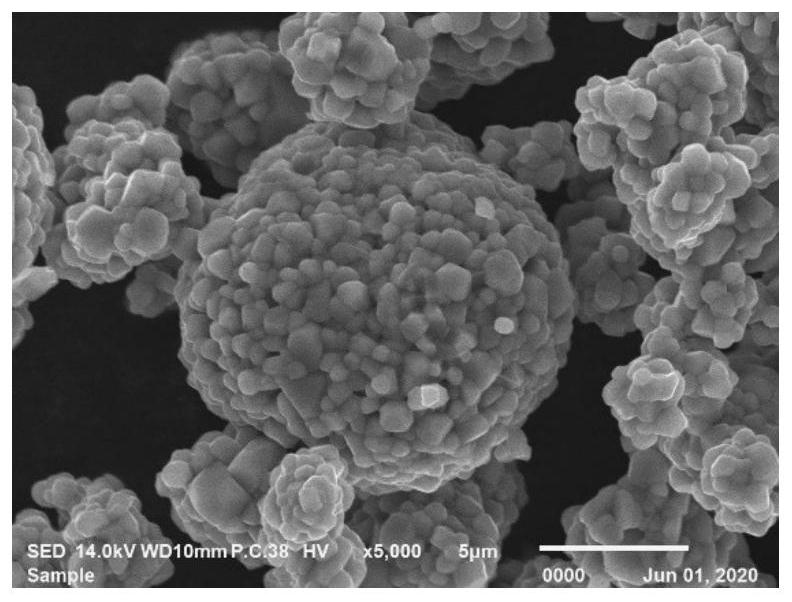

[0030] Step 1, 1g of Li(Ni) before coating 0.5 co 0.2 mn 0.3 )O 2 (Such as figure 1 Shown) is dispersed in 140ml water and 60ml ethanol mixed solvent;

[0031] Step 2, choose TiO 2 As the oxide coating layer, slowly add 0.64g resorcinol, 0.96ml formaldehyde, 0.64ml ethylenediamine, 3ml ammonia water and 0.3ml tetrabutyl titanate at a speed of 300r / min while stirring, and stir for 6h. C in an alkaline environment 16 h 36 o 4 Hydrolysis of Ti to form nano-TiO 2 The layer is coated on the surface of the ternary material, and resorcinol, formaldehyde and ethylenediamine are polymerized to form polybenzoxazine (PB) polymer coated on TiO 2 surface;

[0032] Step 3, after dispersing the filtered material, put it into an oven at 120°C for 10 hours to obtain a TiO 2 and polybenzoxazine PB-coated Li(Ni 0.5 co 0.2 mn 0.3 )O 2 Cathode material.

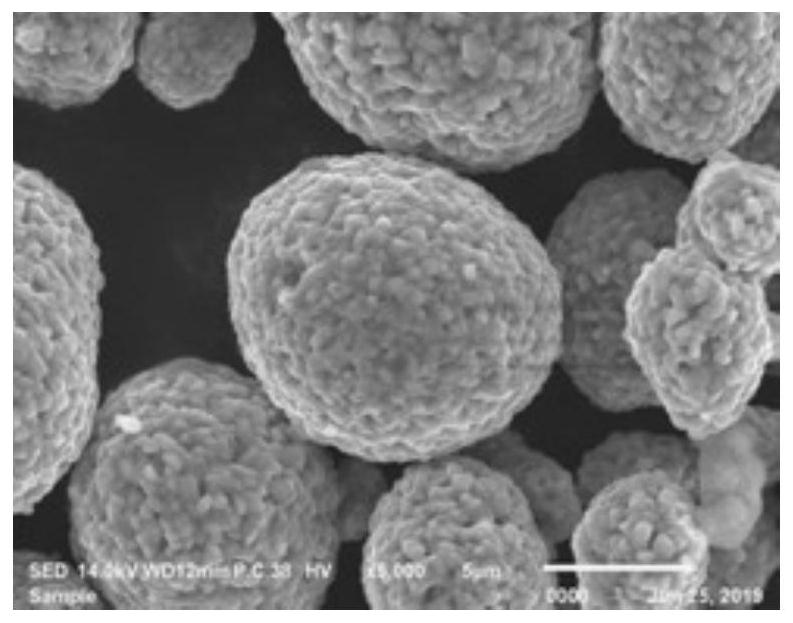

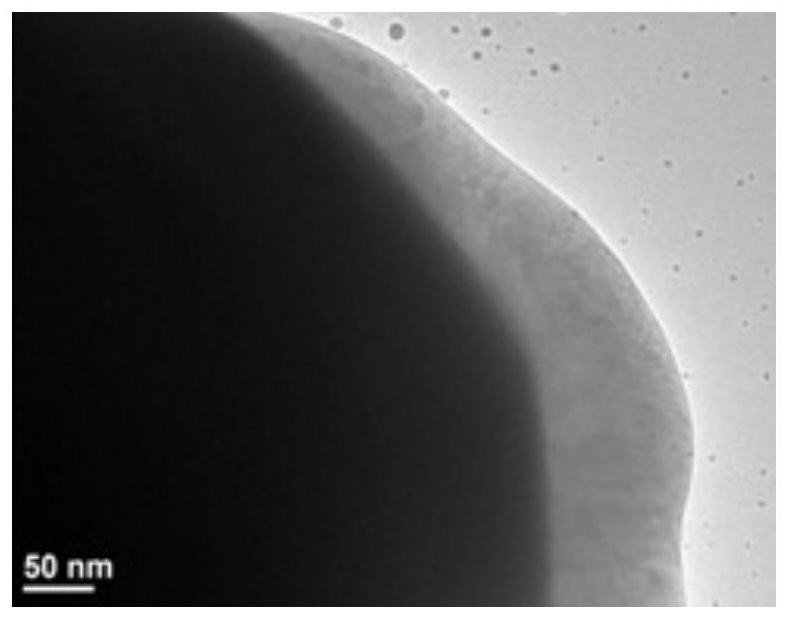

[0033] Such as figure 2 and 3 As shown in the SEM image and TEM coating on the surface of the material, the coated material a...

Embodiment 2

[0035] Step 1, 1gLi(Ni 0.8 co 0.1 mn 0.1 )O 2 Disperse in 140ml water and 60ml ethanol mixed solvent;

[0036] Step two, choose Al 2 o 3 As the oxide coating layer, slowly add 0.64g of ammonium persulfate, 1ml of pyrrole and 0.3g of aluminum isopropoxide while stirring at a speed of 600r / min, stir for 10h, and the aluminum isopropoxide is hydrolyzed to form nano-Al 2 o 3 Layer coated on the surface of the ternary material, pyrrole under the action of ammonium persulfate to form polypyrrole coated on Al 2 o 3 surface;

[0037] Step 3, after dispersing the filtered material, put it in an oven at 100°C for 5 hours to obtain 2 o3 and polypyrrole-coated Li(Ni 0.8 co 0.1 mn 0.1 )O 2 Cathode material.

[0038] Table 1: Carbon-coated Li(Ni 08 co 01 mn 01 )O 2 Comparison of data before and after

[0039]

[0040]

[0041] As shown in Table 1, carbon-coated Li(Ni 0.8 co 0.1 mn 0.1 )O 2 The specific capacity is significantly improved, the amount of residual a...

Embodiment 3

[0043] Step 1, 1g Li(Ni 0.8 co 0.1 mn 0.1 )O 2 Disperse in 120ml water and 60ml ethanol mixed solvent;

[0044] Step 2, choose SiO 2 As the oxide coating layer, continue to slowly add 0.5g dopamine hydrochloride and 3ml tetraethyl orthosilicate while stirring at a speed of 500r / min, stir for 10h, and tetraethyl orthosilicate is hydrolyzed to form nano-SiO 2 Layer coated on the surface of the ternary material, dopamine hydrochloride under alkaline conditions to form polydopamine coated in SiO 2 surface;

[0045] Step 3, after dispersing the filtered material, put it in an oven at 100°C for 5 hours to obtain a SiO 2 and polydopamine-coated Li(Ni 0.8 co 0.1 mn 0.1 )O 2 Cathode material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com