Flexible integrated lithium-sulfur battery positive electrode material and preparation method thereof

A technology for lithium-sulfur batteries and positive electrode materials, applied in battery electrodes, lithium batteries, electrode manufacturing, etc., can solve the problems of low active ingredient loading, poor cycle stability, and poor conductivity, so as to save electrode preparation process and improve electrical conductivity Poor performance and improved insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

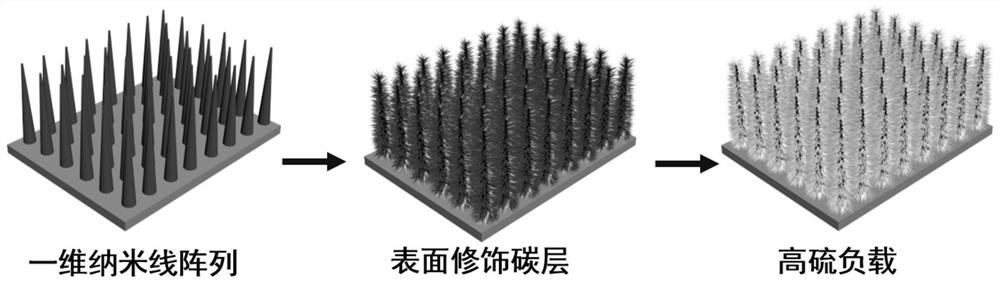

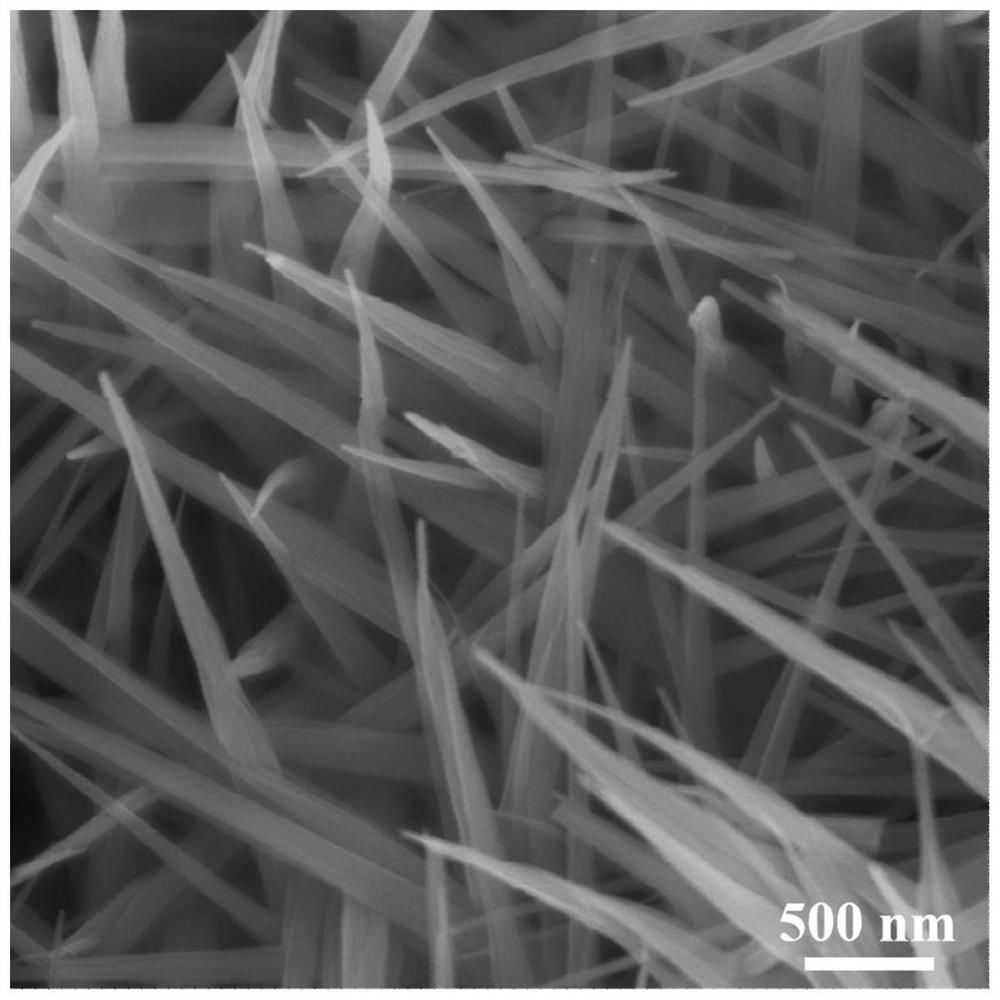

[0025] a: Prepare 100 mL of a mixed solution of 5 mM cobalt nitrate and 25 mM urea, ultrasonically disperse it and transfer it to a reactor, place the nickel foam substrate in the reactor, and then react at a high temperature of 120 ° C for 6 h; obtain in situ grown one-dimensional cobalt hydroxide Nickel foam with nanowire arrays;

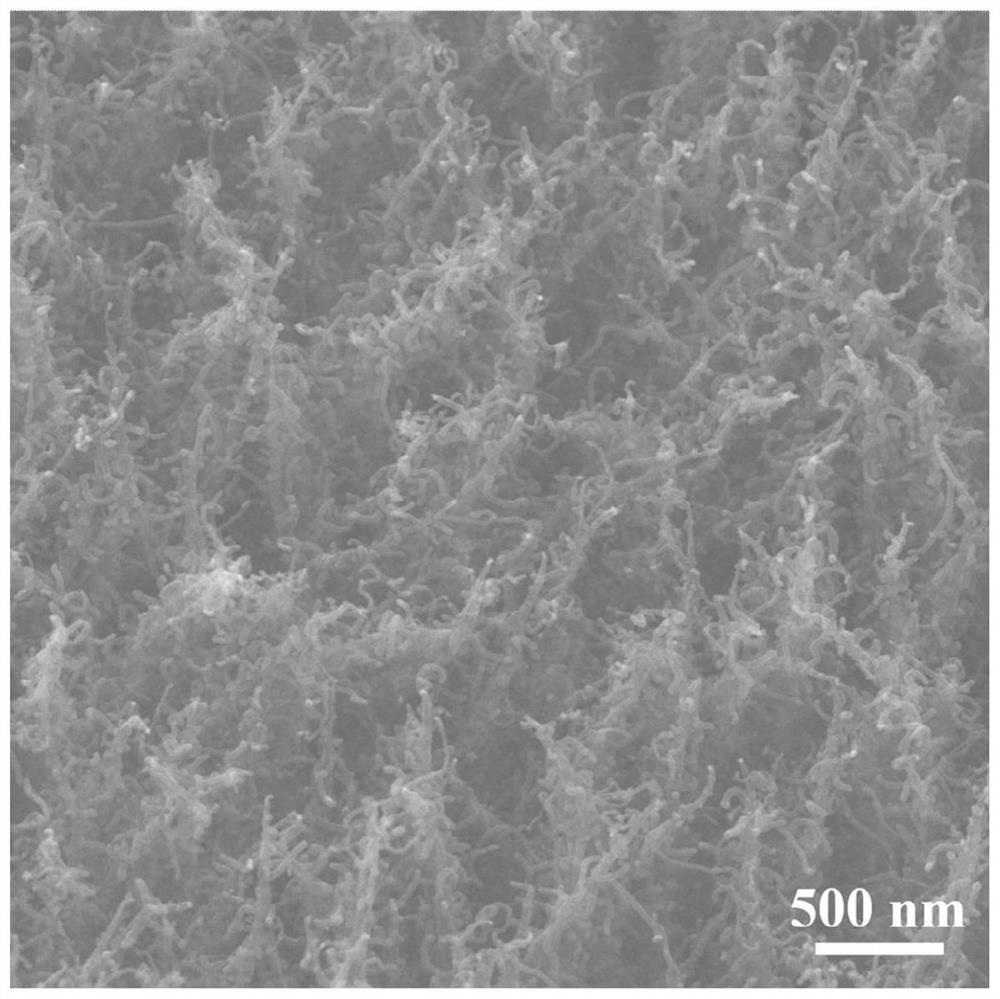

[0026] b: The prepared nickel foam for in-situ growth of one-dimensional cobalt hydroxide nanowire arrays is placed in an atmosphere furnace, and 0.1 g of ZIF-67 is added as a carbon source, and continuously roasted at 800 ° C for 2 h under the condition of nitrogen gas, Obtain a three-dimensional sulfur-fixing carrier;

[0027]c: Disperse 50 mg of sulfur powder in 1 mL of carbon disulfide, ultrasonically disperse it, then dropwise add it onto the three-dimensional sulfur-fixed carrier obtained in step b, dry it in an oven at 60°C, and then heat it in an oven at 155°C for 12 hours , and finally a flexible integrated lithium-sulfur battery cathode...

Embodiment 2

[0029] a: Prepare 100mL of a mixed solution of 5mM nickel nitrate and 25mM urea, ultrasonically disperse it and transfer it to a reaction kettle, place the foamed nickel substrate in the reaction kettle, and then react at a high temperature of 120°C for 6h; obtain in-situ growth of one-dimensional nickel hydroxide Nickel foam with nanowire arrays;

[0030] b: Put the prepared nickel foam for in-situ growth of one-dimensional nickel hydroxide nanowire arrays in an atmosphere furnace, add 0.1 g of ZIF-67 as a carbon source, and continuously bake at 800 ° C for 2 h under the condition of nitrogen gas, Obtain a three-dimensional sulfur-fixing carrier;

[0031] c: Disperse 50 mg of sulfur powder in 1 mL of carbon disulfide, ultrasonically disperse it, then dropwise add it onto the three-dimensional sulfur-fixed carrier obtained in step b, dry it in an oven at 60°C, and then heat it in an oven at 155°C for 12 hours , and finally a flexible integrated lithium-sulfur battery cathode ...

Embodiment 3

[0033] a: Prepare 100 mL of a mixed solution of 5 mM titanium nitrate and 25 mM urea, ultrasonically disperse it and transfer it to a reactor, place the nickel foam substrate in the reactor, and then react at a high temperature of 120 °C for 6 h; obtain in-situ grown one-dimensional titanium hydroxide Nickel foam with nanowire arrays;

[0034] b: Put the prepared nickel foam for in-situ growth of one-dimensional titanium hydroxide nanowire arrays in an atmosphere furnace, add 0.1 g of ZIF-67 as a carbon source, and continuously bake at 800 ° C for 2 h under the condition of nitrogen gas, Obtain a three-dimensional sulfur-fixing carrier;

[0035] c: Disperse 50 mg of sulfur powder in 1 mL of carbon disulfide, ultrasonically disperse it, then dropwise add it onto the three-dimensional sulfur-fixed carrier obtained in step b, dry it in an oven at 60°C, and then heat it in an oven at 155°C for 12 hours , and finally a flexible integrated lithium-sulfur battery cathode is obtained...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com