Composite electrode material of sodium cobalt pyrophosphate/carbon, preparation and application of composite electrode material

A composite cathode material, sodium cobalt pyrophosphate technology, applied in battery electrodes, electrical components, electrochemical generators and other directions, can solve the problems of difficult to control morphology, poor conductivity, difficult preparation, etc., to improve poor conductivity and less impurities , the effect of uniform particle dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

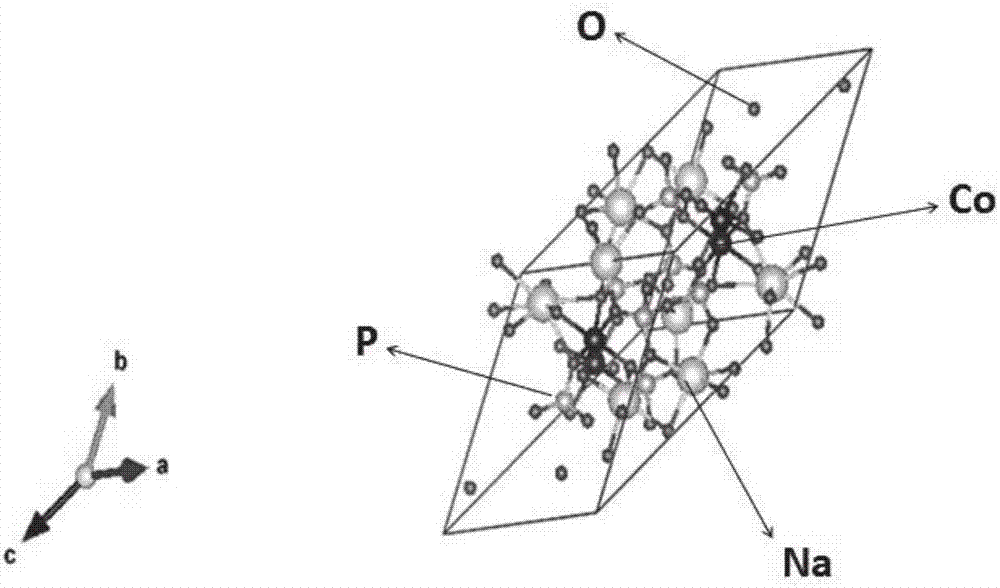

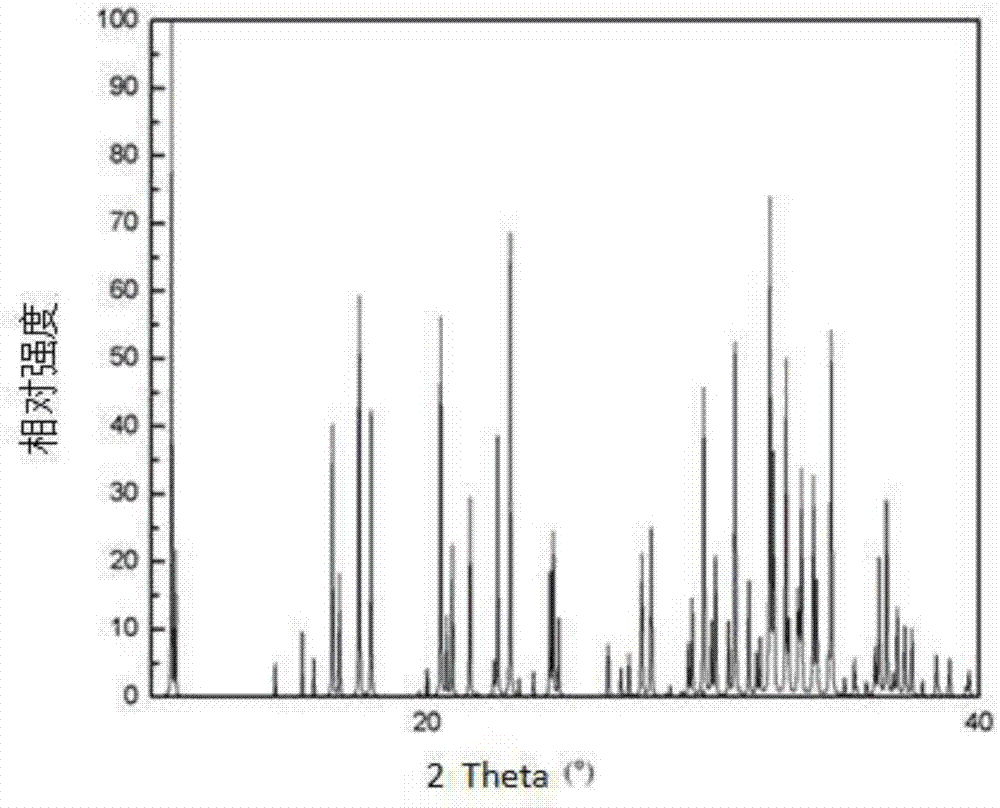

[0071] Weigh 0.011mol of cobalt nitrate, 0.009mol of sodium carbonate and 0.02mol of diammonium hydrogen phosphate and dissolve them in 10ml of deionized water, then add 0.011mol of citric acid to the above solution, stir to form a uniform solution, and bring the aqueous solution to 80° Heat in a water bath to form a gel, and then transfer to a vacuum oven to dry to obtain a precursor. Finally, the above precursors were ground and sintered at 650°C for 3 hours under an argon atmosphere, with a heating rate of 10°C / min. Finally, the product is washed and dried. Get the final product (positive electrode composite material) Na 1.8 co 1.1 P 2 o 7 / C. The crystal form of the material is shown in figure 1 As shown, the XRD pattern is as figure 2 shown.

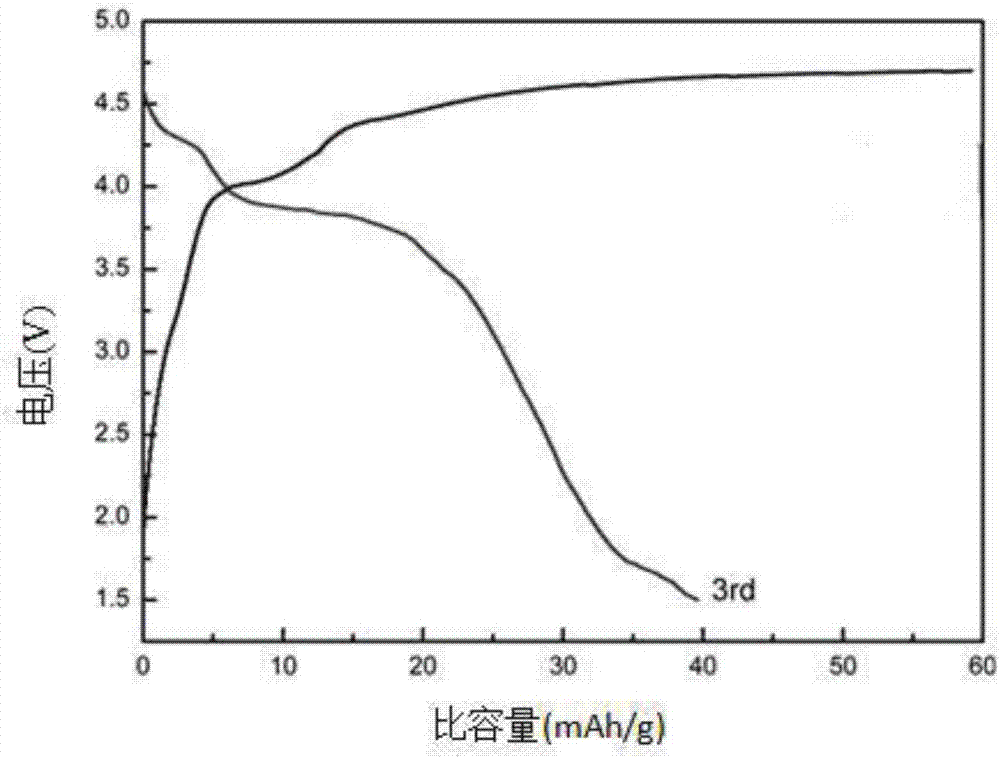

[0072] The positive electrode composite material prepared in this embodiment is used as the working electrode, and the sodium is used as the counter electrode, which is assembled into a button battery, and the cycle perform...

Embodiment 2

[0074] Weigh 0.012mol of cobalt chloride, 0.008mol of sodium oxalate and 0.02mol of diammonium hydrogen phosphate and dissolve them in 15ml of deionized water, then add 0.022mol of ascorbic acid into the above solution, and stir to form a uniform solution. The aqueous solution is heated in an 80 ° water bath to form a gel, and then transferred to a vacuum oven to dry to obtain a precursor. Finally, the above precursor was ground and sintered at 700°C for 5 hours under an argon atmosphere with a heating rate of 15°C / min. Finally, the product is washed and dried. Get the final product (positive electrode composite material) Na 1.6 co 1.2 P 2 o 7 / C.

[0075] The positive electrode composite material prepared in this embodiment is used as the working electrode, and the sodium is used as the counter electrode, which is assembled into a button battery, and the cycle performance is tested at a rate of 2.5C. At 2.5C rate, the specific capacity reaches 38mAh / g, and the voltage p...

Embodiment 3

[0077] Weigh 0.0125 mol of cobalt acetate, 0.015 mol of sodium acetate and 0.02 mol of diammonium hydrogen phosphate and dissolve them in 100 ml of deionized water, then add 0.01 mol of citric acid to the above solution, and stir to form a uniform solution. The aqueous solution was heated in an 80 ° water bath to form a gel, and then transferred to a vacuum oven to dry to obtain a precursor. Finally, the above precursors were ground and sintered at 750°C for 5 hours under an argon atmosphere with a heating rate of 15°C / min. Finally, the product is washed and dried. Get the final product (positive electrode composite material) Na 1.5 co 1.25 P 2 o 7 / C.

[0078]The positive electrode composite material prepared in this embodiment is used as the working electrode, and the sodium is used as the counter electrode, which is assembled into a button cell, and the electrochemical performance is tested at a rate of 2.5C. At a current density of 2.5C, the specific capacity reaches...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com