Method for desiliconizing cobalt white alloy

A cobalt white alloy and desiliconization technology, which is applied in the field of high-purity cobalt salt and preparation of electric copper, can solve the problems of high energy consumption, large energy consumption, long process, etc., and achieves high metal recovery rate, simple operation and easy processing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

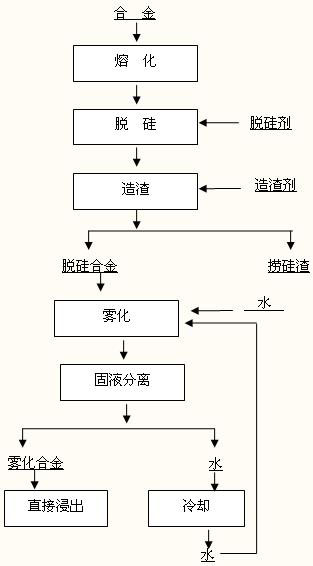

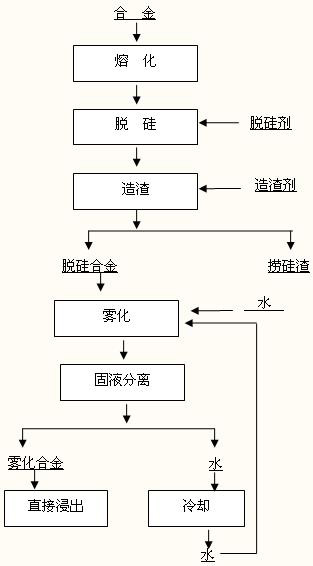

Method used

Image

Examples

Embodiment 1

[0040] The composition of the alloy is Co 34.97%, Fe 36.38%, Cu 15.90%, and Si 6%. The test is carried out in a 2kg intermediate frequency furnace. The crucible is an alumina corundum crucible. The cobalt oxide (Co content is 69%), the amount of one addition is 200g, the slagging agent is calcium oxide, the amount of one addition is 100g, the reaction time is 15min, the slag is removed once, and the alloy powder is atomized to 1070g (dry basis). The alloy composition is Co 45.42%, Cu 14.86%, Fe 33%, Si 1.18%; sulfuric acid leaching is used directly, the pH value is controlled at about 1.0, the temperature is 60°C, and the oxidant sodium chlorate is added to control the slurry potential to 400mv, copper, cobalt The leaching rates are 99.2% and 99.6% respectively.

Embodiment 2

[0042] The composition of the alloy is Co 36.87%, Fe 33.45%, Cu 13.45%, Si 12.15%, using 1000kg

[0043]The intermediate frequency furnace is used for desiliconization, the crucible is a special crucible, the amount of alloy added is 600kg, the melting temperature is 1400°C, the desiliconization agent is waste iron oxide (iron content is 64%), and the amount added at one time is 70kg, and the slagging agent is calcium oxide , the amount added at one time is 60g, the reaction time is 15min, the slag is removed once, and the desiliconization treatment is repeated three times. A total of 210kg of iron oxide and 180kg of calcium oxide are added, and 630kg of alloy powder (dry basis) is obtained by atomization. The alloy composition is Co35. 01%, Cu 12.50%, Fe 40.18%, Si 2.01%, the recovery rates of cobalt and copper in the desiliconization process are 99.70%, 97.58%, respectively, and the removal rate of silicon is 82.63%.

[0044] Take 2kg of alloy powder and directly use sulfuri...

Embodiment 3

[0046] The composition of an alloy is 28.87% Co, 40.45% Fe, 18.45% Cu, and 10.16% Si. A 1000kg intermediate frequency furnace is used for desiliconization. The crucible is a special crucible. The alloy addition is 600kg. The melting temperature is 1350℃. Lithium cobaltate (with a cobalt content of 60%), the amount of one addition is 70kg, the slagging agent is magnesium oxide, the amount of one addition is 50g, the reaction time is 15min, the slag is removed once, and the desiliconization treatment is repeated three times, adding a total of Lithium cobalt oxide 210kg, magnesium oxide 150kg, atomized alloy powder 660kg (dry basis), alloy composition is Co35.34%, Cu 16.71%, Fe 35.48%, Si 0.58%, desiliconization rate is 93.72%.

[0047] The alloy powder is directly leached with sulfuric acid, the pH value is controlled at about 1.0, the temperature is 90°C, and the oxidant sodium chlorate is added to control the slurry potential to 450mv. The leaching rates of copper and cobalt ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com