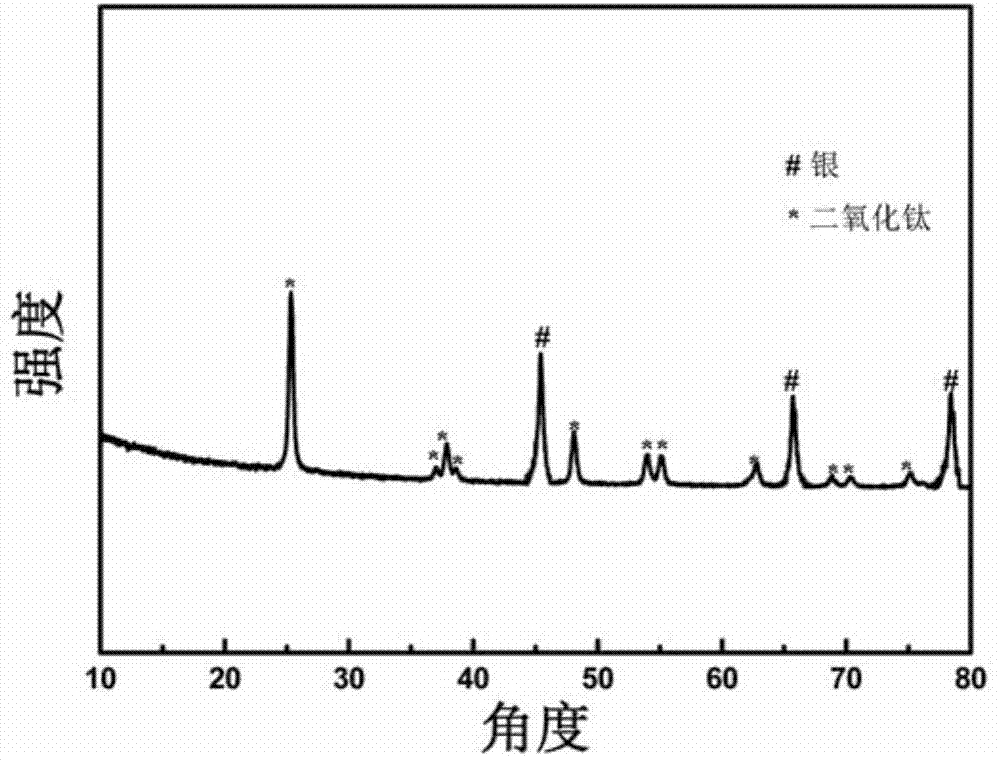

Preparation method of silver-loaded titanium dioxide anode material

A technology of titanium dioxide and negative electrode materials, which is applied in the field of preparation of silver-supported titanium dioxide negative electrode materials, can solve the problems of poor conductivity of titanium dioxide, achieve low price, improve poor conductivity, and enhance the effect of electron transmission speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

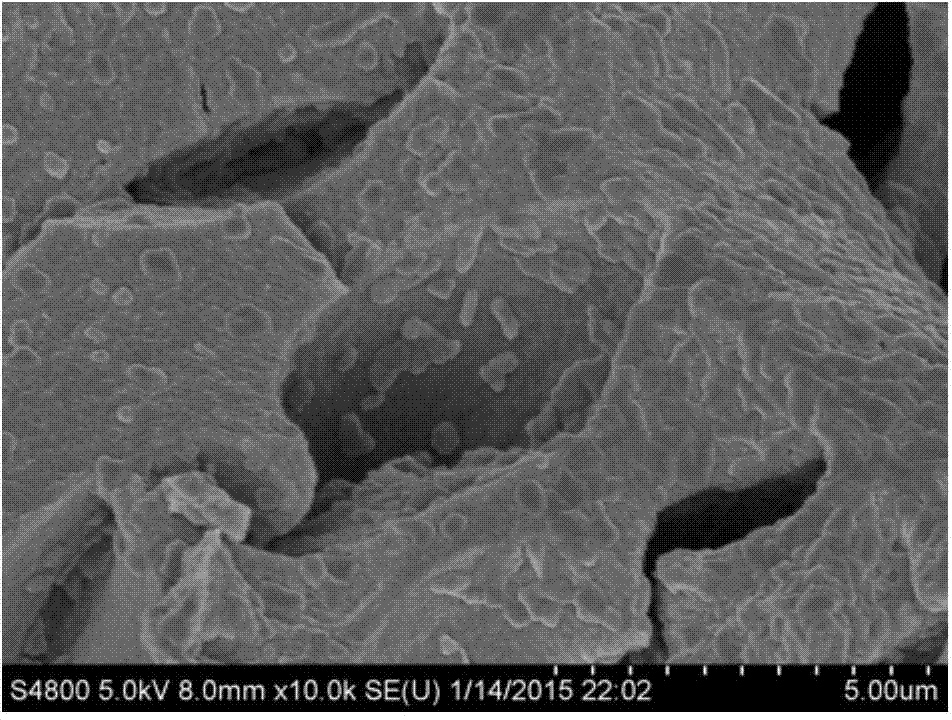

Embodiment 1

[0040] Example 1. A method for preparing a silver-supported titanium dioxide anode material, followed by the following steps:

[0041] 1) Stir 2 ml of deionized water and 0.6 ml of ethylene glycol, and then add 1 g of titanyl sulfate and stir for 2 hours. At this time, the titanyl sulfate is completely dissolved and a clear solution I is obtained.

[0042] 2) Add 0.2 g of polyvinylpyrrolidone to the above solution I, and after stirring for 30 minutes, the polyvinylpyrrolidone is completely dissolved to obtain a light yellow solution II.

[0043] 3). Under vigorous stirring, slowly add 0.5 ml of formamide dropwise (the dropping time is 1 minute) to the solution II obtained in step 2), and perform gel aging at 60°C for 2 hours, and then the obtained gel Dry at 60°C for 12 hours to obtain a dry gel.

[0044] 4). Dissolve 0.2 g of silver nitrate in 20 ml of ethylene glycol to obtain a mixed solution, then add 0.5 g of the dry gel obtained in step 3), stand for 12 hours in a 60℃ water bath...

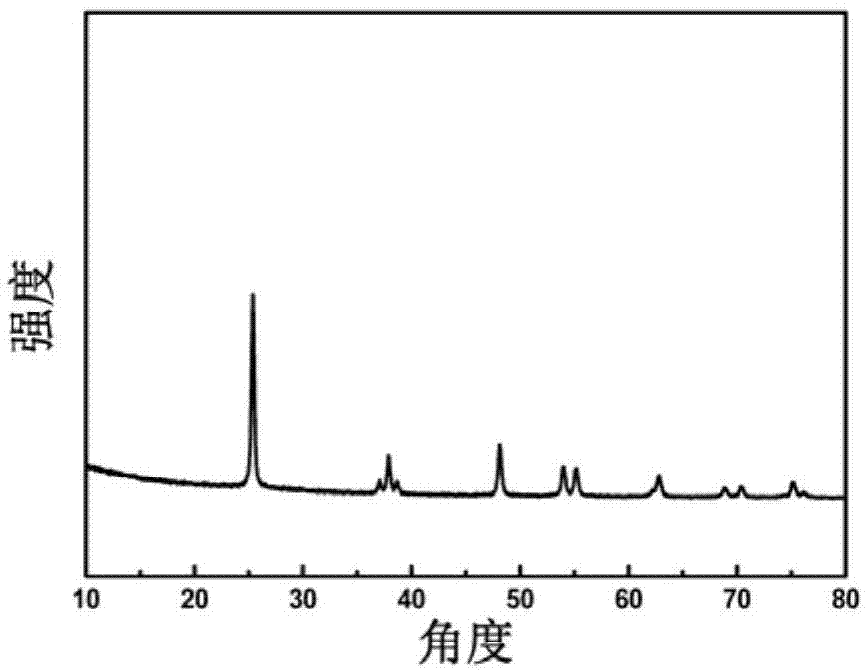

Embodiment 2

[0047] Example 2. A method for preparing silver-loaded titanium dioxide anode material, which includes the following steps:

[0048] 1) Stir 2 ml of deionized water and 0.6 ml of ethylene glycol, and then add 1 g of titanyl sulfate and stir for 2 hours. At this time, the titanyl sulfate is completely dissolved and a clear solution I is obtained.

[0049] 2) 0.3 g of polyvinylpyrrolidone is added to the above solution I, and the polyvinylpyrrolidone is completely dissolved after stirring for 30 minutes to obtain a light yellow solution II.

[0050] 3). Under vigorous stirring, slowly add 0.5 ml of formamide dropwise (the dropping time is 1 minute) to the solution II obtained in step 2). The gel is aged at 60°C for 2 hours, and then the gel is heated at 60°C. Dry at ℃ for 12 hours to obtain a dry gel.

[0051] 4). Dissolve 0.2 g of silver nitrate in 20 ml of ethylene glycol to obtain a mixed solution, add 0.5 g of the dry gel obtained in step 3), stand for 12 hours in a water bath at 60...

Embodiment 3

[0054] Embodiment 3. A method for preparing silver-supported titanium dioxide anode material, which includes the following steps in sequence:

[0055] 1) Stir 2 ml of deionized water and 0.6 ml of ethylene glycol, and then add 1 g of titanyl sulfate and stir for 2 hours. At this time, the titanyl sulfate is completely dissolved and a clear solution I is obtained.

[0056] 2) Add 0.5 g of polyvinylpyrrolidone to the above-mentioned solution I, and after stirring for 30 minutes, the polyvinylpyrrolidone is completely dissolved to obtain a light yellow solution II.

[0057] 3). Under vigorous stirring, slowly add 0.5 ml of formamide dropwise (the dropping time is 1 minute) to the solution II obtained in step 2). The gel is aged at 60°C for 2 hours, and then the gel is heated at 60°C. Dry at ℃ for 12 hours to obtain a dry gel.

[0058] 4). Dissolve 0.2 g of silver nitrate in 20 ml of ethylene glycol to obtain a mixed solution, then add 0.5 g of the dry gel obtained in step 3), stand for 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com