Power lithium ion battery

A lithium-ion battery and power technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of lithium-ion battery charging and discharging performance not being able to achieve good performance, application limitations, electrolyte decomposition, etc. Rate capability, improving poor electrical conductivity, improving ionic conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] 1) Preparation of positive electrode

[0031] 85% to 95% (mass) of nano-sized LiFePO 4 / C, 2% to 10% (mass) of Super P (super conductive carbon black), 2% to 10% (mass) of PVDF (polyvinylidene fluoride) and an appropriate amount of N-methylpyrrolidone (NMP). Positive electrode slurry: using aluminum foil as the current collector, apply the positive electrode slurry evenly on the aluminum foil with a coating machine, and dry it at 70°C±5°C to make a pole piece, and cut the pole piece into a length of 337mm and a width of 22.5mm positive electrode with a thickness of 180μm±10μm.

[0032] 2) Preparation of negative electrode

[0033] 85% to 95% (mass) of nanoscale Li 4 Ti 5 o 12 / C, 1% to 4% (mass) of Super P (super conductive carbon black), 3% to 8% (mass) of SBR (carboxylated styrene-butadiene latex) and 1% to 4% of CMC (carboxymethyl fiber Sodium plain) was stirred to make a negative electrode slurry; using copper foil as a current collector, the negative electrode...

Embodiment 1

[0038] 1. LiFePO 4 / C and Li 4 Ti 5 o 12 Preparation of / C

[0039] 1. LiFePO 4 Preparation of / C:

[0040] Weigh 24.24g Fe(NO 3 ) 3 9H 2 O is placed in a 500ml beaker, add 200ml distilled water, stir to dissolve, then add 5.28g ascorbic acid, stir to dissolve to obtain a light green solution, and then add 6.92gH 3 PO 4 and 2.52g LiOH·H 2 O, stir and dissolve, then add 5.48g carboxymethyl starch, heat and stir at 80°C, starch gelatinization, Li + , Fe 2+ and PO 4 3+ Coexist in the macromolecular network of starch and disperse evenly to obtain uniform starch-based LiFePO 4 Continue heating and stirring the precursor solution until the water is evaporated to dryness to obtain light yellow precursor powder. Put the precursor powder in a crucible, place it in a vacuum sintering furnace, raise the temperature at a rate of 2°C / min under a vacuum of 10Pa, pre-decompose at 320°C for 4 hours, raise the temperature to 650°C at the same rate, and calcine After 15 hours, t...

Embodiment 2

[0055] 1. LiFePO 4 / C and Li 4 Ti 5 o 12 Preparation of / C

[0056] Same as Example 1

[0057] 2. Preparation of power lithium-ion battery

[0058] The preparation of the positive and negative electrodes and the assembly process of the battery are the same as in Example 1, the difference is that the LiFePO in the positive electrode mixed powder 4 The proportions of / C, Super P and PVDF are: 85%, 7%, 8% respectively; Li in the negative electrode mixed powder 4 Ti 5 o 12 The proportions of / C, Super P, SBR and CMC are: 85%, 3%, 8%, 4%, respectively.

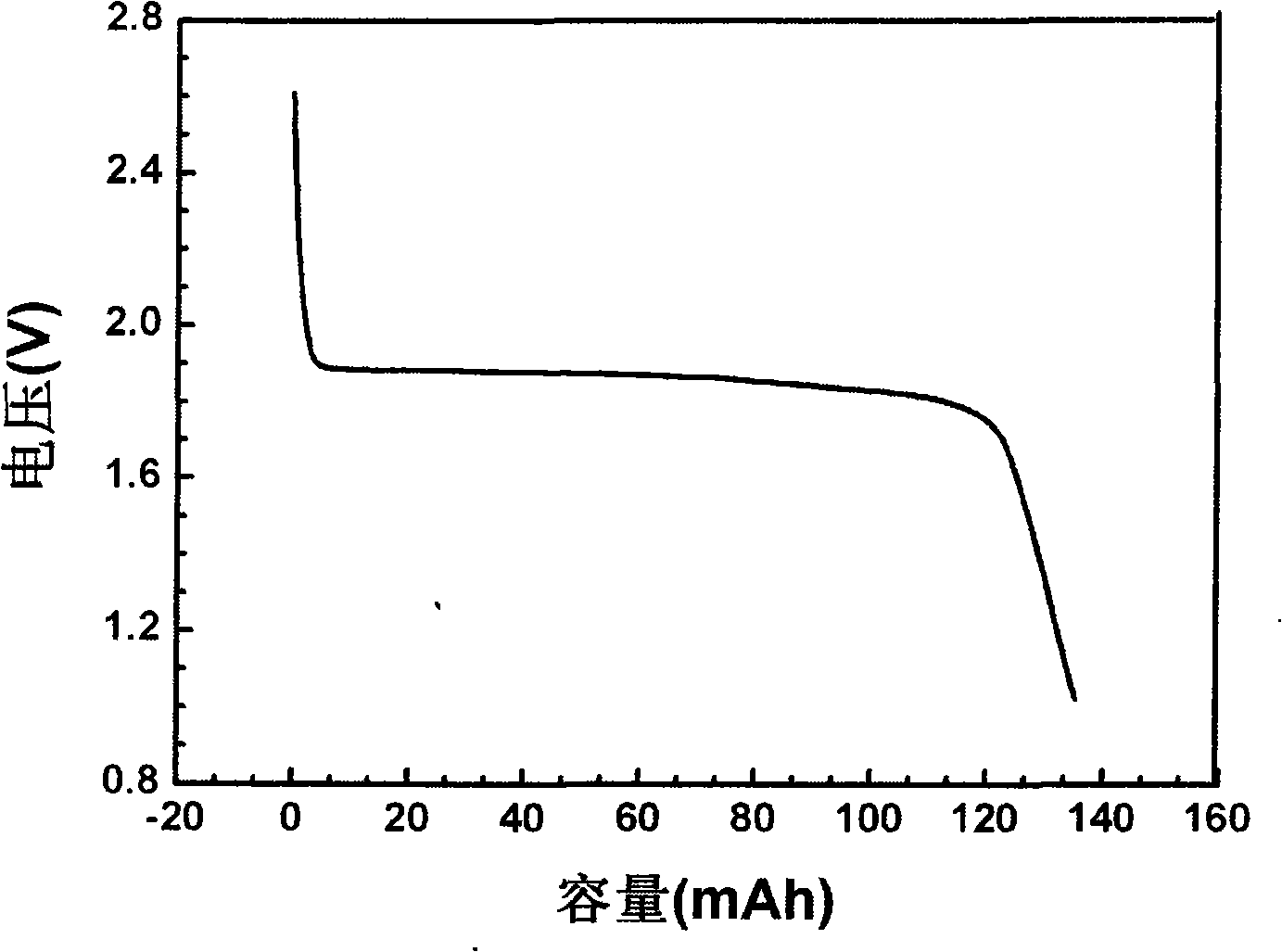

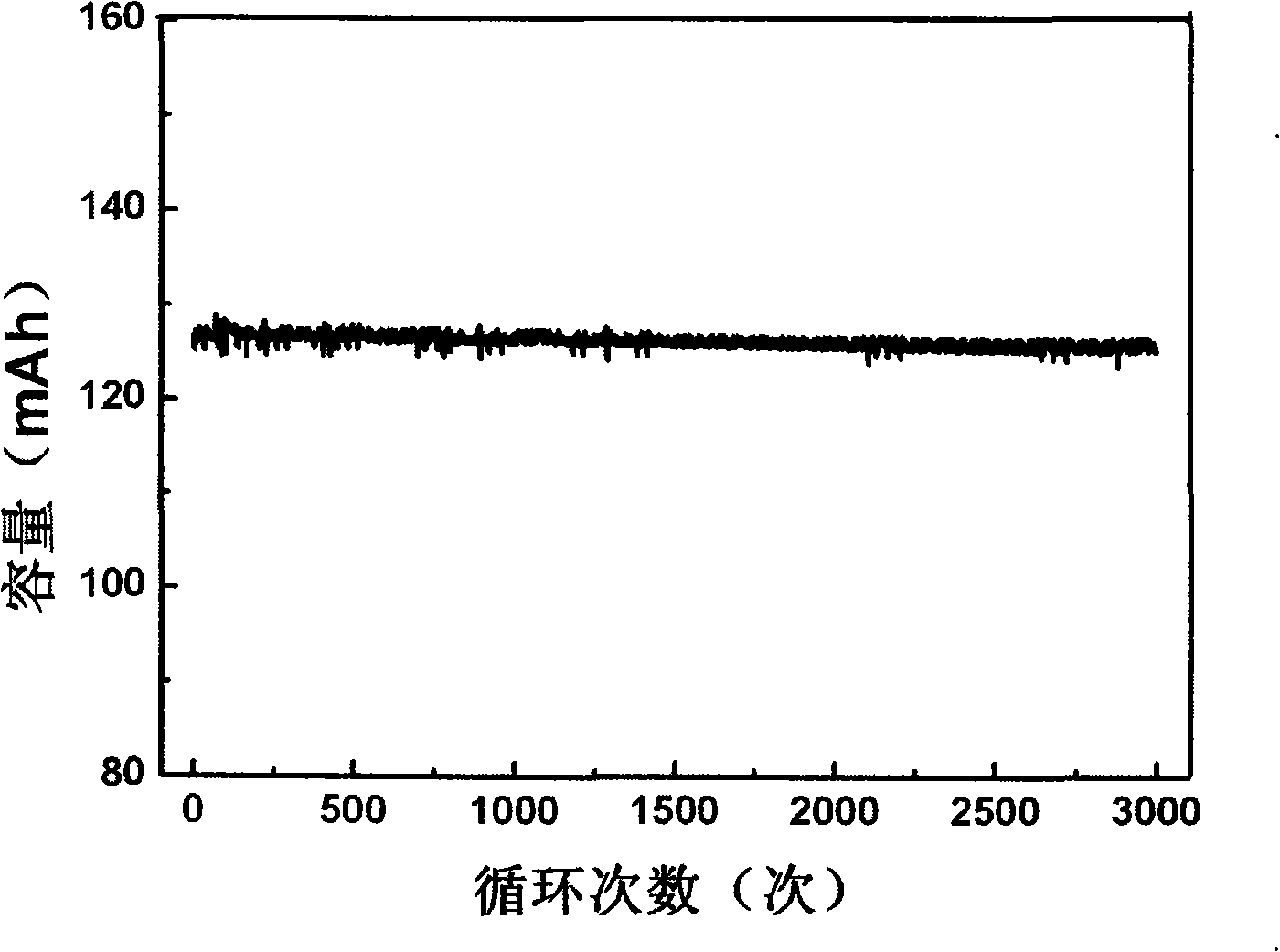

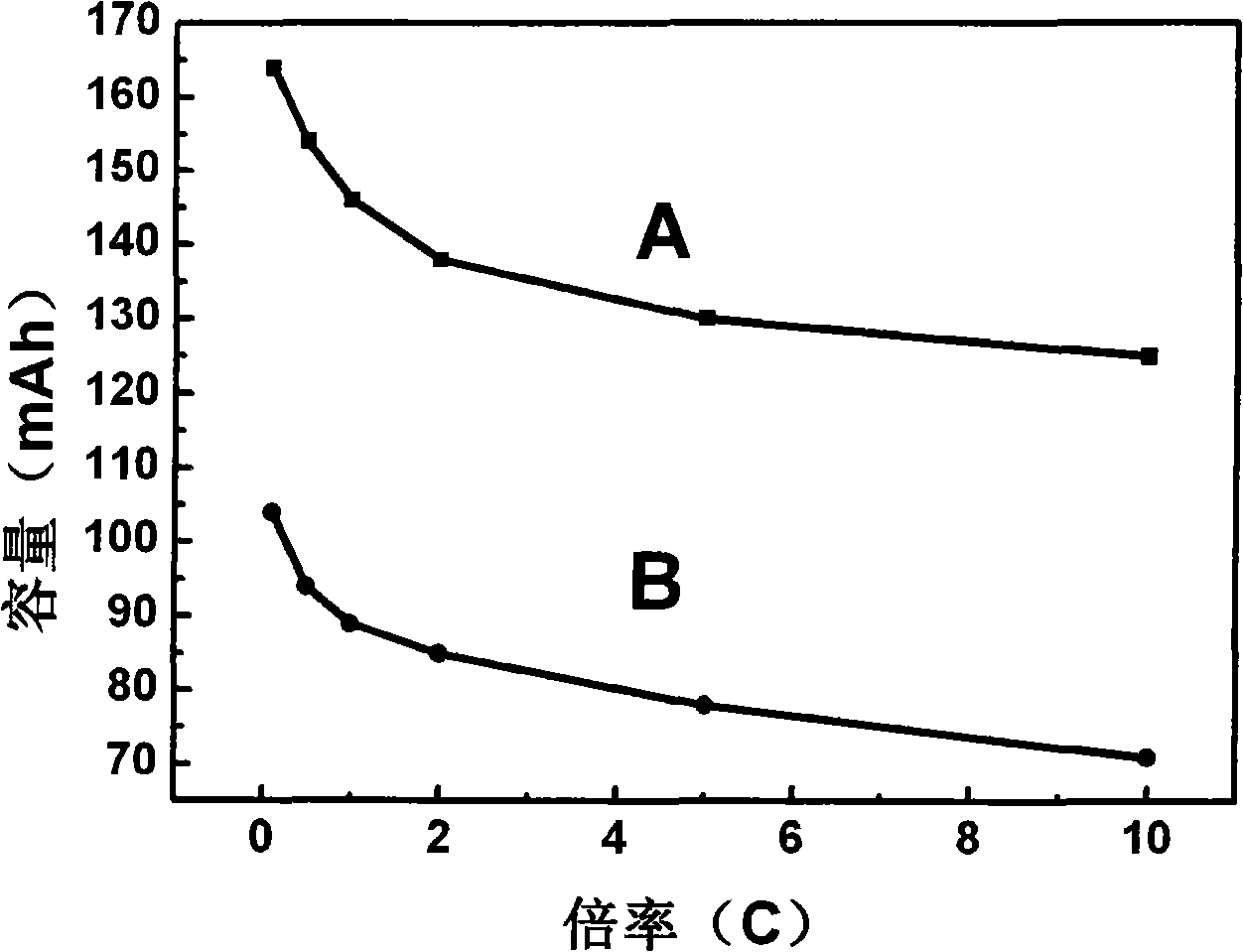

[0059] Under the discharge rate of 0.1C, the specific capacity of the battery prepared in this example reached 158mAh for the first time, and the discharge platform was stable between 1.80 and 1.90; under the discharge rate of 1C, the specific capacity remained above 115mAh / g after 3000 cycles; The high-rate performance is good, and the specific capacity is above 120mAh for the first time under the discharge rate of 10C. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com