Lithium-sulfur battery positive electrode material and preparation method thereof

A cathode material, lithium-sulfur battery technology, applied in battery electrodes, lithium storage batteries, positive electrodes, etc., to achieve the effect of improving utilization, strong adsorption, and improving long-range stability of batteries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

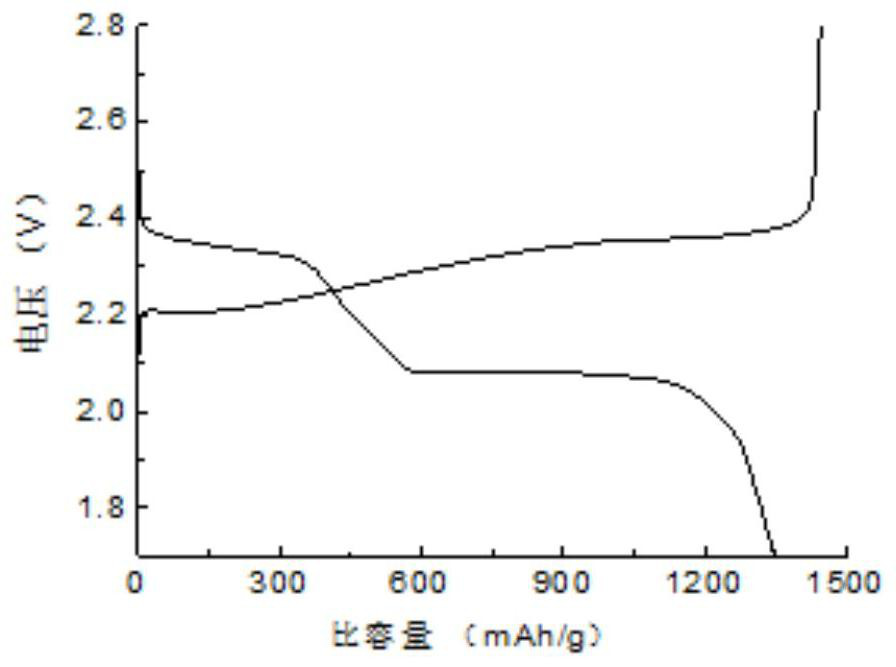

Image

Examples

Embodiment 1

[0019] The anode material of the lithium-sulfur battery is a metallized boron nitride nanotube / sulfur composite material.

[0020] The preparation method of the positive electrode material of the lithium-sulfur battery comprises the following steps:

[0021] (1) Preparation of metallized boron nitride nanotubes: borohydride (HfB 2 ) as the anode and graphite as the cathode, and the initial pressure is 700mbar and filled with a nitrogen atmosphere, and a stable plasma is established at a DC 60A and a voltage of 20V for at least 15min, producing dark gray smoke and depositing on the inner wall of the container, that is, Metallized boron nitride nanotubes;

[0022] (2) Preparation of metallized boron nitride nanotube / sulfur composite material: first, the metallized boron nitride nanotube and sulfur powder obtained in step (1) are weighed and mixed in a ratio of 1:3 by mass, and placed in Grind it into a uniform and fine powder mixture in a mortar; then add carbon disulfide drop...

Embodiment 2

[0024] (1) Preparation of metallized boron nitride nanotubes: borohydride (HfB 2 ) as the anode and graphite as the cathode, the initial pressure is 700mbar and filled with a nitrogen atmosphere, and a stable plasma is established at a DC 60A and a voltage of 40V for at least 15min to produce dark gray smoke and deposit on the inner wall of the container, that is, Metallized boron nitride nanotubes;

[0025] (2) Preparation of metallized boron nitride nanotube / sulfur composite material: first, the metallized boron nitride nanotube and sulfur powder obtained in step (1) are weighed and mixed in a ratio of 1:3 by mass, and placed in Grind it into a uniform and fine powder mixture in a mortar; then add carbon disulfide dropwise into the mortar, grind it thoroughly again for at least 30 minutes, and then place it in a reaction kettle for hydrothermal reaction at 155°C for 12 hours to obtain metallized nitriding Boron nanotube / sulfur composites.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com