Lithium-sulfur battery positive electrode material and preparation method thereof

A positive electrode material, lithium-sulfur battery technology, applied in the direction of battery electrodes, lithium batteries, sulfur preparation/purification, etc., can solve the problems of obvious shuttle effect, poor cycle stability, poor conductivity, etc., to simplify the preparation process and prevent agglomeration , Improve the effect of poor electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

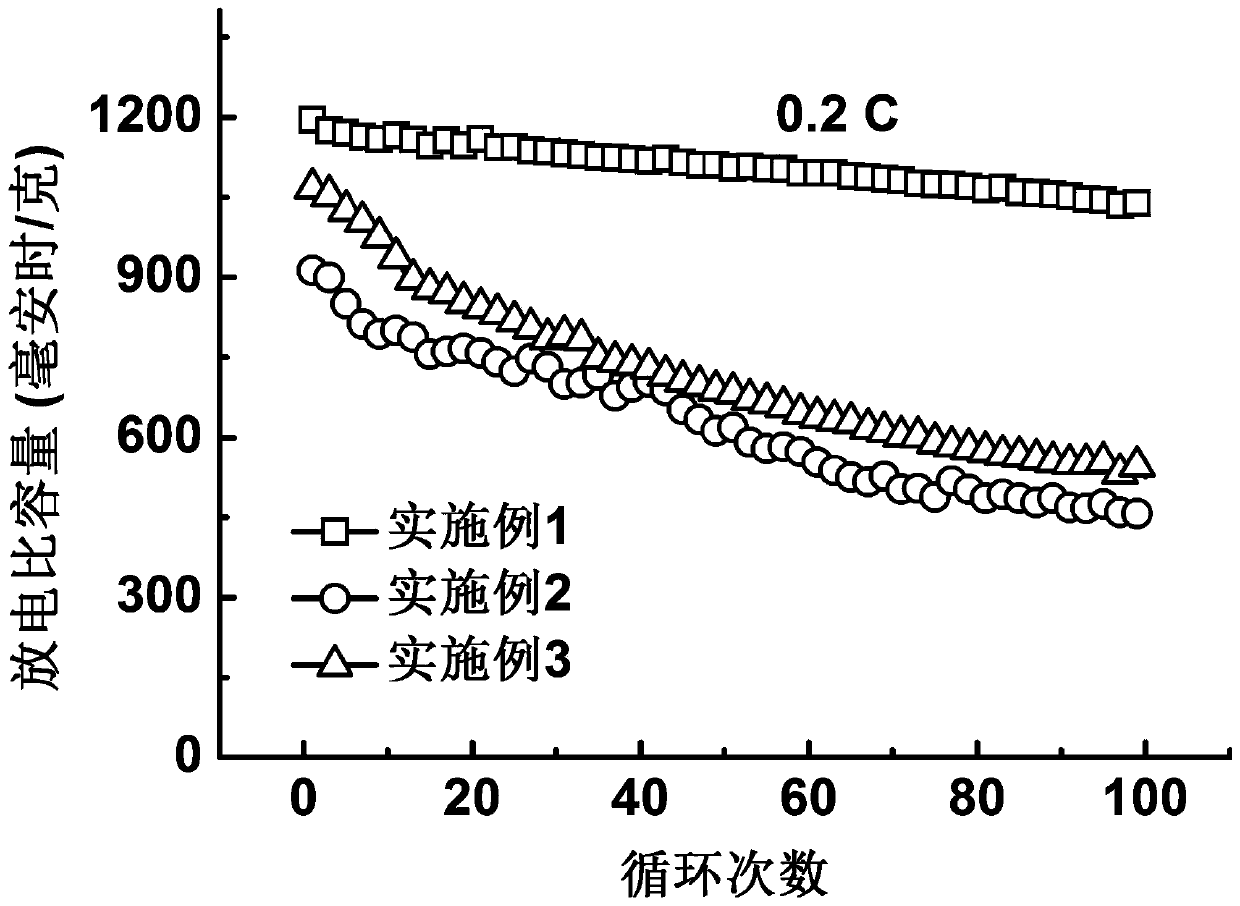

Embodiment 1

[0031] The anode material of the lithium-sulfur battery is a cobalt tetraoxide double-layer hollow sphere-carbon nanotube-sulfur composite material.

[0032] The cobalt tetraoxide double-layer hollow sphere is composed of two inner and outer hollow spheres, the diameter of the inner hollow sphere is 400-500 nm, and the diameter of the outer hollow sphere is 1.2-1.6 μm. The obtained cobalt tetraoxide double-layer hollow microspheres have good size uniformity, rough shell surface, are composed of uniform nanoparticles, have abundant pores, provide abundant ion transfer channels, and are beneficial to the entry of electrolyte as an electrode material. A larger internal cavity between shells favors greater sulfur loading.

[0033] The preparation method of the positive electrode material of the lithium-sulfur battery comprises the following steps:

[0034] (1) Preparation of three-cobalt tetroxide double-layer hollow spheres: after dissolving 15g of glucose and 8g of cobalt nitra...

Embodiment 2

[0037] The preparation method of the positive electrode material of the lithium-sulfur battery comprises the following steps:

[0038] (1) Preparation of three-cobalt tetroxide double-layer hollow spheres: after dissolving 10g of glucose and 5g of cobalt nitrate in 100mL of deionized water, they were placed in a reaction kettle for hydrothermal reaction at 150°C for 12 hours. After the reaction was completed, the suspension was obtained by cooling at room temperature liquid; the resulting suspension was centrifuged, the product was collected and washed three times with deionized water, and dried at 60°C to obtain a powder; then the obtained powder was placed in a muffle furnace and heated at a rate of 1°C / min under air conditions Raise the temperature to 400°C, keep it warm for 1 hour, and then cool down at room temperature to obtain the powder of cobalt tetraoxide double-layer hollow spheres;

[0039] (2) Cobalt tetraoxide double-layer hollow sphere-carbon nanotube-sulfur com...

Embodiment 3

[0041] The preparation method of the positive electrode material of the lithium-sulfur battery comprises the following steps:

[0042] (1) Preparation of three-cobalt tetroxide double-layer hollow spheres: after dissolving 20g of glucose and 10g of cobalt nitrate in 200mL of deionized water, they were placed in a reaction kettle for hydrothermal reaction at 200°C for 24 hours. After the reaction was completed, the suspension was obtained by cooling at room temperature liquid; the resulting suspension was centrifuged, the product was collected and washed three times with deionized water, and dried at 60°C to obtain a powder; then the obtained powder was placed in a muffle furnace and heated at a rate of 5°C / min under air conditions Raise the temperature to 600°C, keep it warm for 2 hours, and then cool down with room temperature to obtain the powder of three-cobalt tetroxide double-layer hollow spheres;

[0043] (2) Cobalt tetraoxide double-layer hollow sphere-carbon nanotube-s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com