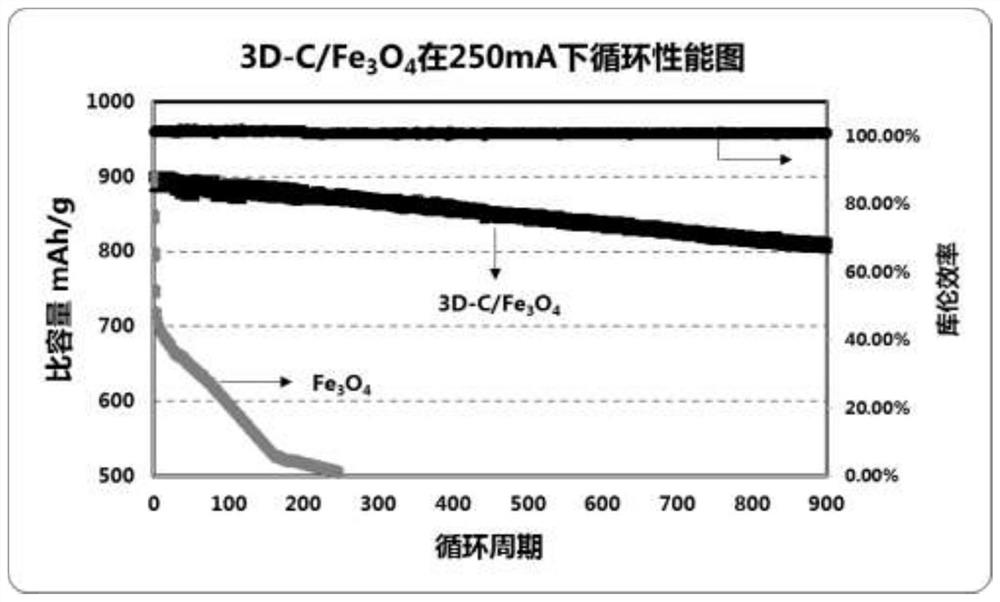

Three-dimensional C/Fe3O4 lithium ion battery negative electrode material and preparation method thereof

A technology for lithium ion batteries and negative electrode materials, applied in battery electrodes, secondary batteries, nanotechnology for materials and surface science, etc., can solve the problems of large volume change and poor conductivity of negative electrode materials, and improve adsorption performance. , Improve the binding ability, promote the effect of load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

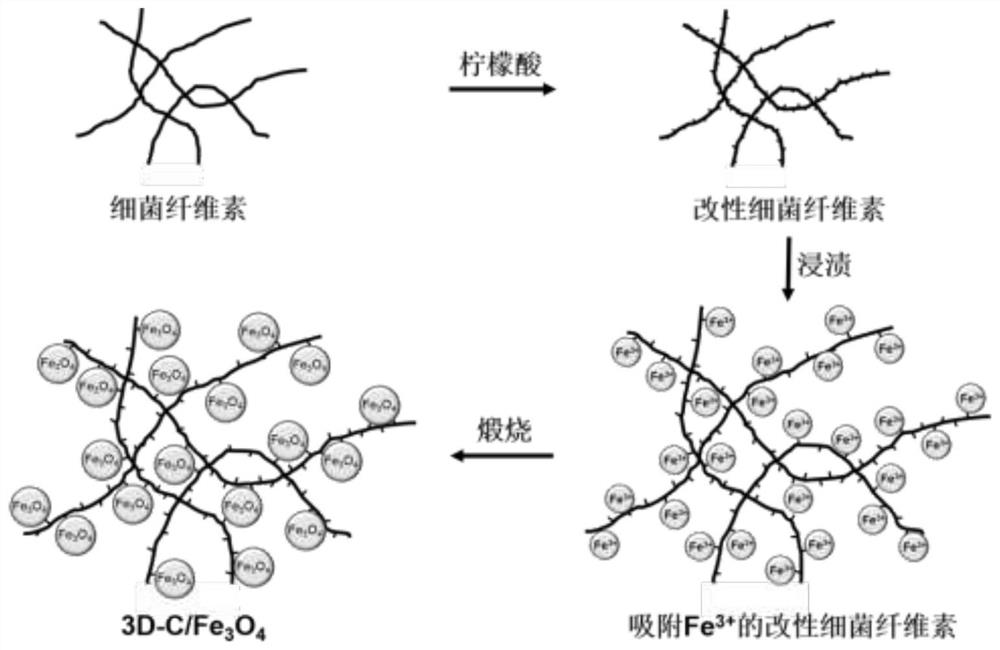

[0026] Preparation of citric acid modified bacterial cellulose:

[0027] Dissolve 3.84g of citric acid in 200mL of water to prepare an aqueous solution of citric acid, then add 5g of bacterial cellulose with a diameter of 40-60nm into the aqueous solution of citric acid and stir at 20°C for 30 minutes, then wash until the pH is 6-7. After drying, the citric acid modified bacterial cellulose was obtained.

[0028] Preparation of three-dimensional C / Fe 3 o 4 Lithium-ion battery anode materials:

[0029] S1, 1.35g FeCl 3 ·6H 2 O was dissolved in 20mL water to prepare FeCl 3 ·6H 2 O aqueous solution, then add 5g of the above-mentioned citric acid-modified bacterial cellulose to FeCl 3 ·6H 2 In the aqueous solution of O, soak at 30°C for 5 hours, then filter and dry, and repeat the soaking, filtering and drying twice;

[0030] S2. Raise the material obtained in step S1 to 300°C at a rate of 3°C / min in a nitrogen atmosphere, keep it warm for 1h, and obtain a three-dimension...

Embodiment 2

[0032] Preparation of citric acid modified bacterial cellulose:

[0033] Dissolve 11.52g of citric acid in 200mL of water to prepare an aqueous solution of citric acid, then add 5g of bacterial cellulose with a diameter of 40-60nm into the aqueous solution of citric acid and stir at 80°C for 60min, then wash until the pH is 6-7. After drying, the citric acid modified bacterial cellulose was obtained.

[0034] Preparation of three-dimensional C / Fe 3 o 4 Lithium-ion battery anode materials:

[0035] S1, 33.83g FeCl 3 ·6H 2 O was dissolved in 100mL water to prepare FeCl 3 ·6H 2 O aqueous solution, then add 5g of the above-mentioned citric acid-modified bacterial cellulose to FeCl 3 ·6H 2 In the aqueous solution of O, soak at 40°C for 8 hours, then filter and dry, repeat the soak, filter and dry for 3 times;

[0036] S2. Raise the material obtained in step S1 to 500°C at a heating rate of 6°C / min in a nitrogen atmosphere, keep it warm for 3 hours, and obtain a three-dimen...

Embodiment 3

[0038] Preparation of citric acid modified bacterial cellulose:

[0039] Dissolve 10g of citric acid in 200mL of water to prepare an aqueous solution of citric acid, then add 5g of bacterial cellulose with a diameter of 40-60nm into the aqueous solution of citric acid and stir at 60°C for 40min, then wash until the pH is 6-7, and dry After drying, the citric acid modified bacterial cellulose was obtained.

[0040] Preparation of three-dimensional C / Fe 3 o 4Lithium-ion battery anode materials:

[0041] S1, first 13.5g FeCl 3 ·6H 2 O was dissolved in 50mL water to prepare FeCl 3 ·6H 2 O aqueous solution, then add 5g of the above-mentioned citric acid-modified bacterial cellulose to FeCl 3 ·6H 2 In the aqueous solution of O, soak at 35°C for 6 hours, then filter and dry, and repeat the soaking, filtering and drying twice;

[0042] S2. Raise the material obtained in step S1 to 400°C at a rate of 5°C / min in a nitrogen atmosphere, keep it warm for 2 hours, and obtain a thre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com