Oxygen evolution/hydrogen evolution two-dimensional cobalt monoxide-coated cobalt diselenide-coated nitrogen-doped carbon nanotube/graphene bifunctional composite catalyst

A composite catalyst, cobalt diselenide technology, applied in physical/chemical process catalysts, catalyst activation/preparation, chemical instruments and methods, etc., to improve catalytic activity and stability, high conductivity, and facilitate the transfer of electrons Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] CoO@CoSe 2 Preparation of @N-CNTs / rGO-500

[0036] GO was prepared by a modified Hummers method. Weigh 1 g flake graphite and 20 g NaCl, mix and grind for 15 min, and use deionized water to wash away NaCl by vacuum filtration. Wet graphite powder was vacuum-dried at 60°C for 30min, then transferred to a 250mL round bottom flask, then added 23mL of concentrated sulfuric acid and magnetically stirred for 24h, then heated to 35°C and added 0.5g NaNO under stirring 3 . After 5 min, the suspension was transferred to an ice bath, and 3 g of KMnO was added very slowly with stirring 4 And control the temperature of the system below 20°C, then heat at 35°C for 120min with stirring, slowly add 46mL of deionized water, heat to 98°C and stir for 30min. When the mixture was cooled to room temperature, stirring was continued for 30 min, and then 140 mL of deionized water and 10 mL of 30 wt% H 2 o 2 . The precipitate was centrifuged, washed five times with 5wt% HCl solution and...

Embodiment 2

[0042] With CoO@CoSe 2 @N-CNTs / rGO-450 is a bifunctional catalyst for OER and HER.

[0043] According to the method of Example 1 in CoO@CoSe 2 The selenization temperature of @N-CNTs / rGO-500 was 450℃ to prepare CoO@CoSe 2 @N-CNTs / rGO-450.

[0044] The evaluation method of catalytic performance is the same as in Example 1.

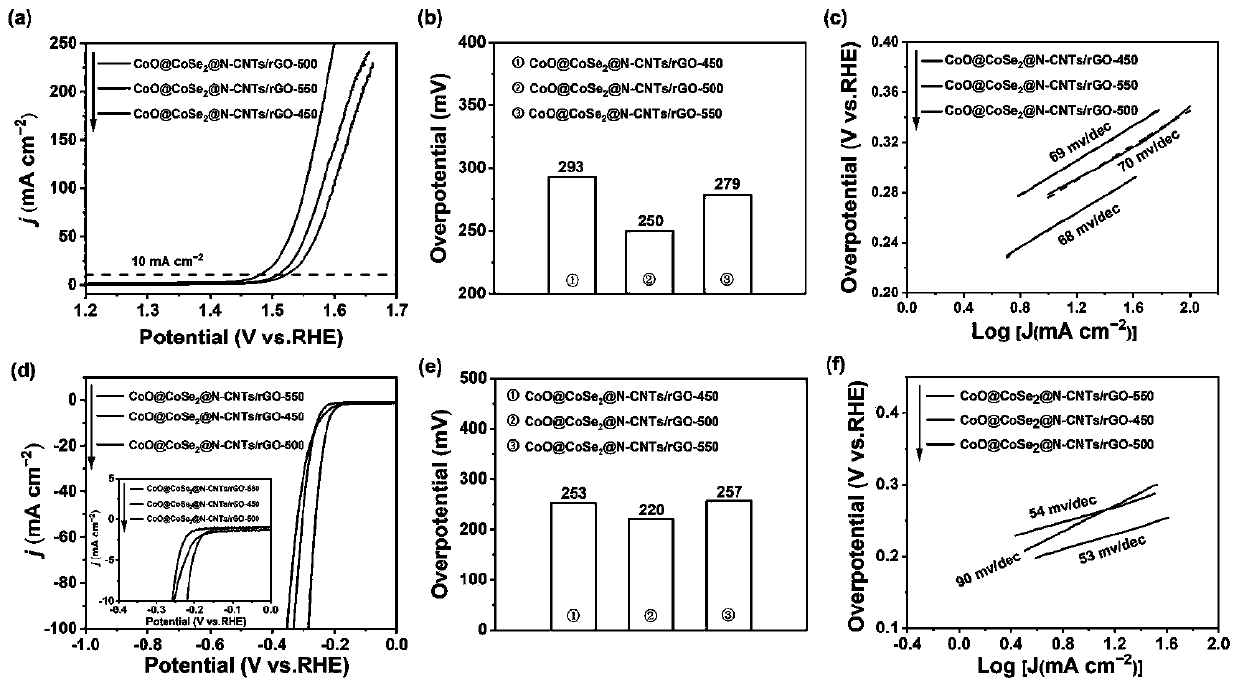

[0045] CoO@CoSe 2 The onset potential of @N-CNTs / rGO-450 as an OER catalyst is 1.426 V (vs. RHE). At a current density of 10mA / cm 2 , the required overpotential η is 293mV (vs.RHE). The Tafel slope is 69mV / dec.

[0046] CoO@CoSe 2 The onset potential of @N-CNTs / rGO-450 as a HER catalyst is close to 0 (vs. RHE). At a current density of 10mA / cm 2 , the required overpotential η is 253mV (vs.RHE). The Tafel slope is 90mV / dec.

Embodiment 3

[0048] With CoO@CoSe 2 @N-CNTs / rGO-550 is a bifunctional catalyst for OER and HER.

[0049] According to the method of Example 1 in CoO@CoSe 2 The selenization temperature of @N-CNTs / rGO-550 was 550℃ to prepare CoO@CoSe 2 @N-CNTs / rGO-550.

[0050] The evaluation method of catalytic performance is the same as in Example 1.

[0051] CoO@CoSe 2 The onset potential of @N-CNTs / rGO-550 as an OER catalyst is 1.415 V (vs. RHE). At a current density of 10mA / cm 2 , the required overpotential η is 279mV (vs.RHE). The Tafel slope is 70mV / dec.

[0052] CoO@CoSe 2 The onset potential of @N-CNTs / rGO-550 as a HER catalyst is -0.089 V (vs. RHE). At a current density of 10mA / cm 2 , the required overpotential η is 257mV (vs.RHE). The Tafel slope is 54mV / dec.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com