Additive for zinc-based battery

A zinc-based battery and additive technology, which is applied in battery electrodes, alkaline storage batteries, battery pack components, etc., can solve the problems of restricting the application and development of nickel-zinc batteries and the difficulty of further improving the cycle performance of nickel-zinc batteries, and achieves suppression of zinc branches. Crystal formation, avoiding battery failure, and high process repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] An additive for a zinc-based battery, which is prepared through the following steps:

[0038] Add 8g of metal gallium, 2g of metal indium, and 1g of metal tin into a mortar at room temperature, grind and stir for about 12 hours to obtain the additive.

[0039] Assembly of nickel-zinc batteries: The obtained additives are coated on the separator of nickel-zinc batteries for normal nickel-zinc battery assembly.

[0040] The test method for the electrochemical performance of the nickel-zinc battery is as follows:

[0041] (1) The simulated battery adopts a button-type CR2032 system, in which the negative electrode is zinc oxide and the positive electrode is nickel hydroxide.

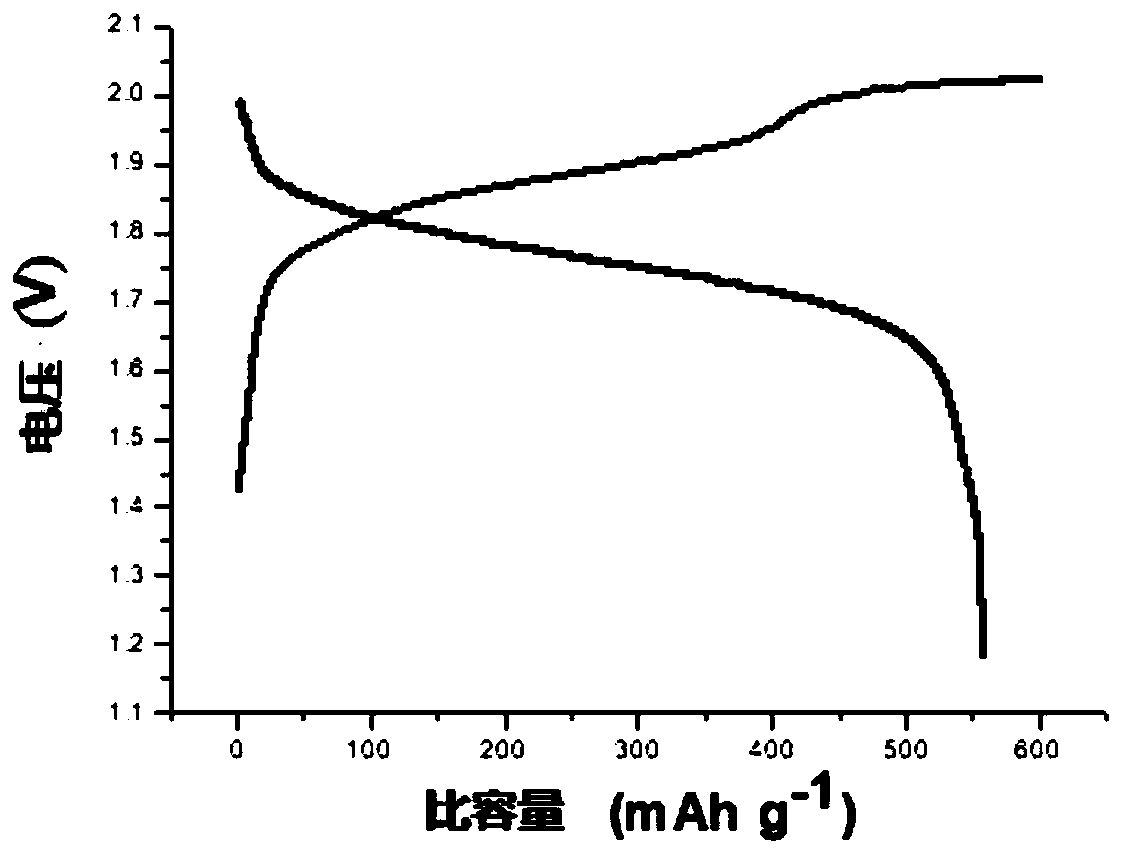

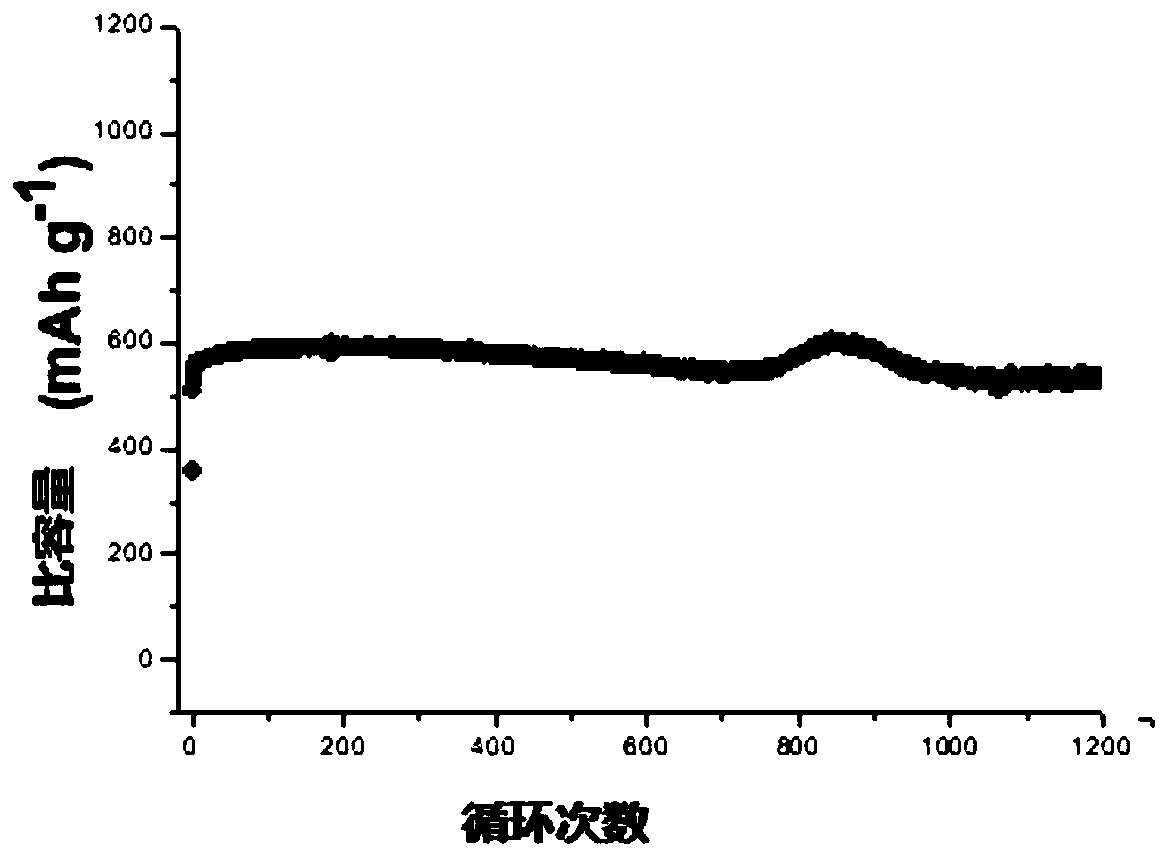

[0042] (2) The experiment adopts the constant current charge and discharge method to test and analyze the reversible capacity and cycle performance of the electrode material. The charge and discharge system is: voltage range: 1.2-2.0V; cycle number: 1-1500 times.

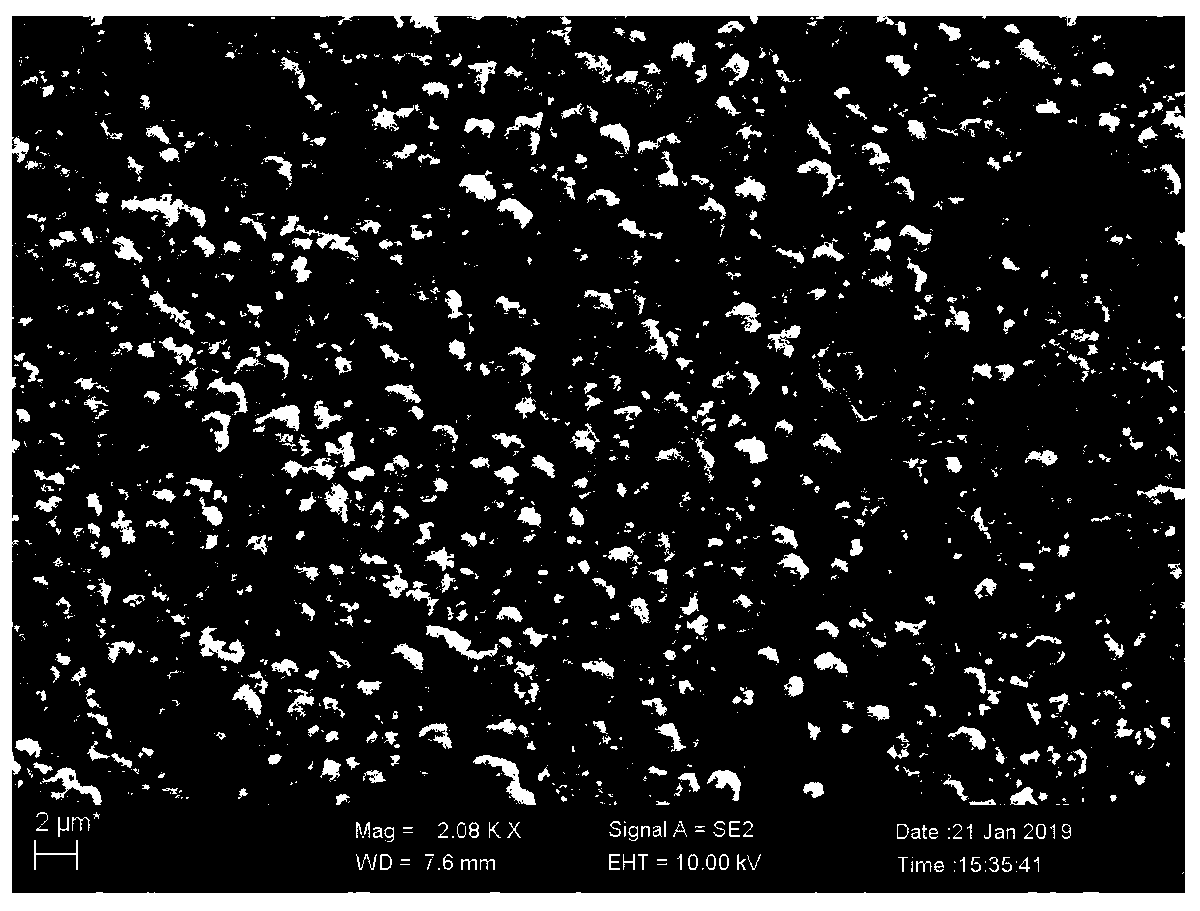

[0043] Characterize the morpholo...

Embodiment 2

[0049] This embodiment provides a nickel-zinc battery. The difference from embodiment 1 is that the additive described in embodiment 1 is placed on the zinc negative electrode.

[0050] Corresponding electrical performance tests were carried out, and the results are as follows: when charging and discharging at 2C, the stable specific capacity is greater than 550mAh / g; when charging and discharging at the above rate, the capacity can maintain 100% of the initial capacity after 500 repeated charging and discharging.

Embodiment 3

[0052] This embodiment provides a nickel-zinc battery. The difference from embodiment 1 is that the additive described in embodiment 1 is placed in the electrolyte.

[0053] Corresponding electrical performance tests were carried out, and the results are as follows: when charging and discharging at 2C, the stable specific capacity is greater than 550mAh / g; when charging and discharging at the above rate, the capacity can maintain 100% of the initial capacity after 500 repeated charging and discharging.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com